Mastering Aluminum Bronze CNC Machining: Properties, Challenges, and Best Practice

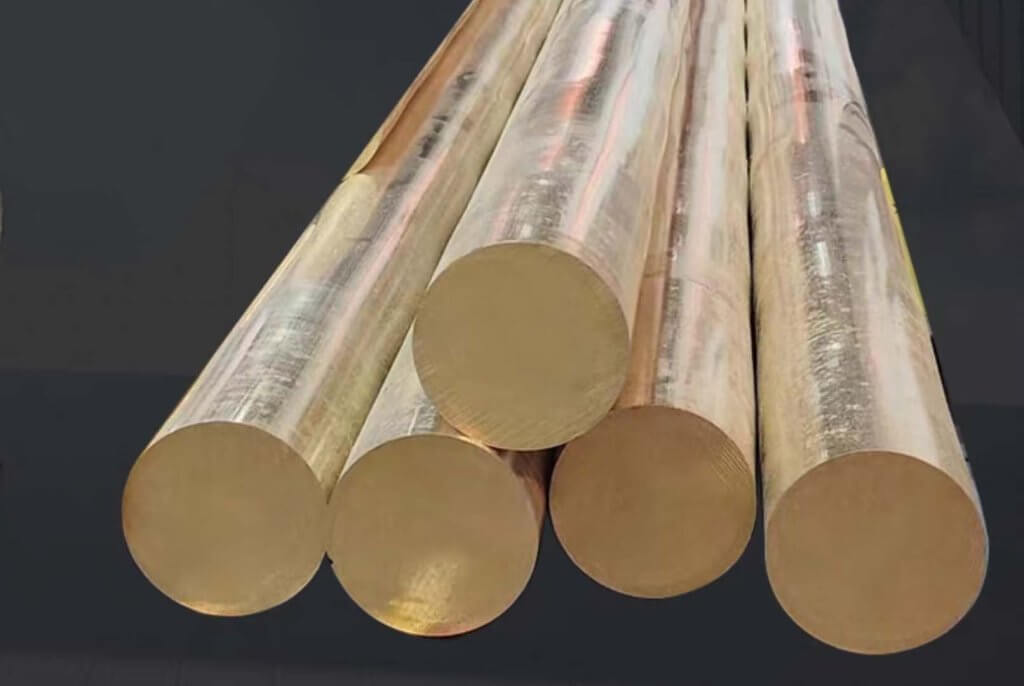

Chapter 1: Understanding Aluminum Bronze I remember the first time I came across aluminum bronze in a machine shop. I was helping a colleague set up a CNC lathe, and he handed me a cylindrical bar with a rich golden color. I asked him what it was, and he said, “That’s aluminum bronze—one of the toughest yet […]

Elevate Your Space with Champagne Bronze Cabinet Pulls – Powered by CNC Technology

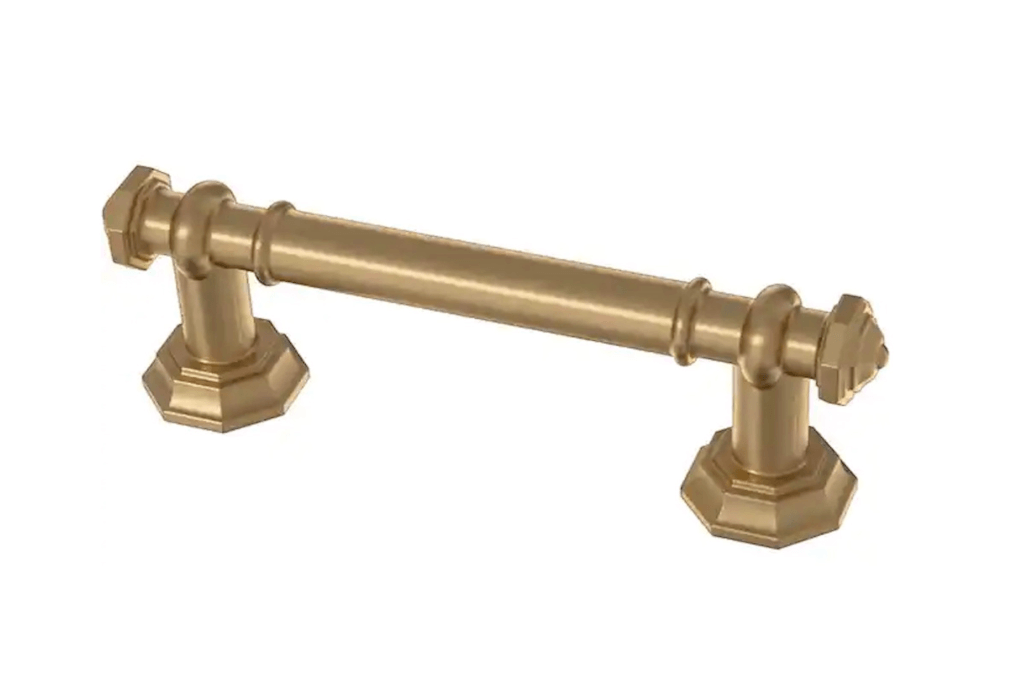

Introduction I’ve always been fascinated by the small details that can transform a space from ordinary to extraordinary. One such detail is the cabinet pull, an overlooked piece of hardware that actually plays a significant role in defining a room’s overall look and feel. In my journey as both a homeowner and a DIY enthusiast, […]

What Is Bronze Made Of? A Deep Dive into Its Chemical Secrets and Uses

Introduction Several years ago, when I first started working in manufacturing, I frequently came across bronze parts. To be honest, initially, I didn’t pay much attention to what bronze was actually made of. But as our projects became more precise and demanding, I had to dive deeper into understanding materials, especially alloys like bronze. In […]

Elevate Your Production Journey: Unlock the Power of CNC Fabrication for High-Precision Results

Introduction Several years ago, when I was managing a small manufacturing shop, I first encountered the term “CNC fabrication.” At that time, like many people, I was mainly relying on traditional, manual machining techniques. The processes were slow, prone to human error, and limited in precision. I vividly remember the day I visited my friend’s workshop that […]

C-276 Alloy CNC Machining: Challenges, Solutions, and Best Practices

Introduction to C-276 Alloy 1.1 Why C-276 Alloy? When I first encountered c-276 alloy, I was looking for a material that could withstand harsh chemicals in a high-temperature environment. My team was designing a reactor component that had to handle strong acids at elevated pressures, and standard stainless steels kept failing. We turned to c-276 alloy because it’s […]

Steering Gear Box CNC Production: Cost, Process, and Quality Guide

Part 1: Introduction If you’re like me and work with automotive, heavy machinery, or any industry that involves precision mechanical systems, you’ve probably encountered the term steering gear box many times. A steering gear box is central to how a vehicle or machine translates steering input into an actual directional change. Over the years, I’ve seen how crucial it […]

Jigs and CNC: Enhancing Precision in Modern Manufacturing

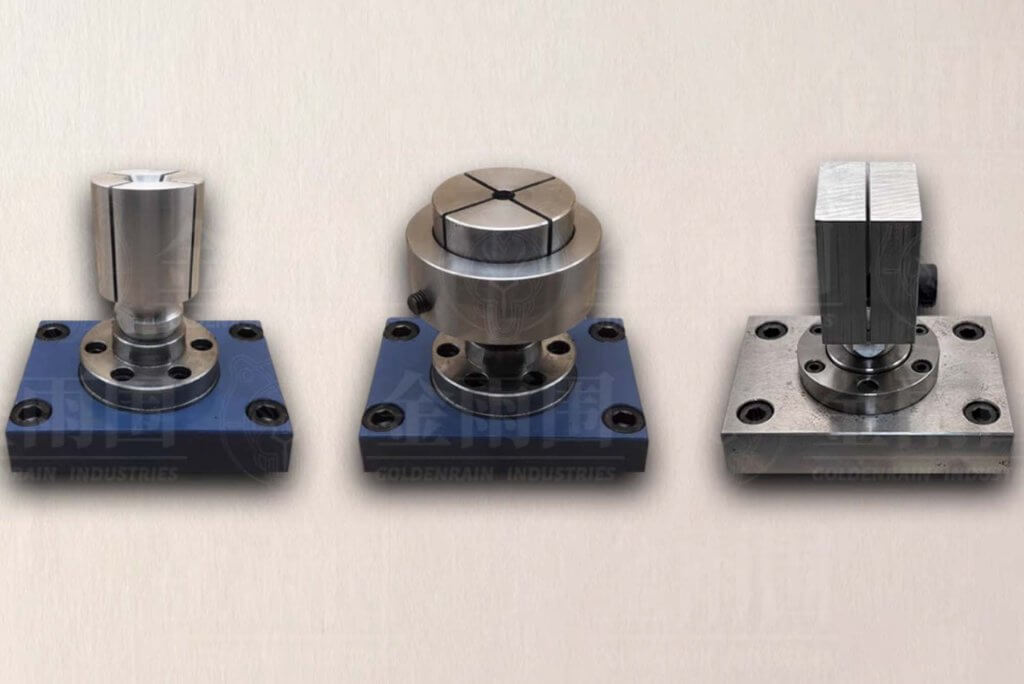

Introduction Jigs are the unsung heroes of CNC machining, making sure every cut lands exactly where it should. In manufacturing, jigs team up with CNC—Computer Numerical Control—to crank out parts with pinpoint accuracy. We’re talking about tools that hold your workpiece steady while a CNC machine mills, drills, or turns it into something useful. Whether […]

Galvanized Square Steel and CNC Machining: The Ultimate Guide

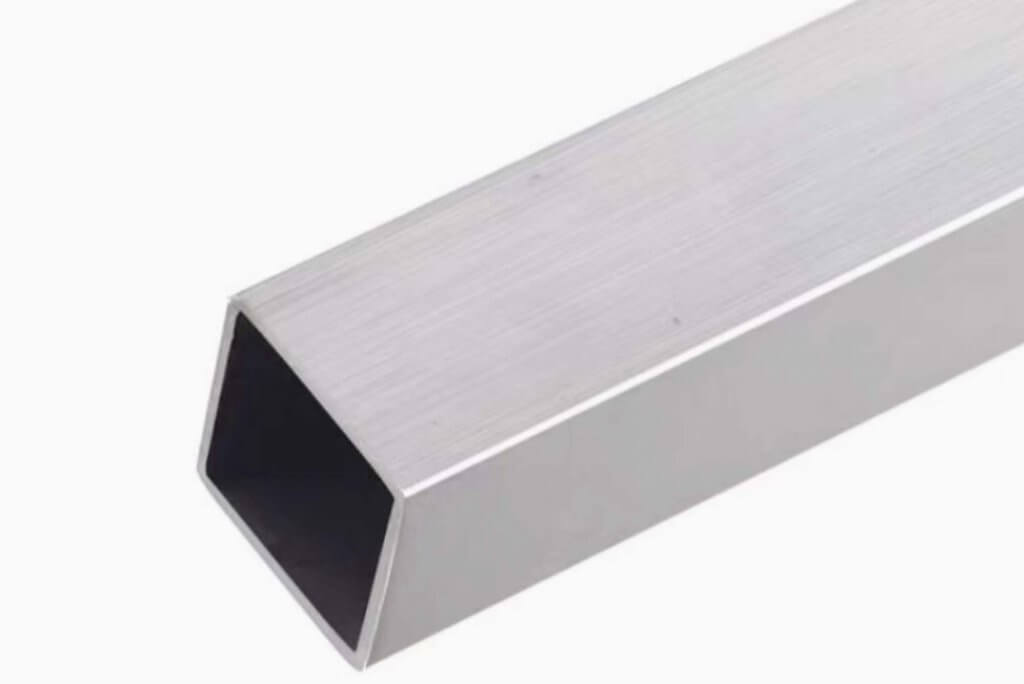

Introduction If you’re involved in construction, metal fabrication, or precision machining like me, you’ve probably encountered galvanized square steel. Galvanized square steel is popular due to its strength, corrosion resistance, and versatility. From structural frames and fencing to decorative architectural features, it offers reliable performance across various applications. Many industries rely on custom machining to produce precise components […]

VG10 Steel and CNC Machining: The Ultimate Guide

Introduction If you’re in manufacturing, custom knife making, or precision machining like I am, you’ve probably heard about VG10 steel quite often. VG10 steel is well-known in the knife-making world for its impressive edge retention, toughness, and resistance to corrosion. I’ve personally seen how custom machining can significantly improve the functionality and aesthetics of VG10 steel products. In this […]

Pinion Gear and CNC Machining: A Comprehensive Guide

Introduction If you’re involved in manufacturing or mechanical design like me, you’ve likely come across the term pinion gear frequently. A pinion gear is simply the smaller gear that meshes directly with a larger gear, playing a crucial role in transmitting motion and torque in various mechanical systems. I’ve worked extensively with Custom Machining, and it’s […]

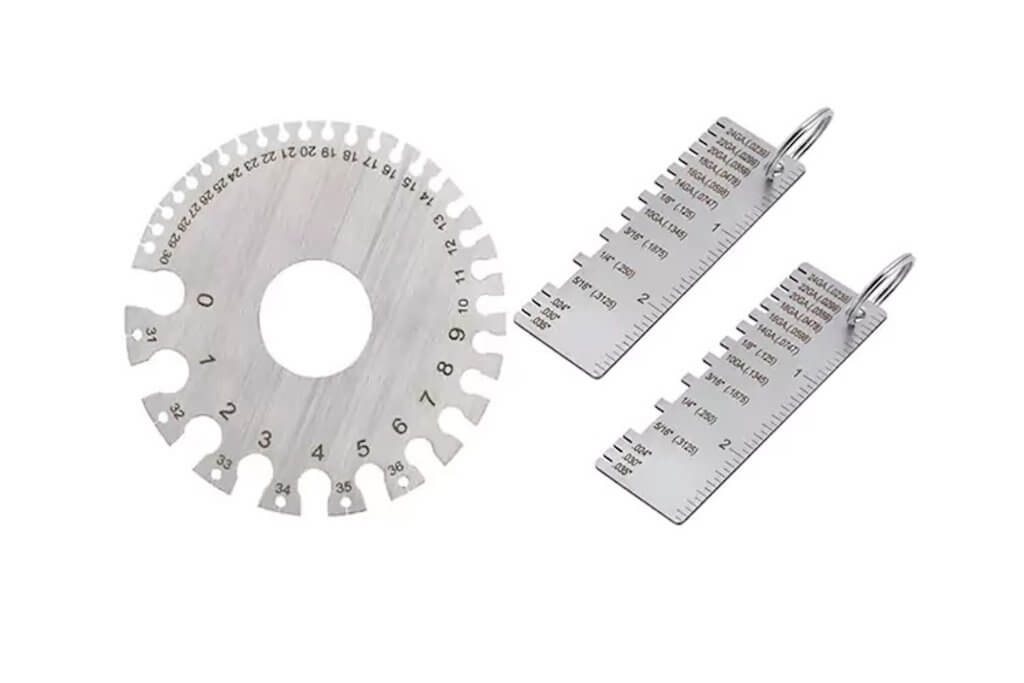

Mastering Sheet Metal Gauge: Your Guide to Thickness and Applications

Introduction Sheet metal gauge is a term that pops up a lot in manufacturing, and it’s all about how thick your metal is. Smaller numbers mean thicker sheets—simple, right? But there’s more to it than that. Sheet metal gauge matters because it decides if your part holds up, bends too easy, or costs a fortune. […]

AR500 Steel Meets CNC: Your Questions Answered

Introduction: Got Questions About AR500 Steel and CNC? We’ve Got Answers Got a question about machining AR500 steel with CNC? You’re in the right place. AR500 steel is tough stuff—hard, durable, and perfect for things like shooting targets or heavy machinery parts. Pair it with CNC machining, and you’ve got a combo that’s all about […]