The Revolution of Electric Vehicles: Manufacturing, Benefits, and Future

Introduction to Electric Vehicles The automotive landscape is undergoing a significant transformation with the rise of electric vehicles (EVs), which represent a pivotal shift away from traditional internal combustion engine vehicles. As concerns for environmental sustainability and reducing greenhouse gas emissions gain momentum, EVs are increasingly seen as a vital solution due to their use […]

Introduction to Waterjet Cutting : Operation Process, Key Advantages, and Industry Applications

Introduction to Waterjet Cutting Waterjet cutting is a versatile and precise material-cutting process that utilizes a high-pressure jet of water, often combined with an abrasive substance, to slice through various materials. The operation hinges on the principle of erosion; water is accelerated through a narrow nozzle at speeds capable of eroding the workpiece, resulting in […]

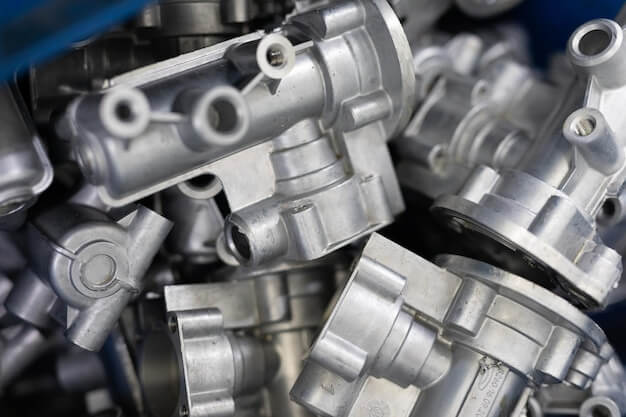

Precision Casting Explained: Technology Process, Unique Benefits, and Its Role in Manufacturing

Introduction to Precision Casting Precision casting, also known as investment casting or lost-wax casting, is a manufacturing process that produces complex and detailed components with exceptional accuracy. Originating over 5,000 years ago for creating art and jewelry, the technique has evolved significantly, especially with advancements in materials and industrial technology post-Industrial Revolution. Today, precision casting […]

Metal Injection Molding (MIM) Explored: Process, Advantages, and Practical Applications

Introduction to Metal Injection Molding Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of wrought metals. It involves mixing metal powders with polymers to create a feedstock, which is then molded into complex shapes using standard injection molding machines. The result is […]

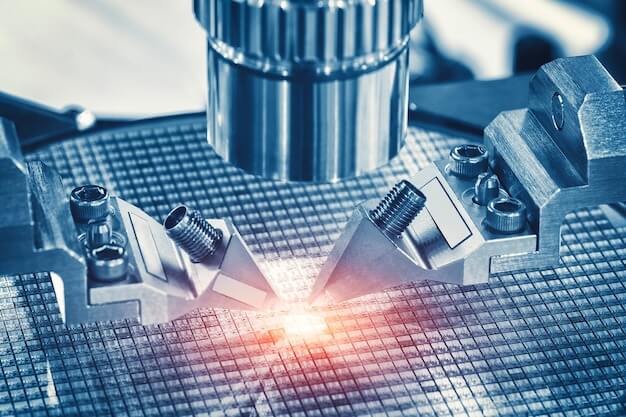

Electrical Discharge Machining (EDM) Basics: Process, Benefits, and Multidisciplinary Applications

Introduction to Electrical Discharge Machining (EDM) Electrical Discharge Machining, commonly referred to as EDM, is a non-traditional machining method that employs electrical discharges or sparks to remove material from a workpiece. The fundamental principle behind EDM involves creating an electrical spark between an electrode and the workpiece which is submerged in dielectric fluid. This precisely […]

Laser Cutting Technology Overview: Process, Benefits, and Wide-Ranging Uses

Introduction to Laser Cutting Technology Laser cutting is a precise method of slicing materials using a high-powered laser beam, characterized by its ability to produce clean cuts with smooth edges on a variety of substances including metal, plastic, glass, and wood. This paragraph sets the stage for an in-depth exploration into the sophistication behind laser […]

Sinker EDM vs Wire EDM: Key Differences and Applications

Introduction to Electrical Discharge Machining (EDM) Electrical Discharge Machining, commonly known as EDM, is an advanced machining technique used to shape hard metals and other conductive materials through the use of electrical discharges or sparks. The process involves creating a series of rapid-fire electrical sparks between an electrode or wire, also referred to as the […]

Vacuum Casting Material Selection: Find the Best-fit Resin

Introduction to Vacuum Casting Vacuum Casting is a highly versatile and efficient manufacturing process widely recognized for its ability to produce high-quality prototypes and small to medium-sized production runs. This method is particularly beneficial in the later stages of product development, allowing for the creation of parts that closely mimic the appearance, properties, and functionality […]

What is Compression Molding? Details Explained

Introduction to Compression Molding Compression molding is a widely utilized manufacturing process, especially in the production of various components across multiple industries. This method is particularly favored for its ability to mold plastics, natural rubbers, composites, and elastomers into desired shapes. The process involves compressing two mold halves with pre-heated material to achieve the final […]

16 Common Types of Welding Defects, Causes, Remedies

Understanding Welding Defects and Their Significance Welding defects are irregularities that occur in welded joints which can compromise the structural integrity of a fabricating project. These imperfections can range from cracks and porosity to incomplete penetration and distortion, each with its own potential impact on the strength and durability of the weldment. Recognizing these defects […]

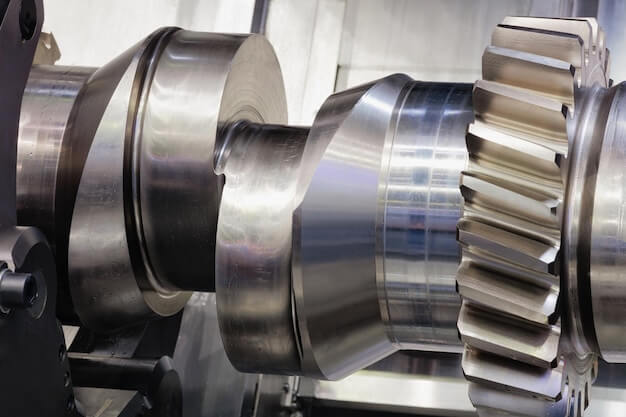

Essential Strategies in CNC Machining Sharp Inside Corners

Essential Strategies in CNC Machining Sharp Inside Corners Achieving sharp inside corners is a critical task in CNC machining that demands precision and expertise, as it has significant implications on the functionality and aesthetics of machined parts. These intricate features are often required in complex components where meeting precise angles and dimensions can be challenging […]

What’s CNC Routing? Its Process, Advantages, and Applications

Introduction to CNC Routing CNC routing technology revolutionized manufacturing by leveraging computer numerical control to cut, carve, and engrave materials with exquisite precision. The routing process begins with a detailed design created in specialized software, which is then translated into commands for the CNC machine. The router, being the critical component of this setup, spins […]