Brass Punch Machining Guide: Materials, Techniques, and Best Practices

I’m excited to share my comprehensive guide on brass punch machining. I’ve spent years working with different CNC setups, trying various alloys, and optimizing cutting parameters. In this guide, I’ll walk you through everything I’ve learned about making a high-quality brass punch. By the end, I hope you’ll feel confident about machining a brass punch, […]

Automotive Fasteners Manufacturing Guide: Precision, Strength & Industry Standards

I’ve spent a good part of my career exploring how Automotive Fasteners shape a vehicle’s overall safety and performance. I’ve personally toured manufacturing facilities, spoken with CNC operators, and tested different types of fasteners in the field. In this guide, I want to combine that first-hand experience with industry research so you can understand exactly […]

No Hub Coupling Manufacturing Guide: From Material Selection to Precision Machining

I’ve spent years exploring different aspects of plumbing and mechanical production, and I’ve come to realize how critical No Hub Coupling manufacturing can be for anyone looking to optimize performance in drainage, sewer, or industrial piping systems. In this guide, I’ll walk you through everything I’ve learned about No Hub Coupling, from its basic definition […]

Custom Brass Fasteners: How CNC Machining Enhances Strength, Precision, and Durability

Hello, and welcome to this comprehensive guide on Brass Fasteners and the pivotal role that CNC machining plays in crafting custom solutions. I’ve spent years working alongside design engineers, procurement managers, and machinists who rely on brass fasteners for everything from high-end electronics to large industrial assemblies. My goal here is to share insights about how custom brass fasteners […]

The Growing Demand for Custom Fasteners: How to Manufacture and Source Specialized Components

Hello, and welcome to my comprehensive guide on fasteners. I’ve spent a significant part of my career working with manufacturers, design engineers, and machining experts who rely on fasteners in countless industries. I realized that many of them struggle with questions like: Which fasteners are best for my application? How do I manufacture custom fasteners? Why […]

Online Metals And Custom CNC Machining: A Step-by-Step Guide to High-Precision Metal Parts

Hello, and welcome to this comprehensive guide on online metals and custom CNC machining. I’ve spent years navigating online metal suppliers and collaborating with CNC machining services to produce precise, high-quality parts. I know the challenges that come with finding the right materials, balancing costs, and choosing a dependable CNC partner. My goal here is […]

Titanium Bolts: The Ultimate Guide to High-Strength, Lightweight Fasteners

Introduction: Why Titanium Bolts and CNC Machining Matter? Welcome, and thanks for reading my in-depth guide on titanium bolts. I’ve been working around metals and machining for a good part of my career, and I’ve always found myself amazed by how crucial fasteners can be. A single bolt can make or break a product’s integrity, […]

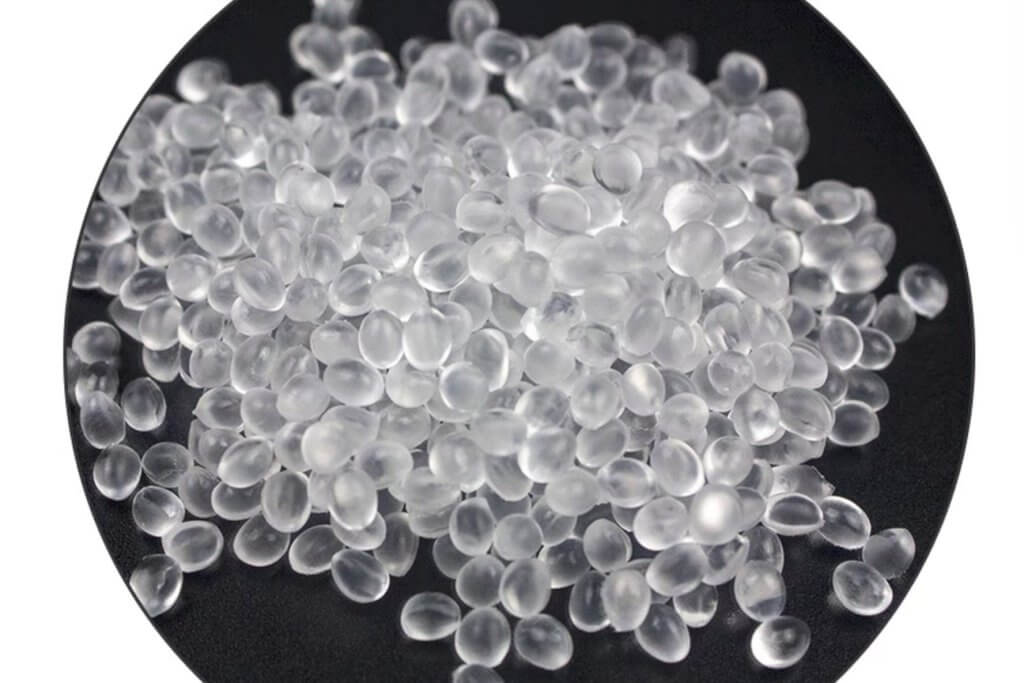

TPE Material: The Ultimate Guide to Flexible, Durable And Recyclable Elastomers

Introduction: What Is TPE Material? I remember the first time I came across TPE material. Someone handed me a flexible grip cover for a tool handle, and I noticed how rubbery it felt in my hands, yet it was still clearly a plastic-based product. I asked around and discovered that TPE material – which stands […]

Carbon Fiber 3D Printer: The Ultimate Guide to High-Strength, Lightweight Printing

Introduction: What Is Carbon Fiber 3D Printing? Hello there, and welcome to my ultimate guide on carbon fiber 3D printer technology. I’ve spent a good chunk of my career around additive manufacturing, and I’ve seen how the push for high-strength, lightweight materials has been an ongoing challenge for engineers, product designers, and everyday tinkerers. Today, […]

Understanding Wheel Hub Bearing And How CNC Machining Ensures Precision

Chapter 1: Why Understanding Wheel Hub Bearings and CNC Machining Matters A wheel hub bearing is a critical component in virtually every vehicle on the road.When I first learned about wheel hub bearing design, I was amazed at how much engineering goes into ensuring a smooth ride.You might think a wheel hub bearing is just […]

How to Powder Coat: A Professional Machinist’s Guide to Perfect Results

Chapter 1: Why Machinists Need to Learn Powder Coating Powder coating is a robust, eco-friendly finishing method that I’ve seen more and more machinists adopt.When people look up “how to powder coat,” they usually want to know the basic steps, equipment, and best practices.I’ve noticed it’s especially popular among those perfecting surface finishes, since powder […]

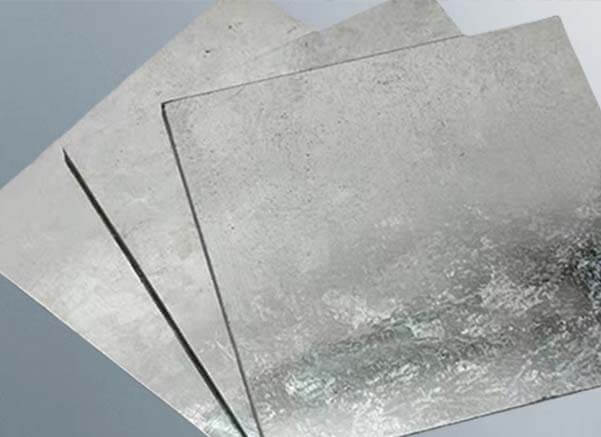

Mastering Machining of Galvanized Steel: Techniques, Challenges & Solutions

Chapter 1: Introduction – Understanding Galvanized Steel and Machining Galvanized steel is everywhere around us. From the cars we drive to the buildings we live in, galvanized steel is a trusted material. It offers excellent corrosion resistance, durability, and strength. I’ve personally dealt with galvanized steel for years in various machining applications. Initially, I thought […]