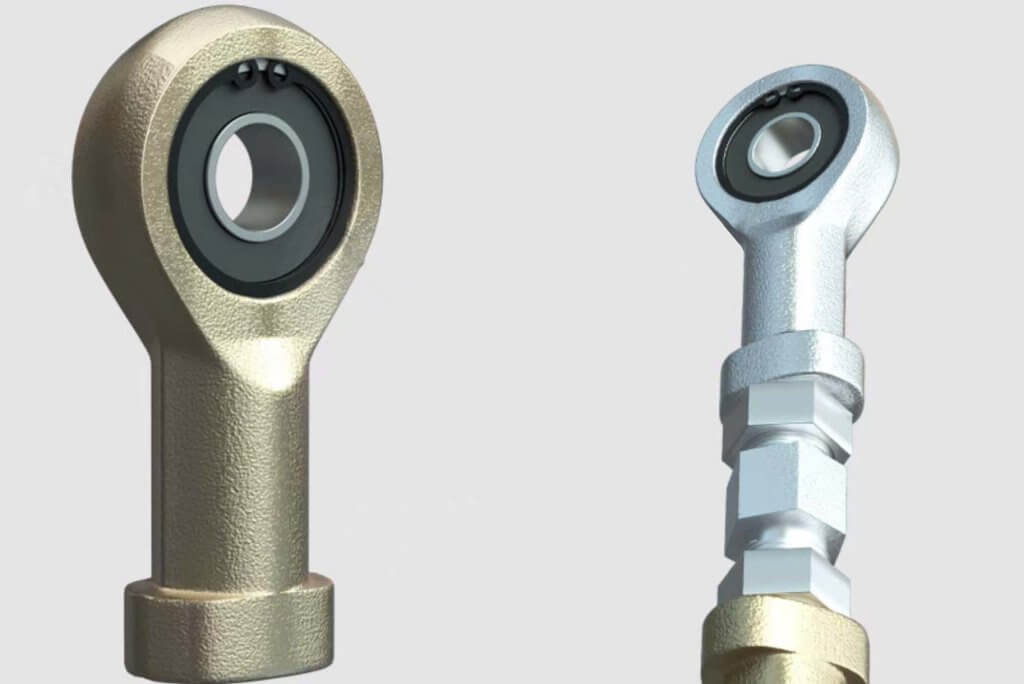

Exploring Rod Bearing: Customization, Machining, and Supply Chain Dynamics

Introduction: What is a Rod Bearing? When I first learned about rod bearing, I was surprised by how such a seemingly small and simple component plays a pivotal role in engine performance. A rod bearing is more than just a connector—it is the heart of an engine’s rotating assembly, ensuring smooth motion and reducing friction […]

Carbon Fiber Phone Case Uncovered: From Material Science to Cutting-Edge Machining

Why Carbon Fiber for Phone Cases? When you hear about a carbon fiber phone case, what’s your first thought? For many, it’s the image of a sleek, lightweight, and durable cover that combines style with performance. But Carbon Fiber Phone Case isn’t just about aesthetics—they represent a fascinating intersection of material science and advanced manufacturing […]

Everything About Types of Gears: Straight, Helical, Bevel, and More

Introduction When I first started learning about types of gears, I thought they all looked alike: just round devices with teeth that mesh together. But as I dug deeper, I realized that gears come in a wide variety of shapes and configurations—each designed to handle specific loads, speeds, and torque requirements. From the simple straight […]

Exploring Bevel Gear Machining: Design, Precision, and Innovation

Introduction I remember the first time I noticed a bevel gear in action. It was part of a complex gear train inside a small industrial machine I was helping to maintain. At the time, I had only read about bevel gear concepts in textbooks. Seeing one up close made me realize how integral these gears […]

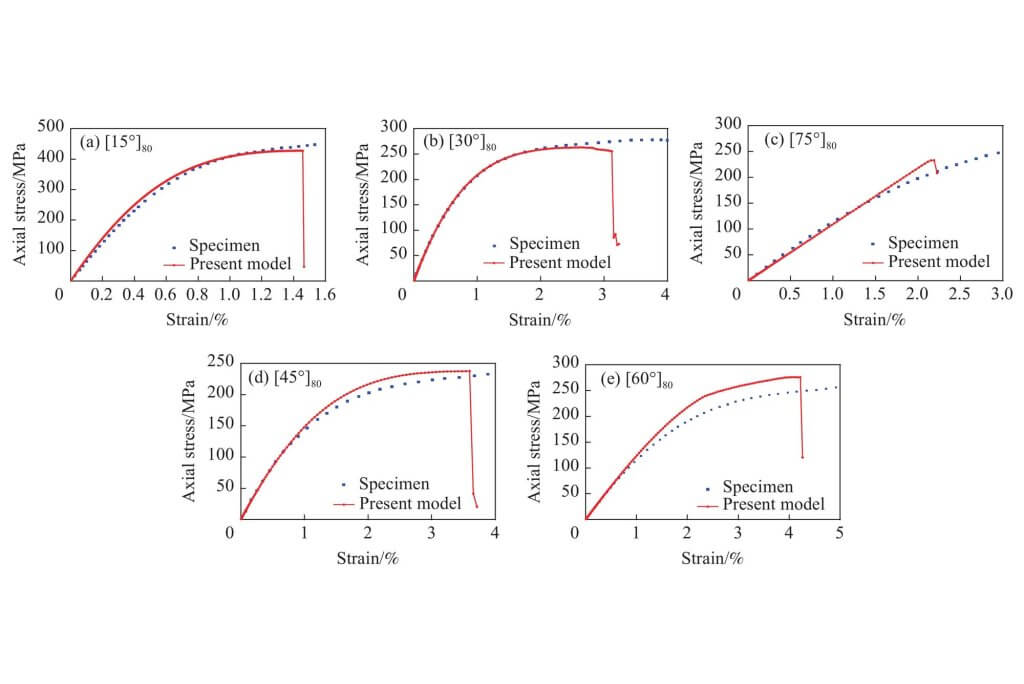

Decoding Carbon Fiber Strain in Advanced Machining Applications

Introduction: The Unique Properties and Applications of Carbon Fiber I’ve always been fascinated by how materials behave under stress. Carbon fiber, in particular, has this almost legendary status in aerospace, automotive racing, and even sporting goods. When I first heard about carbon fiber strain, I realized it wasn’t just a random scientific term—it captured the […]

Bearing Buddy Explained: Benefits, Machining, and Installation

Introduction A bearing is one of those components that I’ve encountered in nearly every piece of machinery I’ve worked with. I’ve seen bearings in car trailers, marine vessels, industrial equipment, and even in hobby-level projects. Whenever there’s a rotating shaft or a wheel involved, you’ll find a bearing. But bearings don’t last forever—at least, not […]

The Ultimate Guide to Bevel Cut and Machining: From Tools to Quality Control

Introduction If you’ve ever worked in machining or fabrication, you’ve probably encountered the term “bevel cut.” A bevel cut is one of those fundamental techniques that shows up in welding, woodworking, construction, and more. It’s essentially the angled cut you make on the edge of a material, whether it’s metal, wood, or even plastic. These […]

Unlocking Carrier Bearing: Custom Innovations in Precision Machining

Introduction Carrier bearing might sound like a small component in the vast world of engineering, but its significance cannot be overstated. These essential components are critical for supporting shafts, ensuring stability, and reducing rotational friction in various industrial and automotive applications. If you’ve ever wondered about the processes behind their manufacturing or the need for […]

Thrust Bearing Manufacturing: A Comprehensive Guide to Precision Machining

Chapter 1: Introduction I’ve worked with industrial components for quite some time, and one element that never ceases to intrigue me is the thrust bearing. A thrust bearing is specifically designed to handle axial loads rather than radial ones, making it crucial in applications where machinery experiences significant forces along the axis of rotation. From […]

Mastering Titanium Alloy Machining: Challenges, Techniques, and Industry Applications

Chapter 1: Introduction When I first began working with Titanium Alloy, I was struck by how unique they were. These materials combine high strength, low weight, and exceptional resistance to corrosion. But machining Titanium Alloy is no easy task. From tool wear to heat management, they challenge even experienced engineers. In this article, titled “Mastering […]

Decoding Ceramic Bearings: Performance, Machining Techniques, and Industry Applications

Chapter 1: Introduction I’ve spent quite a bit of time exploring various mechanical components and how they impact overall machine performance. One of the things that consistently fascinates me is how much difference a single part—like a bearing—can make in terms of efficiency, longevity, and reliability. In recent years, I’ve become particularly interested in ceramic […]

Zinc Alloy Machining Demystified: From Properties to Advanced Techniques

Introduction Zinc alloy is a fascinating material that I’ve encountered many times in my work with various manufacturing teams. I remember the first project where we used zinc alloy for a series of small automotive components. We chose it because of its good strength, decent corrosion resistance, and, honestly, I was intrigued by its surprisingly […]