How do I care for parts made of precision machined copper?

Introduction to Precision Machined Copper and its Care Precision machined copper components are essential in a variety of high-tech industries due to their excellent electrical and thermal conductivity, coupled with good corrosion resistance and mechanical strength. These parts can be found in electrical equipment, heat exchanges, automotive applications, and intricate electronics where precision functionality is […]

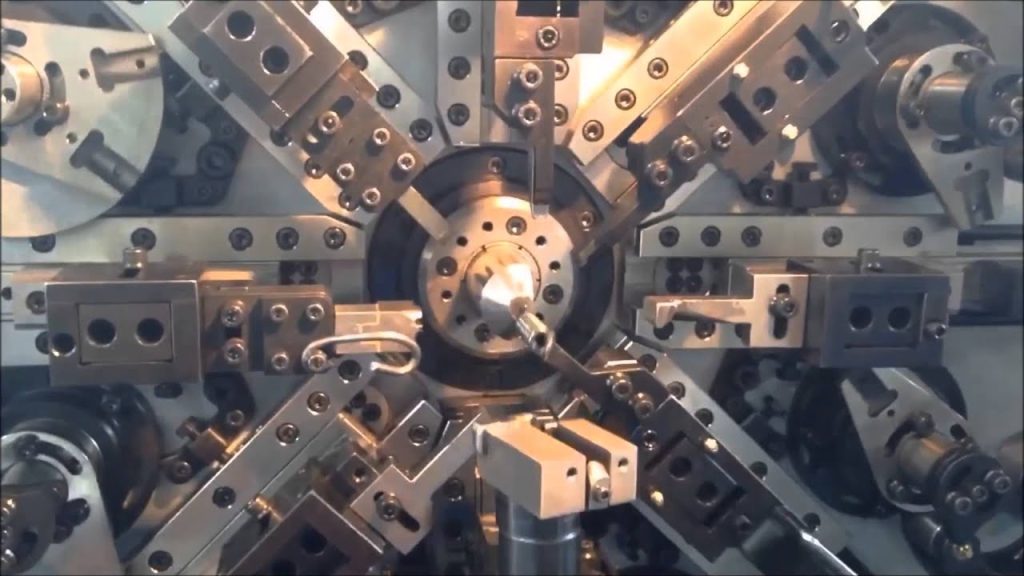

How the key components of a fish fillet cutting machine are processed

Introduction to Fish Fillet Cutting Machines Fish fillet cutting machines play a pivotal role in the seafood industry, streamlining the process of preparing fish for market and consumption. The function of these machines centers on precision cutting to ensure uniformity in fillet size and quality, which is crucial for meeting consumer expectations and regulatory standards. […]

how strong is alloy steel

Introduction to Alloy Steel’s Strength Alloy steel is a versatile material composed of iron with various alloying elements that enhance its mechanical properties, such as strength, hardness, toughness, and wear resistance. The precise attributes of the alloy vary depending on the combination of elements such as chromium, nickel, molybdenum, manganese, vanadium, and silicon among others. […]

Use of bead blaster for precision machining

Introduction to Bead Blasting in Precision Machining Bead blasting is an abrasive finishing process utilized in precision machining to clean or modify the surface finish of a workpiece. This technique involves propelling a stream of bead-shaped abrasive material, such as glass or ceramic beads, against the piece’s surface under high pressure. The primary role of […]

Brittleness, a key material factor affecting the strength of CNC-machined parts

Definition and Importance of Brittleness in Materials Science In materials science, brittleness refers to the tendency of a material to fracture or shatter upon impact or under stress without significant deformation. This characteristic is crucial when evaluating CNC-machined parts since brittle materials can compromise the structural integrity of components that are subjected to dynamic loads […]

In the field of CNC machining Which materials require heat treatment?

Introduction to CNC Machining and the Role of Heat Treatment CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, enabling the precision crafting of parts with minimal human intervention. Through programmed commands, CNC machines repetitively produce complex shapes that are essential in various industries, ranging from automotive to aerospace. Integral to this […]

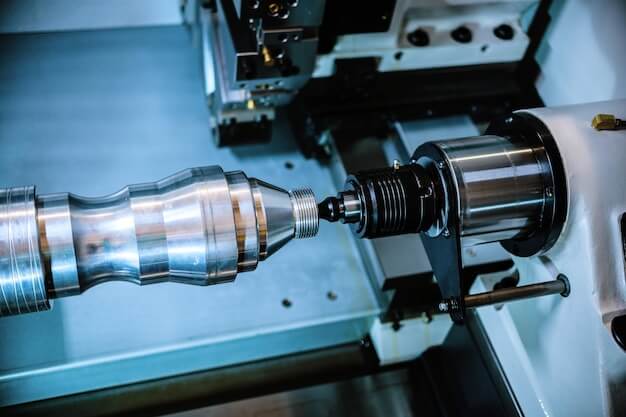

What is a tool path in CNC machining? Impact on machining accuracy

Definition and Importance of CNC Tool Path In the realm of CNC machining, a tool path is critical as it represents the precise route that the cutting tool follows to create the desired part from a solid block of material. This pre-programmed navigation governs everything from the direction, speed, and depth of the cut, ensuring […]

Challenges posed by material ductility in CNC machining

Understanding Material Ductility in CNC Machining In the realm of Computer Numerical Control (CNC) machining, where precision and accuracy are paramount, material ductility represents a significant factor influencing the quality and efficiency of the manufacturing process. The intrinsic ability of metals to deform under tensile stress without fracturing is what defines their ductility. Grasping the […]

Tool compensation in CNC machining, our quest for precision in CNC machining

Introduction to CNC Machining and Precision CNC (Computer Numerical Control) machining stands at the forefront of modern manufacturing, utilizing computerized controls to operate complex machinery with remarkable accuracy. This process entails translating a digital design into numbered coordinates, which guide machine tools to cut and shape material with high precision. Precision is paramount in CNC […]

10 plastic materials frequently used in CNC machining

Introduction to CNC Machining and Plastics CNC machining stands for Computer Numerical Control machining, a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process allows for precise control over complex shapes and surface quality which is essential in diverse industries ranging from aerospace to medical devices. In this […]

Analysis of processing difficulty of different materials in CNC processing

Introduction to CNC Processing and Material Selection CNC processing, a cornerstone of modern manufacturing, stands for Computer Numerical Control machining, a method where pre-programmed software commands the movement of factory tools and machinery. The selection of materials in CNC machining is critical; it not only influences the final product’s attributes but also affects the ease […]

Sheet Metal Fabrication for Automotive Industry

Introduction to Sheet Metal Fabrication in the Automotive Industry Sheet metal fabrication is a cornerstone process in the automotive industry, essential for constructing vehicle frames, bodies, and components. It involves cutting, bending, and assembling sheets of metal to create precise shapes and structures tailored for specific functions within a car. The significance of this technique […]