Chapter 1: What Does “Annealed” Mean in Manufacturing?

If you’re involved in manufacturing or machining, you’ve probably come across the term “annealed” before. But if you’re new to the term, don’t worry. I’ll explain clearly, based on my own experiences and insights from the field.

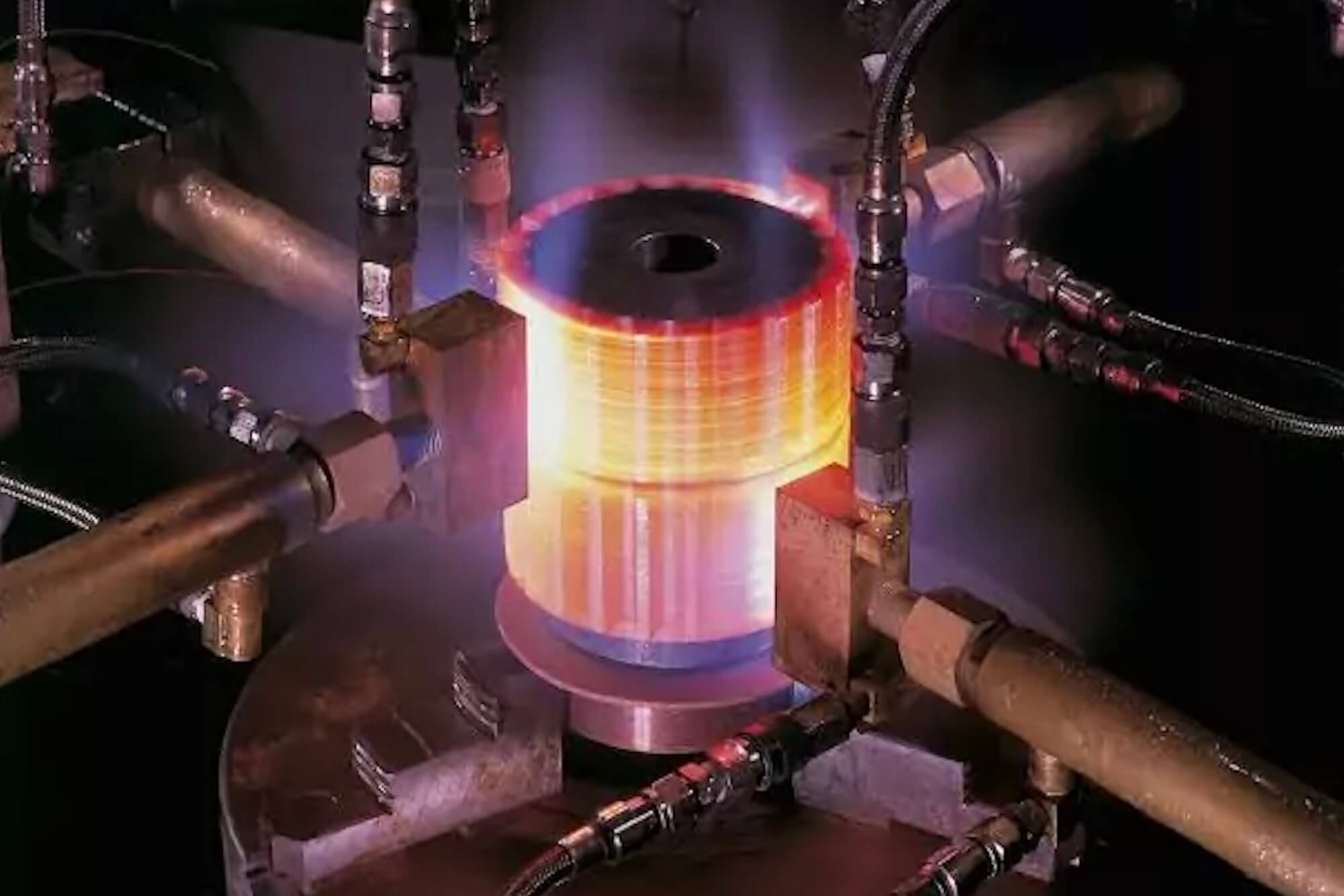

Annealing is a heat treatment process used primarily on metals to soften them, reduce internal stresses, and improve their ability to be machined, shaped, or welded. When metals undergo cold working (like bending, rolling, or drawing), they become harder but more brittle. Annealing reverses that condition, making the metal more workable.

When I first learned about annealing, I was working as a junior process engineer in a small machine shop. One day, we struggled with cracking issues in stainless steel tubing. After much frustration, I learned the tubing we used hadn’t been annealed properly. This meant the material had high residual stress, causing it to crack easily under machining. That incident taught me firsthand why annealing is crucial.

Annealing typically involves three steps:

- Heating: Bringing the metal to a specific high temperature.

- Soaking: Holding the metal at that temperature for enough time to change its internal structure.

- Cooling: Allowing the metal to cool slowly, usually in air or inside the furnace.

But annealing isn’t the only heat treatment available. You’ll also hear terms like “normalizing,” “tempering,” and “stress-relieving.” While similar, they’re not identical. Annealing fully softens the metal, normalizing partially softens it, and tempering generally reduces hardness slightly after quenching. Stress-relieving specifically targets internal stress without dramatically changing hardness.

In short, annealed metals are easier to machine, form, and handle. They resist cracking better and often show improved consistency in mechanical properties. In manufacturing, these advantages can mean the difference between costly production issues and smooth, trouble-free operations.

Chapter 2: Why and When Is Annealing Used?

Annealing isn’t just a nice-to-have process—it solves real manufacturing problems. So, when should you anneal metals? Let’s explore some common scenarios I’ve encountered in my engineering work.

Reducing Internal Stress

When metal is worked (especially cold-formed), internal stresses build up. These stresses can lead to cracking, warping, or dimensional changes. Annealing relaxes these internal stresses, preventing issues down the line.

I remember visiting an automotive parts supplier. They were stamping steel brackets, but parts kept deforming unpredictably. By introducing an annealing step after cold forming, they nearly eliminated these issues overnight. The difference was dramatic.

Improving Machinability

Annealed metals are easier on cutting tools. Hard, brittle metals cause rapid tool wear, higher machining costs, and poor surface finishes. Annealing softens the metal, reducing machining resistance and extending tool life.

I’ve seen tool life improve by as much as 50% just by annealing stainless steel blanks before CNC machining. The lower hardness made cutting smoother, faster, and more predictable. This saved both time and money.

Restoring Ductility After Cold Working

Metals like copper and aluminum harden quickly when cold-worked. Annealing restores ductility, allowing further bending or shaping without cracks.

Once, we struggled to form copper coils for electrical equipment because the wire cracked during winding. By annealing the copper wire beforehand, we regained the flexibility needed to form coils without defects. It was a simple fix but incredibly effective.

Achieving Consistent Properties Across Large Batches

Annealing provides uniform mechanical properties throughout large production batches. Variations in hardness and ductility can create serious quality control headaches. Annealed batches exhibit more uniform characteristics, reducing rejects and ensuring product reliability.

In a high-volume stamping operation I visited, inconsistent steel hardness caused batch rejections. Introducing annealing cycles normalized the metal’s properties, dramatically reducing waste.

Improving Weldability and Joining

Some metals are notoriously difficult to weld in hardened conditions. Annealing before welding significantly reduces cracking and improves joint strength.

I observed this in a construction equipment manufacturer. Their welders struggled with hardened steel plates. Annealing those plates first eliminated weld cracking issues and greatly enhanced weld integrity.

Preparing Metals for Final Treatments

Annealing is sometimes essential as preparation for subsequent heat treatments or surface treatments. For example, steel that needs deep case hardening often requires annealing beforehand to achieve consistent results.

Quick Reference: Common Reasons and Metals for Annealing

| Metal | Common Reason for Annealing |

|---|---|

| Steel | Reduce hardness, improve machinability, stress relief |

| Stainless Steel | Improve machinability, reduce stress, improve welds |

| Aluminum | Restore ductility, reduce cracking risk |

| Copper | Improve bending, formability, conductivity |

| Brass | Enhance machinability, restore ductility |

| Titanium | Improve machinability, reduce internal stresses |

| Nickel Alloys | Reduce internal stresses, facilitate further forming |

Chapter 3: Annealed vs Non-Annealed Materials

When selecting materials for manufacturing, a key decision is whether to use annealed or non-annealed metals. I’ve faced this choice often, and the decision greatly impacts production efficiency, product quality, and costs. Let’s explore the key differences clearly.

Mechanical Property Differences

Annealed metals have distinctly different properties from their non-annealed counterparts:

- Hardness:

Annealed metals have significantly lower hardness than cold-worked or untreated materials. This makes them easier to machine but may reduce their strength. - Ductility:

Annealed metals exhibit high ductility, meaning they deform without cracking. Non-annealed metals, especially cold-worked ones, can crack under stress due to reduced ductility. - Internal Stress:

Annealed metals have minimal internal stress, reducing warping or distortion risks during machining or welding. Non-annealed metals often carry residual stresses, leading to unpredictable dimensional changes.

Real-World Application Examples

When I worked with medical device manufacturers, I noticed how critical choosing the right metal state could be. For instance, surgical tools made from annealed stainless steel could easily be shaped or stamped without cracking. Non-annealed steel, by contrast, often led to costly rework.

Similarly, automotive manufacturers prefer annealed steel for complex stamped parts. Annealing provides consistent mechanical properties across batches, critical for mass production quality control.

On the other hand, applications requiring maximum strength or hardness might avoid fully annealed metals. For instance, spring steel parts rely on high strength and elasticity that annealing would remove. Instead, they are partially annealed or tempered.

Decision-making: Annealed vs Non-Annealed?

From experience, here’s a simplified table I often use for quick decision-making:

| Criteria | Annealed Metal | Non-Annealed Metal |

|---|---|---|

| Machinability | Excellent, reduced tool wear | Poor, increased tool wear |

| Ductility (Formability) | High, easy bending/forming | Low, prone to cracking |

| Internal Stress Level | Low, stable dimensionally | High, risk of distortion |

| Strength and Hardness | Lower | Higher |

| Weldability | Generally better, fewer cracks | Often worse, prone to cracking |

| Ideal Applications | Machined parts, complex forms, welding | Springs, hardened shafts, wear-resistant surfaces |

This quick reference has saved me considerable time and reduced guesswork.

My Personal Perspective

I’ve often found it helpful to evaluate application-specific needs carefully. For example, in machining-intensive operations, choosing annealed metal saved substantial tool costs. In contrast, for certain high-strength components like gear shafts or springs, non-annealed or tempered metals often were necessary.

For example, I once dealt with a gear manufacturer experiencing rapid tool wear. They used hardened (non-annealed) blanks for gears, believing maximum hardness would yield better durability. But the extreme hardness prematurely wore down cutting inserts. When we switched to annealed blanks, machinability improved dramatically, and subsequent heat treatments provided the necessary final hardness.

Common Misconceptions

A common misconception I’ve heard is that annealing inherently weakens metal excessively. That’s not necessarily true. Annealing certainly reduces hardness and tensile strength, but it doesn’t weaken the metal beyond usability. Annealed metal still retains significant structural strength and is often ideal for certain applications, especially if subsequent processing steps (e.g., heat treatment) restore desired final properties.

Another misconception is that annealing is always an unnecessary cost. From what I’ve seen, annealing often reduces overall manufacturing costs significantly. Easier machining, fewer rejects, reduced downtime, and less rework typically offset annealing expenses multiple times over.

Cost Considerations

Annealed materials generally involve extra processing costs initially (due to furnace heating and cooling cycles). But the overall cost-benefit analysis often favors annealing. Lower tooling costs, fewer defects, and improved product quality often outweigh the initial expense.

In one case involving stainless steel components, annealing increased raw material cost by about 10%, yet machining and defect-related savings exceeded 25%. The net savings justified the annealing step clearly.

Quick Reference: Cost-Benefit Comparison Example

| Cost Factor | Non-Annealed Material | Annealed Material |

|---|---|---|

| Raw Material Price (per lb.) | $2.00 | $2.20 (slightly higher) |

| Machining Cost per Piece | $5.50 (high tool wear) | $3.00 (low tool wear) |

| Defect/Rejection Rate | 10% | 2% |

| Rework Cost per Piece | $2.00 | $0.50 |

| Total Cost per 1000 pcs. | $9,250 | $5,970 |

| Net Savings | – | $3,280 |

In this real example, annealing created substantial cost efficiency, even after factoring in slightly higher raw material prices.

Summary: Choosing Annealed or Non-Annealed

To decide between annealed and non-annealed materials, consider:

- Machining Requirements: Annealed metals are ideal.

- Strength Requirements: Non-annealed metals may be better.

- Dimensional Stability: Annealed materials are more predictable.

- Cost Implications: Consider total lifecycle costs, not just raw material.

Understanding these factors, based on my experiences, helps you make informed and cost-effective decisions in your manufacturing processes.

In the next chapter, I’ll detail specific annealing parameters for commonly used metals, offering practical guidance to implement annealing effectively in your processes.

Chapter 4: Material-Specific Annealing Guidelines

Annealing isn’t a one-size-fits-all process. Different metals and alloys need specific annealing temperatures, soaking times, and cooling methods. Here, I’ll share practical annealing guidelines I’ve often referred to in my work, helping you choose the right settings for the most common metals used in manufacturing.

Carbon Steel Annealing

Carbon steels, the workhorses of manufacturing, are widely annealed to improve machinability, formability, and reduce stress. Lower-carbon steels anneal differently than medium- or high-carbon steels:

- Low Carbon Steel (e.g., 1018): Anneal at about 1600°F (870°C), soak for 1 hour per inch thickness, then cool slowly in a furnace or air.

- Medium Carbon Steel (e.g., 1045): Heat to 1550–1600°F (840–870°C), hold for 1 hour per inch, slow furnace cool.

- High Carbon Steel (e.g., 1095): Heat to about 1450–1500°F (790–815°C), short soak (30–60 min), cool slowly in furnace.

In practice, I once had trouble drilling holes in high-carbon steel. It cracked frequently. After annealing at 1500°F for 45 minutes, drilling became smooth, eliminating cracks completely.

Stainless Steel Annealing

Stainless steel annealing varies greatly by alloy type—304, 316, and 410 behave differently. Precise annealing is crucial for optimal machinability and corrosion resistance.

- 304 and 316 Austenitic Stainless Steel:

Anneal between 1850–2050°F (1010–1120°C), soak for 30–60 minutes, rapid air cool or water quench for best corrosion resistance. - 410 Martensitic Stainless Steel:

Heat to 1500–1650°F (815–900°C), soak for about 1 hour, cool slowly in furnace or air for softness.

I found annealing essential with 316 stainless tubing used in medical equipment. Properly annealed, it bends without cracks, drastically improving quality and consistency.

Aluminum Alloys Annealing

Aluminum alloys gain hardness quickly during cold working, requiring frequent annealing. Annealing temperatures are generally lower compared to steel.

- 6061 Aluminum: Anneal at about 775°F (413°C), soak for 2–3 hours, cool at controlled rates (about 50°F/hr to 500°F, then air cool).

- 2024 Aluminum: Anneal at 775°F (413°C), hold 2–3 hours, slow furnace cool for optimal softness and stability.

On an aerospace component project, we needed consistent bend radii on aluminum brackets. Annealing at 775°F allowed clean, uniform bends without cracking or spring-back.

Copper and Brass Annealing

Copper alloys become hard quickly after forming. Annealing restores flexibility and machinability.

- Pure Copper: Anneal at 900–1200°F (480–650°C), short soak (15–30 min), cool slowly or quench in water for softness.

- Brass (e.g., Cartridge Brass): Heat to 800–1100°F (425–595°C), short soak, water quench for maximum ductility.

In electrical wiring applications, I’ve seen how annealed copper drastically improves formability, enabling tight coil formation without fractures.

Tool Steel Annealing

Tool steels (O1, D2, H13) require careful annealing to soften properly for machining or preparation before final heat treatments:

- O1 Tool Steel: Anneal at about 1400°F (760°C), long soak (2–4 hours), slow furnace cool (~20°F/hour to below 1000°F).

- D2 Tool Steel: Heat to 1550–1600°F (845–870°C), hold 2–3 hours, slow cool at ~40°F/hour to below 1000°F, then air cool.

- H13 Hot Work Steel: Anneal at 1550–1650°F (845–900°C), hold 2–3 hours, furnace cool slowly.

On mold-making jobs, D2 steel can wear down cutting inserts quickly. After annealing according to these parameters, cutting speeds increased, tool life doubled, and surface finishes improved notably.

Quick Reference Annealing Guidelines (Table)

Here’s a clear, practical reference I’ve compiled and often used:

| Material | Annealing Temp. (°F) | Soak Time | Cooling Method |

|---|---|---|---|

| Low Carbon Steel (1018) | 1600°F | 1 hr/in thickness | Slow furnace or air cool |

| Medium Carbon Steel(1045) | 1550–1600°F | 1 hr/in thickness | Slow furnace cool |

| High Carbon Steel (1095) | 1450–1500°F | 30–60 min | Slow furnace cool |

| 304/316 Stainless Steel | 1850–2050°F | 30–60 min | Rapid air cool or water quench |

| 410 Stainless Steel | 1500–1650°F | 1 hr | Slow furnace or air cool |

| Aluminum 6061 | 775°F | 2–3 hrs | Controlled cool (50°F/hr), then air |

| Pure Copper | 900–1200°F | 15–30 min | Slow cool or water quench |

| Brass | 800–1100°F | 15–30 min | Water quench |

| O1 Tool Steel | 1400°F | 2–4 hrs | Slow furnace cool (~20°F/hr) |

| D2 Tool Steel | 1550–1600°F | 2–3 hrs | Slow cool (~40°F/hr), then air cool |

| H13 Hot Work Steel | 1550–1650°F | 2–3 hrs | Slow furnace cool |

I recommend verifying results with hardness testing to ensure optimal annealing outcomes.

Practical Tips from My Experience

In my career, I’ve learned these practical tips for successful annealing:

- Uniform Heating: Ensure metal heats evenly to avoid inconsistent annealing.

- Accurate Soak Times: Follow recommended soak times strictly to achieve complete recrystallization.

- Controlled Cooling: Cooling too quickly reintroduces stress; slow cooling is essential for softness.

Following these specific guidelines and my practical tips can greatly improve the effectiveness of your annealing processes. This results in better machinability, higher productivity, and fewer defects—essential for successful manufacturing.

Chapter 5: How Annealing Affects Machining and Fabrication

Annealing significantly impacts machining and fabrication—I’ve personally witnessed how proper annealing can transform manufacturing operations. Let’s dive into why annealed metals are easier and more cost-effective to machine, bend, stamp, and weld.

Improved Machinability

One of the primary reasons engineers prefer annealed metals is their dramatically improved machinability. Annealed metals have reduced hardness, lower internal stress, and increased ductility, all of which make cutting easier and more efficient.

I’ve worked on projects machining stainless steel components, and the difference between machining annealed versus non-annealed metals was remarkable. For instance, machining annealed 304 stainless steel required fewer tool changes, allowed higher cutting speeds, and resulted in better surface finishes. By contrast, hardened or cold-worked stainless steel often broke cutting inserts prematurely, creating downtime and added costs.

When machining metals, lower hardness means reduced cutting force. This directly translates to longer tool life. I recall a case involving 1045 steel shafts. Initially, we used non-annealed material. Frequent tool replacements, slow cycle times, and poor finishes were constant issues. Switching to annealed steel cut tooling costs by nearly half and improved productivity significantly.

Less Tool Wear

Annealed materials place less stress on cutting tools. Brittle or hard materials, conversely, tend to rapidly dull or fracture cutting edges. I’ve observed that with proper annealing, carbide insert life can increase substantially—sometimes even doubling or tripling compared to non-annealed stock.

In one CNC turning project I handled, we machined D2 tool steel for molds. Without annealing, we saw catastrophic tool wear rates. But after annealing the blanks properly at about 1600°F (870°C), we saw inserts lasting over three times longer. Reduced tool wear not only saves tooling costs but also reduces machine downtime for frequent insert replacements.

Better Chip Control

Annealed metals often yield better chip formation. Brittle, hardened metals create fragmented or irregular chips that can damage tools, create safety hazards, and impair finish quality. Annealed metals produce continuous, manageable chips, which are safer and more predictable in high-volume machining.

During a machining operation on aluminum aerospace brackets, annealed metal produced uniform, clean chips. Non-annealed metal, by contrast, produced jagged chips that frequently tangled around cutting tools. Switching entirely to annealed blanks streamlined chip evacuation, improving overall productivity.

Easier Forming and Fabrication

Annealed metals significantly outperform hardened metals during bending, stamping, and forming processes. Annealed materials bend easily without cracking or requiring excessive force.

For instance, in metal stamping processes, I’ve consistently seen annealed steel blanks form smoothly into complex shapes. Non-annealed or hardened steel often cracks, splits, or requires increased press tonnage, leading to higher costs and frequent defects.

Once, I consulted for a manufacturer producing automotive brackets from hardened steel sheets. The press operation frequently resulted in micro-cracks, invisible until quality inspections later. Annealing the sheets prior to stamping eliminated nearly all cracking issues, dramatically reducing waste and improving yield rates.

Enhanced Weldability

Welding annealed metals is typically simpler and less prone to defects than welding hardened or cold-worked metals. Annealing reduces internal stresses and increases ductility, both essential for reducing weld cracking and distortion.

I recall an experience at a construction equipment plant. Welders frequently struggled with hardened steel plates, encountering cracks along the weld lines. We introduced an annealing step before welding, greatly enhancing weld quality and virtually eliminating cracks. The improved weldability saved substantial rework costs and downtime.

Recommended Machining Sequence with Annealing

Based on my experience, here’s the most effective sequence I’ve found:

- Anneal metal blanks fully before rough machining or forming operations.

- Perform rough machining or forming while the metal is soft and stress-free.

- If required, conduct a second annealing or stress-relief step after major machining to remove new stresses from heavy cutting.

- Complete finish machining with minimal distortion risks.

Following this sequence has consistently produced high-quality, dimensionally stable parts across various industries I’ve worked with.

Quick Reference: Machining Benefits of Annealed Metals (Table)

| Benefit | Annealed Metal Results | Non-Annealed Metal Results |

|---|---|---|

| Tool Life | High, longer-lasting inserts | Low, frequent insert changes |

| Cutting Speeds | Higher, improved cycle times | Lower, slower production |

| Surface Finish | Superior, smooth | Inferior, rough, inconsistent |

| Chip Formation | Excellent, manageable | Poor, irregular, hazardous |

| Formability (Bending) | Excellent, minimal cracking | Poor, frequent cracking |

| Weldability | Excellent, fewer defects | Poor, frequent cracks |

In practical terms, annealing has been a game-changer in machining efficiency and overall manufacturing profitability.

Chapter 6: Real-World Case Studies on Annealing

Real-world examples illustrate annealing’s direct benefits. I’ll share some specific case studies from my own experience and observations in various industries.

Case Study 1: Annealed Copper for Electrical Components

Problem:

An electronics manufacturer faced frequent cracking in copper coils. The copper wire hardened during drawing, causing breakage when forming tight coils.

Solution:

Annealing copper wire at approximately 900°F (480°C) restored ductility, preventing cracking. Coil production improved instantly, and defects nearly vanished.

Outcome:

Production yield improved from 82% to over 98%. Annealing added minor initial costs but quickly paid off through reduced scrap and downtime.

Case Study 2: Annealed Stainless Steel for Medical Instruments

Problem:

A medical device manufacturer struggled with excessive tool wear machining non-annealed stainless steel tubing. Surface finish issues and frequent tool replacement increased costs dramatically.

Solution:

Annealed stainless steel tubing (annealed at 1950°F) significantly reduced hardness and internal stresses. Machining became faster, easier, and more predictable.

Outcome:

Tool life increased by 60%, cycle times dropped by 20%, and surface finishes improved significantly. Overall machining costs fell notably, offsetting initial annealing expenses.

Case Study 3: Automotive Parts Stamping

Problem:

An automotive supplier experienced frequent cracks and splits during stamping hardened steel brackets.

Solution:

Introducing a full annealing step prior to stamping dramatically increased metal ductility, virtually eliminating cracking.

Outcome:

Stamping yield improved from approximately 85% to 99%. Annealing effectively eliminated rework and significantly boosted productivity.

Case Study 4: Aerospace Component Machining

Problem:

A manufacturer machining aerospace brackets from hardened aluminum struggled with irregular chips, tool wear, and inconsistent part dimensions.

Solution:

Annealing aluminum at approximately 775°F (413°C) before machining dramatically improved chip control and dimensional consistency.

Outcome:

Improved chip handling significantly boosted machining efficiency. Tool life increased by nearly 50%, and parts consistently met tight dimensional tolerances.

Practical Impact of Annealing (Summary Table)

| Case Study | Problem Faced | Annealing Solution | Outcome Achieved |

|---|---|---|---|

| Copper Coils | Cracking during coil formation | Annealed at ~900°F | Yield improvement from 82% to 98% |

| Stainless Steel Tubing | Excessive machining tool wear | Annealed at ~1950°F | Tool life +60%, machining costs reduced |

| Automotive Stamped Parts | Frequent stamping cracks | Annealed blanks prior stamping | Yield from ~85% to ~99% |

| Aerospace Aluminum Brackets | Poor chips, dimensional issues | Annealed at ~775°F | Tool life +50%, better dimensions |

These cases clearly show annealing’s direct, positive impact on real-world manufacturing operations. I’ve seen firsthand how annealing, though initially viewed as an added step, ultimately enhances productivity, quality, and overall profitability.

Chapter 7: How to Specify “Annealed” in Technical Drawings and Procurement

Clearly specifying “annealed” in technical documentation and purchase orders is crucial. I’ve seen many cases where unclear specifications led to misunderstandings, material rejections, and costly delays. To help you avoid these issues, I’ll share practical guidance on how to clearly and accurately indicate annealed materials in drawings and procurement processes.

Importance of Clear Specifications

Ambiguity in specifying annealing can lead to confusion. Suppliers and machinists may deliver improperly annealed (or non-annealed) materials if documentation is vague. I experienced this first-hand when a supplier mistakenly delivered hardened stainless steel instead of annealed stock due to unclear notes on a drawing. This caused significant downtime and extra costs to fix.

To prevent these issues, always clearly state “annealed” explicitly in drawings, orders, and specifications.

How to Properly Specify Annealing in Drawings

A good drawing specification typically includes:

- Material Type: Clearly state alloy type (e.g., 304 Stainless Steel).

- Condition: Clearly state “Annealed” or specify the exact heat treatment.

- Relevant Standard/Specification: Cite standards (e.g., ASTM, ISO) where applicable.

- Hardness or Mechanical Properties (optional): Provide hardness or strength values if critical.

Here are practical examples from actual drawings I’ve worked with:

- Example 1 (Simple):

Material: 304 Stainless Steel, Annealed, per ASTM A240. - Example 2 (Detailed):

Material: Alloy 6061-T6 Aluminum, fully annealed to O-temper condition per ASTM B209, hardness: maximum 40 HRB.

Including these clear specifications on your drawings eliminates ambiguity, ensuring suppliers deliver precisely what you require.

Communicating Clearly with Suppliers

Clear specifications alone aren’t always enough—effective communication with suppliers is equally important. I’ve found the following communication methods effective:

- Clarify Annealing Requirements in Advance:

Before placing orders, explicitly confirm annealing specifications verbally or via email. - Request Certificates of Compliance (COCs):

Require suppliers to provide certifications confirming annealing has been performed per your specifications. - Specify Acceptable Hardness Ranges:

Include acceptable hardness ranges to verify annealing quality. I usually ask for material hardness tests to validate annealing results.

On one aerospace project, insisting on supplier COCs and hardness verification caught improperly annealed stock before reaching production, preventing costly mistakes.

Recommended Annealing Specification Checklist

Here’s a simple checklist I personally use to ensure clarity:

| Checklist Item | Yes/No | Notes |

|---|---|---|

| Material alloy/type clearly stated? | ||

| Annealed condition explicitly listed? | ||

| Relevant standard specified (ASTM/ISO)? | ||

| Hardness/mechanical properties defined? | (optional, recommended) | |

| Certification required from supplier? | ||

| Supplier acknowledged annealing spec? |

Using a checklist like this helps ensure nothing gets overlooked.

Common Standards for Annealing Specifications

To assist clarity, always reference appropriate industry standards. Here’s a quick guide to some standards I’ve frequently used:

| Material Type | Recommended Standard |

|---|---|

| Carbon & Alloy Steel | ASTM A684 |

| Stainless Steel | ASTM A240, ASTM A666 |

| Aluminum Alloys | ASTM B209 |

| Copper & Copper Alloys | ASTM B152 |

| Brass Alloys | ASTM B36 |

| Tool Steel | ASTM A681 |

Referring to these standards provides a universally understood basis, eliminating ambiguity.

My Practical Experience and Recommendations

Clearly specifying annealed conditions has consistently saved projects I’ve managed from unnecessary headaches. Whenever I’ve deviated from clearly indicating “annealed” status, it inevitably resulted in miscommunication and cost overruns.

In short, always clearly specify “annealed” conditions, verify compliance, and communicate clearly with suppliers. These steps ensure predictable results, fewer defects, and smoother production processes.

Chapter 8: Tools, Charts, and Annealing Process Examples

Having reliable tools and references makes annealing processes more predictable and successful. Over the years, I’ve compiled several essential tools and charts to help me quickly set up proper annealing cycles and validate outcomes. I’ll share them here clearly and practically.

Essential Annealing Charts and Tools

The following tools and charts are essential in annealing operations. Keep them handy to quickly determine annealing temperatures, soak times, cooling rates, and more.

1. Annealing Temperature Reference Chart (°F)

| Metal/Alloy | Recommended Annealing Temp. (°F) | Cooling Method |

|---|---|---|

| Low Carbon Steel | 1550–1650°F | Slow furnace/air |

| Medium Carbon Steel | 1550–1600°F | Slow furnace |

| High Carbon Steel | 1450–1500°F | Slow furnace |

| Stainless Steel (304) | 1850–2050°F | Rapid air/water quench |

| Aluminum (6061) | 750–800°F | Controlled slow cool |

| Copper | 900–1200°F | Air cool or water quench |

| Brass | 800–1100°F | Water quench |

I regularly reference this chart in manufacturing environments to quickly verify annealing parameters.

2. Hardness Conversion Chart (Common Scales)

This quick reference helps you convert between hardness scales commonly used in annealing verification:

| Rockwell B (HRB) | Rockwell C (HRC) | Brinell Hardness (HB) |

|---|---|---|

| 60 | – | 111 |

| 70 | – | 130 |

| 80 | – | 150 |

| 90 | 20 | 178 |

| – | 30 | 286 |

| – | 40 | 371 |

| – | 50 | 481 |

I’ve found this conversion chart essential during inspections to quickly verify hardness readings across different scales.

Annealing Workflow Example (Real-Life Process)

Here’s an example of a successful annealing workflow for 304 stainless steel, based on my own process documentation:

- Step 1 (Preparation): Confirm metal alloy type, thickness, and initial hardness.

- Step 2 (Heating): Heat uniformly to annealing temperature (1950°F).

- Step 3 (Soaking): Maintain temperature for at least 60 minutes to ensure full recrystallization.

- Step 4 (Cooling): Rapidly cool metal via forced air or water quenching for optimum softness and corrosion resistance.

- Step 5 (Verification): Verify hardness (ideally below 90 HRB), document results, and inspect material visually for uniformity.

Following a clear workflow like this ensures predictable, repeatable annealing results.

Personal Recommendations for Annealing Tools

Beyond charts, I recommend:

- Digital Temperature Loggers: Track accurate furnace temperatures and soak times for consistent annealing.

- Portable Hardness Testers: Quickly verify hardness immediately after annealing.

- Data Recording Systems: Document annealing parameters for traceability and continuous improvement.

I’ve found these tools invaluable for consistently successful annealing operations across various manufacturing environments.

Chapter 9: Common Problems and Solutions in Annealing

In my experience working with annealed metals, I’ve encountered several recurring problems. Understanding how to identify and fix these issues is critical. Here, I’ll outline common annealing challenges and practical solutions to handle them effectively.

Problem 1: Uneven Annealing

Cause:

Uneven heating or inadequate soak times can cause inconsistent hardness and ductility across metal pieces.

Solution:

- Use calibrated furnaces to ensure uniform heating.

- Ensure metal pieces have sufficient spacing for proper airflow.

- Verify and follow recommended soak times strictly.

Once, uneven annealing in aluminum brackets caused severe bending inconsistencies. By properly spacing pieces in the furnace and accurately timing soaks, we achieved uniform results.

Problem 2: Excessive Hardness After Annealing

Cause:

Rapid cooling or insufficient soaking can lead to incomplete recrystallization.

Solution:

- Increase soak duration at proper annealing temperatures.

- Slow down cooling rates or adjust the cooling method to recommended standards.

- Confirm furnace calibration and temperature accuracy regularly.

In my experience, adjusting soak times even by 30 minutes significantly improved hardness consistency in tool steel components.

Problem 3: Surface Oxidation and Scaling

Cause:

Exposure to oxygen at high annealing temperatures often creates scaling or oxidation.

Solution:

- Use protective atmospheres (argon or nitrogen gas) during annealing.

- Apply anti-scale coatings to prevent oxidation.

- Anneal in vacuum furnaces when practical.

At one aerospace component plant, introducing nitrogen atmospheres dramatically reduced surface scaling on stainless steel parts, eliminating costly rework.

Problem 4: Warping and Distortion During Annealing

Cause:

Uneven cooling or excessive internal stress release can warp or distort components.

Solution:

- Employ controlled slow cooling (e.g., furnace cooling) to reduce distortion.

- Use fixtures to support complex geometries during annealing.

- Gradually ramp temperatures up and down to avoid thermal shock.

On large aerospace parts, using fixtures and carefully controlling cooling reduced warping from nearly 15% down to under 1%.

Problem 5: Grain Growth and Loss of Mechanical Strength

Cause:

Overheating or excessively long soak times at annealing temperatures can cause grain growth, negatively affecting mechanical properties.

Solution:

- Accurately control soak temperature and duration according to established standards.

- Periodically test samples to verify grain structure.

- Adjust annealing cycles based on testing results.

I found frequent microstructure inspections critical for preventing excessive grain growth in precision automotive parts.

Quick Reference Table: Common Annealing Problems and Solutions

| Problem | Causes | Solutions |

|---|---|---|

| Uneven Annealing | Uneven heating, insufficient soak | Calibrated furnace, spacing, accurate soak |

| Excessive Hardness | Insufficient soak, rapid cooling | Adjust soak, slower cooling, verify temps |

| Surface Oxidation | High-temp exposure to oxygen | Protective atmospheres, vacuum annealing |

| Warping and Distortion | Uneven cooling, stress release | Controlled cooling, fixturing, gradual ramp |

| Grain Growth | Excessive temp/soak time | Accurate temp/soak control, frequent tests |

Implementing these solutions in my experience has consistently produced successful annealing results, significantly improving product quality and reliability.

FAQ About Annealing

Here, I’ll directly address common questions engineers and manufacturers frequently ask me about annealing. This practical FAQ section addresses typical uncertainties clearly and concisely.

1. What is annealing, and why is it done?

Annealing is heating metal to a specific temperature and cooling slowly to soften it, reduce internal stress, and improve machinability and ductility.

2. Is annealed metal softer than untreated metal?

Yes, annealed metal is softer and easier to shape, cut, and form compared to untreated or hardened metal.

3. What types of materials can be annealed?

Most metals, including steel, stainless steel, aluminum, copper, brass, and titanium, can be annealed successfully.

4. Does annealing reduce hardness?

Yes, annealing significantly reduces hardness and brittleness, improving ductility and formability.

5. Is annealing reversible?

Annealing isn’t reversible, but metals can be rehardened through subsequent processes like cold working or heat treatments.

6. Can a metal part be re-annealed after machining?

Yes, re-annealing after machining can relieve newly introduced stresses and prevent cracking or distortion.

7. What happens if I skip annealing in manufacturing?

Skipping annealing can lead to increased tool wear, cracking, warping, inconsistent part dimensions, and overall higher manufacturing costs.

8. Is annealing the same as stress relieving?

No, annealing fully softens metal, whereas stress relieving reduces internal stresses without significantly changing hardness.

9. How long does the annealing process take?

Annealing typically takes from 30 minutes to several hours, depending on metal thickness, alloy, and required properties.

10. Typical annealing temperatures for stainless steel?

Usually between 1850–2050°F (1010–1120°C), depending on specific stainless steel alloys.

11. Does annealing improve corrosion resistance?

For stainless steels, proper annealing can significantly improve corrosion resistance by restoring optimal metallurgical structures.

12. How to verify if metal is annealed?

Conduct hardness tests or check mechanical properties—annealed metals have lower hardness and higher ductility.

13. Can I anneal metals at home?

Small-scale annealing is possible with torches or ovens but may lack precision. Professional annealing methods offer controlled results.

14. How to specify “annealed” in drawings?

Clearly note “Annealed,” reference relevant standards (e.g., ASTM A240), and optionally specify desired hardness.

15. Difference between annealed and normalized steel?

Annealing provides maximum softness; normalizing partially softens steel, maintaining higher strength.

16. Does annealing affect weldability?

Yes, annealed metals typically weld easier and with fewer defects due to lower internal stresses and improved ductility.

17. Should I anneal before or after machining?

Ideally, anneal before rough machining to minimize tool wear, and potentially again after heavy machining to relieve new stresses.

18. Are there risks or disadvantages to annealing?

Potential risks include oxidation, grain growth, or excessive softening if improperly controlled. Properly managed annealing mitigates these risks.

19. How does annealing affect grain size?

Proper annealing refines grain structure, improving mechanical properties. Overheating or excessive annealing can lead to unwanted grain growth.

20. What cooling methods are used after annealing?

Common methods include furnace cooling (slowest), air cooling (moderate), and water quenching (fastest, used selectively).

Authoritative References on Annealing

Throughout this guide, I’ve shared practical experience, real use cases, and technical guidance around working with annealed metals in manufacturing. But like with any technical subject, there’s always more to explore—especially if you’re designing heat treatment processes, specifying materials, or troubleshooting failures on the shop floor.

Below are some reliable resources I personally turn to when I need deeper technical insights or verified data on annealing and related heat treatment methods. These sources are well-known in the engineering and materials science communities and are great for anyone looking to dive deeper into metallurgy fundamentals or process optimization.

- Annealing (Metallurgy) – Wikipedia

A foundational overview of annealing across different metals and treatment types.

https://en.wikipedia.org/wiki/Annealing_(metallurgy) - Heat Treatment – Wikipedia

Offers broader context on heat treatment methods, including annealing, quenching, tempering, and normalizing.

https://en.wikipedia.org/wiki/Heat_treatment - ASM International – Heat Treating Resources

Industry-trusted source for standards, textbooks, and real-world application of heat treatment principles.

https://www.asminternational.org/technical-books/-/journal_content/56/10192/06171G - Materials Science and Engineering: An Introduction – William D. Callister

A staple in materials education, covering microstructure, mechanical properties, and heat treatment fundamentals.

https://www.wiley.com/en-us/Materials+Science+and+Engineering%3A+An+Introduction%2C+10th+Edition-p-9781119405498 - The Heat Treat Doctor – Industrial Heating Magazine

Offers practical annealing and heat treatment advice from professionals working in heat treat operations.

https://www.industrialheating.com/articles/91513-the-heat-treat-doctor-practical-heat-treating - MatWeb – Online Material Property Data

A useful material selection tool with searchable properties for annealed and non-annealed grades.

http://www.matweb.com/ - Total Materia – Material Database

Comprehensive access to international standards and data for metals in all heat treatment states.

https://www.totalmateria.com/ - NIST – Material Measurement Laboratory

Trusted U.S. government resource for advanced material data and metallurgy research.

https://www.nist.gov/mml

These references not only reinforce the principles shared in this article, but also offer deeper technical detail and global standardization frameworks you might need when scaling up processes, validating material specs, or working in cross-border production environments.

If you’re serious about designing better parts, improving machining outcomes, or just understanding the metallurgy behind annealed metals, these are the places to go.

Other Articles You Might Enjoy

- Why Annealing Brass Matters in CNC Machining

Introduction Annealing brass is a key process in CNC machining, as it enhances machinability and improves the final quality of parts. Brass, an alloy primarily of copper and zinc, is…

- Revealing the Annealing Process of Copper and Alloys in CNC Machining Parts

In the realm of CNC machined parts, achieving the perfect balance of strength, flexibility, and durability often requires meticulous heat treatment processes. One such crucial process is annealing, especially for…

- How Ductility Influences CNC Machining Processes

Introduction Ductility is a critical material property that significantly influences the CNC machining processes used in manufacturing. It refers to a material's ability to deform under tensile stress, which allows…

- Do You Need Tempering Before or After Machining? A Practical Guide for Engineers

Introduction Tempering is one of those topics that I’ve seen spark a lot of debate in custom manufacturing circles.I remember the first time I tried to machine a batch of…

- Heat Treatment Insights for Wrought Aluminum Alloys in CNC Machining Parts

In the field of CNC machining, achieving the desired mechanical and physical properties often hinges on effective heat treatment. For wrought aluminum alloys, which are extensively used due to their…

- Machining Techniques for Parts: Unlocking CNC and Cutting-Edge Tech

I. Introduction I remember the first time I realized how critical machining is to modern manufacturing. I was interning at a small shop, watching a CNC machine carve intricate features…