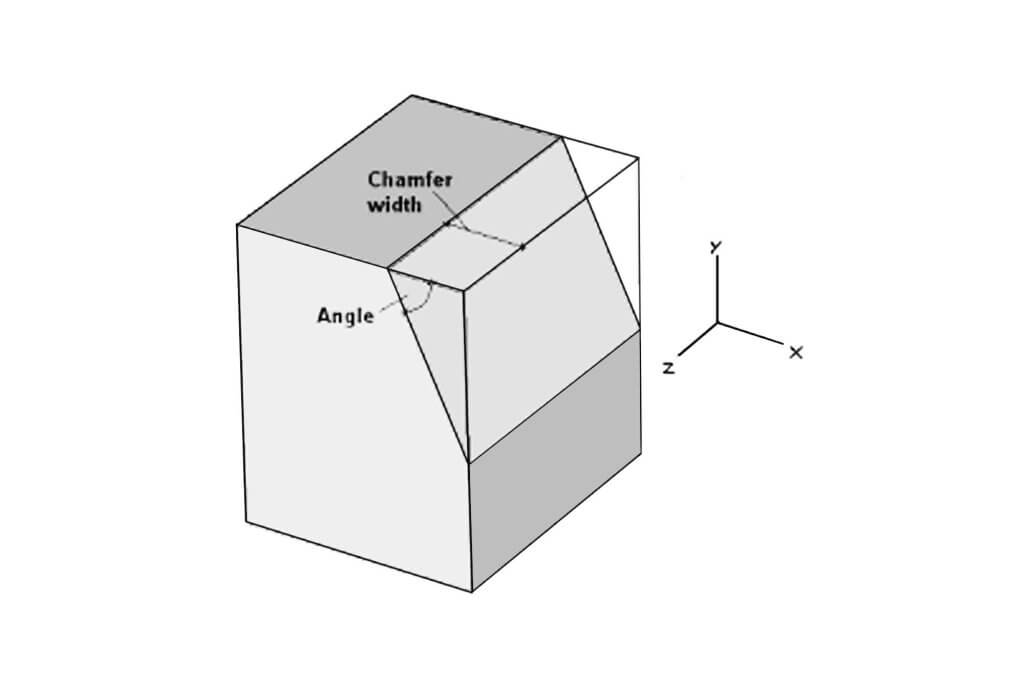

Chamfer in CNC Machining: A Complete Guide to Precision Edge Processing

Chapter 1: Introduction Chamfering is one of the most essential finishing operations in precision manufacturing. Over my many years working in CNC machining, I’ve discovered that a well-executed chamfer does more than just smooth out a sharp edge—it can dramatically enhance a part’s performance, assembly ease, and even safety. Custom Machining techniques allow us to tailor […]

Hex Bolt Manufacturing with CNC: From Standard to Custom Solutions

What is a Hex Bolt? Why is CNC Machining Important for Hex Bolts? Machining has always been an area I’ve enjoyed working in, particularly when it comes to CNC (Computer Numerical Control) machining. Over the years, I’ve had the opportunity to work with various fastening components, but one that keeps coming up time and time […]

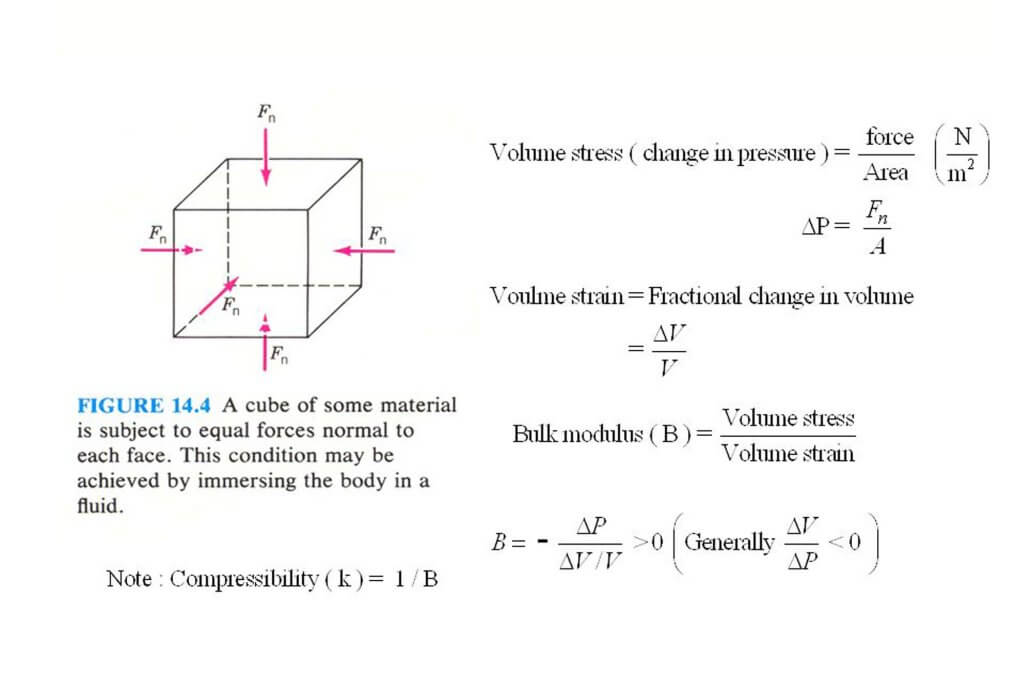

Bulk Modulus in Machining: How It Affects Material Selection and Cutting Performance

Part 1: Introduction – Why Bulk Modulus Matters in Machining Machining has always fascinated me. Over the years, as I’ve worked on various projects—from small CNC setups in my garage to larger production runs in industrial settings—I’ve noticed that one term keeps cropping up: Bulk Modulus. I’ve found that even in custom machining applications, this property […]

Knurling Techniques in CNC Machining: A Complete Guide for Engineers and Designers

Introduction to Knurling and CNC Machining Knurling is one of the most critical yet often overlooked processes in CNC machining, and I’ve come to appreciate its importance after years of hands-on experience. When I first encountered knurling in the field, I was immediately struck by how essential it is for improving both the functionality and aesthetics of […]

Mastering Machining for Carriage Bolts: A Guide to Custom Manufacturing

Introduction to Carriage Bolts and Custom Manufacturing Carriage bolts are widely used in various industries, providing a reliable and efficient solution for fastening wood, metal, and other materials. From construction projects to furniture assembly, these bolts are a go-to for many professionals. I first encountered carriage bolts in a personal DIY project, and what stood […]

Lattice Structure Customization: From Prototyping to Mass Production

Introduction The use of lattice structures is revolutionizing the way industries approach design, performance, and efficiency. From lightweight aerospace components to high-performance medical implants, lattice structures offer engineers the opportunity to create highly optimized parts that would otherwise be impossible with traditional materials. These structures, with their intricate, interconnected patterns, allow for significant reductions in material usage without compromising the strength or […]

Molly Bolt Customization: Best Machining Tips for Engineers

Introduction As engineers, we’re all familiar with the importance of using the right fastener in our projects. Whether it’s securing equipment to drywall or installing shelving in a residential space, the Molly bolt is a versatile solution that engineers have trusted for years. However, like any other fastening solution, there are situations where the standard Molly bolt just doesn’t […]

Main Bearing Performance Boost: How to Achieve It with CNC Machining

Chapter 1:Introduction I remember the first time I heard someone ask, “Isn’t a main bearing just a regular bearing?”My immediate thought was that a main bearing is more specialized than people assume.A main bearing supports a primary shaft in heavy machinery or engines, so it endures massive loads and high speeds. I’ve seen how critical […]

Flange Bearing Manufacturing & Buying Guide: CNC Machining vs. Ready-to-Use Bearings

Introduction: What Are Flange Bearings and Why Are They Important? I can still remember the first time I came across the term “flange bearing.”It was early in my career, back when I was trying to understand the basics of mechanical assemblies in industrial equipment.The word “bearing” itself was already familiar—bearings let shafts rotate with minimal friction […]

Electroplating in CNC Machining: Process, Benefits, and Best Practices

Part 1: What Is Electroplating in CNC Machining? Electroplating is a surface-finishing process that deposits a thin layer of metal onto a workpiece using an electric current. It’s used in many industries to enhance appearance, increase corrosion resistance, and provide wear protection. CNC machining shapes and creates the core geometry of a part, while electroplating […]

Galling in CNC Machining: Causes, Prevention, and Best Practices

Part 1: Introduction to Galling in CNC Machining Galling is a type of severe wear that occurs when metal surfaces rub together under high pressure and friction. It often shows up in CNC machining environments, especially when certain materials and process parameters align to create excessive heat or friction. In custom machining scenarios, galling can unexpectedly […]

Choosing the Right Concrete Anchor Bolts: A Guide for Engineers and Machinists

Why Concrete Anchor Bolts Matter When I first encountered concrete anchor bolts in my career as an engineer, I didn’t fully realize how critical these small, yet highly specialized fasteners are to the stability and integrity of any structure. As I got deeper into projects, ranging from machinery installations to construction projects, I began to […]