Masterful Precision: Elevating Aluminum Craftsmanship with Laser Cutting

Laser cutting penetrates and slices through materials with a high-powered laser beam guided by CNC (Computer Numerical Control). The process achieves high-precision cuts, intricate detail work, and polished edges on numerous metals. Aluminum, in particular, stands out as an extensively used material for this method because of its lightweight properties, excellent strength-to-weight ratio, and corrosion […]

Precision Micro Injection Molding: Essential Advantages and Versatile Applications

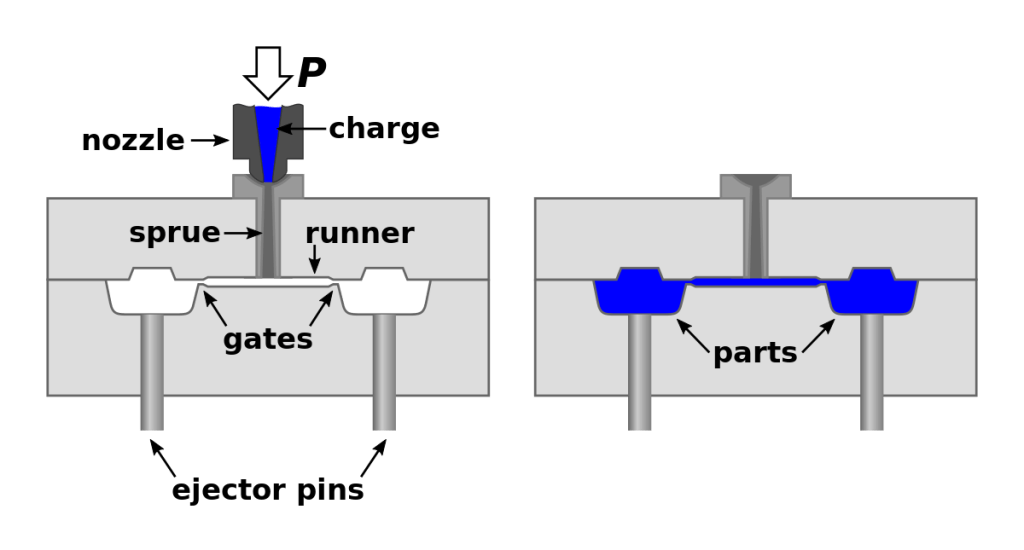

Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with high precision. It stands as an essential technique in various industries, particularly where components must be produced on a micro-scale with tight tolerances, such as medical devices or microelectronics. The process involves injecting molten material […]

Unveiling the Wonders of Wire EDM: Masterful Precision Machining for Intricate Components

Wire Electrical Discharge Machining (EDM) is a specialized manufacturing process where electrical discharges are used to cut metals with high precision, shaping intricate contours and patterns that would be difficult or impossible with traditional machining techniques. This method employs a thin wire as an electrode that creates sparks to erode and cut the metal workpiece […]

Ultimate Guide to CNC Drilling: Mastering Techniques, Varieties, and Practical Uses

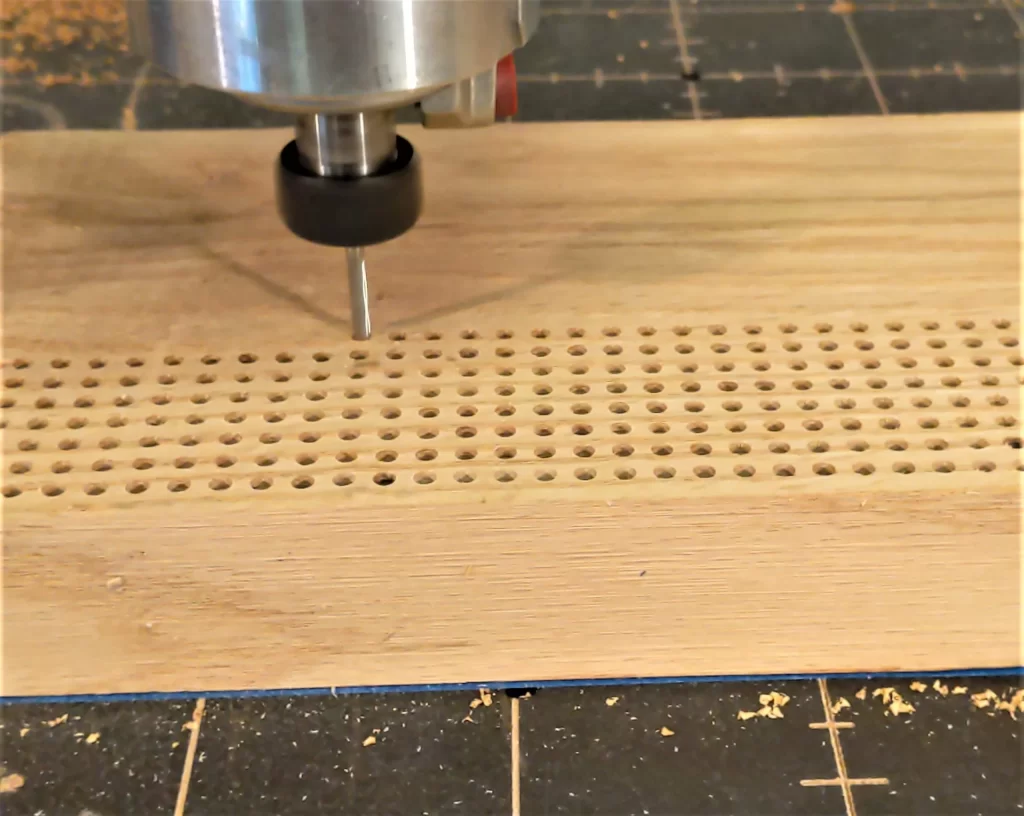

CNC drilling is a precision machining process utilized extensively in the manufacturing sector where holes of various sizes and depths are created in metal, plastic, or wood with high accuracy. It employs computer numerical control (CNC) systems for automating the movement and operation of the drill bits, yielding consistent and repeatable results that are critical […]

CNC Milling vs CNC Drilling? which one to Choose?

In the context of manufacturing and industrial applications, Computer Numerical Control (CNC) processing plays a crucial role. Two such techniques integral to these operations are CNC milling and drilling. 1.1 Definition of CNC Milling and CNC Drilling CNC milling is defined as a machining process where rotating cutting tools remove material from a workpiece in […]

Understanding the Different Types of Plastic for CNC Machining

Title: Understanding the Different Types of Plastic for CNC Machining Introduction CNC machining, a revered and precise manufacturing process, is not limited to metals and alloys. Plastics, with their versatile properties, have become a staple in CNC machining, offering unique advantages in various applications. This article delves into the world of plastics in CNC machining, […]

Galvanized Steel vs Aluminum: Understanding the Key Differences

Introduction In the realm of metalworking and manufacturing, two materials often dominate the conversation: Galvanized Steel and Aluminum. Both are extensively used across various industries, from construction to automotive manufacturing, due to their unique properties and benefits. This article delves into the fundamental differences between these two metals, exploring aspects like composition, durability, applications, and […]

Title: Galvanized Steel: Process, Methods, Properties, and Uses

Introduction: Galvanized steel, an innovation in the world of construction and manufacturing, represents a pinnacle in material engineering. It’s a process where steel is coated with a protective layer of zinc, enhancing its durability and resistance to environmental factors. This article delves deep into the galvanization process, exploring its methods, properties, and the diverse applications […]

Hot-Dip Galvanizing: Purpose, Process, and Uses

Introduction to Hot-Dip Galvanizing Hot-dip galvanizing, a process widely recognized in the industrial world, plays a crucial role in enhancing the durability and longevity of steel and iron products. This process involves coating metal items with a thin layer of zinc, offering them robust protection against rust and corrosion. This article delves into the details […]

Galvanized vs. Galvanneal: What Are the Differences?

In the realm of metal finishing and corrosion protection, two processes often come up: galvanizing and galvannealing. Both methods enhance the durability and longevity of steel and other metal products, but they serve different purposes and exhibit distinct characteristics. This article delves into the nuances of these two processes, highlighting their differences, applications, and advantages. […]

Types of Stainless Steel and Stainless Steel Grades

Stainless steel, renowned for its corrosion resistance, is a vital material in various industries, from construction to culinary tools. This article delves into the types of stainless steel and their grades, offering a comprehensive understanding of their unique properties and applications. What is Stainless Steel? Stainless steel is an iron alloy with a minimum of […]

ions that demand durability and wear resistance.

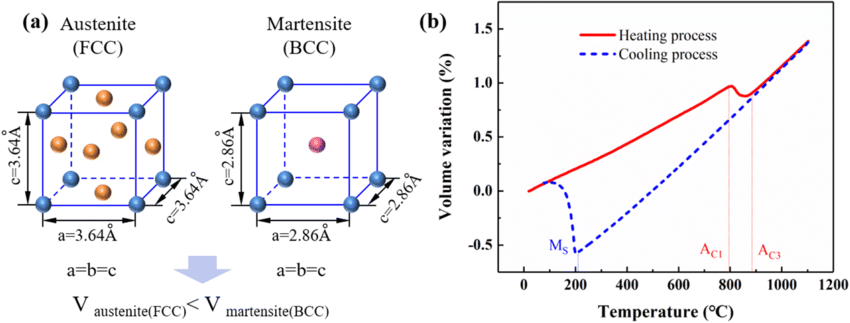

Title: Understanding Martensite Structure: Characteristics and Applications in Materials Science Introduction: Martensite is a unique and highly significant microstructure in the field of materials science, particularly in metallurgy. It is formed in steel and other alloys by a transformation process that drastically changes their mechanical properties. This article delves into the martensite structure, its formation […]