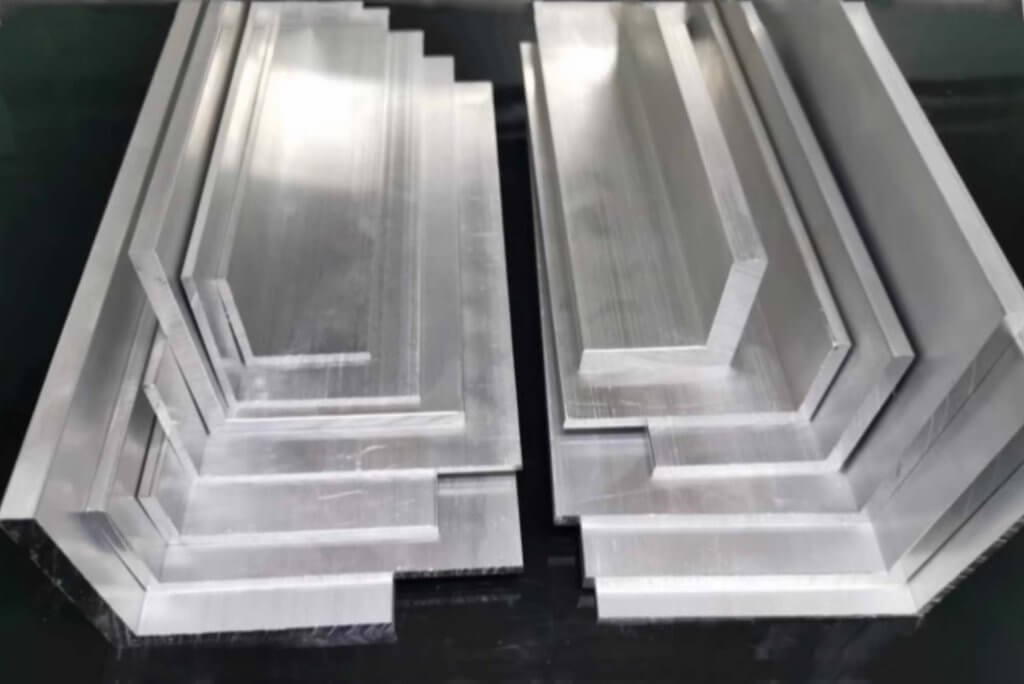

Aluminum Angle Uncovered: Tips for Machining, Industry Application, and Beyond

Introduction: Unique Advantages of Aluminum Angle I’ve always been fascinated by the lightweight properties of aluminum angle and the sheer range of possibilities it opens up for different industries. Aluminum angle has repeatedly proven its versatility in construction, automotive applications, and various machining scenarios. Whenever I think about aluminum angle, I’m reminded of the first […]

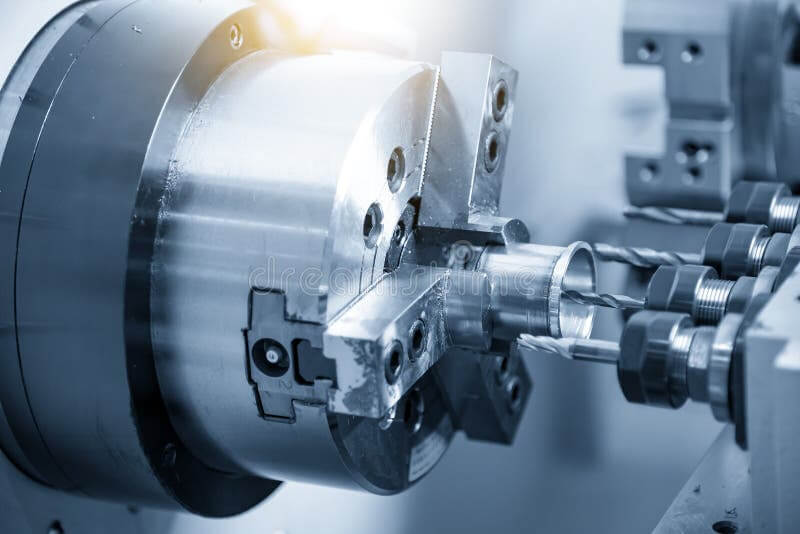

Creative Lathe Projects: Transform Ideas into Real Creations

I. Introduction Lathes are one of the most versatile tools in any workshop. Whether you’re crafting a wooden bowl, turning a precision metal part, or experimenting with CNC designs, lathe projects allow you to bring your ideas to life. Over the years, I’ve explored various lathe projects and discovered that they’re not only practical but […]

Harbor Freight Lathe: A Beginner’s Guide to Machining Basics

Introduction: Why Choose a Harbor Freight Lathe? I remember the first time I wanted to try my hand at metalworking. I didn’t have a huge budget, and I needed a lathe that was affordable but still capable of real machining. That’s when I discovered the Harbor Freight lathe lineup. These lathes are known for their […]

What is a Turret Lathe? Comprehensive Guide for Beginners and Professionals

Introduction to Turret Lathe If you’ve ever worked in manufacturing or machining, you’ve likely come across the term turret lathe. This machine, known for its versatility and efficiency, bridges the gap between traditional and CNC lathes, offering a blend of precision and productivity. Whether you’re a seasoned machinist or new to the field, understanding what […]

In-Depth Analysis of Nylon 66: Machining Properties and Applications

Introduction I want to share my personal experiences and observations regarding the remarkable material called Nylon 66. I’ve seen plenty of engineering plastics throughout my career, and each has its own characteristics. But Nylon 66 stands out due to its balance of strength, flexibility, and heat resistance. When I first encountered Nylon 66 as a […]

How Nylon Washers Are Made: From CNC Machining to Injection Molding

Introduction: What Are Nylon Washers and Why They Matter in Machining? Nylon washers are one of the unsung heroes of modern manufacturing. These simple yet versatile components are indispensable in a wide range of industries, including automotive, electronics, aerospace, and medical equipment. While their small size may make them seem insignificant, nylon washers play a […]

Decoding Steel Plate Choices: Your Path to Machining Success

Introduction: Steel Plates and Their Role in Machining Success Steel plates are the foundation of modern manufacturing and construction. From towering skyscrapers to precision medical equipment, they play a critical role in a wide range of industries. But not all steel plates are created equal, and understanding their types, properties, and applications can be the […]

Exploring Corrugated Plastic in Machining: A Comprehensive Guide

Overview When it comes to versatile and cost-effective materials, corrugated plastic stands out. This lightweight, durable, and waterproof material has applications across industries ranging from construction and logistics to advertising and agriculture. Over the years, I’ve seen corrugated plastic evolve from a basic packaging solution to a key material in precision manufacturing, particularly through CNC […]

Mastering Plastic Fasteners: Comprehensive Machining Techniques and Applications

Overview When it comes to modern manufacturing, plastic fasteners have become indispensable. From lightweight solutions in aerospace to non-conductive components in electronics, their versatility makes them a go-to option for engineers and designers. I’ve spent years exploring how plastic fasteners integrate into various industries, and I’ve seen firsthand how their machining processes impact product reliability […]

How to Machine Austenitic Stainless Steel: Tips and Tools You Need

Introduction When it comes to machining materials that combine durability and corrosion resistance, austenitic stainless steel is a go-to choice. This versatile metal alloy finds applications across industries such as medical devices, food processing, construction, and marine engineering. However, working with austenitic stainless steel comes with challenges, including heat accumulation, tool wear, and work hardening, […]

Mastering 440 Stainless Steel Machining: Techniques, Tools, and Applications

Introduction When it comes to machining, 440 stainless steel stands out for its exceptional hardness, wear resistance, and corrosion resistance. These qualities make it indispensable in industries such as aerospace, medical devices, and precision tools manufacturing. However, these same attributes also make machining it a challenging task, even for experienced machinists. Having worked on numerous […]

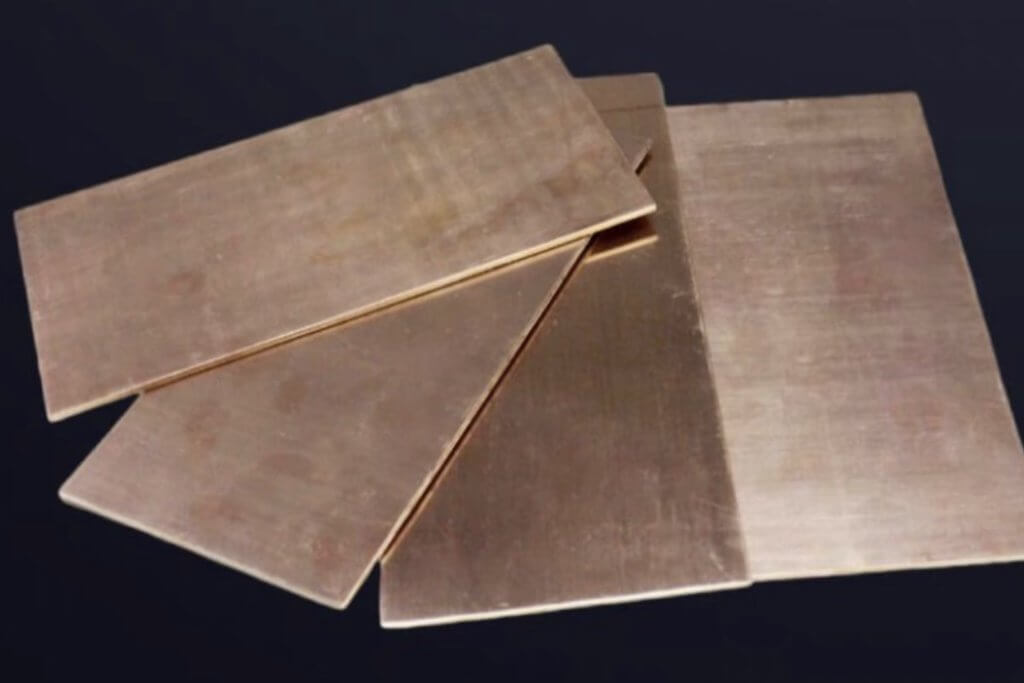

Everything You Need to Know About Phosphor Bronze and Its Machining Potential

I. Introduction Phosphor bronze is a highly versatile material used across industries for its unique combination of strength, corrosion resistance, and machinability. This alloy, made primarily from copper, tin, and a small percentage of phosphorus, stands out due to its ability to handle high loads and harsh environments. Over the years, it has become a […]