Linear Bearing Guide: Types, Applications, and Selection Tips for CNC Systems

Introduction If you’ve worked with CNC machines, you know how critical precision and smooth motion are to achieving consistent results. At the heart of this precision lies an often-overlooked component: the linear bearing. A linear bearing enables smooth, low-friction motion along a linear axis, making it indispensable in CNC systems, industrial automation, and other high-precision […]

Carbon Fiber Sheets in CNC Machining: Applications, Techniques, and Cost Insights

Introduction When it comes to lightweight and high-strength materials, carbon fiber sheets are among the top choices for industries like aerospace, automotive, and electronics. Their unique properties, such as rigidity, corrosion resistance, and low weight, make them ideal for applications where performance and efficiency are critical. However, successfully working with carbon fiber sheets requires precision, […]

Straight Cut Gears Explained: What They Are and Why They Matter in CNC Machining

Introduction If you’ve worked with high-performance machinery or explored CNC machining, you’ve likely come across the term straight cut gears. These gears are renowned for their efficiency in transferring power and their use in precision-driven industries like automotive, aerospace, and industrial equipment. Straight cut gears are also a popular choice in custom machining, where specific […]

How to Choose a Grinding Wheel for CNC: Tips to Avoid Common Pitfalls

Introduction: Grinding Wheel and CNC Machining If you’ve ever worked with CNC or custom machining, you already know how important the right tools are to achieving precision and efficiency. Among these tools, the grinding wheel plays a pivotal role, especially when dealing with materials that require high accuracy or a polished finish. Selecting the wrong […]

Journal Bearing Machining: Mastering Techniques for Precision and Performance

I. Introduction Journal bearing, a staple in many industries, serve as a critical component for supporting rotating machinery. Whether you’re working with high-speed turbines in energy plants or automotive crankshafts, journal bearing is essential for reducing friction, bearing heavy loads, and ensuring operational efficiency. But achieving their peak performance isn’t just about the design; it’s […]

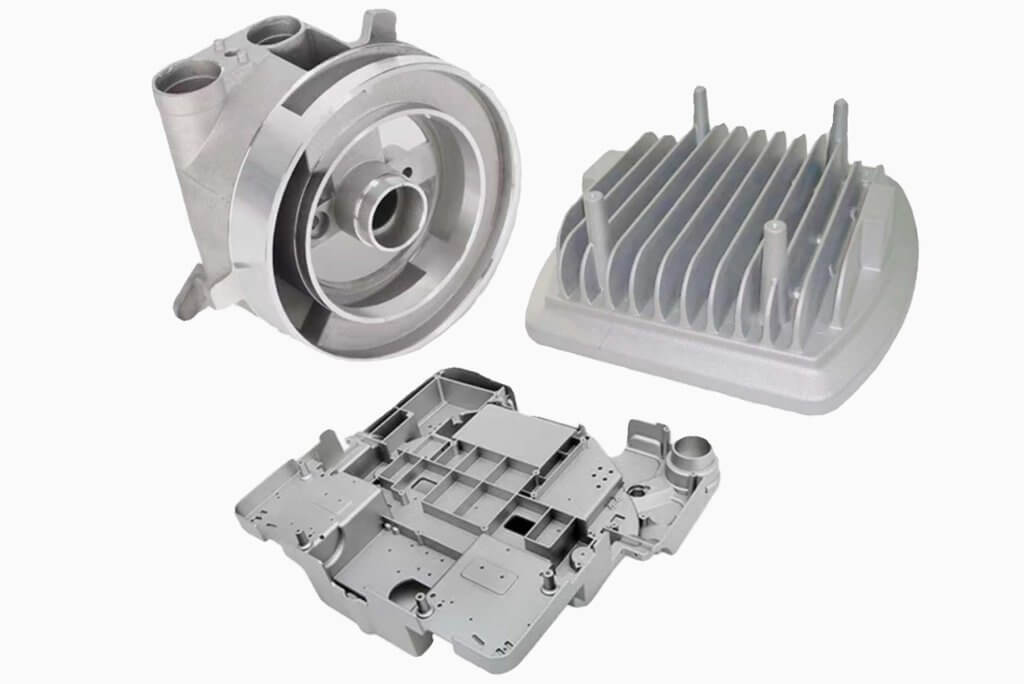

Die Casting and Machining Synergy: A Complete Guide for Manufacturers

Die casting and machining are two indispensable manufacturing processes that have transformed industries worldwide. By combining the strengths of these processes, manufacturers can achieve superior precision, quality, and efficiency in producing complex components. Furthermore, custom machining allows for additional flexibility and personalization, ensuring that components meet unique specifications and industry standards. In this comprehensive guide, I’ll explore […]

Mastering stl to gcode: A Complete Guide for 3D Printing and CNC Enthusiasts

Chapter 1. Introduction I remember the first time I tried converting stl to gcode for a simple 3D printing project.I thought it would be as straightforward as clicking a button.But soon, I realized there are many steps and nuances. In the field of custom machining, the conversion of STL to Gcode is essential for both […]

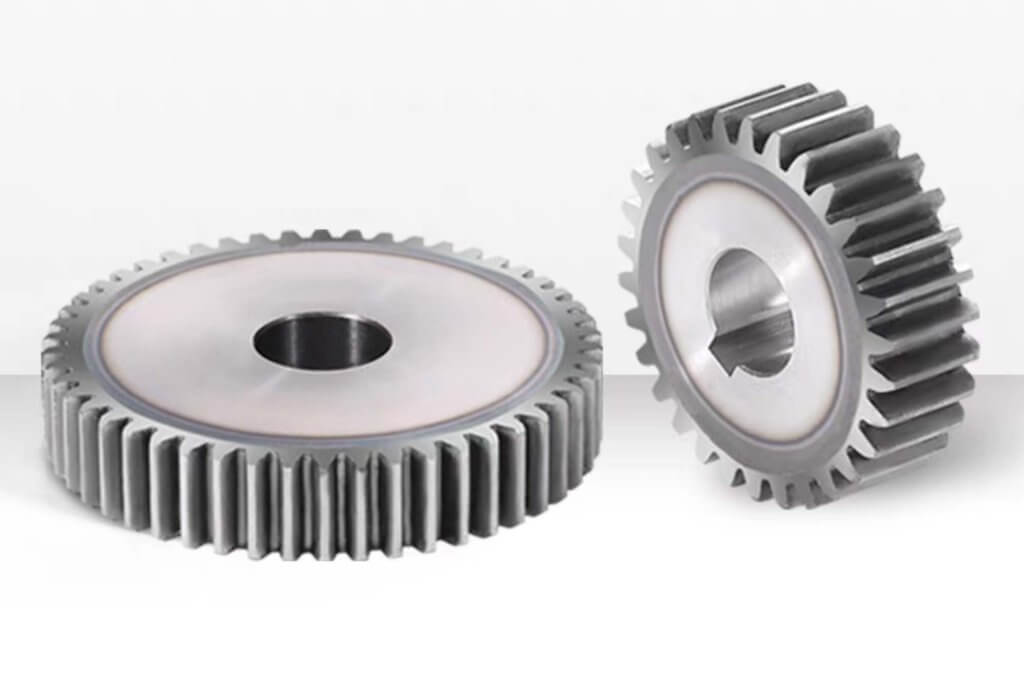

Spur Gear Machining: A Complete Guide to Design and Manufacturing

Introduction: The Role of Spur Gears in Modern Industry I’ve worked with mechanical systems for several years, and along the way, I’ve realized how crucial a spur gear can be. A spur gear might look simple—it’s a wheel with straight teeth that mesh with another gear—but it’s often the heart of countless machines. When I […]

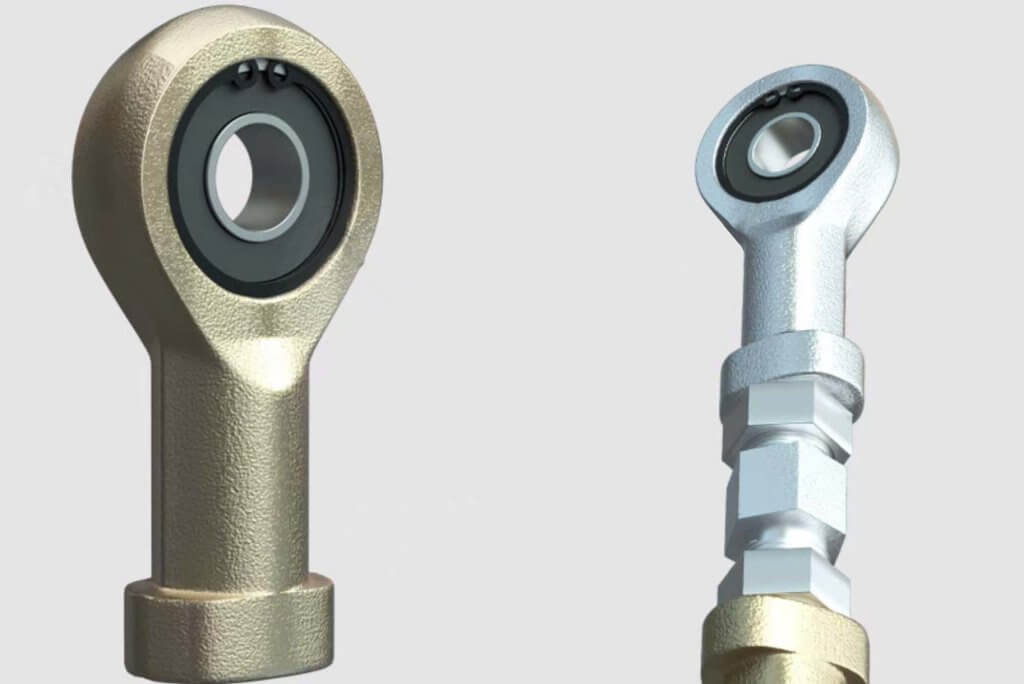

Exploring Rod Bearing: Customization, Machining, and Supply Chain Dynamics

Introduction: What is a Rod Bearing? When I first learned about rod bearing, I was surprised by how such a seemingly small and simple component plays a pivotal role in engine performance. A rod bearing is more than just a connector—it is the heart of an engine’s rotating assembly, ensuring smooth motion and reducing friction […]

Carbon Fiber Phone Case Uncovered: From Material Science to Cutting-Edge Machining

Why Carbon Fiber for Phone Cases? When you hear about a carbon fiber phone case, what’s your first thought? For many, it’s the image of a sleek, lightweight, and durable cover that combines style with performance. But Carbon Fiber Phone Case isn’t just about aesthetics—they represent a fascinating intersection of material science and advanced manufacturing […]

Everything About Types of Gears: Straight, Helical, Bevel, and More

Introduction When I first started learning about types of gears, I thought they all looked alike: just round devices with teeth that mesh together. But as I dug deeper, I realized that gears come in a wide variety of shapes and configurations—each designed to handle specific loads, speeds, and torque requirements. From the simple straight […]

Exploring Bevel Gear Machining: Design, Precision, and Innovation

Introduction I remember the first time I noticed a bevel gear in action. It was part of a complex gear train inside a small industrial machine I was helping to maintain. At the time, I had only read about bevel gear concepts in textbooks. Seeing one up close made me realize how integral these gears […]

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu