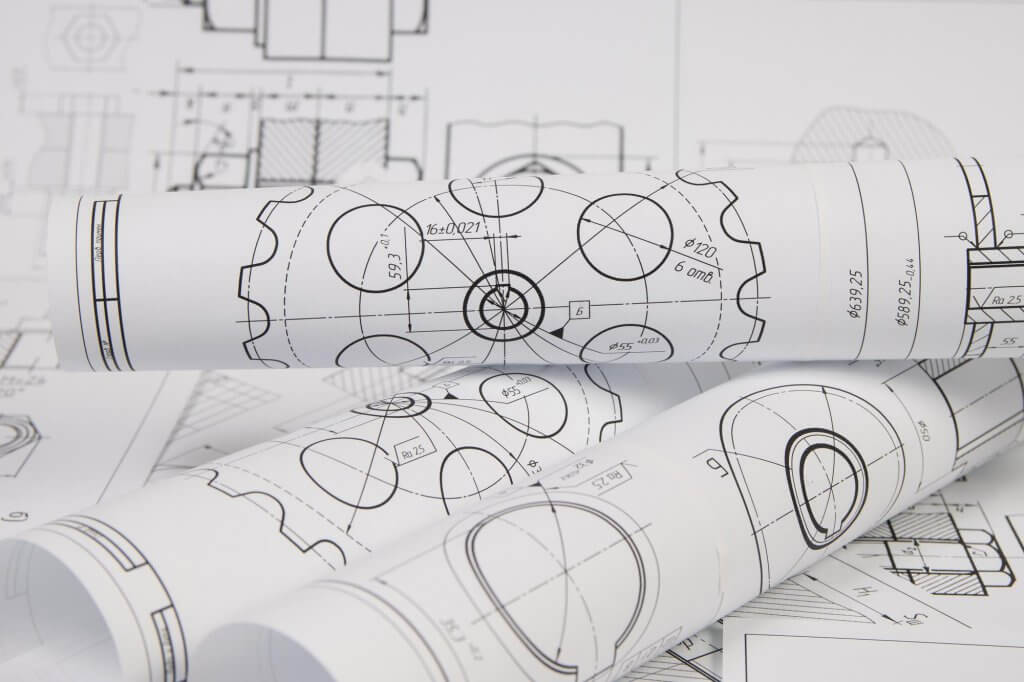

Mechanical Drawing Annotation Methods and Common Issues and Requirements

In mechanical processing, drawing annotations play a crucial role. The first key point is that the true size of the part should be based on the dimensions indicated on the drawing, rather than the size of the graphics or the accuracy of the drawing. The dimensions marked on the drawing are usually in millimeters, and […]

Mechanical Machining Surface Quality: From Principles to Practical Application

Mechanical machining surface quality is a crucial aspect of mechanical manufacturing that directly impacts the performance and longevity of parts. This article will discuss the principles, influencing factors, and practical applications of mechanical machining surface quality to help readers better understand and apply this knowledge. online cnc machining service Principles of Mechanical Machining Surface Quality […]

Comprehensive Guide to Metal Cutting Tools

In modern mechanical manufacturing, metal cutting processes are the most widely used methods, accounting for over 50% of the total workload in mechanical manufacturing. Whether it’s a conventional lathe, an advanced CNC machine, or a machining center, high-performance cutting tools are indispensable. This article will delve into the geometric angles, cutting elements, common tool types, […]

Common Materials and Processability of Mechanical Parts

Mechanical parts are indispensable components in various machines and equipment. To ensure these parts operate efficiently under different working conditions, it is essential to understand the common materials used for mechanical parts and their processability. This chapter provides a detailed introduction to the commonly used materials for mechanical parts, their selection, heat treatment processes, and […]

Cutting Corners (Literally): Smart Tips for Easier Machining

Mechanical design might sound dull, but it actually encompasses a lot of interesting and useful knowledge. Let’s explore some key design principles that not only apply to industrial machinery but also help us better understand the intricacies of this field. The Importance of Standardization Standardization is a core concept in mechanical design. It not only […]

Mastering Machining Precision: Fun and Practical Insights

Machining precision is crucial in CNC machining. Whether you’re crafting high-tech gadgets or everyday items, getting every detail right matters. Let’s dive into the basics of machining precision, focusing on various factors and methods to achieve high accuracy, all while keeping it light and engaging. Understanding Machining Precision Machining precision includes dimensional accuracy, shape accuracy, […]

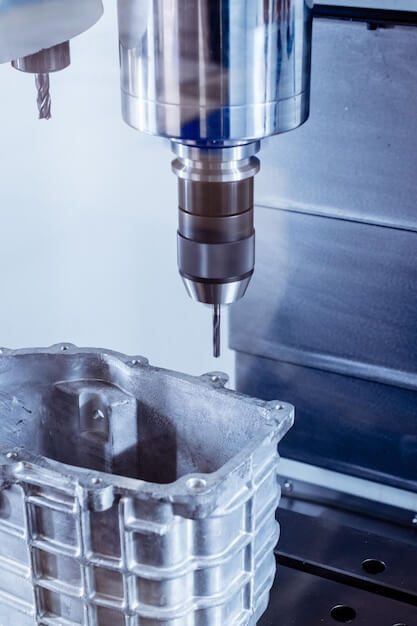

Exploring 5 Key Techniques in CNC Machining: Detailed Methods for Surface Treatment

In the exciting world of CNC machining, knowing the various methods for processing part surfaces is essential. Each technique has its unique perks and is perfect for different scenarios. Let’s dive into some conventional methods of machining part surfaces, focusing on rotational and planar surfaces, with a touch of fun and practicality. Machining Rotational Surfaces […]

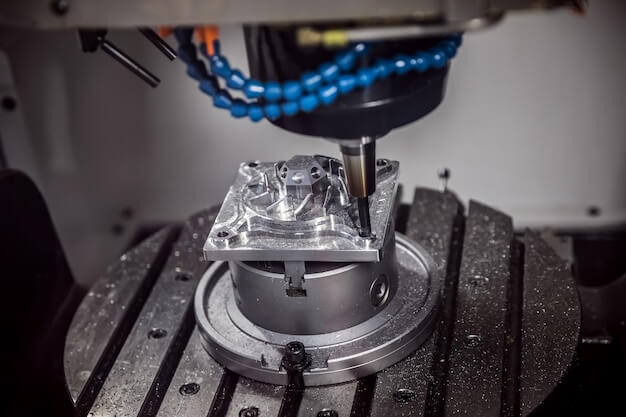

The Industrial Magic of Precision

In modern industrial production, CNC (Computer Numerical Control) technology has become indispensable. With its characteristics of high precision, high efficiency, and high automation, CNC technology plays a crucial role in various fields. From automotive manufacturing to aerospace, CNC technology demonstrates its unique advantages and powerful capabilities. Applications of CNC in the Automotive Industry Automotive manufacturing […]

Heat Treatment of Mechanical Part Materials and Their Applications

Introduction to Steel Heat Treatment Steel heat treatment involves heating, holding, and cooling the steel in solid-state to change its internal structure, thereby improving its mechanical and process properties. The main heat treatment methods include: Annealing Annealing involves heating the steel to a temperature above the critical temperature, then cooling it slowly in the furnace. […]

Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining and its Role in High-End Audio Equipment Manufacturing The production of high-end audio equipment relies heavily on precision-driven processes to ensure the best quality sound. One such process is Precision CNC (Computer Numerical Control) machining, which plays an instrumental role. This method involves the use of computers to control machine tools with […]

Custom CNC Machining Solutions for Aerospace Instrumentation

Introduction to CNC Machining in Aerospace Instrumentation In the modern era, Custom Numerical Control (CNC) machining has emerged as a pivotal capability in the aerospace industry. Pioneering advancements in technology have allowed for an increased requirement for precision and efficiency, which CNC machining provides effectively. CNC machines are essentially robotic mechanisms that are powered by […]

Revolutionizing Renewable Energy with CNC Machined Components

Introduction to Renewable Energy Rewindable energy is inherently replenished on a human timescale, meaning it harnesses natural elements that naturally renew themselves. These sources traditionally include sunlight, wind, rain, tides, waves, and geothermal heat. The importance of renewable energy can’t be understated in today’s world. The utilization of renewable energy presents numerous benefits, both for […]