A Popular Science Guide to Composite Materials

Composite materials are made by combining two or more different materials to achieve properties that are superior to those of the individual components. These materials offer unique advantages such as lightweight, high strength, high stiffness, and corrosion resistance, making them widely used in aerospace, automotive, construction, and sports equipment industries. This article introduces several common […]

The Basics of CNC Turning-Milling Compound Machining

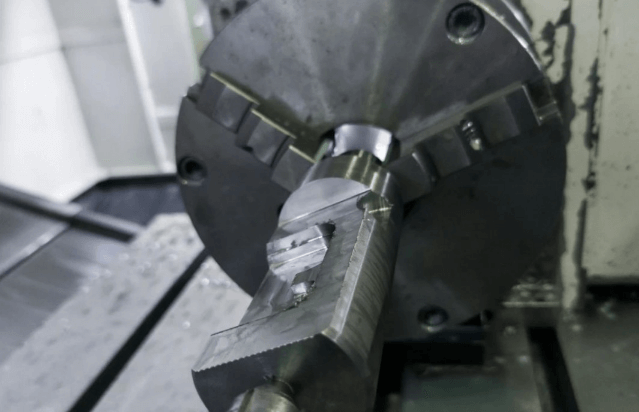

The Basics of CNC Turning-Milling Compound Machining Programming The programming basics for CNC turning-milling compound machining can vary due to different CNC systems used in milling machines. These systems may differ in their commands’ definitions and functions, but their basic functions and programming methods remain consistent. Main Functions of CNC Milling Machines Machining Range of […]

Requirements for CNC Machining Parts

Preparation Work Complete the necessary preparation before machining, including process analysis, process route design, tool and fixture selection, and program compilation. online cnc machining service Operating Steps and Contents Start the Machine: Manually return each coordinate axis to the machine origin. Tool Preparation: Load Tools into the Tool Magazine Manually: Clean the Worktable: Input Processing […]

What maintenance and upkeep are required for a CNC drilling and milling machine?

A CNC drilling and milling machine is a versatile tool that can perform various processes such as drilling, milling, chamfering, and tapping. It operates through CAD/CAM software programming, CNC system execution, and motor control to perform complex procedures. Proper maintenance and upkeep are crucial to ensuring

The difference between traditional drilling and helical milling processes

As a new hole machining method, helical milling technology offers the advantages of stable cutting, lower cutting forces on the tool, and the ability to meet precision requirements in a single operation. This technology has become a hot and challenging topic in material processing research both domestically and internationally. So, how do traditional drilling and helical milling processes differ?

What are the differences between three-axis, four-axis, and five-axis CNC machining centers?

In recent years, CNC machining centers have continuously evolved through innovation, resulting in the development of three-axis, four-axis, and five-axis machining centers, as well as turning-milling composite CNC machining centers. Today, we will discuss the distinct characteristics of three-axis, four-axis, and five-axis CNC machining centers. Three-Axis CNC Machining: This typically involves three axes of movement […]

Introduction to Precision Parts Machining: Cutting and Special Processes

Precision parts cutting machining primarily includes precision turning, mirror grinding, and lapping. Using finely ground single-crystal diamond tools on precision lathes, ultra-fine turning is performed with a cutting thickness of about 1 micron

Reaming Process for Stainless Steel Parts

The reaming process for stainless steel parts involves the following steps: Tool Geometry Design Cutting Parameters Selection Cutting Fluid Selection For reaming stainless steel materials, using an oil-based coolant or molybdenum disulfide as a cooling medium is recommended.

Basic Knowledge of CNC Turning-Milling Compound Machining

Due to the different CNC systems configured on CNC milling machines, the instructions used vary in definition and function, but their basic functions and programming methods remain the same

What should be noted about materials when machining parts with CNC?

When machining parts with CNC, not all materials can be precisely processed. Some materials are too hard and may damage the CNC machining tools, making them unsuitable for precision machining unless they are special materials or laser-cut. So, what are the requirements for materials in CNC machining? CNC Machining Parts Materials for CNC machining parts […]

The advantages of CNC machining compared to 3D printing

3D printing and CNC machining are common production processes in the field of precision machining today. While they share some similarities, they also have significant differences. For instance, CNC machining is suitable for mass production.

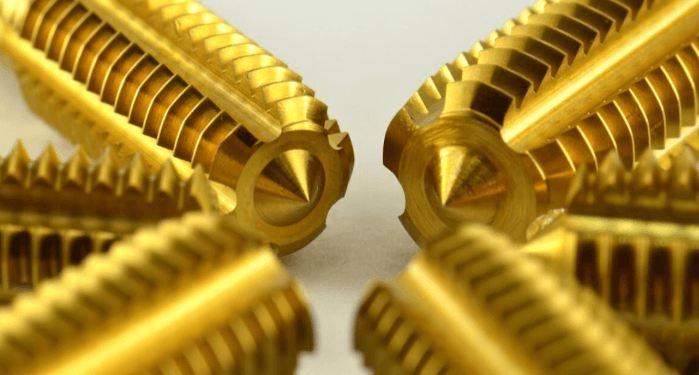

Tapping Methods in CNC Machining

Classification and Characteristics of Tapping in CNC Machining Tapping, using taps to machine threaded holes, is the most commonly used method for creating threaded holes. It is mainly suitable for smaller diameter holes (D < 30) and for holes where the positional accuracy requirements are not high. Flexible Tapping In the 1980s, flexible tapping was […]