Understanding Counterbore and CNC Techniques Tools and Applications

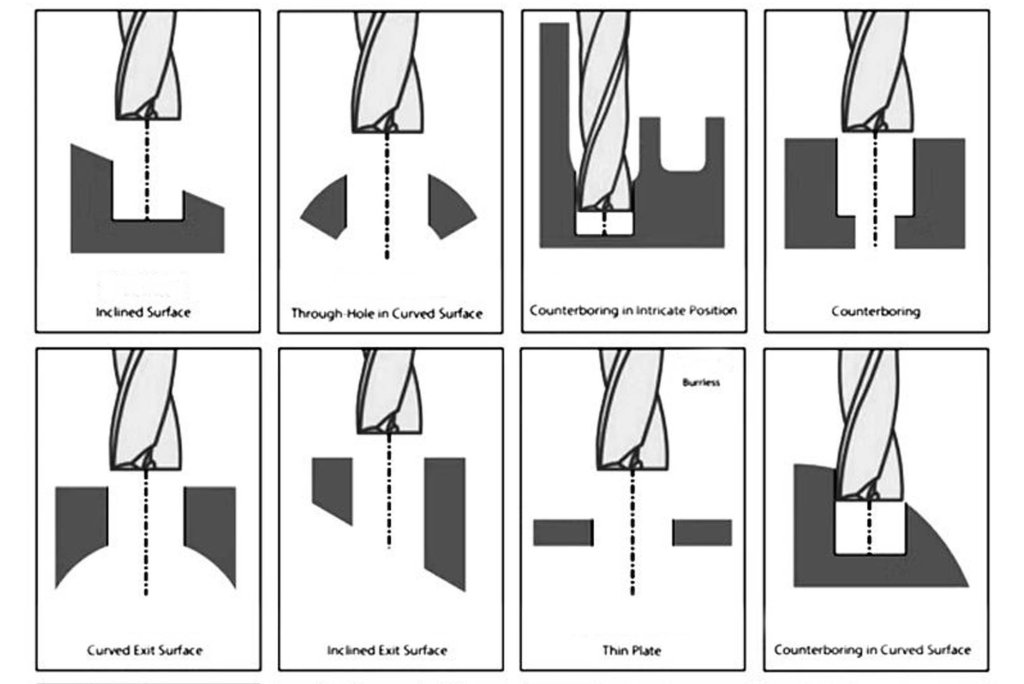

What is Counterbore and Why Does It Matter in CNC Machining? Counterbore is a term that frequently comes up in machining and manufacturing, especially in industries that require precision assembly. A counterbore is a cylindrical, flat-bottomed recess cut into a material, typically at the entry point of a hole. It allows screws or bolts to […]

Iron vs Steel: Decoding Their Strengths for Real-World Needs

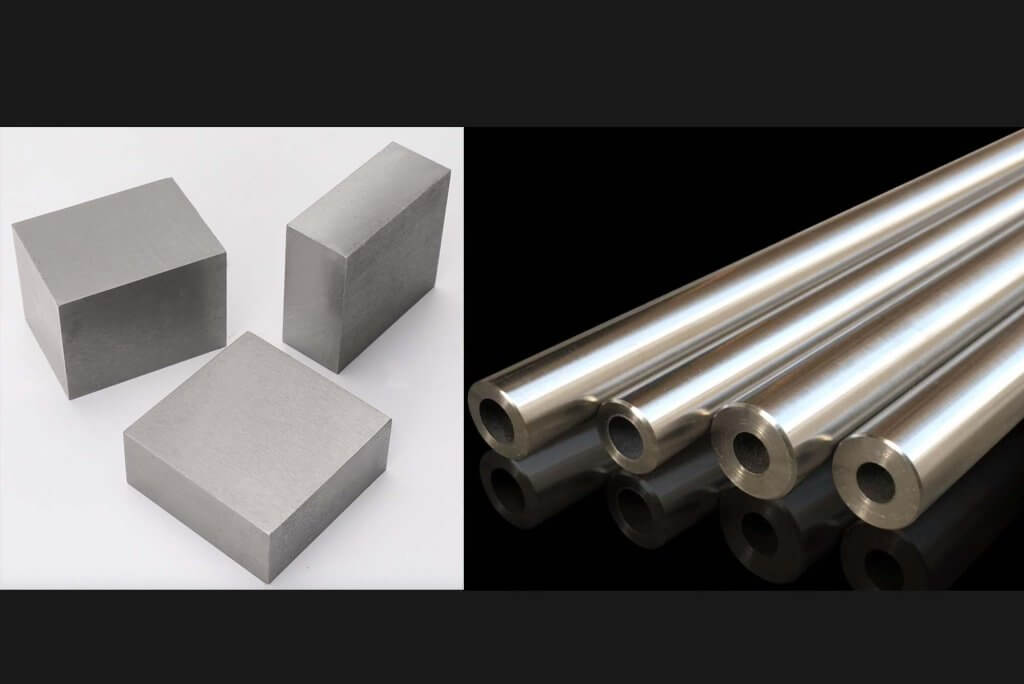

What Is Iron and Steel? Their Definitions and Basic Properties Iron and steel are two materials that have shaped human civilization for centuries. Iron, a chemical element (Fe), is one of the most abundant metals on Earth and has been used since ancient times. Steel, on the other hand, is an alloy primarily composed of […]

Metal Engraving Techniques Explained: From CNC to Laser

Introduction: The Art and Science of Metal Engraving with CNC Metal engraving has always been a craft that combines precision, artistry, and functionality. Historically, it was the realm of skilled artisans who spent hours, even days, etching intricate patterns or creating identifiable markings. Today, technological advancements such as CNC (Computer Numerical Control) and laser engraving […]

How to Choose the Best Metric Drill Bits for CNC Projects

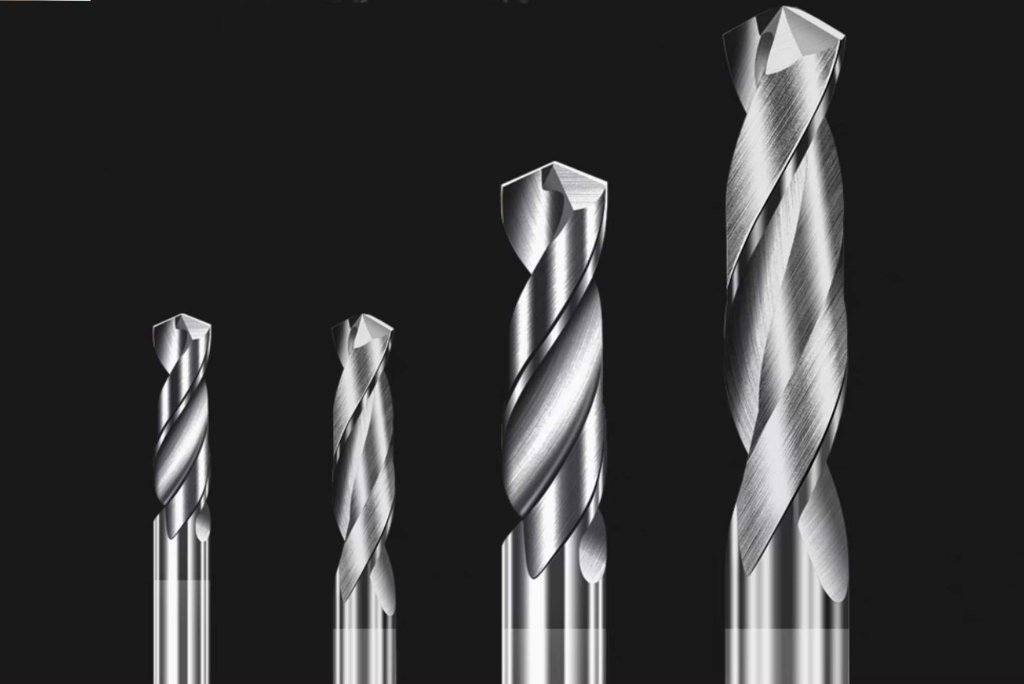

Why Metric Drill Bits Are Essential in CNC Machining When it comes to CNC machining, precision isn’t just a goal—it’s a requirement. The quality of your project often depends on the tools you use, and one of the most essential tools in your arsenal is the metric drill bit. Whether you’re working with delicate materials […]

What Does Fiberglass Look Like? A Comprehensive Guide for Identification and Application

Why Knowing What Fiberglass Looks Like Matters Fiberglass is a material that has permeated many industries, yet it remains somewhat mysterious to those outside of manufacturing, construction, or engineering. It’s lightweight, strong, and resistant to corrosion, which makes it an invaluable resource in a wide array of applications. But despite its versatility, people frequently find […]

Top 5 Techniques for Prototype Manufacturing: CNC Machining, 3D Printing, and More

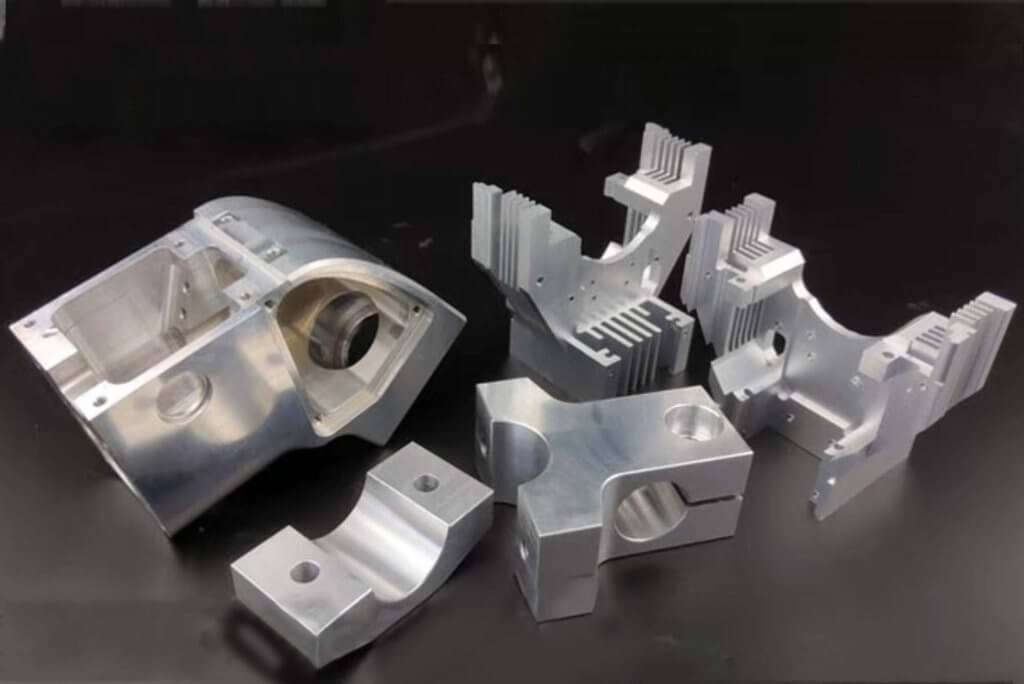

Introduction: What Is Prototype Manufacturing and Why Is It Important? When I first encountered the term “prototype manufacturing,” I realized it was a turning point in how products come to life. Prototype manufacturing is the process of creating early models or samples of a product before going into full-scale production. These prototypes let us test […]

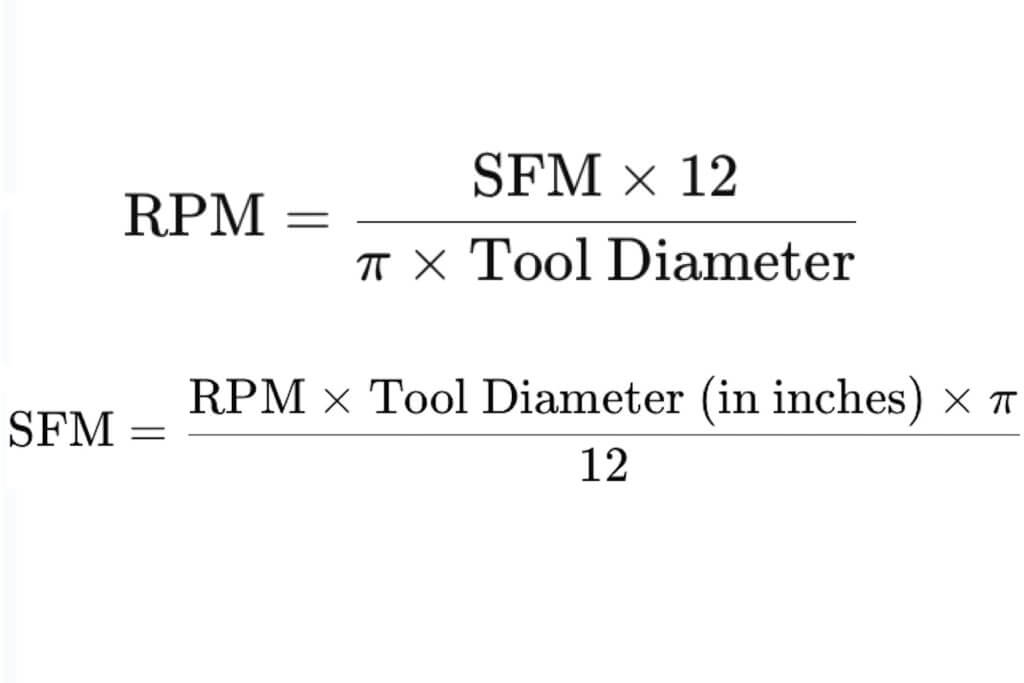

SFM Meaning and Its Importance in CNC Machining for Different Materials

Introduction: What Is SFM and Why Does It Matter in CNC? When I first heard the phrase “sfm meaning” in the context of CNC machining, I remember feeling a bit unsure. I knew CNC machining involved precise measurements, speeds, and feeds, but what exactly was SFM, and why did everyone seem to care about it […]

Is Brass Magnetic? How to Test, Use, and Identify Brass in Practical Scenarios

Introduction: Why People Ask “Is Brass Magnetic?” “Is brass magnetic?” is a question that seems simple on the surface. I recall the first time I asked myself this question when I held a brass door handle and wondered if a magnet would stick. Brass is such a common material, found in decorative fixtures, mechanical parts, […]

How CNC Machining Enhances Brass Color for Perfect Finishes

Chapter 1: Understanding Brass Color and Its Unique Characteristics I’ve always found the natural appeal of brass color to be something that sparks an immediate sense of warmth and sophistication. When I think of “brass color,” I picture that distinctive golden tone that somehow manages to feel both classic and modern. Brass color is not […]

Types of Screws Perfected Through CNC Precision

How CNC Precision Redefines Types of Screws Screws are fundamental components in countless industries, from construction to aerospace. Yet, many people overlook the role that precision plays in their design and manufacturing. As someone who has spent years working with CNC machining, I’ve seen firsthand how this technology has transformed the production of screws. It’s […]

Unlocking the Secrets of Types of Screws: A Must-Read for Every User

Introduction: Why Knowing Types of Screws Matters Screws are one of those everyday items that most people overlook until they’re needed. But when it comes to fixing, building, or even just hanging something on the wall, the right screw can make all the difference. As someone who has spent countless hours working on DIY projects […]

How to Choose the Best EDM Machine for Your Manufacturing Needs

Why Choosing the Right EDM Machine Matters When I first explored the world of EDM machines, I quickly realized their transformative potential in modern manufacturing. These machines go beyond the capabilities of traditional machining, offering unmatched precision for hard-to-machine materials and intricate geometries. Yet, their diversity can make choosing the right machine daunting, especially when […]