Using Super Duplex Stainless Steel in CNC Machining: Advantages for High-Corrosion Resistance Parts

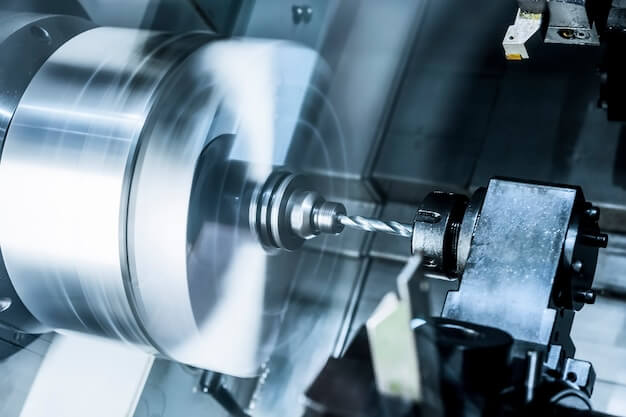

Introduction to Super Duplex Stainless Steel and CNC Machining Super duplex stainless steel, a prominent material in the manufacturing industry, possesses an optimized balance of properties that make it desirable for numerous demanding applications. Characterised by its dual phase structure – containing roughly equal parts of ferrite and austenite – super duplex stainless steels exhibit […]

Inconel vs. Monel: Choosing the Superior Alloy for CNC Machining in Extreme Environments

Inconel vs. Monel: A Background and Their Relevance in CNC Machining in Extreme Environments In the sphere of advanced manufacturing practices, particularly CNC machining for extreme environments, two categories of heat-resistant “superalloys” – Inconel and Monel – have consistently gained prominence due to their exceptional mechanical properties and corrosion resistance. Originating from the family of […]

CNC Machining of Rare Metals: Beryllium Copper vs. Tantalum for Specialized Applications

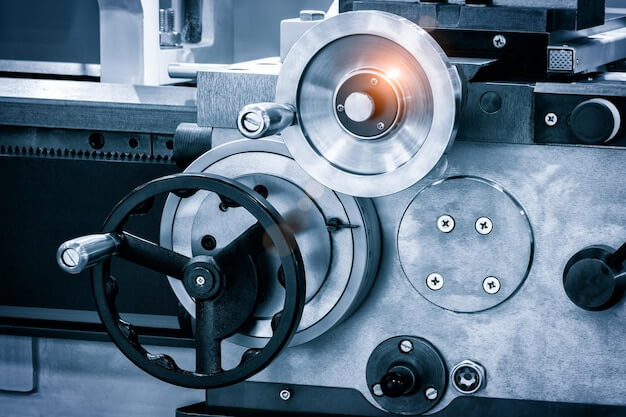

Understanding CNC Machining In manufacturing, Computer Numerical Control (CNC) machining is a crucial method that enables high precision and efficiency through automated control of machine tools. Its significance rests on its ability to produce complicated parts with limited human intervention, thereby increasing productivity while reducing errors and production time. When it comes to specialized applications […]

Hardened Tool Steels for CNC: Is D2 or A2 Better for Your Precision Manufacturing Needs?

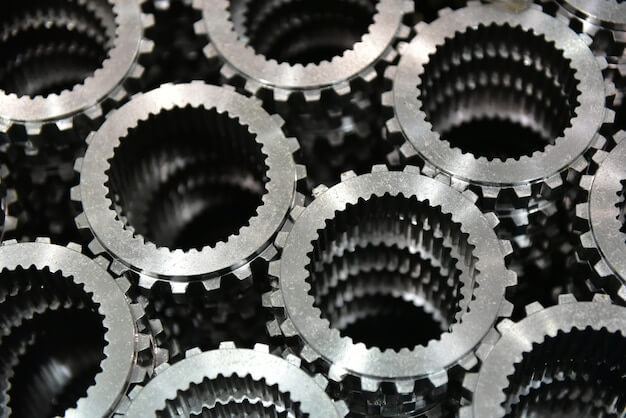

Introduction: The Importance and Basics of Choosing Right Tool Steels in CNC Manufacturing In precision manufacturing, especially in Computer Numerical Control (CNC) processes, the selection of the most appropriate tool steel greatly impacts production efficiency, product quality, and overall cost-effectiveness. The importance of this choice is rooted in the inherent properties of the steel used […]

Inconel vs. Monel for Advanced CNC Applications: Which Alloy Stands Up to the Challenge?

Inconel and Monel Alloys: An Introduction The realm of advanced CNC applications presents the challenge of choosing suitable alloys, with Inconel and Monel standing as key contenders. Predominantly composed of nickel, chromium, and iron, Inconel is renowned for its high-strength properties, excellent corrosion resistance and ability to withstand extreme temperatures, making it an ideal choice […]

Zirconium vs. Titanium in CNC Machining: Which Material Offers Superior Performance?

Introduction to CNC Machining and the Role of Zirconium and Titanium Computer Numerical Control (CNC) machining is a widely used manufacturing process where pre-programmed software commands guide the motion of factory machinery. This technology often applies in handling complex three-dimensional shapes, making it essential for diverse industries like transport, healthcare, aerospace, and electronics. The significance […]

Ceramic Composite Materials in CNC Machining: Are They the Future of Aerospace Components?

Introduction to CNC Machining and Ceramic Composite Materials CNC (Computer Numerical Control) machining is a pivotal manufacturing process in the aerospace industry. It’s characterized by automated control of machine tools through software inputs, ensuring precision-engineering of components that are critical for constructing aircrafts and their engines. This meticulous approach enhances accuracy, quality control and contributes […]

Ceramics in CNC: Zirconia vs. Alumina – Which Offers Superior Durability?

Ceramics in CNC: Zirconia vs. Alumina In the realm of Computer Numerical Control (CNC), ceramics are widely used due to their exceptional mechanical properties, including durability and resistance to wear. Specifically, zirconia and alumina have become standout materials in various manufacturing contexts. Both constitute advanced ceramic materials that afford enhanced performance capabilities compared to traditional […]

Tool Steel Grades in CNC Machining: Is D2 Better than A2?

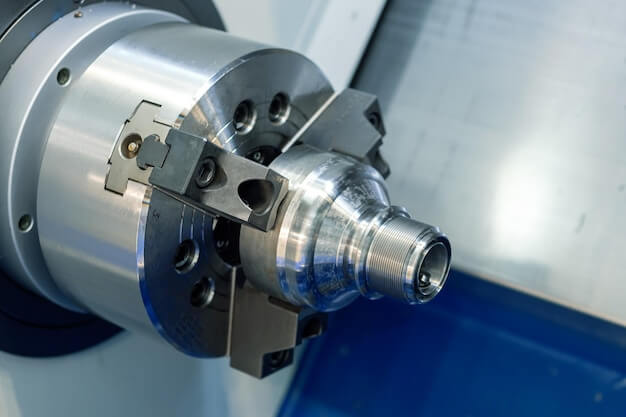

CNC Machining and Tool Steel Grades D2 and A2 In the realm of manufacturing and fabrication, Computer Numerical Control (CNC) machining is a highly prevalent method. CNC allows for precision shaping and forming of materials, typically metal, through pre-programed processes executed by machines. Crucial to successful CNC work is the choice of tool steel used […]

Is Machining with Titanium Worth the Cost for Aerospace Applications?

Machining with Titanium in Aerospace Applications The manufacturing process that involves the use of titanium, particularly in aerospace applications, is referred to as machining with titanium. This method has been increasingly adopted due to titanium’s unique properties such as its strong resistance to corrosion, high heat performance, and exceptional strength-to-weight ratio. These characteristics make it […]

Molybdenum Alloys in CNC Machining: Applications and Challenges

CNC Machining and the Use of Molybdenum Alloys Computer Numerical Control (CNC) machining is a process used in the manufacturing sector that involves the use of computers to control machine tools such as lathes, mills, routers, and grinders. The precision of CNC machining allows for complex shapes and designs to be created with unparalleled accuracy. […]

Tantalum vs. Niobium: Which is Better for Advanced CNC Machining?

Introduction to CNC Machining CNC (Computer Numerical Control) machining, an essential process in contemporary manufacturing industries, utilizes pre-programmed computer software to control the movements of machinery. This sophisticated technology enhances accuracy, precision, and speed of production by eliminating manual input and manipulation. Industries such as aerospace, automotive, electronics, and medical device manufacturing significantly rely on […]