Due to the different CNC systems configured on CNC milling machines, the instructions used vary in definition and function, but their basic functions and programming methods remain the same.

1. Main Functions of CNC Milling Machines

- Point Control Function: The point control of CNC milling machines is mainly used for hole machining, such as center drilling positioning, drilling, reaming, countersinking, reaming, and boring various holes.

- Continuous Control Function: By using linear interpolation, circular interpolation, or complex curve interpolation movements of the CNC milling machine, the machine can mill planes and curved surfaces of the workpiece.

- Tool Radius Compensation Function:If the programming is done directly according to the workpiece contour line, when machining the inner contour of the workpiece, the actual contour line will be larger by one tool radius value; when machining the outer contour of the workpiece, the actual contour line will be smaller by one tool radius value. By using tool radius compensation, the CNC system automatically calculates the tool center trajectory, causing the tool center to deviate from the workpiece contour by one tool radius value, thus machining the contour that meets the drawing requirements. Using the tool radius compensation function, changing the tool radius compensation value can also compensate for tool wear and machining errors, achieving rough and finish machining of the workpiece.

- Tool Length Compensation Function: Changing the tool length compensation value can compensate for the length deviation after a tool change, and can also change the planar position of the cutting process, controlling the axial positioning accuracy of the tool.

- Fixed Cycle Machining Function: Using fixed cycle machining commands can simplify the machining program and reduce programming workload.

- Subprogram Function: If the workpiece has identical or similar shapes, it can be written as a subprogram and called by the main program, simplifying the program structure. The subprogram function modularizes the machining program, dividing the machining process into several modules, each written as a subprogram and called by the main program to complete the CNC turning-milling compound machining of the workpiece. This modular program is easy to debug and optimizes the machining process.

- Special Functions: By configuring profiling software and devices on the CNC milling machine, sensors can scan and collect data from physical objects. After data processing, the NC program is automatically generated, enabling profiling machining and reverse engineering. Configuring certain software and hardware can expand the functional capabilities of the CNC milling machine.

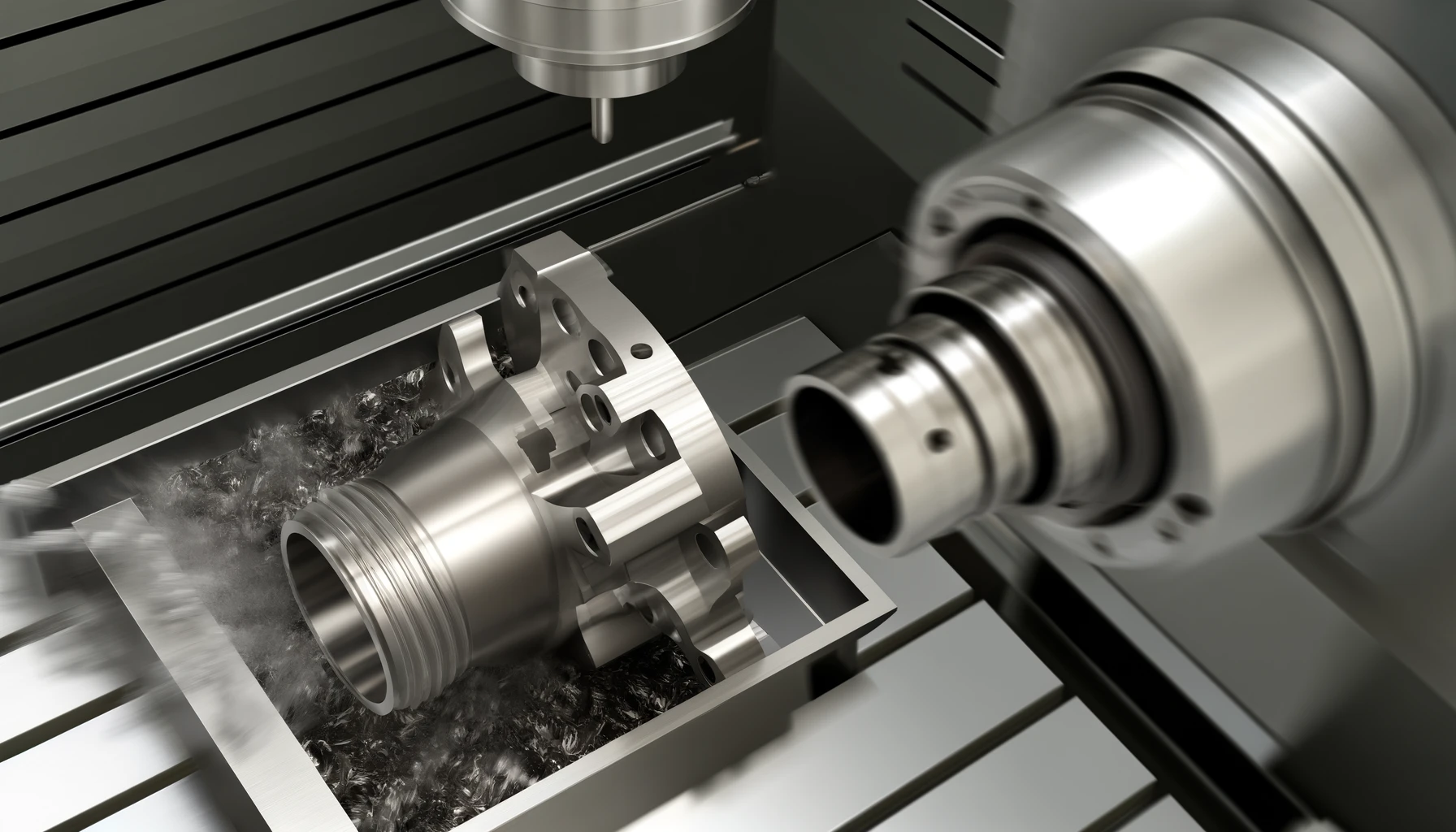

2. CNC Milling Machine Turning-Milling Compound Machining Range

- Plane Machining: CNC milling machines can mill planes, which include horizontal planes (XY machining), front planes (XZ machining), and side planes (YZ machining) of the workpiece. Such plane milling can be completed using a two-and-a-half-axis control CNC milling machine.

- Surface Machining: Milling complex surfaces requires a CNC milling machine with three or more axes for simultaneous control.

3. Equipment of CNC Milling Machines

- Fixtures: General fixtures for CNC milling machines include vices, magnetic chucks, and clamping devices. For machining medium to large batches or complex-shaped workpieces, combination fixtures need to be designed. Using pneumatic and hydraulic fixtures, controlled by programs, can achieve automatic loading and unloading of workpieces, further improving work efficiency and reducing labor intensity.

- Tools: Common milling tools include end mills, face mills, form mills, and hole machining tools.

Other Articles You Might Enjoy

- Revolutionizing Renewable Energy with CNC Machined Components

Introduction: Renewable Energy and CNC Machined Components Renewable energy harnesses power from natural sources such as the sun, wind, and water, making it a sustainable and eco-friendly alternative to traditional…

- Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical…

- CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown?

Introduction to CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown? In this article, we delve into the debate between brass and bronze machining for an important manufacturing process…

- Precision Aluminum Machining for Aerospace: Custom CNC Services

Precision Aluminum Machining for Aerospace: Custom CNC Services In the world of manufacturing, precision aluminum machining plays a pivotal role, particularly in aerospace industries where superior precision is required. As…

- Custom CNC Machining Services: When to Choose Low Volume over High Volume Production?

Introduction to Custom CNC Machining and Volume Selection in Production Custom CNC machining is a technically advanced process that involves the use of computerized machinery to design, produce, and finish…

- Innovative CNC Machining for Complex Surgical Tools

Introduction to CNC Machining and its Significance in Surgical Tools Manufacturing CNC machining, an acronym for Computer Numerical Control machining, plays a significant role in the manufacturing world. Being an…

- Revolutionizing Renewable Energy with CNC Machined Components

Introduction: Renewable Energy and CNC Machined Components Renewable energy harnesses power from natural sources such as the sun, wind, and water, making it a sustainable and eco-friendly alternative to traditional…

- CNC Milling: Revolutionizing Automotive Part Production

When it comes to versatile materials, few can match the capabilities of aluminum. Its lightweight and flexible nature make it an ideal choice for various industries, including automotive, aerospace, and…

- Using the Right Milling Technique: Down Milling vs. Back Milling

In the world of CNC milling, experts employ a myriad of techniques to maximize the capabilities of their CNC machines. These techniques are tailored to the size, shape, features, and…

- What is Micro Milling?

The ever-changing needs of the market necessitate constant updates and advancements in manufacturing technology. In order to maintain a competitive edge, manufacturers must keep pace with these changes or risk…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Prototype CNC Machining Services: Custom Aluminum Solutions

Introduction to Prototype CNC Machining and Custom Aluminum Solutions Prototype CNC (Computer Numerical Control) machining is a manufacturing technique that entails the use of pre-programmed computer software to dictate the…

- The Cost Breakdown of CNC Milling Service

If you've ever sought out CNC milling services for custom parts, you're likely aware that the price tag can sometimes be a cause for surprise. When faced with the total…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…