Typical Machining Processes for Mechanical Manufacturing

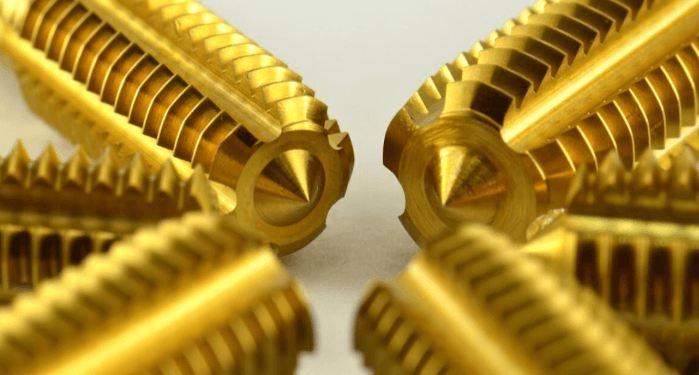

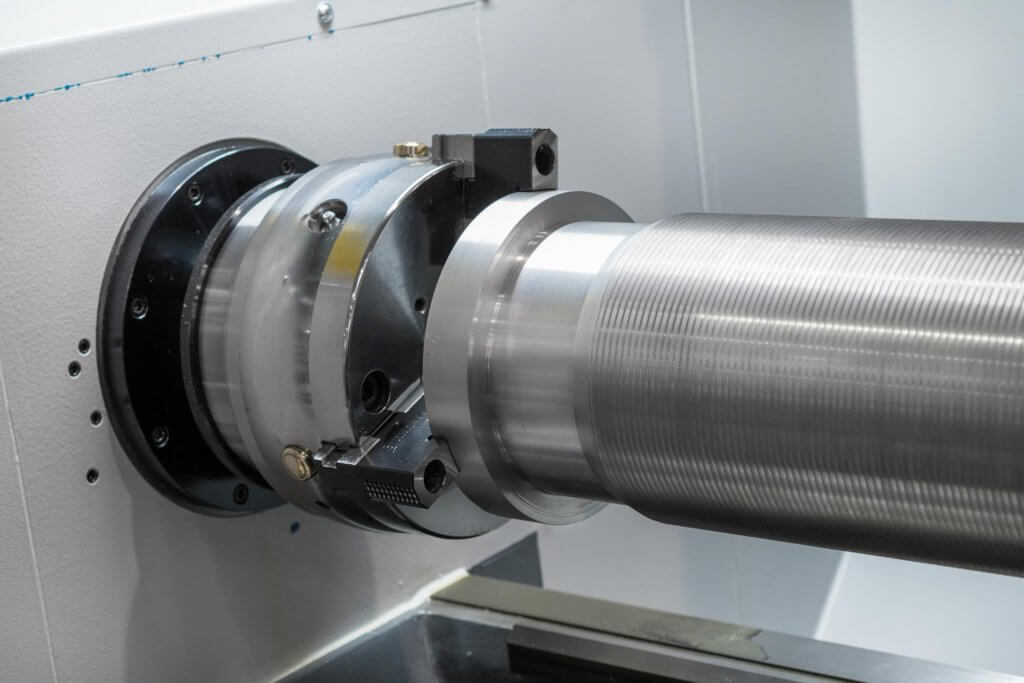

Shaft Parts Machining Function of Shaft Parts Shaft parts are primarily used to support transmission components and transmit torque. Common shaft parts include plain shafts, hollow shafts, half shafts, stepped shafts, spline shafts, cross shafts, eccentric shafts, screws, crankshafts, and camshafts. online cnc machining services Materials, Blanks, and Heat Treatment of Spindle Parts Spindles commonly […]

Common Metal Materials and Their Properties

Classification and Designation of Industrial Steels Steel is widely used in various industries, and different types of steel are classified based on their composition and properties. According to carbon content, steel can be divided into low carbon steel, medium carbon steel, and high carbon steel. Low carbon steel has a carbon content of less than […]

Common Metal Materials and Their Characteristics

Metal materials are ubiquitous in our lives, playing a crucial role in various industrial fields from automobiles and construction to electronic products. Understanding the properties and applications of different metal materials can help us make better material choices. Here, we delve into several common metal materials and their specific characteristics. online cnc machining service 1. […]

Common Metal Materials and Their Properties

Classification and Grades of Industrial Steel Steel Classification In the steel industry, there are several ways to classify steel. The first is by carbon content: Additionally, steel can be classified by metallurgical quality into ordinary steel, high-quality steel, high-grade high-quality steel, and super high-grade high-quality steel. According to the degree of deoxidation, steel can be […]

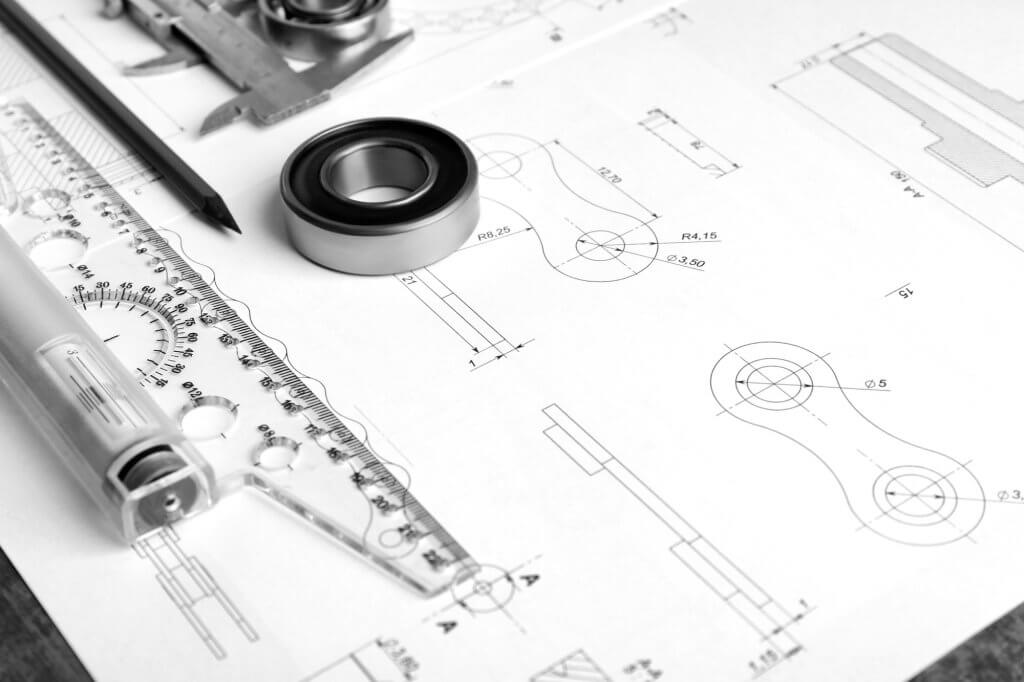

Analysis of the Structural Manufacturability of Parts

Understanding Structural Manufacturability Structural manufacturability of parts refers to the feasibility and economic efficiency of manufacturing the designed parts while meeting the requirements. Good structural manufacturability means that parts can be conveniently manufactured under existing process conditions at a lower cost. This not only saves resources but also minimizes unnecessary complications during actual operations. online […]

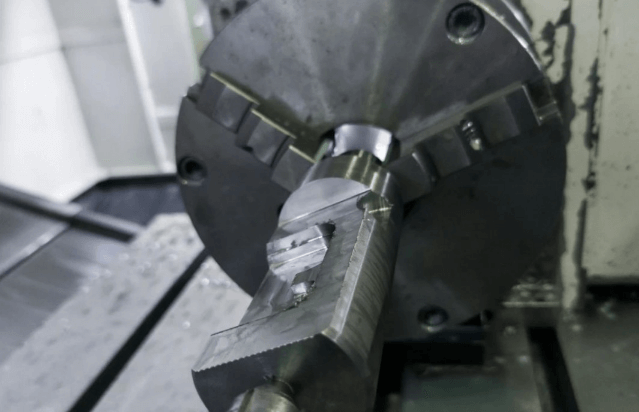

Summary of CNC Turning Tool Knowledge

Insert Shapes and Naming Standards International Insert Naming Standards The naming of CNC turning inserts follows international standards, which mainly include the shape, material, and suitable machining conditions of the inserts. The shape of the inserts is represented by letters, for example: These shapes correspond to different machining conditions and workpiece material selections. Choosing the […]

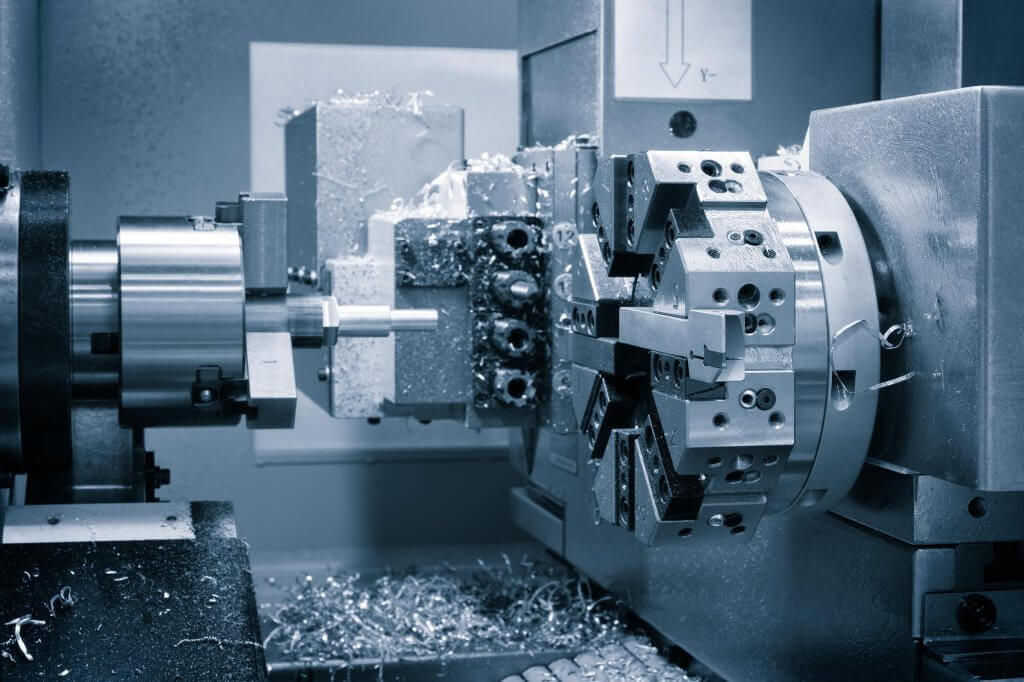

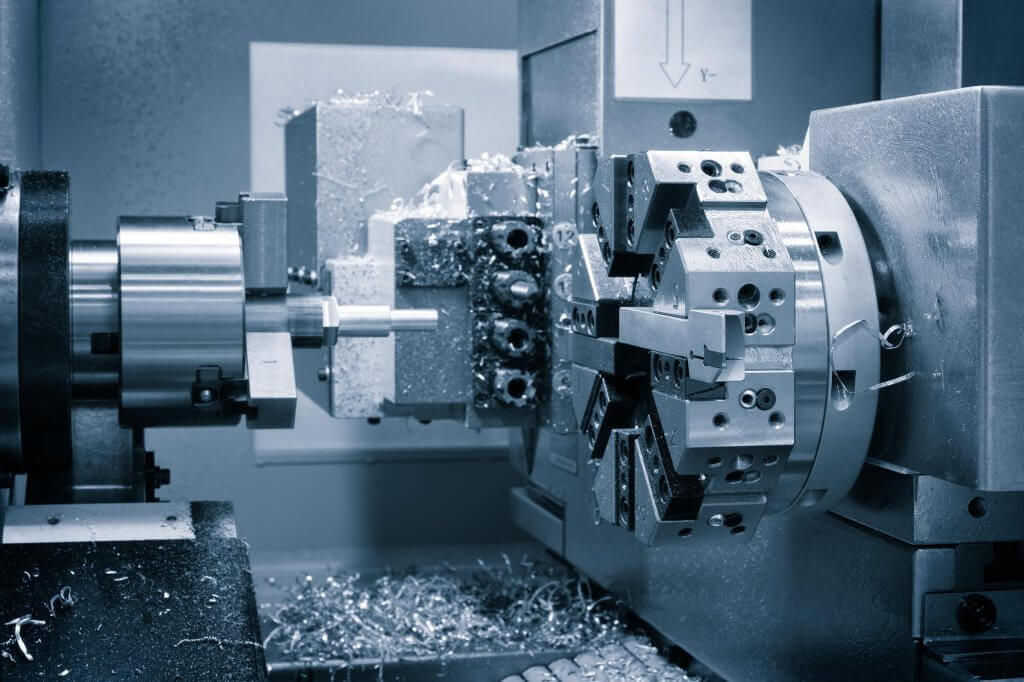

Metal Cutting Machine Tool Design: Exploring the Fascinating World of Metal Processing

Overview of Metal Cutting Machine Tools Metal cutting machine tools are machines that use tools or abrasives to cut metal workpieces. They are known as the “mother machines,” the machines that make other machines. The development of China’s mechanical manufacturing technology, especially cold processing technology, is continuously improving and expanding. It is moving towards high […]

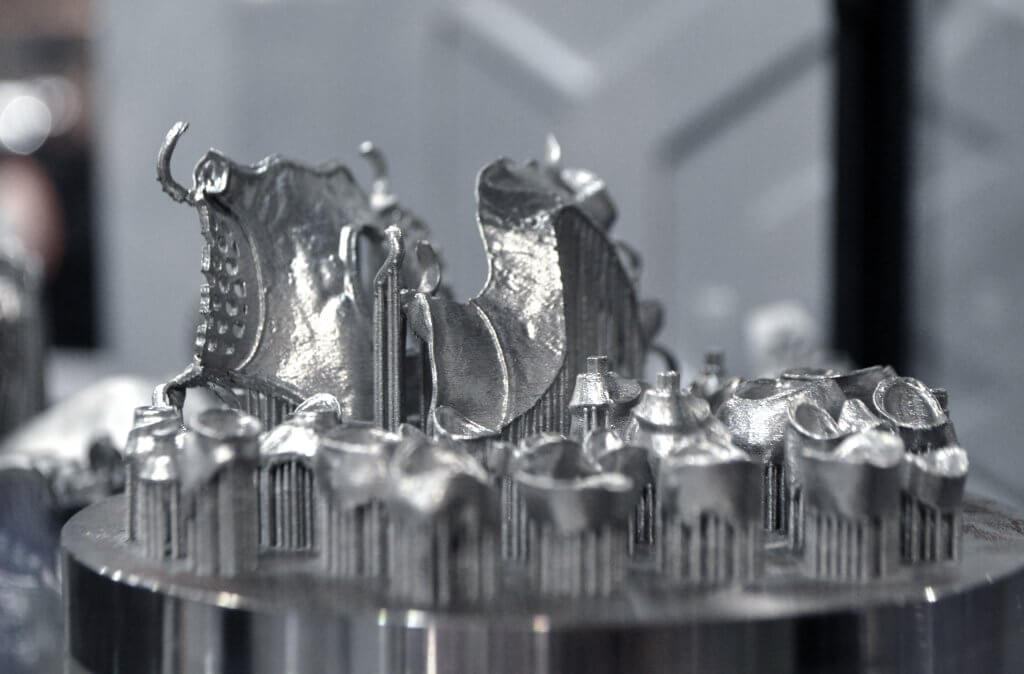

Selection and Comparison of Blank Forming Methods for Parts

Principles of Blank Selection In mechanical manufacturing, the selection of blanks is crucial as it not only affects product quality but also influences manufacturing costs and final performance. Therefore, choosing the right blank is an essential step in the manufacturing process. online cnc services Processability Principle Different parts have varying requirements for blanks, specifically in […]

Machining Precision and Its Control

In machining, controlling precision is a crucial aspect that directly affects the quality and performance of the final product. This chapter details the factors influencing machining errors, geometric errors of the process system, deformation due to forces, thermal deformation, and ways to improve machining precision. online cnc services Overview of Machining Precision Machining precision refers […]

Control of Machining Precision

Machining precision refers to the degree to which the actual geometric parameters of a machined part conform to the ideal geometric parameters (such as size, shape, and positional relationships). Improving machining precision is a crucial task in mechanical processing. This article will delve into the factors influencing machining precision and their control methods, presenting the […]

Analysis of Part Structural Manufacturability

Part structural manufacturability refers to the feasibility and cost-effectiveness of manufacturing a designed part while meeting the required standards. Designing a part that is easy to manufacture and cost-effective is the goal of every engineer. This article will discuss several key aspects of part structural manufacturability, aiming to explain this complex engineering issue in a […]

Unveiling the Technological Craftsmanship of Part Structures

Common Casting Structures Taper To facilitate the removal of the cast from the mold and reduce resistance, a certain degree of taper is added in the design along the molding direction. This taper helps the cast to be easily removed from the mold without getting stuck or damaged. Typically, the taper is set around 3 […]