Basic Classification of Composite Materials

Composite materials can be divided into three main categories: Metal Matrix Composites (MMC), Polymer Matrix Composites (PMC), and Ceramic Matrix Composites (CMC). Each category has unique properties and applications based on its matrix material.

Metal Matrix Composites (MMC):

-

Alumina-Reinforced Metal Matrix Composites: These composites are made from a metal matrix, typically aluminum, combined with alumina (Al2O3) or other reinforcing materials. They offer excellent mechanical properties, wear resistance, and high-temperature performance. Common applications include aerospace, automotive, and engineering machinery.

Polymer Matrix Composites (PMC):

-

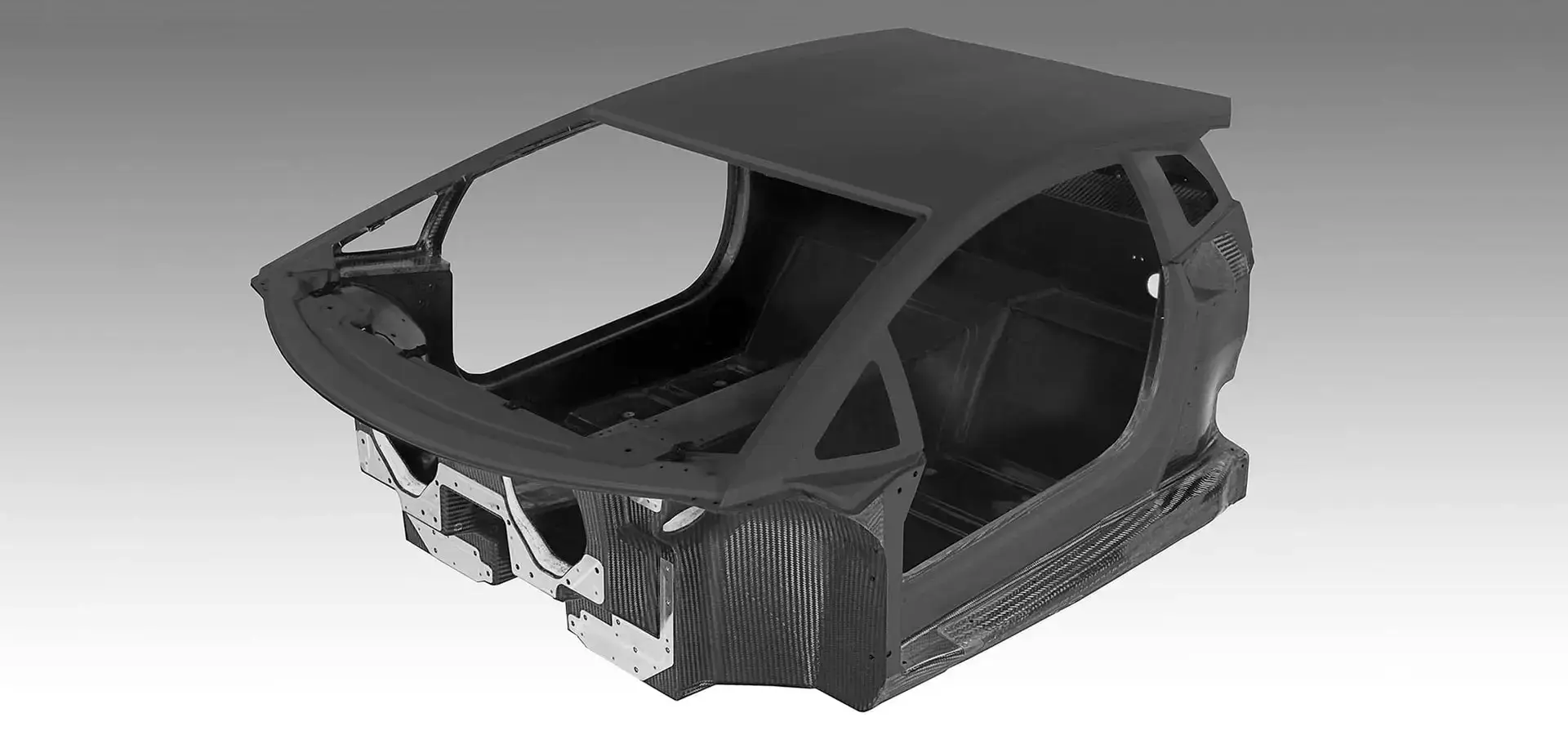

Carbon Fiber Reinforced Polymer (CFRP): Composed of carbon fibers embedded in a polymer matrix, CFRPs are known for their lightweight, high strength, and high stiffness. These composites are widely used in high-performance applications like aerospace, automotive, and sports equipment.

-

Glass Fiber Reinforced Polymer (GFRP): Made by embedding glass fibers into a polymer matrix, GFRPs are known for their durability, high strength, and excellent corrosion resistance. They are commonly used in construction, transportation, and marine industries.

-

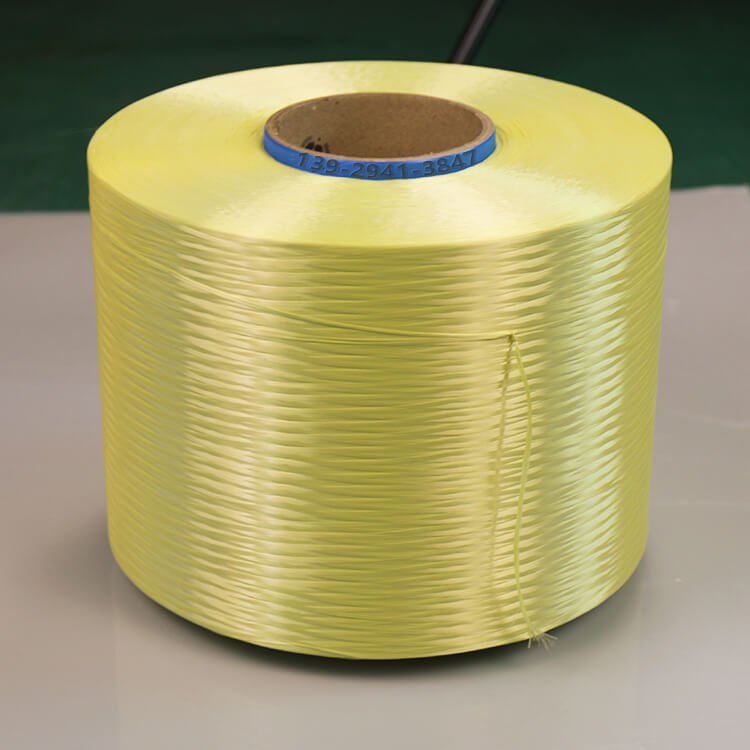

Kevlar Fiber Reinforced Polymer (KFRP): Kevlar fibers, known for their high tensile strength and impact resistance, are combined with polymers to produce KFRPs. These composites are often used in body armor, helmets, and protective clothing.

Ceramic Matrix Composites (CMC):

-

Silicon Carbide Reinforced Aluminum Matrix Composites (SiC/Al): These composites combine silicon carbide with aluminum, providing exceptional wear resistance, strength, and thermal stability. They are commonly used in high-stress, high-temperature environments, such as in automotive and aerospace components.