CNC Machining for Aerospace: Aluminum 2024 vs. 6063

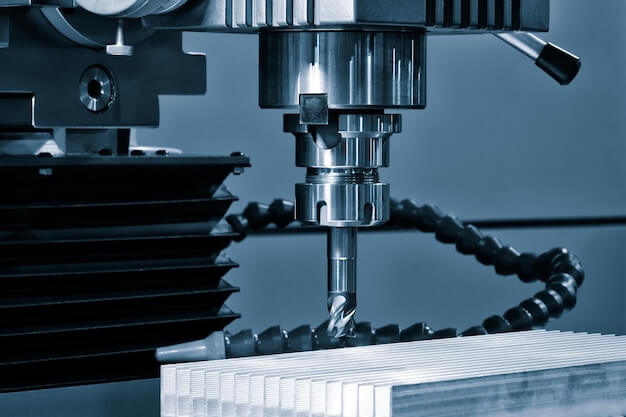

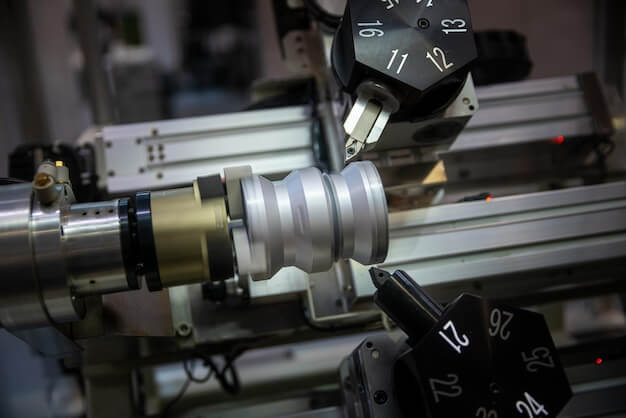

CNC Machining and Aerospace Manufacturing In the world of aerospace manufacturing, CNC (Computer Numerical Control) machining carries significant importance. As a modern machining method that leverages computer programming to dictate complex machinery’s operation, CNC processes enable high precision and repeatability – both critical factors for aerospace components’ production. Two commonly machined materials in the aerospace […]

CNC Machining for Medical Devices: Titanium vs. Cobalt Chrome Alloys

Introduction to CNC Machining in Medical Device Manufacturing The industrial process of computer numerical control (CNC) machining plays a pivotal role in the creation of medical devices. Essentially, CNC machining is a method used in manufacturing where pre-programmed computer software directs the movement of machinery and tools. Precision, reliability, repeatability, high speed, and ability to […]

Inconel vs. Monel for CNC Machining: A Comprehensive Material Comparison

CNC Machining and Material Importance in Manufacturing Computer Numerical Control (CNC) machining is a manufacturing process that leverages computers to control machine tools including lathes, mills and grinders among others. Its usage in industries is primarily for the creation of complex three-dimensional parts through subtractive methods where material is taken away, as opposed to additive […]

CNC Machining and the Aerospace Industry: Rene 41 vs. Waspaloy Material Considerations

CNC Machining and its Crucial Role in AeroSpace Industry with Rene 41 & Waspaloy Materials Computer Numerical Control (CNC) machining plays a crucial role in the aerospace industry as it provides unprecedented precision, flexibility and efficiency in manufacturing complex components. Two materials frequently used are Rene 41 and Waspaloy owing to their robust characteristics suitable […]

Zirconium vs. Titanium: A CNC Machining Material Showdown

Introduction to CNC Machining and Materials CNC machining, short for Computer Numerical Control machining, serves as a critical component in contemporary manufacturing processes. This computer-aided method builds components by removing material layer by layer according to instructions derived from a digital file. Given its high precision levels, it is widely applied in various sectors requiring […]

Copper Alloys in CNC Machining: C10100 vs. C11000

Copper Alloys and CNC Machining: An Introduction In the world of Computer Numerical Control (CNC) machining, materials play an essential role in producing quality results. Among these materials are copper alloys, specifically C10100 and C11000. Copper alloys exhibit outstanding electrical conductivity, ease of fabrication, corrosion resistance, and they also have notable mechanical properties which make […]

How to solve surface roughness problems in cnc machining?

Introduction to CNC Machining and Surface Roughness Problems The process of Computer Numerical Control (CNC) machining plays a vital role in the manufacturing industry. This automated process uses computers to control machine tools, ensuring precision and efficiency in production. However, one common issue faced within this sector is the surface roughness problem. The surface finish […]

Aluminum vs. Brass in CNC Machining: Determining the Best Metal for Your Precision Components

Introduction to CNC Machining and Precision Components CNC machining, an acronym for Computer Numerical Control machining, is a manufacturing process in which pre-programmed computer software dictates the movement of machinery. This sophisticated technique allows a high level of automation and offers exceptional precision, making it essential in creating intricate parts that require exact specifications. One […]

CNC Machining for Aerospace Applications: Titanium vs. Aluminum Alloys

CNC Machining in Aerospace: An Introduction and Overview Computer Numerical Control (CNC) machining is a manufacturing process that utilizes software-directed machines to fabricate complex parts with high accuracy and repeatability. Being able to program the machine’s movements allows for precise control, enabling a level of detail that would be difficult to achieve manually. This characteristic […]

Choosing the Right Coolant for CNC Machining: Water-Based vs. Oil-Based Solutions

Understanding The Role of Coolant in CNC Machining The utilization of coolant, also known as cutting fluid, is an integral aspect of Computer Numerical Control (CNC) machining processes. This crucial substance aids to dissipate the heat generated during the machining operations thereby preventing any damages to both the machine and workpiece due to excessive temperatures. […]

The Role of Surface Finish in CNC Machining: Comparing Anodized vs. Powder Coated Finishes

The Importance of CNC Machining and the Significance of Surface Finish Process CNC (Computer Numerical Control) machining plays a pivotal role in today’s manufacturing industry, providing undoubtedly high speed, precision, and automation for the fabrication of diverse metal components. This crucial manufacturing process involves automatically operated tools controlled by computer programming inputs that allow engineers […]

The Efficiency of CNC Machining: Titanium vs. Steel for High-Performance Components

Introduction to CNC Machining and Material Selection Computer Numerical Control (CNC) machining revolutionizes the manufacturing space by enabling highly accurate, repeatable, and complex component production. In high-performance industries like aerospace and automotive, precision and reliability are vital, making CNC machining an indispensable solution. However, the success of this process pivots around one critical factor – […]