Alloys are materials composed of two or more metal elements, offering superior properties compared to pure metals. By combining different metallic elements in specific proportions, alloy materials can achieve enhanced hardness, corrosion resistance, high-temperature performance, and better machinability. As a result, alloys are widely used in aerospace, automotive, construction, energy, and other industries. This article introduces several common types of alloy materials and explores their processing and manufacturing methods.

Basic Classification of Alloy Materials

Alloy materials are categorized based on their base metal. Common types of alloys include Aluminum Alloys, Copper-Based Alloys, Iron-Based Alloys, Nickel-Based Alloys, and Titanium Alloys.

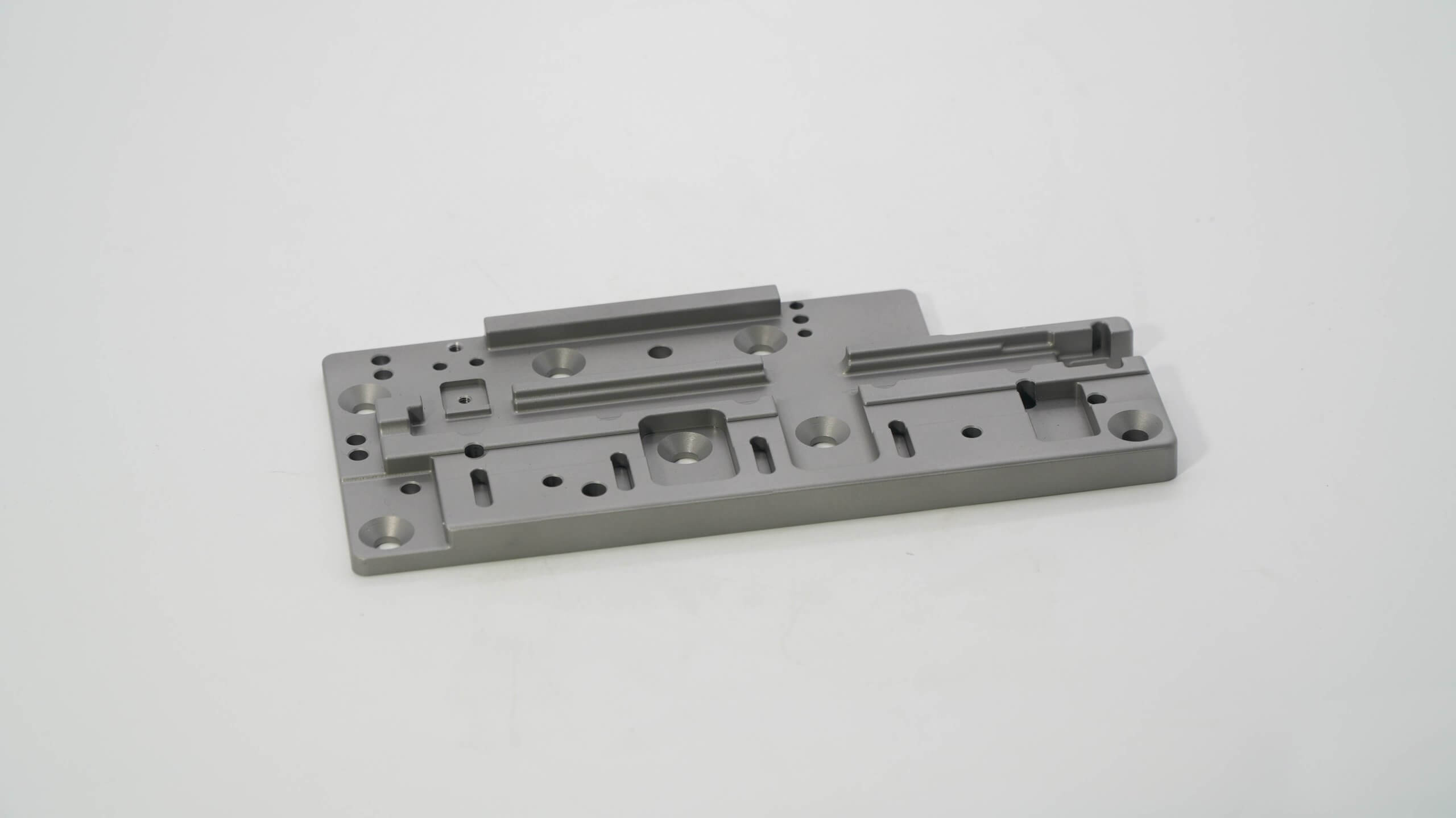

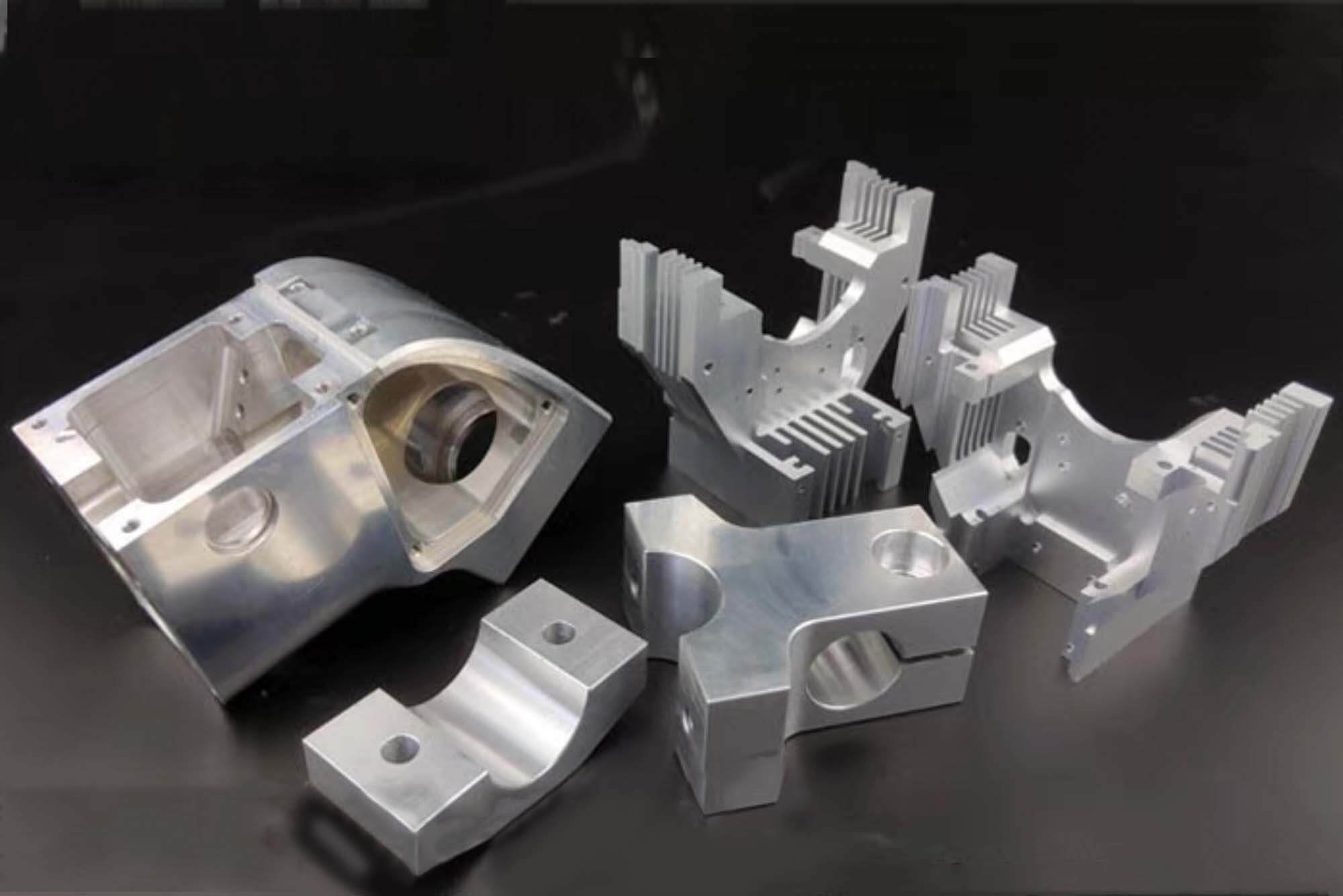

Aluminum Alloys: Aluminum alloys are made by combining aluminum with other metal elements such as copper, manganese, and silicon. They are lightweight, corrosion-resistant, and easy to process, making them widely used in aerospace, automotive, construction, and packaging industries. Aluminum alloys are classified into different series based on the alloying elements, such as the 1000 series (pure aluminum), 2000 series (aluminum-copper alloys), and 6000 series (aluminum-magnesium-silicon alloys).

Copper-Based Alloys: Copper-based alloys consist of copper combined with other metals like zinc, tin, or lead. Common copper alloys include brass (copper-zinc) and bronze (copper-tin). These alloys are known for their excellent electrical and thermal conductivity, corrosion resistance, and formability. Brass, for example, is used in plumbing, electrical components, and musical instruments, while bronze is used in bearings, ship components, and sculptures.

Iron-Based Alloys: Iron-based alloys, primarily consisting of iron combined with carbon and other elements, are among the most widely used materials in manufacturing. The most common iron-based alloy is steel, which is formed by adding varying amounts of carbon and other elements such as chromium, manganese, and nickel. Steel can be classified into carbon steel, alloy steel, and stainless steel, depending on the alloying elements. These alloys are widely used in construction, automotive, and machinery industries due to their strength, durability, and versatility.

Nickel-Based Alloys: Nickel-based alloys are composed of nickel combined with other metals like chromium, iron, and molybdenum. These alloys have excellent resistance to corrosion, high-temperature stability, and oxidation resistance, making them ideal for use in harsh environments. They are commonly used in chemical processing, aerospace, and power generation industries.

Titanium Alloys: Titanium alloys are made by alloying titanium with elements such as aluminum, vanadium, and molybdenum. Titanium alloys are known for their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. They are commonly used in aerospace, medical, and military applications.

-scaled.jpg)