Mastering Aluminum Frame CNC Machining Parts: Overcoming Deformation from Residual Stress

Aluminum frames are essential components in aerospace, replacing traditional assembly structures with large integral structures. These frames, such as the X3280 frame for helicopters, have significantly improved the manufacturing cycle, quality, and mechanical performance of products. However, they also bring challenges, especially when it comes to machining deformation. This deformation is largely influenced by residual […]

Revolutionizing High-Speed Cutting in CNC Machining Parts with Ceramic Tools

Ceramic tools have brought a significant transformation in the realm of high-speed cutting for CNC machining parts. These tools are celebrated for their superior hardness, exceptional wear resistance, and impressive performance at high temperatures. They’ve effectively replaced traditional tools in many areas, enabling machinists to cut harder materials and achieve faster cutting speeds. This article […]

Advanced Thread Turning Techniques: G76 Cycles in CNC Machining Parts

In the early days of CNC development, the G92 simple thread cutting cycle was a breakthrough in computer technology, providing an efficient method for thread turning. However, as technology advanced, CNC programmers were offered more powerful tools, simplifying program development significantly. One of the key advancements in this area is the G76 compound fixed cycle, […]

The Essential Guide to Feed Rate and Spindle Speed in CNC Thread Turning

When it comes to CNC machining, understanding the intricacies of feed rate and spindle speed is essential, especially for thread turning. These two parameters play a pivotal role in determining the quality and precision of the threads you produce. Let’s dive into how to optimize feed rate and spindle speed to achieve the best results […]

Mastering Single-Head Thread Turning in CNC Machining Parts

Thread turning is an essential process in machining, particularly in the realm of CNC (Computer Numerical Control) operations. It involves creating helical grooves on cylindrical or conical surfaces, essential for connecting parts without damage during assembly and disassembly. Threads are vital in various applications, such as fastening devices like screws and bolts, measuring tools like […]

Precise Grooving Methods to Enhance Quality of CNC Machining Parts

Grooving on CNC lathes is a multi-step operation crucial for creating specific, high-quality parts. Grooving usually involves cutting narrow slots of a particular depth on cylindrical, conical, or end faces of parts. The shape of the groove (at least the important part of it) depends on the shape of the cutting tool. Grooving tools are used for […]

Mastering CNC Machining Parts Cut-Off Operations

Cut-off operations on a CNC lathe are common and essential for many manufacturing processes. This task typically involves separating a completed part from a bar of material using a cut-off tool. The cut-off process requires careful planning and precision to ensure the quality of the final product and prevent damage. Here, we will explore the […]

Elevating Surface Finish of CNC Machining Parts with High-Speed Techniques

High-speed cutting techniques have revolutionized CNC machining, offering not only increased production efficiency but also superior surface finishes on machined parts. The appeal of high-speed machining lies in its ability to produce high-quality surfaces, which are essential for the performance and longevity of the parts. In this article, we’ll explore the factors influencing the surface […]

Superior Performance of CBN Tools in High-Speed CNC Machining Parts

In the realm of high-speed CNC machining, the choice of cutting tool material is paramount. Over the last three decades, the development of advanced cutting tool materials has seen significant strides, with cubic boron nitride (CBN) emerging as a standout performer. This synthetic material, with its remarkable hardness and thermal stability, has revolutionized the machining […]

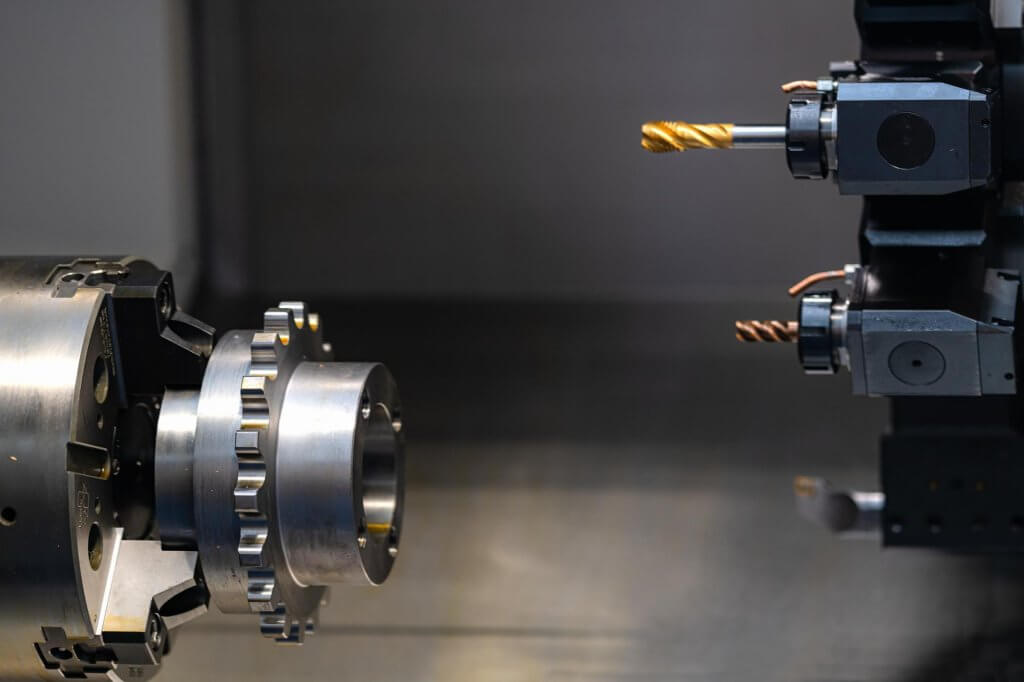

Enhancing Efficiency in CNC Machining Parts Production with Cutting-Edge Machining Centers

Machining centers are game-changers in the world of CNC machining. Imagine a workshop where a single machine can perform multiple operations—turning, milling, drilling, and more—without moving the workpiece from one machine to another. This is not just a dream but a reality with modern machining centers. These advanced machines integrate high-speed computer technology with flexible […]

Mastering Automatic Corner Transitions in Precision Machining

In CNC turning and boring operations in the world of precision machining, transitioning from shoulders to outer diameters (or vice versa) often requires corner transitions. Many engineering drawings will specify these transitions, but they don’t always provide exact dimensions. This is where the programmer steps in, typically choosing values between 0.005 to 0.020 inches (0.125 […]

Precision Machining with Tool Offsets for CNC Lathe Parts

When it comes to CNC machining, precision is key. Achieving high precision in CNC lathe parts requires a deep understanding of tool offsets and their functions. Let’s dive into the essentials of tool offsets for CNC precision machining parts, exploring how they work and how to use them effectively. Tool Offsets: The Basics Tool offsets […]