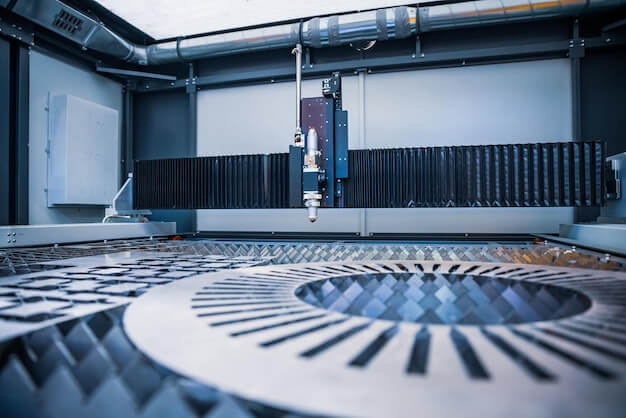

Introduction to High-Speed CNC Machining of Stainless Steel

The process of High-speed CNC machining is an advanced technological innovation extensively utilized in the manufacturing sector. It involves utilizing Computer Numeric Control (CNC) systems to conduct rapid milling and drilling operations on stainless steel materials. The precision, speed, and efficiency conferred by this method make it a vital tool in diverse fields ranging from aerospace engineering to medical equipment production. This sophistication offers distinct advantages over traditional manufacturing techniques, including:

- Enhanced Precision: With its automated operation, CNC machining can deliver components with accurate dimensions that manual processes may not achieve.

- Time Efficiency: High-speed machining mechanisms significantly cut down the execution time for complex tasks, thereby boosting productivity levels.

- Versatility: The adaptable nature of CNC machines allows them to work with various types of stainless steel grades, each serving different purposes across numerous industries.

In summary, high-speed CNC machining of stainless steel revolutionizes manufacturing processes, ensuring operational excellence while bolstering product quality and output volumes.

Demystifying the High-Speed CNC Machining Process in Stainless Steel

High-speed CNC machining in stainless steel requires precision and expertise. To maintain efficiency, it is essential to consider:

- Optimizing cutting parameters

- Utilizing high-performance tooling

- Implementing advanced cooling techniques

Advantages of High-Speed CNC Machining of Stainless Steel

The utilization of high-speed CNC machining in the processing of stainless steel brings a multitude of advantages including precision, speed and cost-effectiveness. One of the main benefits is its ability to produce precise and complex parts without human error. For instance, if a company manufacturing automobile components needs a specific type of gear with intricate details, high-speed CNC machining can handle that level of complexity effortlessly. Furthermore, this process carries out operations at an incredibly swift pace, hence speeding up production time significantly as compared to conventional methods.

- Precision: The high-speed CNC machines are known for their accuracy because they are guided by digital blueprints which leaves no room for manual errors. For example, industries such as aerospace or medical where there's absolutely no margin for error benefit tremendously from this technology.

- Speed: These machines work tirelessly around the clock without taking breaks, delivering an unmatched efficiency. This means products reach the market faster, giving companies a competitive edge.

- Cost-effective: While the initial investment may seem high, these machines effectively pay for themselves over time due to decreased labor costs, less waste materials and increased productivity.

In testament to the practicality and effectiveness, it’s not uncommon for large scale manufacturers to rely heavily on high-speed CNC machining, especially when working with durable materials like stainless steel.

Challenges in High-Speed CNC Machining of Stainless Steel

The high-speed CNC machining of stainless steel presents several challenges related to tool wear and overheating, which can significantly impact the process efficiency. First and foremost, the intense friction during the machining process causes rapid tool wear, necessitating frequent tool replacements that disrupt continuous production. Overheating, on the other hand, is a result of increased cutting speed, influencing both the tool’s lifespan and workpiece’s integrity. The following factors contribute to this issue;

- Thermal Conductivity: Stainless steel is characterized by lower thermal conductivity compared to non-alloy steels. This means that heat generated during the machining process does not dissipate quickly but rather builds up at the cut site causing tool degradation.

- Cutting Force: The inherent strength of stainless steel requires greater cutting force in machining, translating into higher temperatures along the cutting edge of the tool.

- Material Adhesion: Metallic particles from stainless steel tend to adhere to the cutting tools due to temperature increase, resulting in an uneven cutting surface and consequent tool degradation.

Maintaining efficiency while dealing with these issues often requires consistent monitoring, use of appropriate coolants for effective heat dissipation, and selection of proper tool materials resistant to early wear and able to withstand high temperatures.

Tips for Maintaining Efficiency in High-Speed CNC Machining of Stainless Steel

Maintaining efficiency during high-speed Computer Numerical Control (CNC) machining of stainless steel fundamentally relies on correct setup and choice of equipment, as well as appropriate parameters and techniques. An incorrect machine setup can lead to repeated adjustments and delays, dramatically reducing efficiency.

- An optimal setting involves not only physical set up but also programming the CNC controller accurately so that the desired design specifications are eventually met.

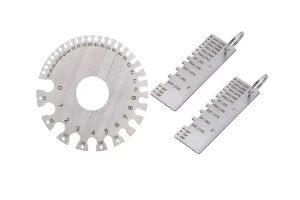

- The importance of selecting the right cutting tools cannot be overstated. Different types of stainless steel would need corresponding cutting tools to perform most effectively and efficiently—thereby reducing wear and tear, and prolonging tool lifespan. It is vital to consider specific properties such as hardness, toughness, and heat resistance while choosing these tools.

- Lastly, a sound knowledge and application of proper machining parameters and techniques like speed and feed rate play a crucial part in achieving efficient outcomes. A lower feed rate should generally be applied when working with harder materials, whereas higher speeds and feeds could suffice for softer ones. Consistently monitoring and adjusting these settings according to material behavior will help maintain optimal machining conditions.

All these components work together to ensure the smooth operation and output of high-speed CNC machining of stainless steel.

Innovative Solutions for High-Speed CNC Machining of Stainless Steel

Technological advancements in today’s industry have significantly impacted the efficiency of high-speed CNC machining, particularly with stainless steel. The introduction and usage of specialized software applications aid operators in determining optimal cutting parameters, thus increasing productivity and precision. For instance:

- The implementation of AI technology allows machines to learn as they operate, analyzing past performance data to maximize future output.

- Prediction tools that can assess wear on tool components enhance the longevity and effectiveness of the machinery.

- Vibration reduction technologies mitigate any potential disturbances and promote smooth operation during processes.

- CAD/CAM software permits absolute control over design outputs, facilitating real-time adjustments when needed.

All these innovations contribute towards a more streamlined operational process and fostering steadiness in results: enhanced quality, reduced downtime, and improved cost-efficiency.

Case Study: Maintaining Efficiency in High-Speed CNC Machining of Stainless Steel

In a recent case encountered by our team, we had the task of producing high-precision components from stainless steel within strict deadlines. To maintain efficiency, we adopted few strategies such as proper selection of tools, planning optimal feeds and speeds, devising smart work-holding methods and ensuring effective cooling methods. Proper tool selection entailed picking carbide tools with sharp edges and positive geometries for excellent surface finish while minimizing heat generation.

- The feeds and speeds were optimized keeping in mind both the toughness of stainless steel and the need to avoid excessive heat build-up which leads to decreased life of the tool tip.

- We came up with efficient work-holding strategies that maintained rigidity yet allowed easy positioning and removal of parts to save time.

- Last but not least, using high pressure coolant systems ensured to dissipate heat effectively thus maintaining dimensional stability of machined parts and increasing tool life.

This combined approach resulted in achieving maximum throughput and consistently high quality outputs, helpfully vindicating these tips for maintaining high efficiency when conducting the high-speed CNC machining of stainless steel.

Conclusion: The Impact of Efficient High-Speed CNC Machining of Stainless Steel

In conclusion, the utilization of high-speed CNC machining in stainless steel productions significantly increases efficiency by reducing production time and enhancing overall productivity. Primarily, the careful selection of machine tools – with consideration to spindle speed, feed rates, and tool paths – underpins this boost in effectiveness. Moreover, adopting proper cooling techniques mitigates heat accumulation preventing warp and tool damages. Equally important is affirmative programming for part geometry and considering chip thickness that contribute to optimal operations and longer tool-life.

- Selecting appropriate machine tools has a direct impact on output quantities and quality.

- Cooling methodologies play a crucial role in maintaining structural integrity during operation.

- Affirmative programming not only streamlines manufacturing processes, but also extends the longevity of the machinery itself.

- The principle of chip thickness is especially significant when working with materials such as stainless steel due to its increased propensity towards work hardening.

All these factors collectively influence the degree of efficiency achievable within an industrial setting, substantiating the importance of establishing proficient high-speed CNC machining practices particularly when dealing with stainless steel.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Enhancing CNC Machining Process with Bead Blasting(cast iron vs steel Marcus)

In the world of manufacturing and production, bead blasting plays a significant role in creating smooth surface finishes on various materials. Specifically, when incorporated into Computer Numerical Control (CNC) machining…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…