Revealing How High-Speed Machining Optimizes Surface Residual Stress in CNC Machined Parts and Flanges

The Secrets of Efficient Cutting for Hard-to-Cut Materials in CNC Machining When it comes to procuring custom flanges and CNC machined parts, one critical aspect often overlooked is the residual stress left behind after machining. Residual stress can significantly impact the performance and longevity of these components, especially when they are exposed to high-pressure or […]

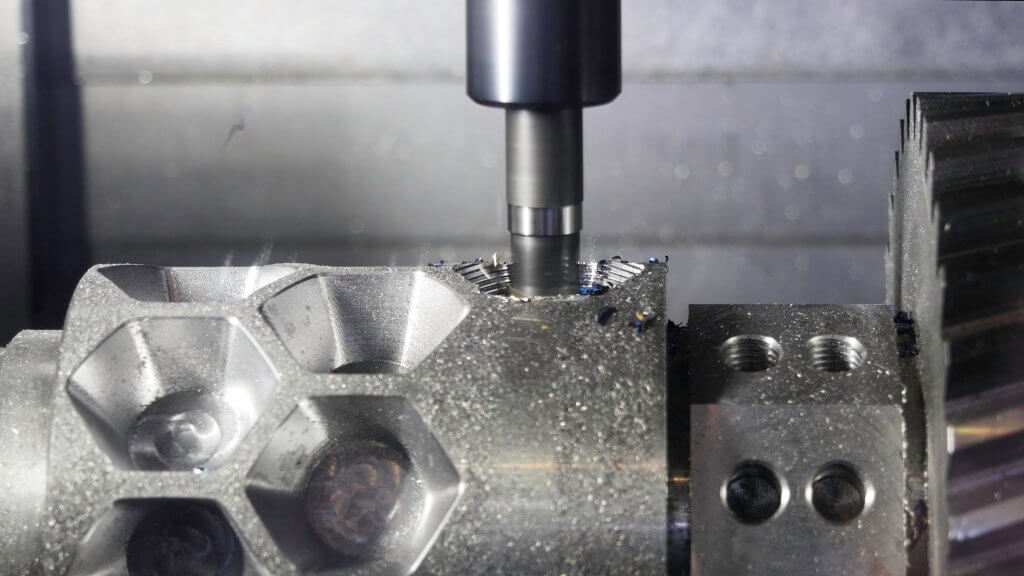

Enhancing Surface Quality in CNC Machined Parts and Flanges Through High-Speed Machining

In the world of CNC machining, achieving high surface quality in machined parts and flanges is crucial. Especially when dealing with complex geometries and hard-to-cut materials, the challenge becomes even more significant. This article will delve into how high-speed machining (HSM) plays a pivotal role in enhancing the surface quality of CNC machined parts, with […]

The Secrets of Efficient Cutting for Hard-to-Cut Materials in CNC Machining

Introduction: The Unique Challenges of Hard-to-Cut Materials In the fast-paced world of manufacturing, precision is key, and the ability to work with a wide range of materials is essential. However, not all materials are easy to machine, and some can be downright difficult. These hard-to-cut materials are often the backbone of industries requiring high-performance components—think […]

Investigating PMCRLF in CNC Machining: From Surface Roughness to Subsurface Damage

Introduction to PMCRLF and Its Relevance in CNC Machining In the rapidly evolving world of manufacturing, materials that combine high strength with lightweight properties are in constant demand. One such material is the long fiber-reinforced polymer matrix composite (PMCRLF). PMCRLF stands out due to its excellent strength-to-weight ratio, high specific stiffness, and remarkable mechanical properties. […]

High-Speed CNC Machining Parts: The Secret Sauce of Tool Material Selection

To high-speed CNC machining, the selection of tool materials is crucial. Imagine you’re a chef preparing a gourmet meal; the ingredients you choose will significantly impact the final dish. Similarly, the materials used for cutting tools in CNC machining determine the quality, efficiency, and precision of the finished parts. Let’s dive into the world of […]

Heat Treatment Insights for Wrought Aluminum Alloys in CNC Machining Parts

In the field of CNC machining, achieving the desired mechanical and physical properties often hinges on effective heat treatment. For wrought aluminum alloys, which are extensively used due to their excellent strength-to-weight ratio and corrosion resistance, heat treatment processes are critical. These processes enhance their workability, mechanical strength, and durability. Let’s explore the various heat […]

Revealing the Annealing Process of Copper and Alloys in CNC Machining Parts

In the realm of CNC machined parts, achieving the perfect balance of strength, flexibility, and durability often requires meticulous heat treatment processes. One such crucial process is annealing, especially for copper and its various alloys. Annealing not only relieves internal stresses but also enhances the metal’s workability and overall performance. Let’s delve into the fascinating […]

High-Speed Cutting in CNC Machining Parts: The Power of TiC(N)-Based Hard Alloys

To CNC machining, the choice of tool material is crucial, especially for high-speed cutting. TiC(N)-based hard alloys have emerged as a game-changer, offering a unique blend of properties that sit somewhere between traditional hard alloys and ceramics. These materials are transforming the way we approach high-speed machining, making processes faster, more efficient, and ultimately more […]

Exploring the Wonders of Cutting Fluids in CNC Machining Parts

Cutting fluids play a crucial role in the world of CNC machining, and their significance cannot be overstated. Whether it’s reducing friction and wear, cooling down the cutting zone, or ensuring the longevity of both the tools and the workpiece, cutting fluids are the unsung heroes of the machining process. Let’s delve into the fascinating […]

G32 Programming and Manual Threading in CNC Machining

When it comes to CNC machining, threading is one of those tasks where precision is paramount. Most of the time, the G76 threading cycle is the go-to for machinists, handling about 95% of all threading jobs effortlessly. But what about that remaining 5%? What if the G76 cycle isn’t available or suitable for the task […]

Unlocking the Secrets of Thread Insertion in CNC Machining Parts

When it comes to CNC machining, thread insertion methods are crucial for ensuring high-quality results. Different approaches to thread insertion can significantly impact the efficiency, durability, and precision of the final product. Let’s dive into the fascinating world of thread insertion in CNC machining parts and explore the various methods and their unique advantages. The […]

Mastering Aluminum Frame CNC Machining Parts: Overcoming Deformation from Residual Stress

Aluminum frames are essential components in aerospace, replacing traditional assembly structures with large integral structures. These frames, such as the X3280 frame for helicopters, have significantly improved the manufacturing cycle, quality, and mechanical performance of products. However, they also bring challenges, especially when it comes to machining deformation. This deformation is largely influenced by residual […]