CNC Machining Guide Choosing the Right Tools for Drilling Polymer Composites

Drilling polymer composites in CNC machining is a task that demands precision, expertise, and the right tools. As composite materials continue to grow in popularity due to their high strength-to-weight ratio and versatility, understanding how to efficiently machine these materials becomes crucial, especially for procurement professionals seeking to ensure quality and cost-effectiveness in their production […]

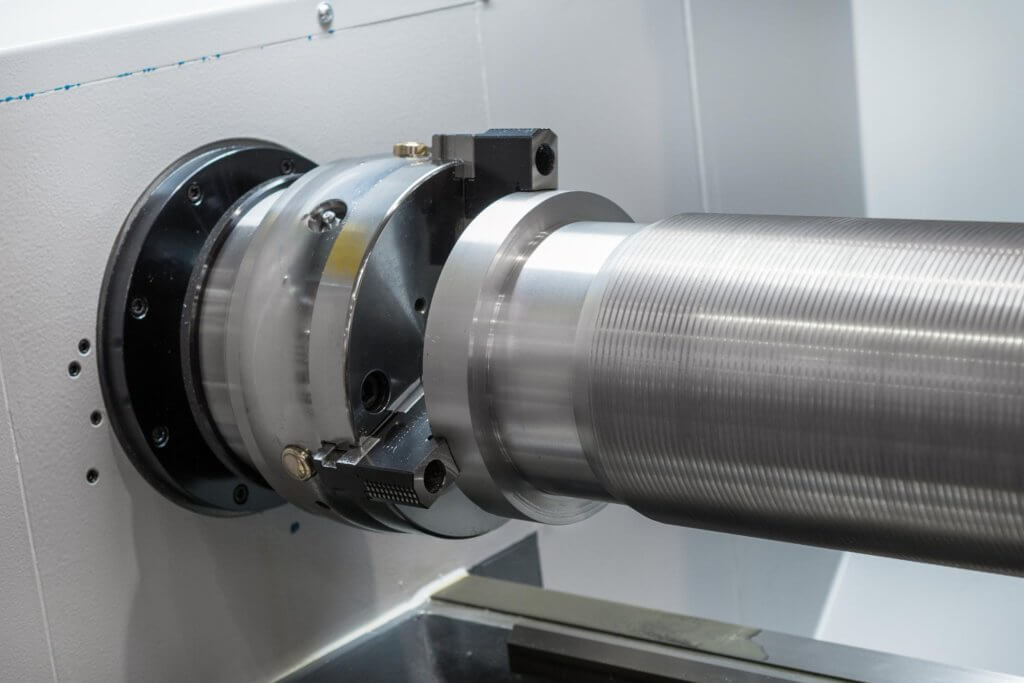

Handling Composite Materials in CNC Turning A Straightforward Approach to Tools and Techniques

Composite materials have become increasingly important in modern manufacturing due to their superior strength-to-weight ratios and excellent resistance to corrosion and fatigue. As industries such as aerospace, automotive, and construction continue to grow, the demand for CNC machined parts made from composites, particularly through turning processes, has risen significantly. However, turning composite materials presents unique […]

Conquering High-Strength and Ultra-High-Strength Steel in CNC Machining Precision and Techniques Revealed

High-strength and ultra-high-strength steels (HSS and UHSS) are engineering marvels, known for their exceptional combination of strength and toughness. These steels are crucial in industries such as aerospace, automotive, and heavy machinery, where durability and reliability are paramount. However, their impressive properties also make them some of the most challenging materials to machine. For buyers […]

Cracking the Code to Stainless Steel in CNC Machining A Complete Guide to Tools and Techniques

Stainless steel is a go-to material in industries ranging from aerospace to medical devices, thanks to its corrosion resistance, strength, and aesthetic appeal. However, these same properties can make it a challenge to machine, especially when precision and efficiency are paramount. For buyers sourcing CNC machined parts made from stainless steel, understanding the complexities of […]

Mastering Quenched Steel in CNC Machining Tips on Tool Selection and Optimization

In the demanding world of CNC machining, mastering the art of cutting quenched steel is crucial for both suppliers and buyers. Quenched steel, known for its high hardness and strength, poses significant challenges during machining. However, with the right tools, techniques, and strategies, these challenges can be effectively managed, leading to high-quality parts that meet […]

Tough Opponents in the CNC World The Clash of Flanges and Difficult to Cut Materials

In the world of CNC machining, the battle between machine tools and difficult-to-cut materials is nothing short of a high-stakes chess match. For buyers seeking top-quality flanges, understanding this clash is crucial to making informed purchasing decisions, especially when the materials involved demand precision and durability. Understanding Difficult-to-Cut Materials When we talk about difficult-to-cut materials, […]

Understanding Material Machinability in CNC Machining: What Every Engineer Should Know

Introduction When it comes to CNC machining, the material you choose can make or break your project. Whether you’re working on a high-precision component or a bulk order of simple parts, understanding material machinability is key to ensuring the efficiency, quality, and cost-effectiveness of your production process. For purchasing managers, engineers, and anyone involved in […]

CNC Machined Parts Unveiled: Mastering Ceramic Drilling with Precision Tools

When it comes to CNC machining, drilling ceramic materials presents a unique set of challenges. Ceramics are hard, brittle, and require specialized techniques to achieve precision without compromising the material’s integrity. For those involved in the procurement of custom flanges or other precision-engineered parts, understanding the intricacies of CNC drilling in ceramics is crucial. This […]

CNC Machined Parts Precision Ceramic Milling with Diamond-Coated Tools

Introduction When it comes to precision in manufacturing, particularly in industries where durability and heat resistance are paramount, ceramic materials often take center stage. Whether it’s aerospace, medical devices, or specialized machinery, the demand for high-quality ceramic components is growing. However, machining ceramics is not without its challenges. This is where CNC machined parts, paired […]

CNC Machined Parts Mastering Advanced Ceramic Machining Techniques

In the realm of CNC machining, ceramics represent a significant challenge and opportunity. Their extraordinary properties, such as high hardness, wear resistance, and thermal stability, make them ideal for high-performance components like flanges, insulators, and various industrial parts. However, these same properties also make ceramics notoriously difficult to machine. For those in the business of […]

From Tools to Coatings Efficient Milling Strategies for Composite CNC Machined Parts

Composite materials like Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) have revolutionized industries such as aerospace, automotive, and marine. Their unique combination of strength, light weight, and resistance to corrosion makes them ideal for high-performance applications. However, machining these materials, especially through CNC milling, presents significant challenges. This article delves into […]

Deep Dive into CFRP Cutting Secrets in CNC Machining

In the world of CNC machining, Carbon Fiber Reinforced Polymer (CFRP) stands out as a revolutionary material that has transformed industries ranging from aerospace to automotive. Known for its exceptional strength-to-weight ratio, corrosion resistance, and durability, CFRP is increasingly being used in the production of high-performance parts, including flanges, motor shafts, and custom nozzles. However, […]