Residual stress is a crucial factor affecting the performance and durability of aluminum alloy components in aerospace applications. These parts are often large, thin-walled, and complex in structure, making them particularly susceptible to the adverse effects of residual stress. Understanding and controlling this stress is essential for ensuring the structural integrity and reliability of these critical components.

Importance of Residual Stress Analysis

Residual stress impacts several key properties of aluminum alloy parts:

- Fatigue Strength: Residual stress can significantly affect the fatigue life of components, leading to premature failure.

- Corrosion Resistance: Stress can create sites for corrosion initiation, reducing the part’s lifespan.

- Dimensional Stability: Uncontrolled residual stress can cause warping and deformation during and after machining.

- Service Life: Overall, residual stress influences the long-term performance and safety of aerospace components.

Given these impacts, controlling and measuring residual stress in aluminum alloy parts is a top priority in aerospace manufacturing.

Methods for Measuring Residual Stress

Several methods exist for measuring residual stress, but the choice depends on the material, the required accuracy, and whether a non-destructive technique is preferred. The two primary methods discussed here are the hole-drilling method and the layer-by-layer cutting method.

- Hole-Drilling Method:

- This method involves drilling a small hole in the part and measuring the resulting deformation around the hole to calculate the residual stress.

- It’s a semi-destructive technique, suitable for measuring surface and near-surface stresses.

- Its accuracy decreases with depth, making it less suitable for thick components.

- Layer-by-Layer Cutting Method:

- This method involves sequentially removing thin layers of material from the part and measuring the resulting deformation after each cut.

- It provides a detailed stress profile through the thickness of the part.

- Although it’s a destructive method, it’s highly accurate and particularly useful for materials with low residual stress levels, like pre-stretched aluminum alloy plates.

Implementing the Layer-by-Layer Cutting Method

The layer-by-layer cutting method was selected for this study due to its high accuracy and ability to measure through-thickness residual stress distributions in aluminum alloy plates.

Experimental Setup

- Sample Preparation:

- Aluminum alloy plates are marked with a 25mm x 25mm grid around the measurement point.

- Strain gauges are attached in specified directions on the grid to measure strain during cutting.

- Cutting Process:

- The marked area is cut slowly using a milling machine to separate the measurement point from the surrounding material.

- After each cut, strain gauges record the strain released from the material.

- Data Collection:

- Strain data is collected using a high-precision dynamic resistance strain gauge.

- Measurements are taken after each 2mm cut to ensure accurate stress distribution profiling.

Calculating Residual Stress

The residual stress is calculated from the measured strains using Hooke’s law. Depending on the known stress state:

- For uniaxial stress, a single strain gauge is used.

- For biaxial stress, two strain gauges at known angles are used.

- For unknown stress states, three strain gauges at 0°, 45°, and 90° are used to fully characterize the stress state.

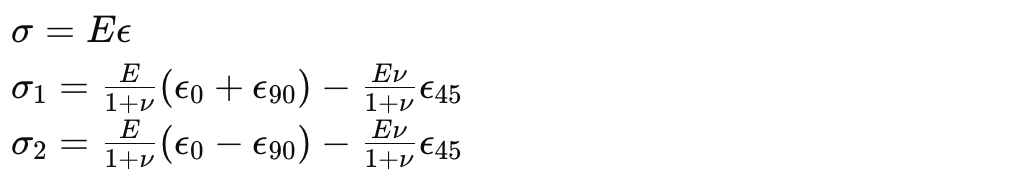

The equations used are:

Where ϵ represents the measured strain, E is the Young’s modulus, and ν is Poisson’s ratio.

Results and Discussion

The layer-by-layer cutting method revealed the residual stress distribution within the aluminum alloy plates. Typical results showed:

- Residual stress levels varied significantly with depth.

- Surface layers exhibited higher stress levels, which decreased with depth.

- The stress distribution was consistent with the expected profile for pre-stretched aluminum alloy plates.

These findings highlight the importance of residual stress management in CNC machined parts. By understanding the stress profile, manufacturers can adjust machining processes to minimize adverse effects, leading to higher quality and more reliable aerospace components.

Data Table

| Layer Depth (mm) | Measured Strain (µε) | Calculated Stress (MPa) |

|---|---|---|

| 0-2 | 150 | 35 |

| 2-4 | 120 | 28 |

| 4-6 | 100 | 23 |

| 6-8 | 80 | 18 |

| 8-10 | 60 | 14 |

This table illustrates the typical strain and calculated stress values measured at various depths in an aluminum alloy plate. It shows a clear trend of decreasing stress with increasing depth, validating the effectiveness of the layer-by-layer cutting method in capturing residual stress profiles.

Managing residual stress is critical in CNC machining of aluminum alloy parts, especially in aerospace applications where precision and reliability are paramount. The layer-by-layer cutting method provides an accurate and detailed understanding of residual stress distributions, enabling better process control and improved part performance.

Other Articles You Might Enjoy

- Mastering CNC Machining: Overcoming Thin-Walled Aluminum Alloy Part Deformations

In the world of CNC machining, creating precise and complex parts from aluminum alloys is a common yet challenging task. When it comes to thin-walled parts, deformation can be a…

- CNC Machining Materials: Acrylic vs. Polycarbonate for Transparent Components

CNC Machining: An Introduction and the Importance of Material Type Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Aluminum Grades: Key Characteristics and CNC Machining(Aluminum Grades and Properties Gemma)

As advancements in manufacturing technologies continue to evolve, industries are leveraging more efficient methods like CNC machining for their production processes. One of the commonly used materials in these operations…

- Overcoming Deformation Issues in CNC Machining of Aerospace Aluminum Parts

In the aerospace industry, large aluminum alloy thin-wall structures are prized for their lightweight and high-strength properties. However, machining these components presents a set of unique challenges, primarily due to…

- Understanding Aluminum Grades and Properties in CNC Machining (Aluminum Grades and Properties Lynn)

In the field of computer numerical control(CNC) machining, understanding aluminum grades, their properties, as well as how they influence the manufacturing process is vital. Aluminum, owing to its favorable properties…