Understand the difference between fillets and chamfers (in the field of CNC machining)

Understanding Finishing Processes in CNC Machining In the realm of CNC machining, finishing processes such as fillets (rounded edges) and chamfers (beveled edges) are essential techniques for enhancing the functionality and aesthetics of machined parts. The choice between a fillet and a chamfer is not merely cosmetic; it profoundly impacts the part’s performance, assembly, and […]

Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with precision. The process involves injecting thermoplastic or thermosetting polymers into a mold at high pressure, which results in the material conforming to the shape of the mold cavity. Unlike traditional […]

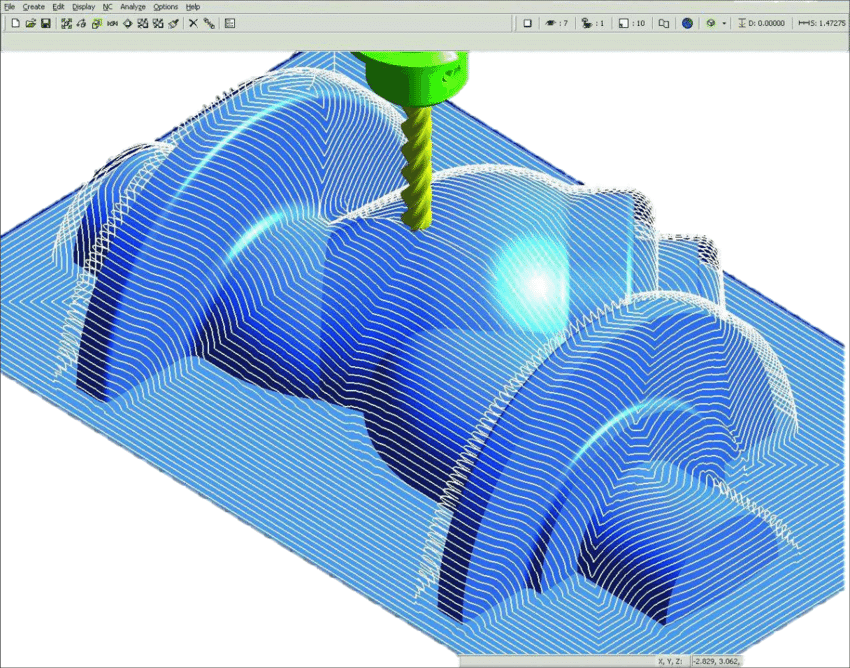

Here are 7 tips for reducing costs in CNC machining.

Introduction to Cost Reduction in CNC Machining CNC machining stands as a pivotal manufacturing process where computer-guided machinery produces complex parts with precision. In an industrial landscape where the push for cost-effectiveness parallels demands for high quality, strategies to trim down expenditures without compromising on output are essential. The upcoming tips highlight how manufacturers can […]

Pewter: What It Is, Properties, Importance, Uses, and Advantages

Definition and Brief History of Pewter Pewter is a malleable metal alloy traditionally composed primarily of tin, with small amounts of copper and antimony added for strength and durability. Historically, lead was also included in the mix, but due to its toxicity, it has been largely phased out in modern pewter formulations. Originating over two […]

Titanium is used in the production of medical and aerospace instruments.

Unique Properties of Titanium Titanium, a lustrous transition metal with a low density and high strength, stands out for its remarkable resistance to corrosion and ability to withstand extreme temperatures. These unique properties make it an ideal material for demanding engineering applications, particularly in the medical and aerospace sectors. Its biological inertness allows for its […]

Is titanium dioxide safe? what is titanium ?

Introduction to Titanium Dioxide Titanium dioxide, a white pigment that is chemically inert, stable, and nontoxic, boasts widespread use in various industries due to its ability to impart brightness and opacity. Found in items ranging from paints and plastics to foods and cosmetics, it serves as a vital component by enhancing durability and ensuring longevity […]

does titanium rust? what is titanium ?

Introduction to Titanium Titanium is a lustrous, silver-gray metal known for its high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. Widely used in aerospace designs, medical devices, and sporting equipment, titanium’s properties make it valuable in applications where durability and lightness are paramount. Moving beyond its practical uses, a question often arises […]

Exploring the World of Non-Ferrous Metals: Characteristics, Applications, and Innovations

Introduction to Non-Ferrous Metals Non-ferrous metals, distinguished by their lack of iron content, are highly valued for their versatility and distinct properties such as resistance to corrosion, high conductivity, and lightweight. These characteristics make them indispensable across a wide array of industries including aerospace, automotive, electronics, and construction. For example, aluminum’s combination of low density […]

Understanding Delrin: A Comprehensive Guide to the Versatile Engineering Plastic

Understanding Delrin and the Role of Engineering Plastics Delrin, formally known as Polyoxymethylene (POM), is an engineering plastic renowned for its high tensile strength, rigidity, and resilience against friction and wear. This thermoplastic polymer consists primarily of carbon, hydrogen, and oxygen in a chain structure that provides remarkable stability and mechanical properties. The advent of […]

Delrin: The Engineering Marvel in Plastic Innovation

Introduction to Delrin Delrin, a trade name for polyoxymethylene (POM), stands as a groundbreaking synthesis in the world of engineering polymers. Renowned for its high tensile strength, stiffness, and dimensional stability, Delrin is frequently used where precision parts require high resilience and low friction performances. In the realm of plastic innovation, it has carved out […]

Acetal Polymers: Versatility and Applications in Modern Material Science

Introduction to Acetal Polymers Acetal polymers, often known under trade names such as Delrin, are highly crystalline thermoplastics characterized by their excellent mechanical strength, rigidity, and chemical resistance. These polymers are comprised of repeating units formed through the polymerization of formaldehyde or other cyclic ethers, resulting in a backbone with unique, stable acetal linkages (-C-O-C-). […]

Different types of casting

Introduction to Casting in Manufacturing Casting is a foundational manufacturing process wherein molten material—often metal—is poured into a pre-shaped mold and allowed to solidify, forming a replica of the mold’s internal geometry. This technique enables the production of complex shapes that would be challenging or uneconomical to achieve through other methods. The versatility of casting […]