Part structural manufacturability refers to the feasibility and cost-effectiveness of manufacturing a designed part while meeting the required standards. Designing a part that is easy to manufacture and cost-effective is the goal of every engineer. This article will discuss several key aspects of part structural manufacturability, aiming to explain this complex engineering issue in a clear and engaging manner.

Analysis and Review of Part Drawings

Part drawings are the main basis for formulating process procedures. To ensure high-quality manufacturing, it is essential to thoroughly analyze the part drawings. This is not only to understand the technical requirements and structural features of the part but also to understand its purpose and its compatibility with other parts through assembly drawings and acceptance standards. During the analysis process, any issues with technical requirements, dimension annotations, or structural design should be promptly addressed with the design personnel and corrected. This helps to avoid rework and cost increases during manufacturing.

Analysis of Part Manufacturability

When evaluating the manufacturability of mechanical product structures, the following aspects need to be considered:

- Quantity and Standardization of Parts: Designs with fewer parts and more standard parts generally have better manufacturability. For example, using standard parts (such as screws, nuts, bearings) as much as possible can reduce the complexity of design and manufacturing and improve cost efficiency.

- Processing Accuracy and Material Selection: The requirements for part size accuracy, shape accuracy, and surface roughness should be economically reasonable. Over-pursuing high precision increases manufacturing costs. Additionally, selecting materials that are easy to process and cost-effective is crucial.

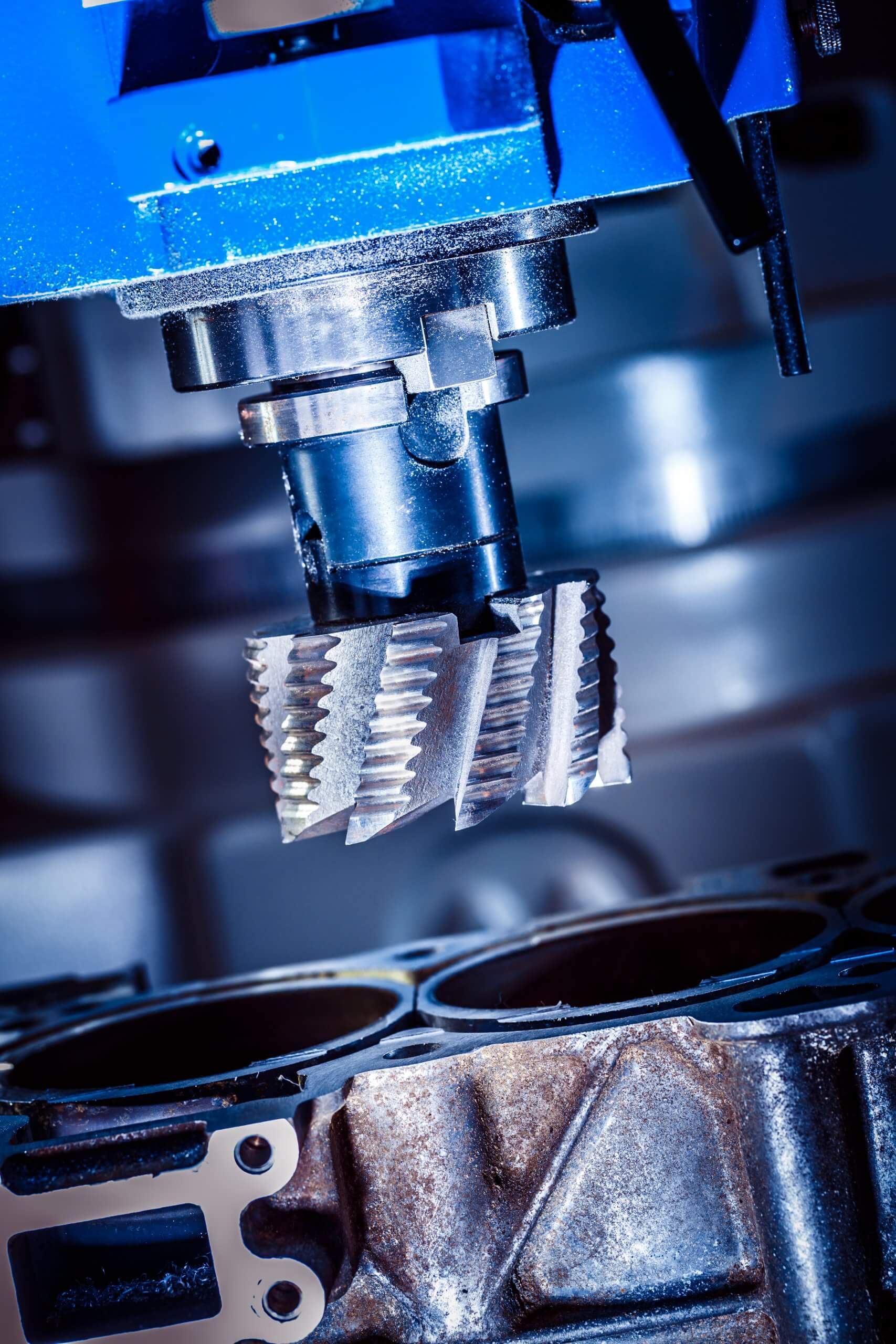

- Processing Methods and Assembly Complexity: Using cost-effective non-cutting processing methods and simplifying the assembly process can reduce production costs. For instance, reducing the number of internal surface processes, ensuring simple processing surface shapes, and arranging them on the same plane or axis can minimize tool adjustments and machining steps.

Principles of Part Structural Design

To improve the manufacturability of parts, attention should be paid to the following points during the design process:

- Ease of Processing: Processing surfaces should allow easy entry and exit of tools, and major surfaces should be processed in a single clamping whenever possible. This not only improves processing efficiency but also ensures quality.

- Simplification and Standardization of Structures: The structural elements of parts should be as uniform as possible, with standardized and standardized dimensions to reduce the variety of tools and measuring instruments. For example, the widths of relief grooves on shafts should be consistent to reduce tool changes and types.

- Rational Dimension Annotation: Part dimension annotations should follow the shortest dimension chain principle and consider the coincidence of design and process benchmarks for easier processing and measurement.

- Improvement of Manufacturability: The design of parts should facilitate clamping and processing. For example, adding process flanges or holes to large workpieces can facilitate clamping and processing. Additionally, reducing the processing area and number of processed surfaces can improve processing efficiency and quality.

Practical Improvements in Manufacturability

In practical applications, the manufacturability of parts can be improved through the following methods:

- Design Improvements: Adjusting the shape and structure of parts to reduce the number of processing steps. For example, designing multiple key slots in the same direction can reduce installation and adjustment times and ensure positional accuracy.

- Optimization of Processing Methods: Avoid drilling holes on curved or inclined surfaces to ensure that the hole axis is perpendicular to the end face, improving productivity and processing accuracy.

- Reduction of Cutting Steps: Designing bosses with consistent heights allows for the processing of multiple surfaces in a single cut, improving productivity.

- Adoption of Combined Structures: For complex parts, decomposing and reassembling can turn internal surface processing into external surface processing, simplifying the process and ensuring quality.

Example Data Table

To visually demonstrate the impact of different designs on processing manufacturability, below is a simple data table:

| Item | Original Design | Improved Design |

|---|---|---|

| Consistency of Relief Groove Width | Inconsistent, requires tool change | Consistent, reduces tool change |

| Key Slot Arrangement | Different directions, requires multiple installations | Same direction, completed in one installation |

| Hole Processing Position | Drilling on inclined surfaces, easy to deflect | Perpendicular end face, ensures accuracy |

| Number of Processing Surfaces | Multiple processing surfaces | Reduced processing surfaces |

| Clamping and Positioning | Complex clamping, inconvenient operation | Added process flanges, easy clamping |

Other Articles You Might Enjoy

- Analysis of processing difficulty of different materials in CNC processing

Introduction to CNC Processing and Material Selection CNC processing, a cornerstone of modern manufacturing, stands for Computer Numerical Control machining, a method where pre-programmed software commands the movement of factory…

- Reaming Process for Stainless Steel Parts

The reaming process for stainless steel parts involves the following steps: Tool Geometry Design Most reaming of stainless steel materials uses carbide reamers. The structure and geometric parameters of these…

- Phosphor Bronze vs. Silicon Bronze for CNC Machining: A Detailed Analysis

Introduction to CNC Machining CNC (Computer Numerical Control) Machining signifies a pivotal advancement in the fields of manufacturing and engineering. This process utilizes computer software for the control and manipulation…

- Requirements for CNC Machining Parts

Preparation Work Complete the necessary preparation before machining, including process analysis, process route design, tool and fixture selection, and program compilation. online cnc machining service Operating Steps and Contents Start…

- What are the requirements for CNC machining of bearing parts?

Bearings are common and important parts in the automotive industry, which can support transmission components and transmit torque. Generally, CNC machining centers are used to process bearing parts. So what…

- The use of plastics in food processing machinery

Introduction to Plastics in Food Processing Machinery The incorporation of plastics into food processing machinery plays a pivotal role in the modern food industry. These synthetic materials are employed for…