Metal materials are generally divided into ferrous metals and non-ferrous metals. Ferrous metals mainly consist of iron and steel, which account for the largest share of global metal usage and are widely used in construction, transportation, and heavy industries. For these applications, the thickness of steel, often measured as Sheet Metal Gauge, determines its suitability—thicker gauges for structural strength, thinner ones for lighter panels. In contrast, non-ferrous metals are less commonly used in terms of volume but play a crucial role in high-tech industries such as electronics, aerospace, and medical equipment. Materials like aluminum and copper, prized for their conductivity and corrosion resistance, shine in these fields. Both categories shape our world, but their roles depend on properties like weight, durability, and how they’re processed.

Ferrous Metals include:

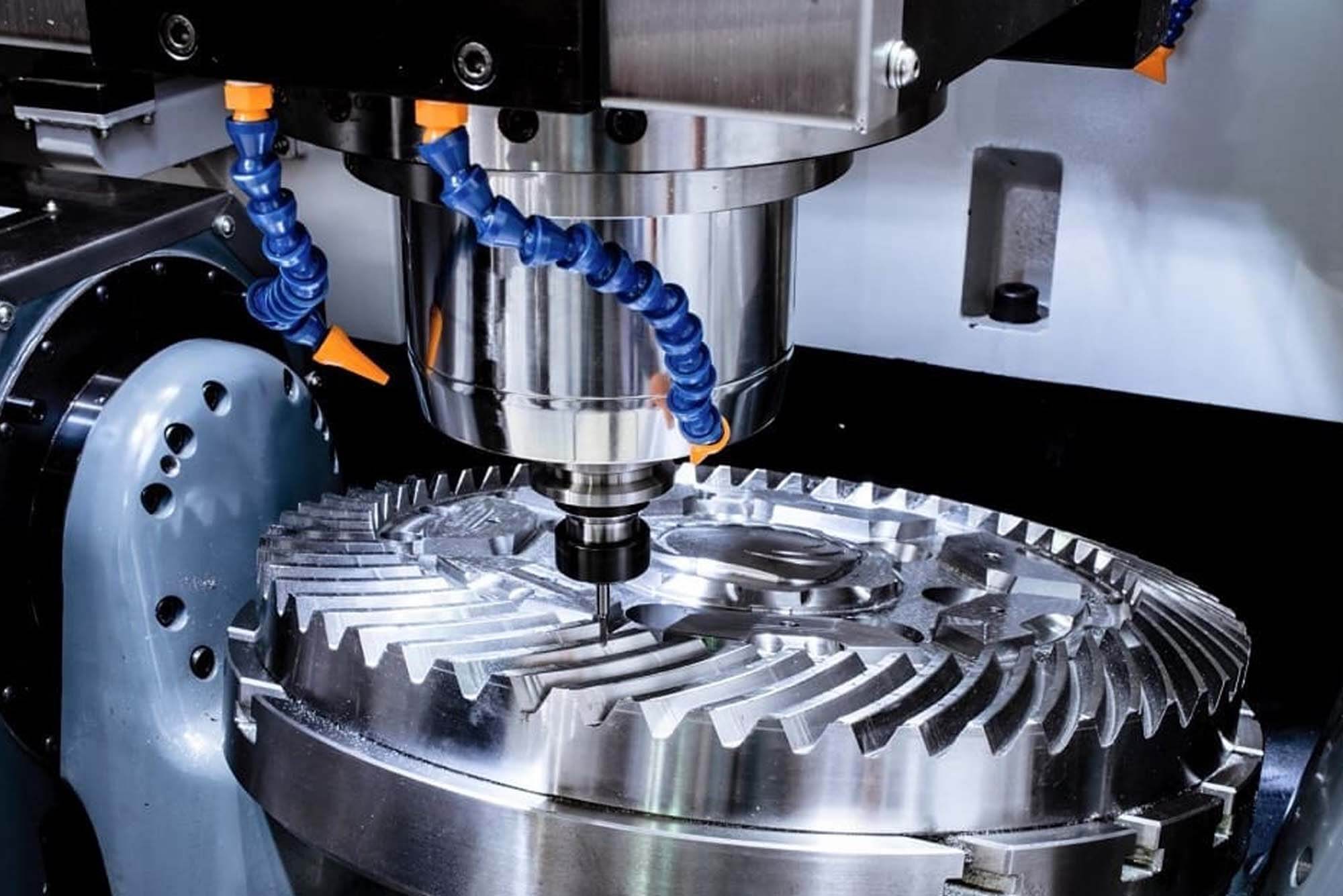

- Steel: Steel is the most commonly used ferrous metal, known for its strength, ductility, and machinability, making it ideal for manufacturing a wide variety of structural and mechanical parts.

- Cast Iron: Composed primarily of iron and carbon, cast iron has a high carbon content and is known for its hardness. It is often used in parts that require wear resistance and corrosion resistance, such as engine blocks.

Non-Ferrous Metals include:

- Aluminum and its Alloys: Lightweight, corrosion-resistant, and easy to machine, aluminum alloys are widely used in industries like aerospace, automotive, and construction.

- Copper and its Alloys: Copper has excellent electrical and thermal conductivity, making it ideal for use in electrical and electronic equipment manufacturing.

- Titanium Alloys: Known for their outstanding corrosion resistance and high-temperature strength, titanium alloys are used in industries such as aerospace and medical equipment.

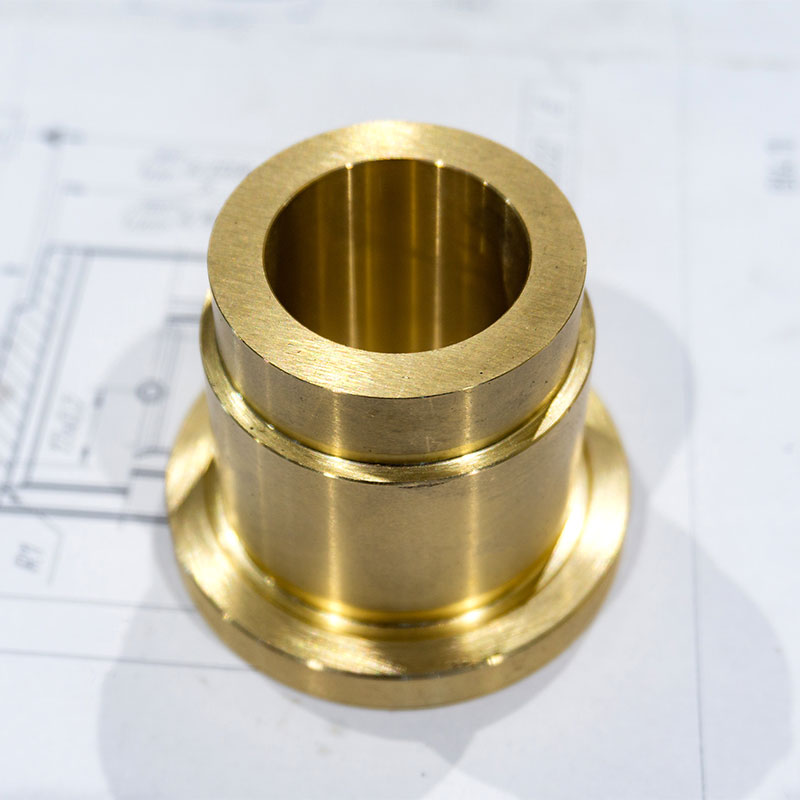

- Brass: Composed of copper and zinc, brass is known for its good machinability, corrosion resistance, and attractive appearance. It is commonly used in mechanical components and electronic parts.

- Bronze: Primarily made of copper and tin, bronze has high strength and corrosion resistance, making it suitable for applications in marine environments and machinery.

- Zinc: Zinc is often used as a protective coating for other metals due to its corrosion resistance and is used in die-casting, galvanizing, and battery production.