Everything You Need to Know About Phosphor Bronze and Its Machining Potential

I. Introduction Phosphor bronze is a highly versatile material used across industries for its unique combination of strength, corrosion resistance, and machinability. This alloy, made primarily from copper, tin, and a small percentage of phosphorus, stands out due to its ability to handle high loads and harsh environments. Over the years, it has become a […]

Unlocking the Potential of Bronze Bushings with CNC Machining

I. Introduction Bronze bushings are an indispensable component in the world of mechanical engineering. They provide critical support for rotating parts, reduce friction, and enhance the efficiency of countless machines. With the advent of CNC machining, the possibilities for customizing and improving the performance of bronze bushings have expanded significantly. From my experience, I’ve seen […]

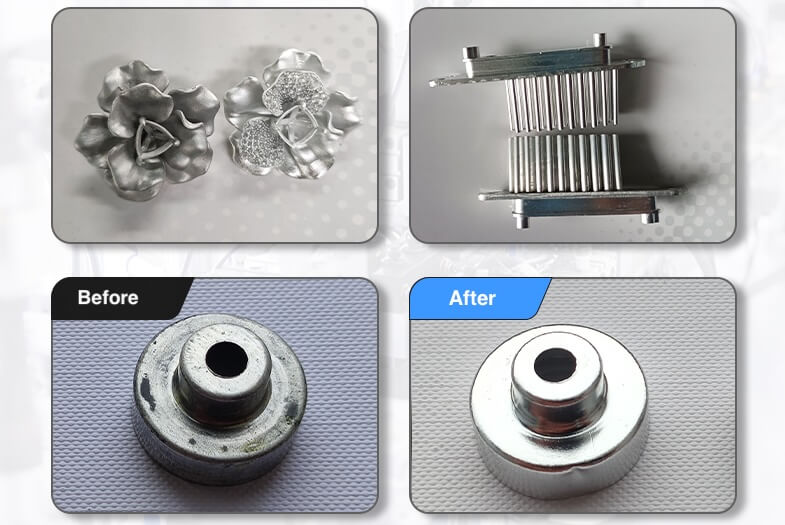

The Art of Burnished Bronze: Exploring Machining and Polishing Methods

Introduction Burnished bronze has been a material of fascination for many over the centuries. Whether you’re an artist crafting a masterpiece or an engineer designing industrial components, burnished bronze offers a remarkable combination of beauty, strength, and functionality. As someone who has spent years experimenting with different alloys and finishes, I can personally attest to […]

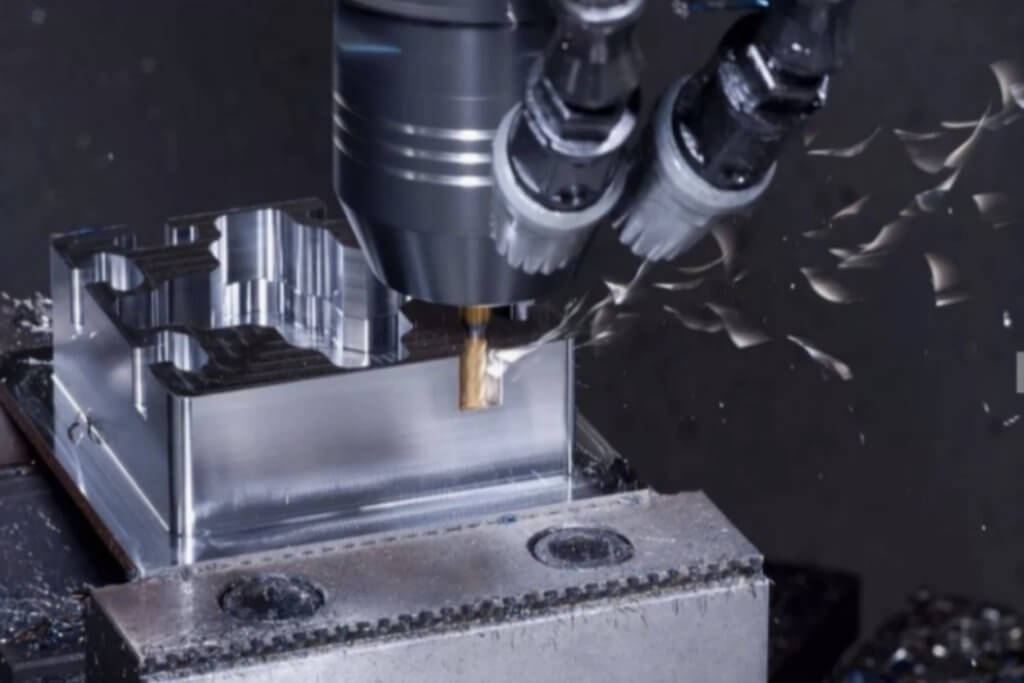

Creative CNC Projects: Ideas, Techniques, and Profitable Applications

Chapter 1: Introduction What Are CNC Projects? CNC projects involve using Computer Numerical Control (CNC) machines to create physical objects. These machines operate based on precise digital instructions to cut, carve, or mill various materials such as wood, metal, acrylic, and plastics. CNC technology eliminates human error, providing unparalleled accuracy and efficiency in manufacturing processes. […]

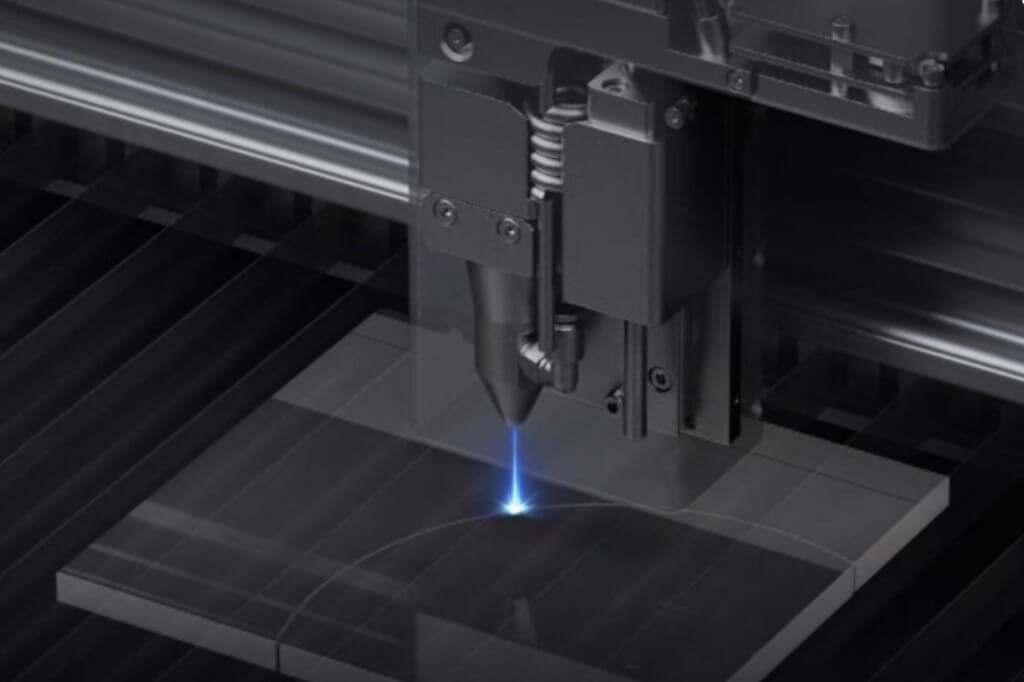

CNC Laser Applications That Are Reshaping Industries Today

I’ve spent a significant amount of time looking into how different manufacturing technologies evolve, and one technology that keeps grabbing my attention is CNC laser. When people talk about CNC laser solutions, they’re often referring to cutting-edge systems that combine the precision of computer numerical control (CNC) with the power of laser beams. But what […]

Brass Tacks Demystified: A Deep Dive into Machining Techniques and Innovations

I’ve spent a fair bit of time learning about different metal fasteners, and brass tacks are one of those intriguing items that bridge function and design. When you look at a finished piece of furniture or a detailed decorative panel, you might notice small round-headed tacks that seem to enhance the overall look. Those are […]

Billet Aluminum Unlocked: Expert Machining Techniques and Real-World Applications

Introduction: Why Billet Aluminum Matters in Machining I’ve worked with various metals and alloys, but billet aluminum has always stood out for its potential and versatility. Billet aluminum refers to aluminum stock—often in the form of a solid block or bar—that’s machined into complex shapes. It’s different from cast or extruded aluminum because it starts […]

The Complete Guide to Polishing Aluminum: Challenges and Solutions for Machinists

Introduction – Polishing Aluminum and Why It Matters I remember the first time I tried polishing aluminum. I wanted a clean, glossy finish but ended up with swirl marks and uneven patches. Later, I realized that polishing aluminum can be simpler once you understand the right techniques, tools, and alloy traits. My goal here is […]

Brushed Aluminum Demystified: From Elegance to Engineering

I’ve spent a fair amount of time working with different metals, and Brushed Aluminum has always caught my eye. It’s a material that combines an appealing, decorative surface with properties that are seriously valued in engineering. Whether you’re a designer looking for the perfect finish or an engineer aiming for a specific performance, brushed aluminum […]

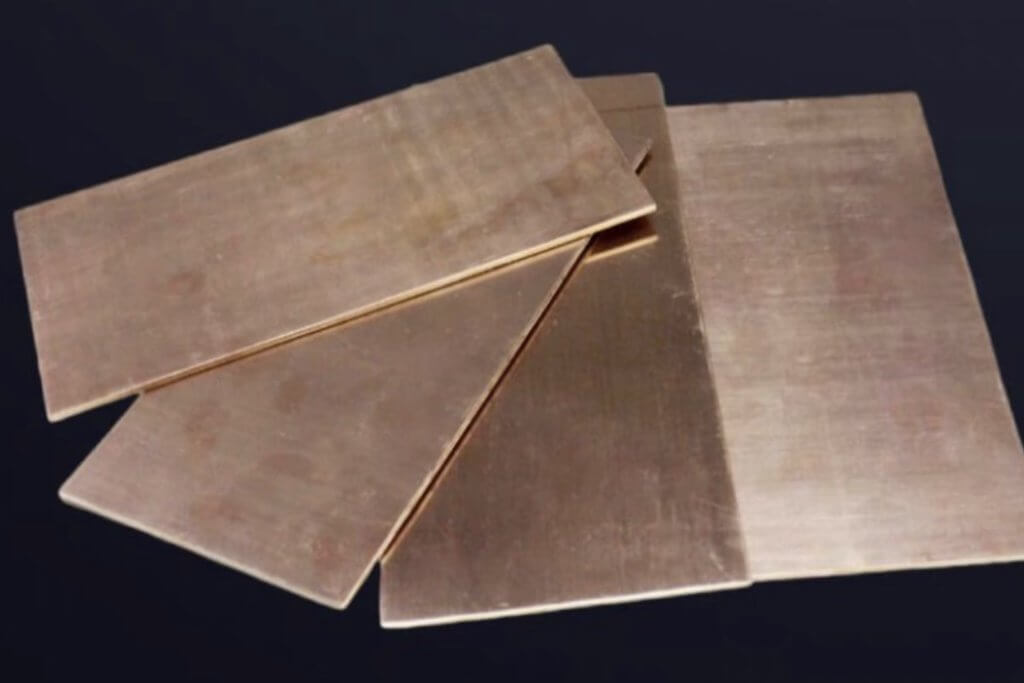

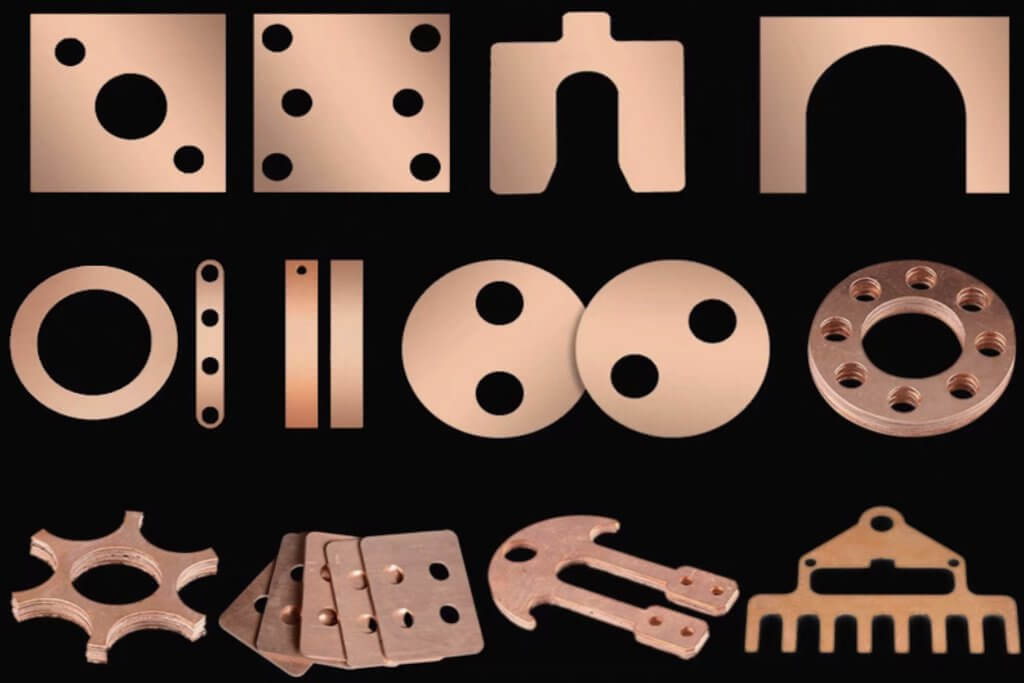

Copper Custom Innovations: Exploring New Alloys and Hybrid Manufacturing

I’ve spent a significant amount of time exploring various manufacturing processes, and one of the most intriguing areas I’ve encountered is what I call “Copper Custom.” This term encapsulates the innovative ways we use copper—through new alloys, advanced manufacturing methods, and environmentally conscious strategies—to produce components that meet modern industry demands. I want to share […]

Red Copper Machining: Techniques and Best Practices

Introduction: Why Focus on Red Copper Machining? Red copper, also known as pure copper, has long been a material of choice across industries due to its unparalleled properties. Its unique combination of electrical conductivity, thermal efficiency, and corrosion resistance makes it indispensable in sectors like electronics, construction, and cookware manufacturing. However, these benefits come with […]

Machining Techniques for Parts: Unlocking CNC and Cutting-Edge Tech

I. Introduction I remember the first time I realized how critical machining is to modern manufacturing. I was interning at a small shop, watching a CNC machine carve intricate features into a piece of aluminum. That day, it became clear that machining wasn’t just about removing material—it was a gateway to precision, innovation, and limitless […]