CNC Lathe Processing Based on Material, Contour Shape, and Machining Precision of Workpiece: Selection of Suitable Machine Tools, Development of Processing Plan, and Determination of Processing Sequence, Tools, Fixtures, and Cutting Parameters.

1. Selection of CNC Lathe:

When processing parts on a CNC lathe at Lianrongda Industry, there are generally two scenarios:

- When part drawings and raw blanks are available, the appropriate CNC machine tool must be selected for processing the part.

- When a CNC machine tool is already available, parts suitable for processing on that machine must be selected.

In both scenarios, factors to consider when processing parts on a CNC lathe include the material and type of the blank, the complexity of the part’s contour shape, dimensions, machining precision, quantity of parts, and heat treatment requirements.

Key points to summarize:

- Ensure that the technical requirements of the processed parts are met to produce qualified products.

- Improve production efficiency.

- Minimize production costs (processing expenses) as much as possible.

2. Technological Analysis of CNC Lathe Machining Parts

Technological analysis of CNC machining is extensive. Here, Lianrongda Industry focuses on the feasibility and convenience of CNC machining.

(A) Dimensional Data on Part Drawings Should Follow Programming Convenience Principles

- Dimensioning on Part Drawings Should Adapt to CNC Machining Characteristics:

- Dimensions should be referenced from a common datum or given directly as coordinate dimensions on CNC machining part drawings. This approach facilitates programming and coordination of dimensions, ensuring consistency among design, process, inspection benchmarks, and programming origin. Designers often prioritize assembly characteristics, leading to scattered dimensioning methods, which can complicate process arrangement and CNC machining. Due to the high precision and repeatability of CNC machining, local scattered dimensioning can be converted to a common datum or direct coordinate dimensions.

- Geometric Element Conditions Forming Part Contours Should Be Sufficient:

- Manual programming requires calculating base point or node coordinates, and automatic programming requires defining all geometric elements forming part contours. Therefore, it’s necessary to analyze whether the given conditions for geometric elements are sufficient. For instance, arcs and lines or arcs and arcs that are tangential in drawings might not meet tangency conditions due to given dimensions, resulting in intersection or separation. Such issues should be resolved through consultation with the part designer.

(B) Structural Technological Features of Parts Should Align with CNC Machining Characteristics

- Use Uniform Geometric Types and Sizes for Inner Cavities and Outer Shapes:

- This reduces tool specifications and changeover times, simplifying programming and enhancing production efficiency.

- Avoid Too Small Inner Groove Corner Radii:

- Inner groove corner radii determine the tool diameter, hence should not be too small. The quality of part technology is related to the height of the processed profile and the transition arc radius.

- Avoid Too Large Slot Bottom Corner Radii When Milling Flat Surfaces:

- Adopt Unified Datum Positioning:

- Without a unified datum, reinstallation of workpieces can cause misalignment in contour positions and sizes on different surfaces. To prevent such issues, ensure accuracy by using a unified datum. Preferably, parts should have suitable holes as datum positioning holes, or process holes should be added on the blank or in areas that will be milled later. If process holes can’t be created, at least a machined surface should be used as the unified datum to minimize errors from double clamping. Additionally, analyze if the required machining precision, size tolerance, and other specifications can be met, avoiding any redundant or conflicting dimensions.

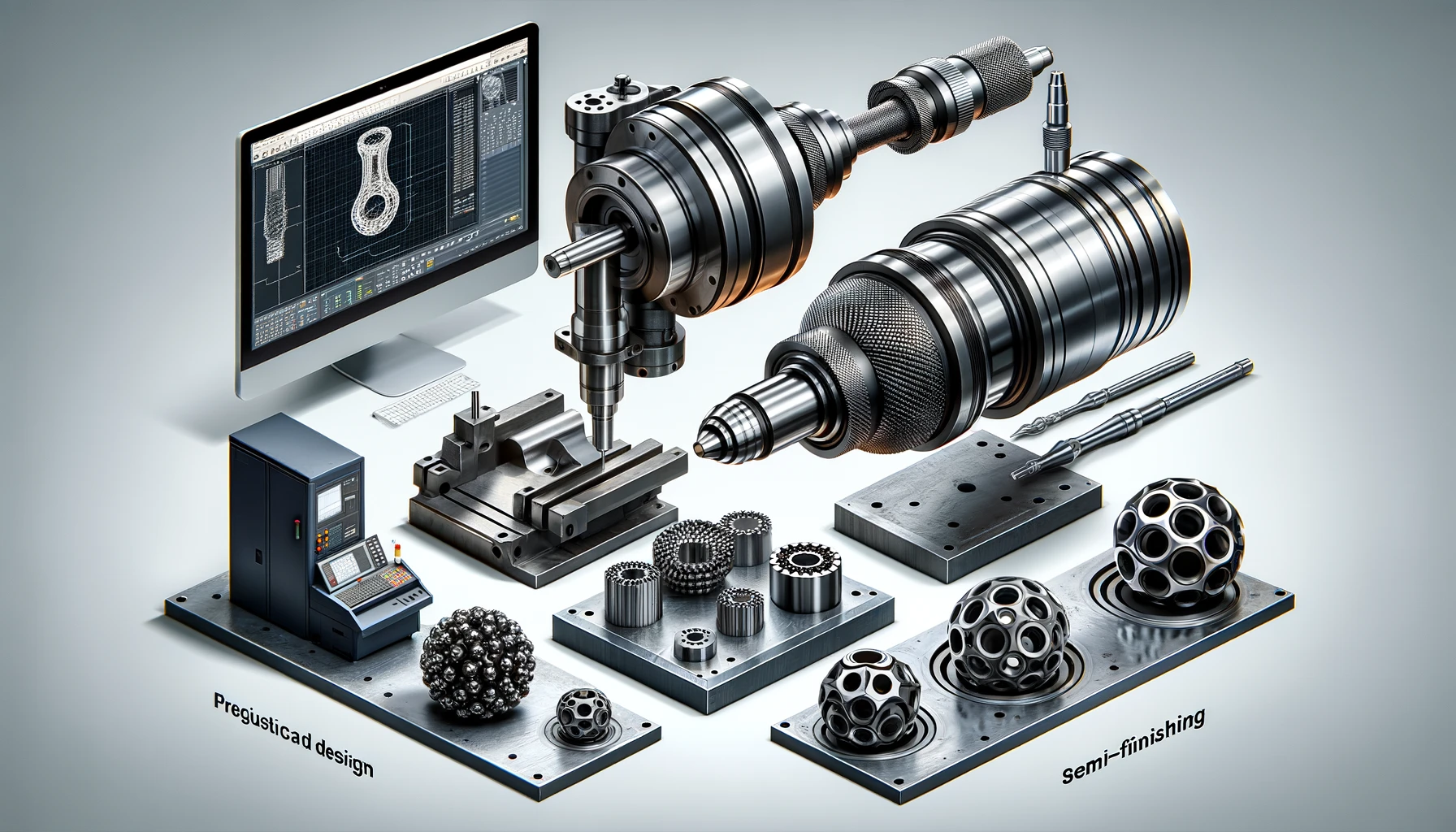

3. Selection of Processing Methods and Determination of Processing Plan

(A) Selection of Processing Methods

- The selection principle is to ensure the surface machining precision and roughness requirements. Various methods can achieve the same precision and roughness, thus consider the part shape, size, and heat treatment requirements. For instance, boring, reaming, and grinding can achieve IT7 precision holes, but for box holes, boring or reaming is preferred over grinding. Small box holes are usually reamed, while larger ones are bored. Also, consider production efficiency, cost-effectiveness, and available equipment. Refer to process manuals for economic machining precision and surface roughness of common methods.

(B) Principles for Determining Processing Plans

- Precision surfaces often require rough, semi-finish, and finish machining steps. Merely choosing the final machining method based on quality isn’t enough; determine the process from blank to final form correctly. Start by preliminarily selecting methods to meet the main surface precision and roughness requirements. For example, for small IT7 precision holes finished by fine reaming, the process usually includes drilling, expanding, and rough reaming before fine reaming.

4. Selection of Tools and Determination of Cutting Parameters

(A) Selection of Tools

- Tool selection is crucial in CNC machining processes, affecting both machining efficiency and quality. Consider the machining capability, process content, and workpiece material. CNC machining requires high precision, rigidity, durability, stable size, and easy installation and adjustment. Hence, use new high-quality materials and optimized tool parameters.

- Tools should match the surface dimensions and shapes of the workpiece. Flat contours are often machined with end mills; hard alloy insert milling cutters for flat surfaces; high-speed steel end mills for protrusions and slots; and carbide insert corn mills for rough machining blanks or holes. Experience-based parameters should guide end mill selection for curve machining, usually employing ball end mills. For flatter surfaces, use annular cutters. In single or small batch production, cylindrical or conical cutters replace multi-axis machines for variable angle parts on aircraft.

- On machining centers, tools are stored in a tool magazine for automatic selection and replacement per program instructions, requiring a set of connecting rods to quickly and accurately mount standard tools for drilling, boring, expanding, reaming, and milling. Programmers should know tool holder dimensions and adjustment methods, particularly the TSG tool system in Chinese machining centers, with straight and taper shanks for 16 different uses.

(B) Determination of Cutting Parameters

- Cutting parameters include spindle speed (cutting speed), depth of cut, and feed rate. Different methods require different parameters, integrated into the program sheet. The principle is to prioritize productivity in rough machining, considering economics and cost; balance quality, efficiency, and cost in semi-finish and finish machining. Refer to machine tool manuals, cutting parameter handbooks, and experience for specific values.

Other Articles You Might Enjoy

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…

- Beyond Cutting: Exploring the Multifaceted CNC Machining Process

1. Introduction: Unveiling the Layers of CNC Machining In this introductory section, we peel back the layers of the CNC machining process, going beyond the traditional understanding of cutting. It…

- Understanding CNC Machining: The Bead Blasting Process(cnc machining tools Valentina)

In the world of manufacturing, precision is paramount. One widely adopted method known for its precision is CNC machining. An integral subcomponent in the broader spectrum of CNC (Computer Numerical…

- Unlocking New Possibilities in CNC Machined Titanium Medical Devices

Introduction to CNC Machined Titanium Medical Devices The prevalence of CNC machined titanium medical devices in the healthcare sector demonstrates their immense significance and usefulness. This technology furnishes an essential…

- Understanding the Process of Bead Blasting in CNC Machining(cnc machining china Gwendolyn)

In the world of Computer Numerical Control (CNC) machining, bead blasting is an integral process that greatly enhances the final look and feel of produced parts. As a metal finishing…

- Custom CNC Machining for High-Quality Lighting Fixtures

Introduction to Custom CNC Machining For High-Quality Lighting Fixtures In this article, we aim to explore the integral role of custom Computer Numerical Control (CNC) machining in the production of…