Enhancing Durability with Copper and Nickel Plating on CNC Machining Parts

Electroplating is like giving metal parts a shiny, protective armor. Imagine turning a dull, rusty piece of metal into a gleaming, robust part ready to withstand the test of time. This transformation is crucial in various industries, especially in CNC machining, where precision and durability are paramount,it need to be strengthened by surface finishes technology. […]

Mastering Chemical Coloring for CNC Machining Copper Parts

In the world of metal surface finishes, chemical coloring has gained significant traction, especially for aluminum and copper. This technique not only enhances the aesthetic appeal of the parts but also adds a layer of protection against corrosion and wear. Let’s dive into the fascinating process of chemical coloring for CNC machining copper parts. online […]

The Essential Guide to Countersinking, Counterboring, and Spotfacing in CNC Machining Parts

In every machine shop, Often, after CNC drilling is complete, it is necessary to enlarging holes.There are three common methods for enlarging holes from the top: countersinking, counterboring, and spotfacing. These techniques are crucial for ensuring that mating parts fit precisely, particularly when bolt heads need to sit flush against a flat surface. Each method […]

High-Speed Spiral Milling Techniques for CNC Machining Parts

In the world of mold and aerospace machining, two-dimensional cavity machining stands out as one of the most material-intensive and time-consuming processes. For example, the machining of integral wall panels in aerospace involves removing up to 90% of the material. These panels often have numerous triangular and rectangular cavities, making the task even more demanding. […]

From Rust to Shine: Chemical Conversion Films in CNC Machining Parts

Many metals naturally form a protective oxide film on their surfaces, a process known as passivation. Chemical conversion films take advantage of this by creating a stable compound layer on the metal surface through chemical or electrochemical means, effectively passivating the metal. These films can protect the metal from corrosion, improve the adhesion and durability […]

High-Speed Cutting Legends Transforming CNC Machining Parts

High-speed cutting (HSM or HSC) is not just a technological advancement; it’s a fascinating journey of innovation that has transformed CNC machining parts over the decades. Let’s take a trip down memory lane and explore the evolution of high-speed cutting, from its humble beginnings to its modern-day applications. online cnc machining services The Early Days […]

Mastering CNC Machining Parts With G76 and G87 Boring Tricks

Boring holes with precision and quality in CNC machining can be a bit tricky, but with the right techniques, it becomes much more manageable. Two critical fixed cycles in this process are the G76 and G87 cycles, both of which require the tool to offset from the current hole’s centerline. Let’s dive into how these […]

Detailed Analysis of Single-Point Boring Techniques in CNC Machining Parts

What is CNC Machining Boring CNC boring is an advanced machining process that uses computer numerical control (CNC) technology to enlarge or refine pre-existing holes in a workpiece with precision and efficiency. Unlike conventional boring, CNC boring utilizes programmed commands to control the movements of the cutting tool, ensuring accuracy, repeatability, and consistency, which are […]

Simulation Analysis of Deformation in Aluminum Alloy Frame Parts during CNC Machining

Introduction Aluminum alloy frame parts are like the unsung heroes of the aerospace industry. These components, found in aircraft frames, beams, and bulkheads, are critical for ensuring structural integrity and performance. However, machining these large, complex parts can be a nightmare due to deformation issues. Imagine working on a piece that starts out weighing 550 […]

Techniques and Optimization of Reaming Operations in CNC Machining Parts

Introduction Reaming might not be the most glamorous topic in the world of CNC machining, but it’s an essential process that can make or break the quality of your parts. Imagine you’re building a high-precision engine, and every tiny hole must be perfect. That’s where reaming steps in, taking an already drilled hole and making […]

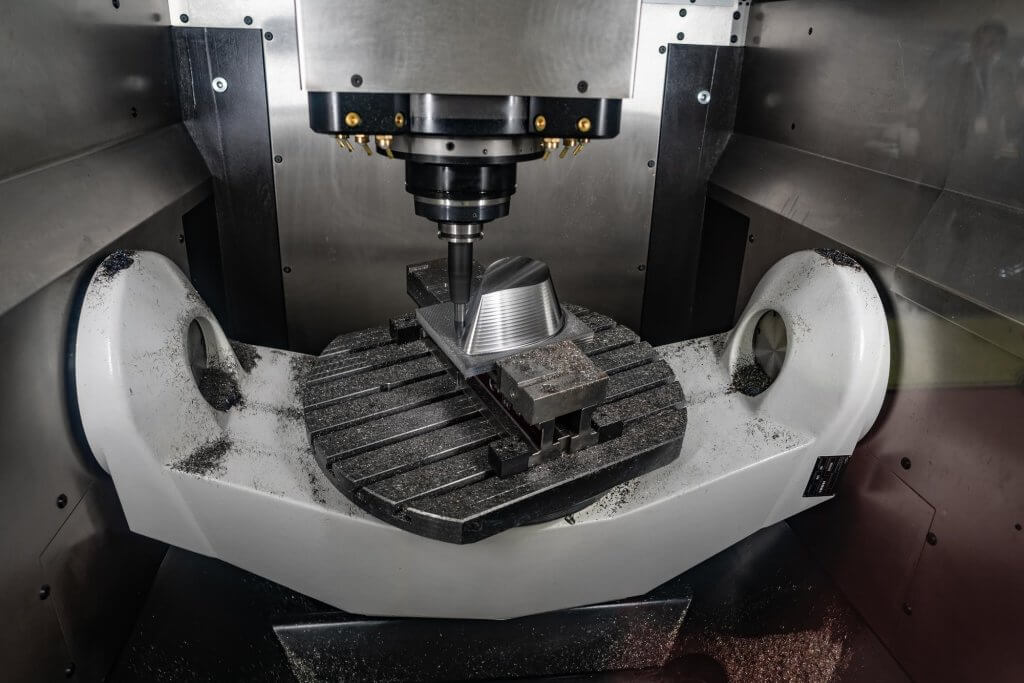

Detailed Analysis of Five-Axis Flank Milling and Ruled Surface Technology in CNC Machining Parts

Introduction In the realm of CNC (Computer Numerical Control) machining, the need for precision and efficiency is paramount. One of the advanced techniques employed to achieve these goals is five-axis flank milling, particularly useful when dealing with complex surfaces. This method has revolutionized the production of intricate parts, including those used in the aerospace and […]

Analyzing Residual Stress in Aluminum Alloy CNC Machining Parts

Residual stress is a crucial factor affecting the performance and durability of aluminum alloy components in aerospace applications. These parts are often large, thin-walled, and complex in structure, making them particularly susceptible to the adverse effects of residual stress. Understanding and controlling this stress is essential for ensuring the structural integrity and reliability of these […]