Low volume plastic injection molding is a manufacturing process used to produce small quantities of intricate plastic parts. This technique is essential in industries requiring unique, high-quality plastic components in lower quantities. In this article, we will delve into the specifics of low volume plastic injection molding, including its process, tools, and machine types.

What is Low Volume Plastic Injection Molding?

Definition and Basic Process

Low volume plastic injection molding is a process where molten plastic is injected into a mold cavity to form a part. This technique is similar to standard injection molding but is optimized for smaller production runs. It is ideal for producing high-quality, detailed plastic parts in quantities typically ranging from a few dozen to several thousand units.

Application and Purpose

This method is used when the demand for a part is not high enough to justify the high costs of traditional mass production. It’s perfect for prototype development, market testing, or niche products. The parts produced are often used in industries like medical, aerospace, automotive, and electronics.

Advantages of Low Volume Plastic Injection Molding

Low volume plastic injection molding offers several benefits:

- Cost-Effectiveness: Reduces the upfront costs of mold production, making it feasible for small-scale production.

- Flexibility in Design: Allows for modifications and iterations without incurring the high costs associated with changing large-scale production molds.

- Rapid Production: Ensures a quicker turnaround time from design to finished product.

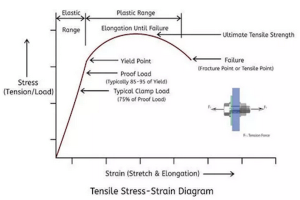

- Quality and Consistency: Maintains high-quality and consistent dimensional accuracy, surface finish, and mechanical properties.

How Does Low Volume Plastic Injection Molding Work?

Here’s a step-by-step overview of the process:

Step 1: Designing the Part

Designers create a 3D model of the part using CAD software, considering the material properties and molding requirements. This design acts as a blueprint for the molding process.

Step 2: Creating the Mold

A mold is designed and manufactured, often using less expensive or faster-to-produce materials than those used in high-volume molding. This mold will shape the injected plastic into the desired part.

Step 3: Selecting the Right Plastic Material

Choose from a variety of plastics based on the part’s application, strength requirements, and desired aesthetic. Materials range from standard plastics to engineering-grade thermoplastics.

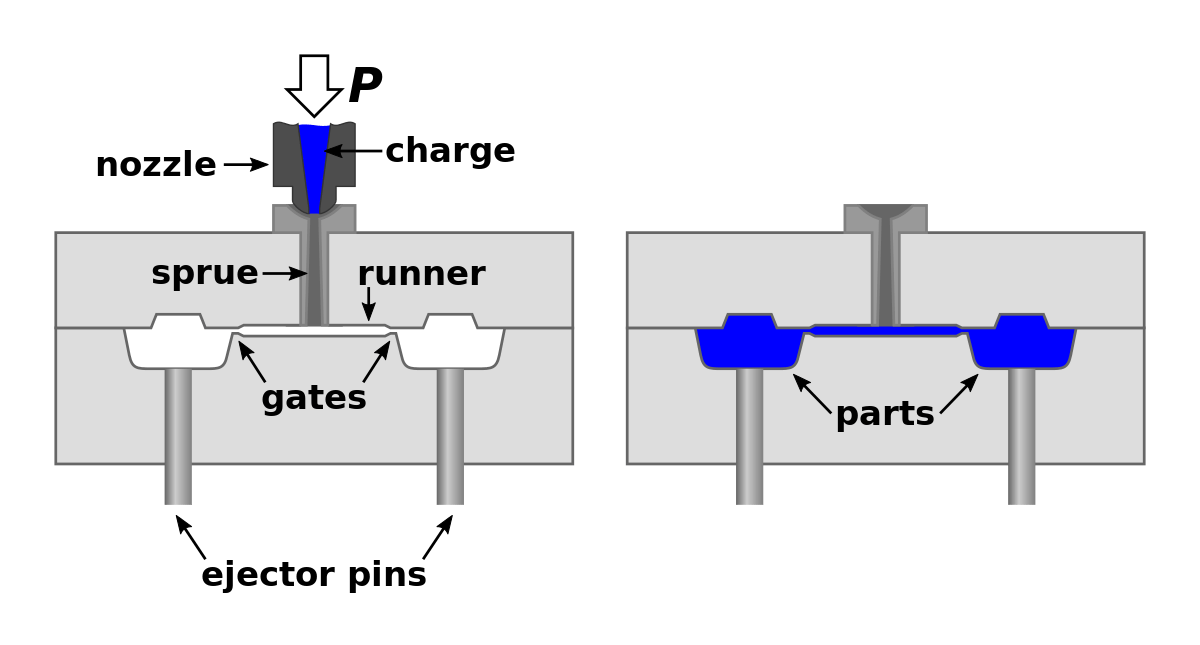

Step 4: Injection Molding Process

The chosen plastic material is melted and injected into the mold. After cooling, the part is ejected. This process can be repeated quickly for multiple production runs.

Step 5: Post-Processing and Finishing

Additional processes like trimming, painting, or surface texturing are performed to meet the final specifications.

Step 6: Quality Assurance

Each batch of parts undergoes stringent quality checks to ensure they meet the desired specifications and tolerances.

Key Components of a Low Volume Plastic Injection Molding Machine

Understanding the machinery is vital. Key components include:

- Injection Unit: Melts and injects the plastic into the mold.

- Clamping Unit: Holds the mold in place during injection and cooling.

- Control Panel: Operators use this to set up and monitor the molding process.

- Mold: Custom-designed for each part, it shapes the molten plastic.

- Ejector System: Ejects the finished part from the mold.

Types of Low Volume Plastic Injection Molding Machines

There are several types, each suited to different applications:

- Hydraulic Injection Molding Machine: Offers powerful clamping force, ideal for complex parts.

- Electric Injection Molding Machine: Highly accurate and energy-efficient, suitable for precision parts.

- Hybrid Injection Molding Machine: Combines the advantages of hydraulic and electric systems.

Applications in Various Industries

Low volume injection molding is crucial in many sectors. Some examples:

- Medical Devices: Produces prototypes and custom components for medical equipment.

- Automotive: Used for developing new components or limited edition parts.

- Consumer Electronics: Ideal for producing prototypes and small batches of electronic components.

Conclusion

Low volume plastic injection molding is a versatile and cost-effective method for producing high-quality plastic parts in small quantities. Whether you need prototypes, custom parts, or small production runs, this process offers flexibility, efficiency, and precision.

For those interested in exploring low volume injection molding services, seeking a professional and experienced provider is key to ensuring high-quality results tailored to your specific needs.

Other Articles You Might Enjoy

- Plastic Injection Molding in Medical Manufacturing: Advantages & Disadvantages

Plastic injection molding is used to make many medical products. This manufacturing process is proven reliable and can produce large quantities at low costs per part. Injection molding allows for…

- Silicone vs. Plastic Injection Molding: Which Material Fits Your Product Best?

Introduction to Injection Molding In the manufacturing industry, injection molding is a commonly used technique. It is a process where material, either silicone or plastic, is heated until it melts…

- Silicone vs. Plastic Injection Molding: Which Material Fits Your Product Best?

Silicone vs. Plastic Injection Molding: An Overview Injection molding is a widely used method to produce parts from both silicone and plastic materials. To briefly elucidate, silicone injection molding involves…