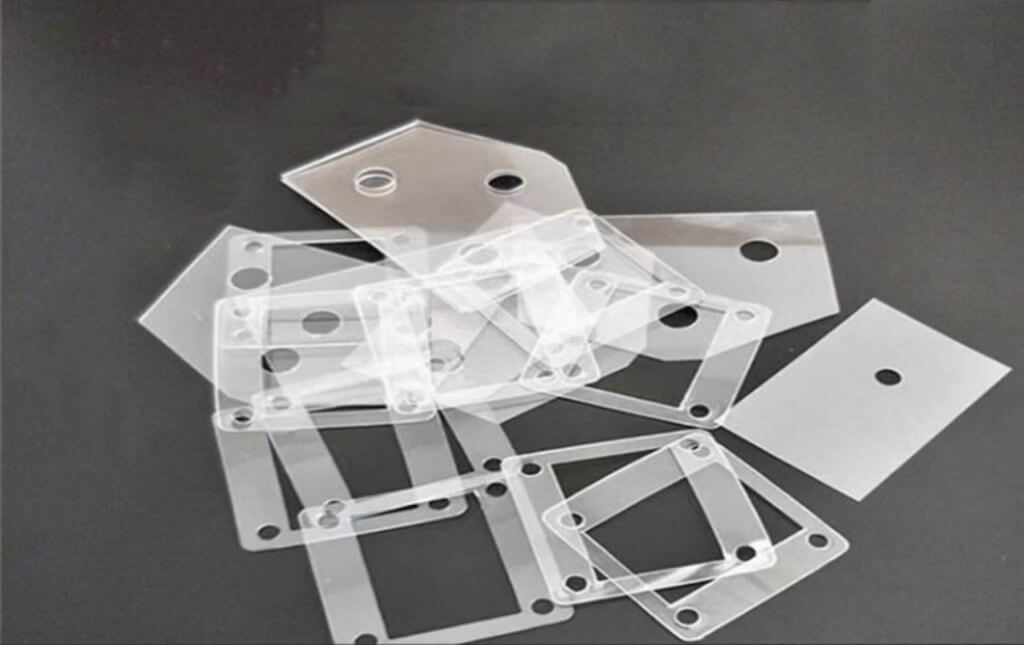

Plastic Shims: How to Make Custom Parts with CNC Machines

Introduction Plastic shims are one of those components you don’t think much about—until you really need them. I first got into making custom plastic shims when I was building a small fixture that needed perfect spacing between two aluminum plates. Off-the-shelf metal shims were either too thick or too rigid, and cutting plastic by hand […]

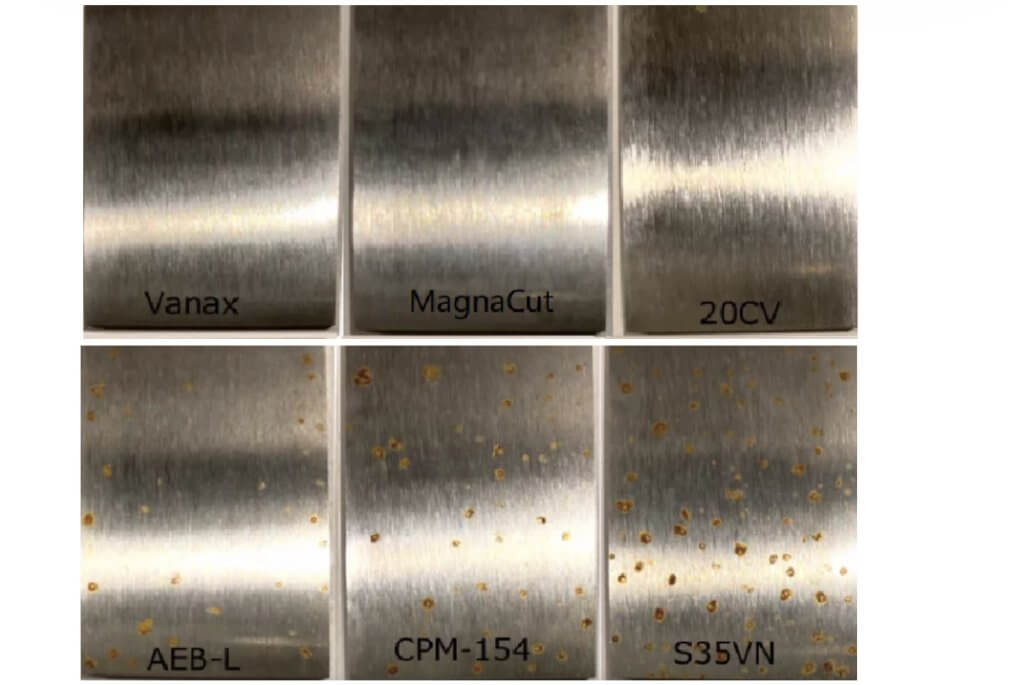

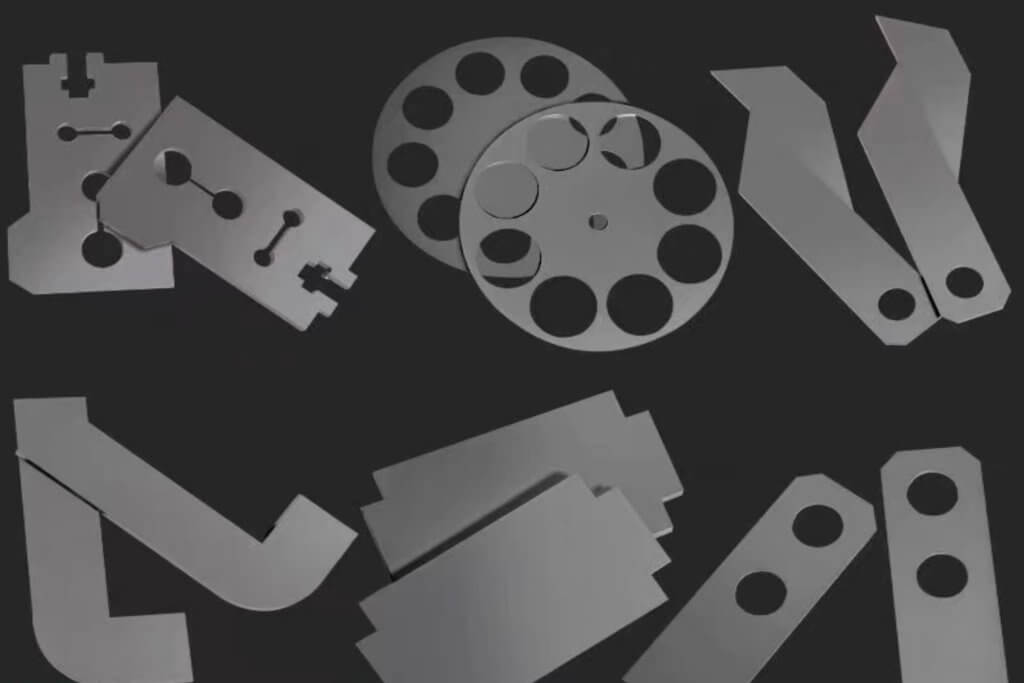

Mastering MagnaCut Steel with CNC: Tips for Precision Knife Crafting

Introduction MagnaCut Steel has taken the knife-making world by storm, and for good reason. This powder metallurgy stainless steel offers an incredible balance of hardness, toughness, and corrosion resistance, making it a top choice for crafting high-performance knives. When paired with CNC machining, MagnaCut Steel unlocks precision and efficiency that can elevate your knife-making game. […]

The Ultimate Guide to HSS Steel Cutting Tools in CNC Machining

I. Introduction: What is HSS Steel Cutting Tool? Understanding HSS Steel and Its Role in CNC Machining HSS Steel (High-Speed Steel) is a specialized alloy that’s widely used in the manufacturing of cutting tools. It’s composed of iron, carbon, and other alloying elements like tungsten, molybdenum, chromium, and vanadium, which give it the hardness, heat resistance, and toughness necessary for […]

Best Cutting Tools and Feeds for HSS Steel Machining

I. Introduction: What is HSS (High-Speed Steel)? High-speed steel (HSS) is an alloy designed to withstand the intense heat generated during cutting operations. It’s not only used for tool manufacturing but also plays a crucial role when HSS steel itself is the material being machined. What Makes HSS Steel Special? HSS steel is an alloy primarily made […]

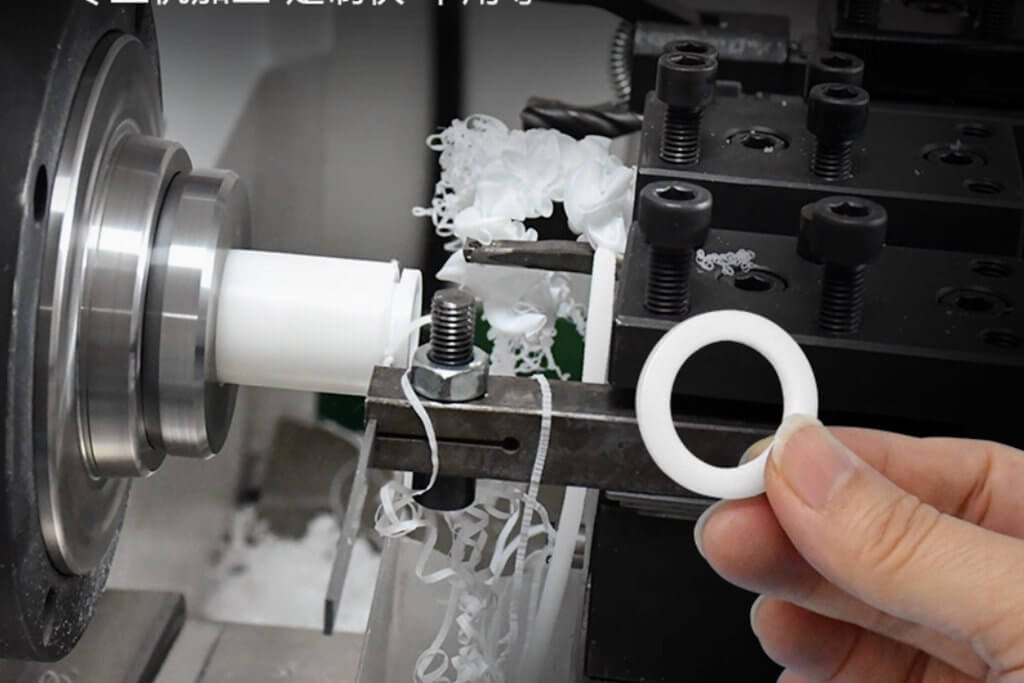

Plastic Washers Too Specific for Off-the-Shelf? CNC Machining Has the Answer

Introduction (Brief) Plastic washers often seem like simple, minor parts. I used to think the same—until I faced an issue where standard off-the-shelf plastic washers just couldn’t solve my problem. My project demanded specific thicknesses, unique diameters, and a material tough enough for extreme conditions. That’s when I first discovered the power of CNC machining. […]

S30V Steel CNC Machining Guide: Tools, Techniques, and Real-World Tips

Introduction When I first started working with S30V steel, I thought I knew what I was doing. I had years of CNC machining experience, a decent tool library, and a solid understanding of stainless steels. But S30V? It humbled me. S30V steel isn’t your average high-end material. It’s aggressive, abrasive, and brutally unforgiving if you don’t treat […]

The Ultimate Carbon Fiber Case CNC Machining Manual for Custom Enclosures

Chapter 1: Introduction If you’ve ever held a carbon fiber case, you probably noticed how ridiculously light it feels—yet somehow, it feels tougher than metal. That’s not just a gimmick. Carbon fiber offers a unique combo: aerospace-grade strength with feather-light weight. When combined with the precision of CNC machining, it becomes a dream solution for crafting sleek, […]

Which Titanium Plate to Choose for Machining? Material Grades, Machinability, and Supplier Tips

Why Choosing the Right Titanium Plate Matters When I first got involved in custom manufacturing, I underestimated just how significant the choice of material—especially titanium plate—could be. Selecting the right titanium grade isn’t just about checking boxes on a specification sheet. It affects machining time, tool life, product performance, and even how profitable a project becomes. […]

Precision Meets Performance: A Comprehensive Guide to CNC Machining of M390 Steel

Introduction When I first encountered M390 steel, I wasn’t aware of the challenges and possibilities this remarkable metal offered. My experience began in a CNC workshop, facing persistent tool wear and inconsistent surface finishes. Curious and somewhat frustrated, I delved deep into understanding why CNC machining M390 steel was proving challenging. If you’ve landed here, chances are you’re […]

What Makes 1095 Steel Ideal (or Not) for CNC Projects

Introduction Choosing the right material for CNC machining can make or break your project. It’s not just about whether a material is hard or tough. It’s about how it behaves under pressure, how it interacts with tools, and how it holds up over time. That’s where 1095 steel comes into play. I first came across […]

Cold Rolled Steel Machining Explained: From Material Choice to Cutting Strategy

Introduction When I first got into CNC machining, I didn’t pay much attention to material types. I just followed blueprints, mounted the blocks, and let the machine do its thing. But over time, I realized that what really determines the quality—and cost—of a part isn’t just the design or the toolpath. It’s the material. And […]

Brass Metal Use Cases You Didn’t Know: Machining for Electronics, Plumbing, and More

Why Brass Metal Is More Versatile Than You Think Most people I talk to associate brass metal with antique doorknobs, trumpet bells, or decorative light fixtures. That’s fair—brass is eye-catching and polished. But that’s only scratching the surface. In my experience working with both product designers and CNC machine shops, brass metal comes up in conversations far more often […]