Nimonic Alloys in CNC Machining: Enhancing Performance in High-Temperature Applications

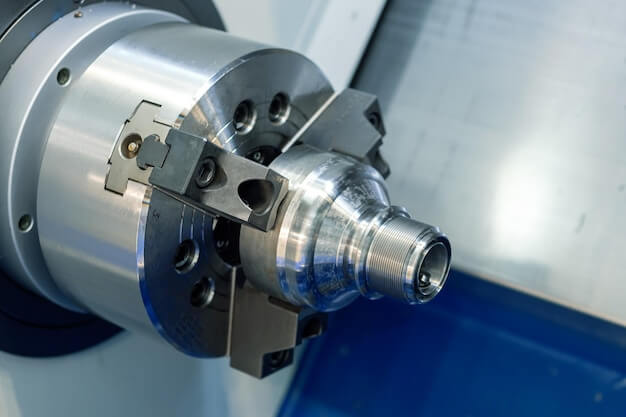

Introduction to CNC Machining and Nimonic Alloys CNC machining is a prevalent manufacturing process that leverages computerized controls to operate, manipulate, and control machine shop tools. This high-tech method negates manual operations by utilizing digitally coded programs that prompt factory machinery and tools to accomplish jobs in an efficient and precise manner. On the other […]

Titanium Grade 5 vs. Grade 23: Selecting the Ideal Alloy for Your CNC Projects

Introduction to Titanium and CNC Projects Titanium, renowned for its high strength-to-density ratio and resistance to corrosion, plays a pivotal role in an array of applications across diverse industries. This tough metal and light-weight substance is particularly valuable within the aerospace industry, where durability and weight considerations are imperative. Furthermore, titanium’s biocompatibility makes it ideal […]

The Impact of Material Selection on CNC Machining Costs and Performance: Alumel vs. Chromel

Introduction to CNC Machining and Understanding Alumel and Chromel CNC machining is a subtractive manufacturing technology that employs computerized controls to manipulate and operate machine tools, facilitating the production of parts with high precision and accuracy. This process involves feed rates, spindle speeds, energy consumption, tooling, and setup costs, making it imperative for manufacturers to […]

Choosing Between Brass C36000 and C37000 for Precision CNC Machining

Introduction to Precision CNC Machining and its Significance in Manufacturing Precision CNC machining is a manufacturing process that utilizes computerized controls for operating various machine tools such as lathes, mills, routers, and grinders. Through advanced software, this technology enables marking accurate cuts and fabricating detailed parts swiftly with remarkable precision. It plays an integral role […]

A Guide to Machining Wear Resistant Alloys: Stellite vs. Tungsten Carbide

Introduction to Machining Wear Resistant Alloys Machining wear resistant alloys is an indispensable process in the manufacturing industries, directly impacting both durability and performance of machineries. These alloys, including prominent examples like Stellite and Tungsten Carbide, are uniquely designed to endure wear and tear, corrosion, and high temperatures with remarkable resilience. Used predominantly in tools, […]

Phosphor Bronze vs. Silicon Bronze for CNC Machining: A Detailed Analysis

Introduction to CNC Machining CNC (Computer Numerical Control) Machining signifies a pivotal advancement in the fields of manufacturing and engineering. This process utilizes computer software for the control and manipulation of machine tools such as mills, routers, and grinders. Most commonly known for its crucial role in the production sector, it enables enhanced precision, speed […]

CNC Machining with Precious Metals: Silver vs. Gold

CNC Machining with Precious Metals: Silver vs. Gold Computer Numerical Control (CNC) machining is a contemporary manufacturing process that leverages computerized controls for both designing and fabricating precision products. CNC machining applies to a vast range of materials, including precious metals like silver and gold. These luxurious resources are well-known for their superior theatrics in […]

Nickel Aluminum Bronze vs. Manganese Bronze in CNC Machining Applications

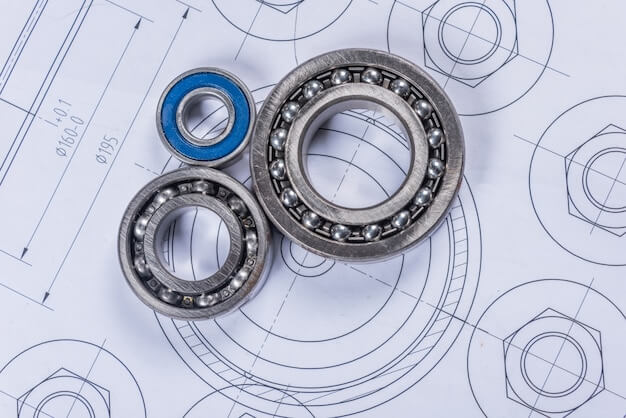

Nickel Aluminum Bronze vs. Manganese Bronze in CNC Machining Applications In the realm of metals used in CNC (Computer Numerical Control) machining applications, Nickel Aluminum Bronze and Manganese Bronze hold significant positions due to their distinct characteristics. Nickel Aluminum Bronze, in layman’s terms, is a high-strength alloy made from copper, aluminum, nickel, iron, and manganese […]

Durable Materials for CNC Machining: Tool Steel Grades Compared

Introduction to CNC Machining and its Importance in Manufacturing CNC (Computer Numeric Control) machining, a cornerstone of modern manufacturing, plays a pivotal role due to its precision, efficiency, and versatility. This superior technology can manipulate a wide range of durable materials using programmed instructions to control machine tools like lathes, mills or routers, performing complex […]

Advantages of Using Beryllium Copper in CNC Machining Applications

Introduction to Beryllium Copper and CNC Machining Beryllium copper, often referred to as beryllium bronze or spring copper, is a strong, corrosion-resistant, and highly conductive metal alloy. Notably, it contains approximately 0.5-3% beryllium by weight with the remainder largely consist of copper. It’s admired in various industrial applications due to its non-magnetic and non-sparking properties. […]

High Performance Plastics for CNC Machining: PEEK vs. Ultem

Introduction to CNC Machining and High Performance Plastics CNC (Computer Numeric Control) machining is a manufacturing process that utilizes pre-programmed computer software to guide the movement of shop machinery. This programmability allows for customized, precise parts production in fields ranging from aerospace engineering to medical technology. In recent years, there has been increasing demand for […]

The Role of Superalloys in Modern CNC Machining: Inconel 718 vs. Hastelloy C-276

The Role of Superalloys in CNC Machining Computer Numerical Control (CNC) machining is a modern manufacturing process where pre-programmed computer software dictates the movements of factory tools and machinery. An essential facet of this procedure is the use of superalloys, metal mixtures designed for high strength and resistance to wear, corrosion, and heat. These alloys […]