How to Machine 316L Stainless Steel with CNC: Tips and Techniques

Introduction to 316L Stainless Steel in CNC Machining When I first encountered 316L stainless steel, I was struck by its versatility and exceptional properties. It’s not just another stainless steel variant—it’s one of the most reliable materials for applications that demand corrosion resistance, durability, and precision. But as I’ve learned through my experience, machining 316L […]

Deep Dive into Metal Fabrication Unleashed: Key Techniques and Industry Trends

Introduction to Metal Fabrication When I first started learning about metal fabrication, I was fascinated by the complexity and precision required to transform raw metal into the finished products we use every day. From cutting and welding to precision machining and assembly, the world of metal fabrication is a dynamic and ever-evolving field. But what […]

Avoid Common Pitfalls When Choosing or Working with a Metal Fabrication Company: Insider Advice

Chapter 1: Introduction Choosing the right metal fabrication company can be the difference between a successful project and a costly failure. Whether you’re in the automotive, aerospace, or construction industry, finding a metal fabrication partner that aligns with your goals, standards, and expectations is crucial. Having been involved in several projects over the years, I’ve […]

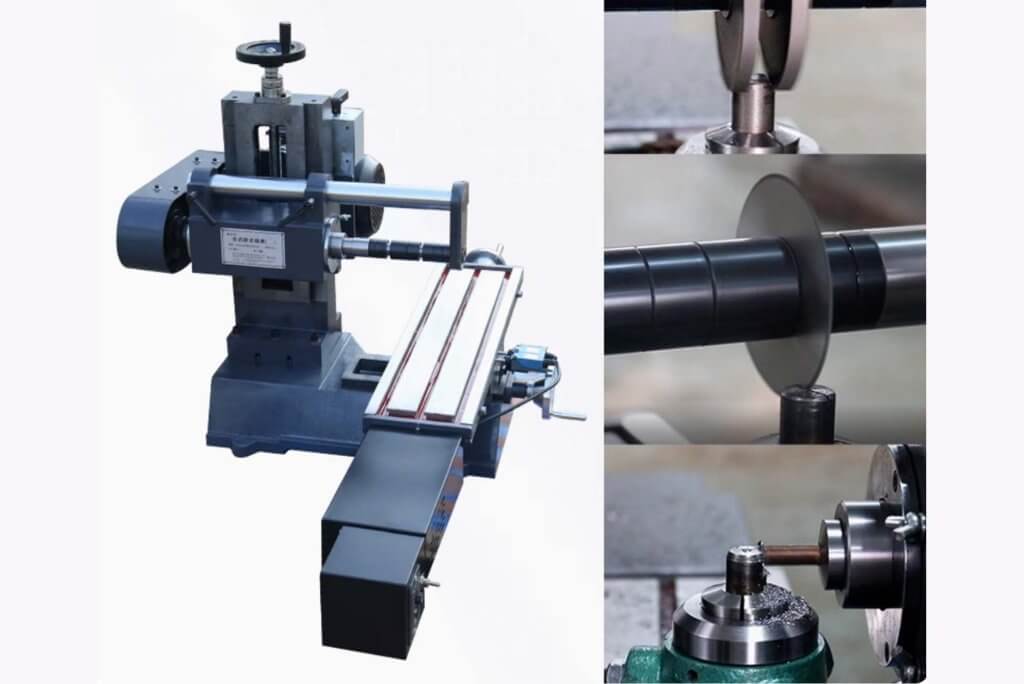

Unlocking the Power of Horizontal Milling Machine in CNC Operations

Introduction In the ever-evolving world of CNC machining, the horizontal milling machine stands as one of the most powerful tools for precision, efficiency, and versatility. When I first started working with these machines, I was amazed by how much their design and capabilities could transform machining operations, especially when it comes to complex, high-precision parts. […]

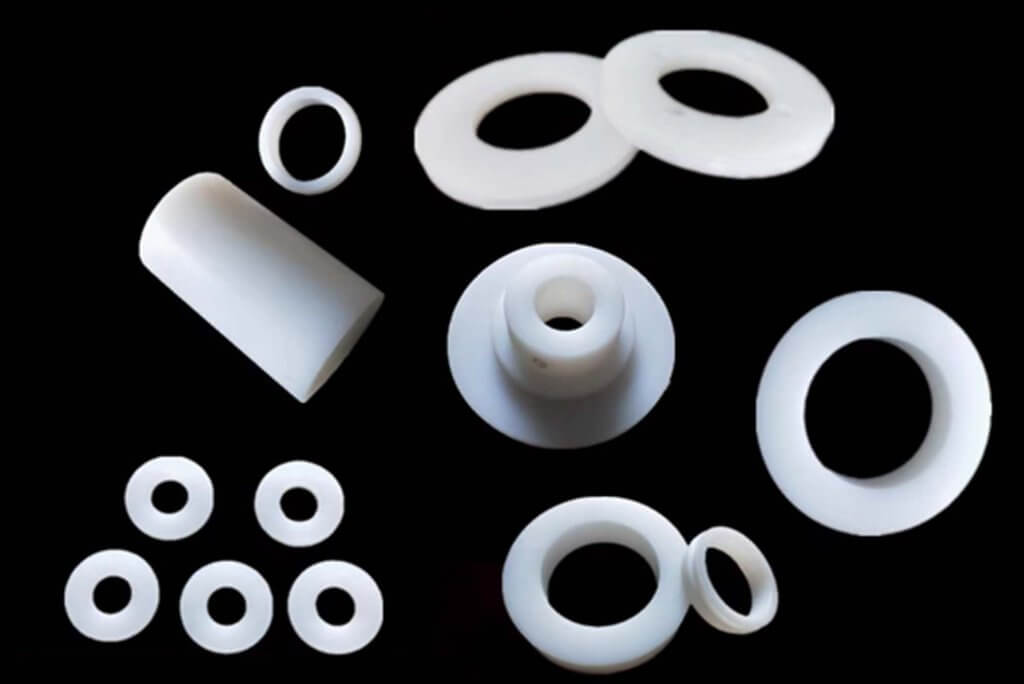

The Benefits of Using Nylons in CNC Machining for Precision Parts

Introduction to Nylons and CNC Machining As someone who has worked extensively with materials in CNC machining, I’ve come to appreciate the versatility and advantages of using nylons in precision manufacturing. Whether you’re designing a part for automotive, medical, or aerospace applications, nylons have consistently proven to be one of the most reliable materials for […]

Does Titanium Rust? Exploring the Corrosion Resistance of Titanium in CNC Machining

Introduction: Understanding Titanium’s Properties What is Titanium? Titanium is a metal that has gained significant attention in engineering, aerospace, medical, and industrial applications due to its unique properties. As a transition metal, it’s well known for being lightweight, strong, and highly resistant to corrosion, making it an ideal material for a wide range of high-performance […]

How to CNC Machine UHMW for High-Performance Parts in Industry

Introduction: Understanding UHMW and CNC Machining When it comes to manufacturing high-performance parts for industries such as mining, food processing, and automotive, the choice of material plays a crucial role. One material that has gained significant attention in these sectors is UHMW (Ultra High Molecular Weight Polyethylene). This material’s remarkable combination of wear resistance, low […]

What is 4140 Steel and Why is it Popular in CNC Machining

What is 4140 Steel? What are Its Key Characteristics? When I first encountered 4140 steel in CNC machining projects, I was struck by its versatility and dependability. It’s a chromium-molybdenum alloy steel known for its unique balance of strength, toughness, and wear resistance. These properties make it an exceptional choice for applications requiring high performance. […]

From Table to Tool:Where Are Metalloids Located on the Periodic Table for CNC Efficiency

Introduction I’ve spent years working with CNC machines, and there’s always one piece of advice I return to: understanding the material’s properties is as important as mastering the machine’s settings. Every metal, alloy, or composite I work with isn’t just a random block of material. It has a story rooted in the periodic table. When […]

Chamfer Tool Essentials: Boost Your CNC Machining Efficiency

As I embarked on my journey in the world of CNC machining, one tool quickly became indispensable in my arsenal—the Chamfer Tool. Whether you’re a seasoned machinist or just starting out, understanding the nuances of Chamfer Tool can significantly enhance your machining efficiency and the quality of your finished products. In this comprehensive guide, I’ll […]

Vertical Milling Machine Operation: Essential Steps for Accurate Machining

I. Introduction When I first heard the term “vertical milling machine”, I didn’t realize just how central this piece of equipment would become to modern manufacturing. At the time, I was simply looking into ways to improve my workshop’s capabilities, hoping to create more precise components and experiment with complex geometries. Over the years, however, […]

What Does CNC Stand For? A Deep Dive into Industry Applications and Trends

What Does CNC Stand For?