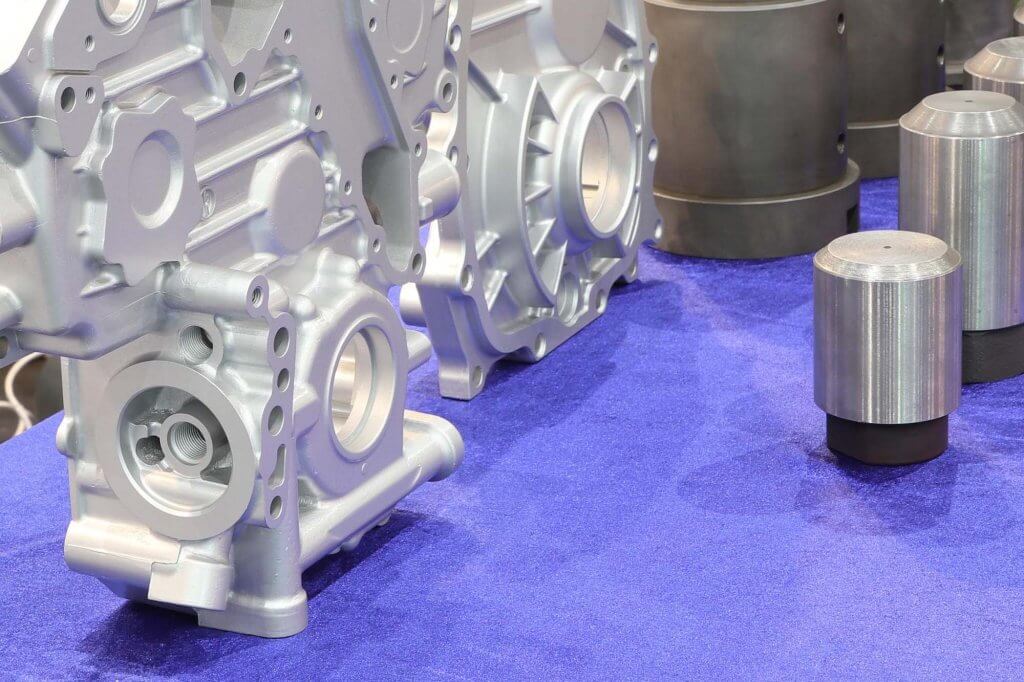

7075 vs 7050 Aluminum Alloys: How to Minimize Deformation in CNC Machining

Aluminum alloys, particularly 7075 and 7050, are widely used in the aerospace industry due to their high strength-to-weight ratio, excellent corrosion resistance, and good machinability. However, when it comes to CNC machining, especially for large thin-walled structures, these materials present unique challenges, particularly in terms of deformation during the machining process. This article explores the […]

Mastering CNC Drills for Precision in Composite Materials

CNC drilling is a critical process in modern manufacturing, particularly when working with composite materials. As industries like aerospace, automotive, and renewable energy continue to demand lightweight, high-strength components, achieving precision in machining these complex materials becomes increasingly essential. This article provides an in-depth guide to CNC drilling techniques specifically for composite materials. By understanding […]

Key Techniques for Stainless Steel Cutting: How CNC Machining Enhances Electrical Enclosure Design

Stainless steel, known for its corrosion resistance and high strength, is a popular material choice in the manufacturing of electrical enclosures. However, cutting and machining stainless steel present unique challenges due to its toughness and work hardening properties. For technical professionals and procurement specialists involved in CNC machining, understanding the key techniques for cutting stainless […]

Exploring Milling and Filing Techniques for CNC Precision Machining and Moulding Line Management

In the world of CNC precision machining, managing and refining moulding lines is a critical aspect that can significantly impact the quality of the final product, particularly in mold-making processes. For technical professionals and procurement specialists, understanding the techniques involved in CNC machining—especially milling and filing—can be crucial in evaluating a supplier’s capabilities and ensuring […]

A Guide to Finishing Techniques and Their Application in CNC Production of Micro Molding Machines Parts

When it comes to producing parts for micro molding machines, the finishing techniques used in the CNC machining process play a crucial role in ensuring that these components meet the high precision and quality standards required. For technical professionals and procurement specialists looking to understand or assess a supplier’s capabilities, it’s essential to have a […]

How CNC Machining Centers Tackle the Complex Challenges of Sink Molding Parts

In today’s fast-paced manufacturing environment, finding the right supplier for complex, custom-shaped parts like sink molding is crucial. CNC machining centers have revolutionized the way these intricate components are produced, offering unparalleled precision, efficiency, and versatility. This article will guide you through the intricate world of CNC machining centers, helping you understand why these advanced […]

Mastering CNC Machining Techniques for Tooling Die Casting with High-Strength Steels

In the world of precision manufacturing, CNC machining plays a crucial role, especially when it comes to tooling die casting with high-strength steels. These materials, known for their durability and resistance to wear, are vital in creating molds that withstand the extreme conditions of die casting processes. This article is tailored for procurement professionals seeking […]

Tackling Tough High-Temperature Alloys in CNC Machining with Sand Blasting Glass Beads

High-temperature alloys, also known as superalloys, are designed to withstand extreme environments where ordinary materials would fail. These alloys are crucial in industries such as aerospace, power generation, and chemical processing, where components must maintain mechanical integrity under high heat and stress. However, the properties that make these alloys so valuable also make them difficult […]

Optimizing High-Speed CNC Machining Surface Quality Using Glass Beads for Blasting

Introduction to CNC Machining and Surface Quality CNC machining is a cornerstone of modern manufacturing, enabling the production of intricate and precise components across various industries. As the demand for high-speed CNC machining grows, the importance of surface quality becomes increasingly significant. Surface quality, often quantified by surface roughness, directly impacts the performance, durability, and […]

Controlling Surface Roughness Challenges and Solutions in High-Speed CNC Machining of Galvanneal Sheet Metal

In the world of manufacturing, surface quality is a critical factor that can determine the success of a product. For buyers and engineers involved in CNC machining, particularly those working with Galvanneal sheet metal, understanding the nuances of surface roughness is essential. This article delves into the complexities of controlling surface roughness during high-speed CNC […]

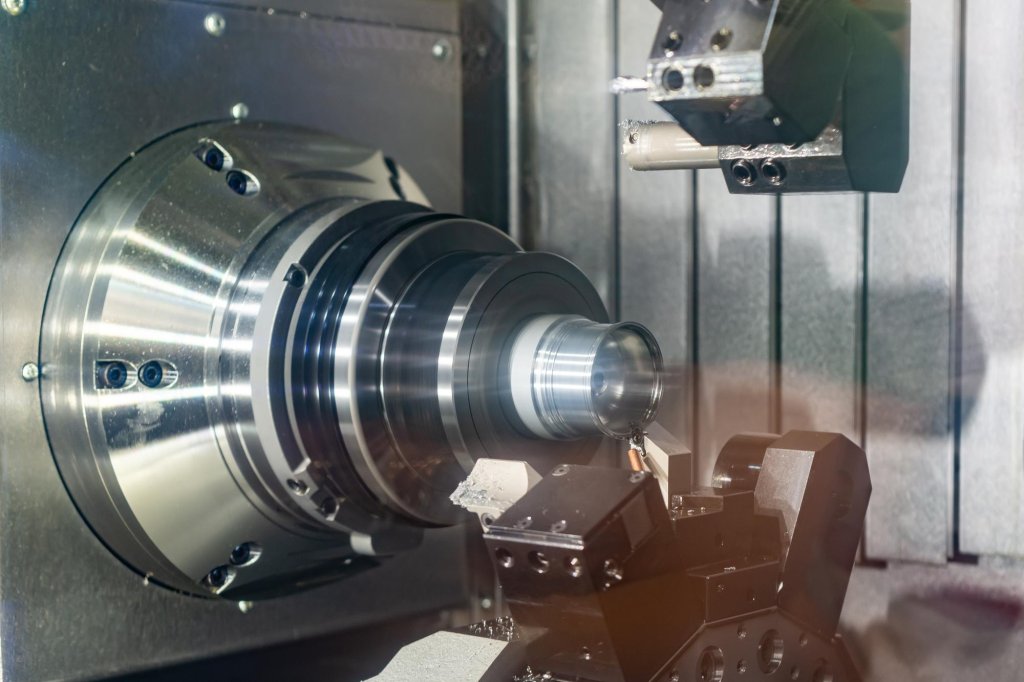

Mastering Titanium Alloy CNC Machining A Practical Guide

Introduction In the world of CNC machining, titanium alloys have carved a niche for themselves, known for their excellent strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These properties make titanium alloys highly desirable in industries such as aerospace, medical devices, and automotive. However, the very characteristics that make titanium alloys valuable also […]

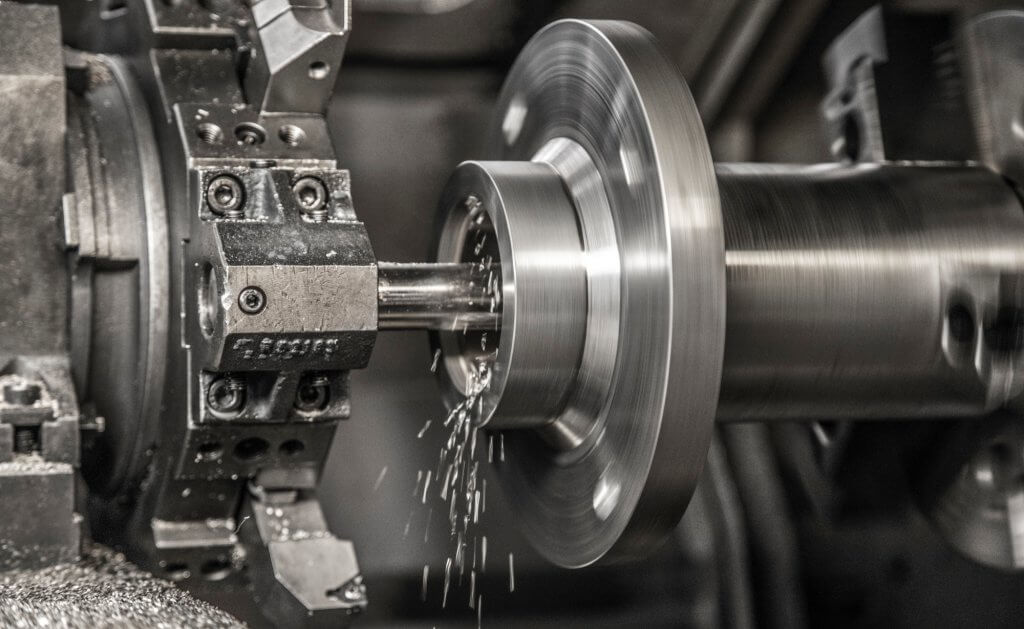

Mastering Flanges Production Tips for Cutting High-Manganese Steel in CNC Machining

Introduction High-manganese steel is renowned for its exceptional wear resistance and toughness, making it an ideal choice for producing durable flanges. However, its high strength and toughness also present significant challenges in CNC machining. For buyers looking to procure flanges made from high-manganese steel, understanding the intricacies of machining this material is crucial for ensuring […]