CNC machining is a highly precise and effective method of creating custom parts and components for various industries. Among the numerous procedures in this modern manufacturing process, bead blasting stands as an essential finishing technique. Regardless if you are new to the realm of manufacturing or an industry expert exploring advanced techniques, understanding the intricacies of bead blasting in CNC machining would undoubtedly come in handy.

So what exactly is bead blasting?

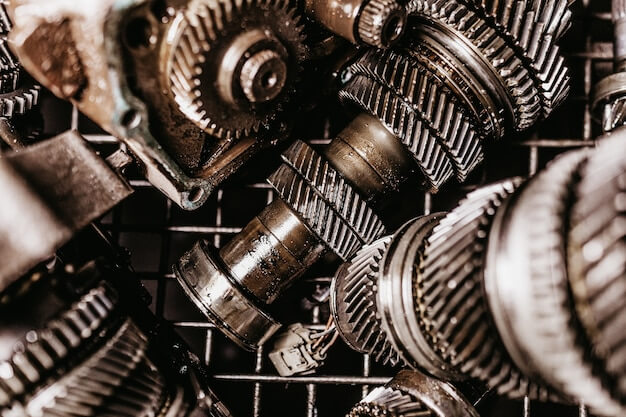

Bead blasting is a type of shot blasting that involves propelling fine glass beads at high pressure onto a surface to smooth it or remove impurities. The outcome? Exceptionally clean finishes with a textured, matte appearance. While there are other smoothing processes associated with CNC machining, such as abrasive or sand blasting, bead blasting delivers gentle ablation without compromising the material’s structural integrity.

How does Bead Blasting fit into CNC Machining?

Simply put, bead blasting enhances the visual appeal and performance of machined products. It provides more than just aesthetics; it also offers increased corrosion resistance, better adhesion qualities for coatings or paints, and removed burrs or defects on fabricated parts.

In essence, after a product has been carved out using a CNC machine, it usually goes through bead blasting. This process effectively removes any imperfections caused by cutting tools, resulting in an immaculate finish – something particularly crucial when final quality matters, such as aerospace, automotive, medical, and machinery applications.

The Bead Blasting Process

The first step in bead blasting centers around keeping the part secure and loading it into the blast cabinet. The operator then initiates the blasting procedure – which entails directing fine glass beads towards the component using compressed air to achieve the desired results.

Due to its aggressive nature, personal safety must always be prioritized during bead blasting. Operators should wear appropriate protective gear like gloves, eye protection, hearing aids, and dust masks.

Creating an Efficient Bead Blasting Setup

Well-structured bead blasting setups widely depend on factors such as the size of components, volume of production, and tolerances for surface roughness. Here are a few tips:

1. Choose the right media: Different jobs require different abrasives or ‘media.’ Glass beads are perfect for light duties intending to add decorative finishes or clean surfaces without altering their dimensions.

2. Control nozzle distance and angle: The extent of the work depends on the distance between the nozzle and the workpiece and the action’s chosen trajectory.

3. Blast pressure setting: Controlling the blasting pressure is vital in achieving desired results–higher operating pressures often lead to quicker material removal rates but could also degrade parts after extended exposure.

4. Recycling system: Beads can be recycled in certain systems for cost savings. However, it should be noted that each successive reuse degrades the abrasive quality of the glass beads.

Benefits of Bead Blasting

Bead blasting offers numerous benefits, including:

1. Improved appearance: It provides uniformity in color and texture, giving machined parts a visually pleasing finish.

2. Corrosion & scratch resistance: A well-blasted part improves its corrosion protection by creating more surface area for coatings to bind onto.

3. Better adhesion: With the enhanced surface terrain after bead blasting, paint and sealants bind better, offering a professional and longer-lasting painted surface.

In Conclusion,

CNC machining has revolutionized manufacturing with accuracy, speed, and capabilities – and within this industry, bead blasting stands as an established procedure that grants products the final touch they need to maximize functionality and design. Whether you’re into automotive, aerospace, machinery or medical field, understanding CNC machining and bead blasting can open new avenues of innovation and productivity for your business.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…