Introduction: Custom Metal Fabrication & CNC Machining

The art of custom metal fabrication and CNC machining is essential in many industries such as construction, automotive, aerospace, and shipbuilding. These manufacturing processes bring precision and mechanical strength to a vast range of products. Custom metal fabrication deals with the bending, cutting, and assembling metal structures from various metal pieces while CNC (computer numerical control) machining involves precise subtraction of materials by computer-controlled equipment for high accuracy work.

- In Construction industry metal fabrication plays an important role in producing steel frames which are used in building infrastructure.

- In Automotive sector CNC machines are leveraged for making engine parts due to its ability to produce complex shapes that would be almost impossible to achieve by manual machining.

Both these techniques provide flexibility to manufacturers thus enabling them to create customized solutions based on distinctive client requirements.

Custom Metal Fabrication and Its Importance in Different Industries

Custom metal fabrication refers to the shaping, cutting, and combining of metal for specific tasks or projects. This process allows for high-quality products with precise specifications that can’t be achieved through mass production techniques. It involves diverse methods like casting, welding, forging, soldering, chiseling, among others, that transform raw materials into finished goods.

- Aerospace Industry: In this sector, custom metal fabrication is essential in creating airframe components, engine parts, etc. which require absolute precision.

- Construction Industry: The construction domain depends heavily on fabricated steel due to its strength and flexibility for building infrastructure.

- Automotive Industry: Car manufacturers frequently use customized parts, including stainless-steel exhaust systems or bronze fixtures.

- Medical Industry: Hospitals also use countless specialized steel tools made from high-grade metals machined to exact measurements.

The Detailed Process of Custom Metal Fabrication and CNC Machining:

- Material Selection: Choose the appropriate metal based on the specific requirements of the custom part, considering factors such as strength, corrosion resistance, and machinability.

- Design Analysis: Conduct a thorough analysis of the design to ensure it aligns with the capabilities of CNC machines and sheet metal fabrication techniques.

- Programming: Utilize advanced computer programming to create precise toolpaths for the CNC machines, optimizing the machining process for custom metal fabrication.

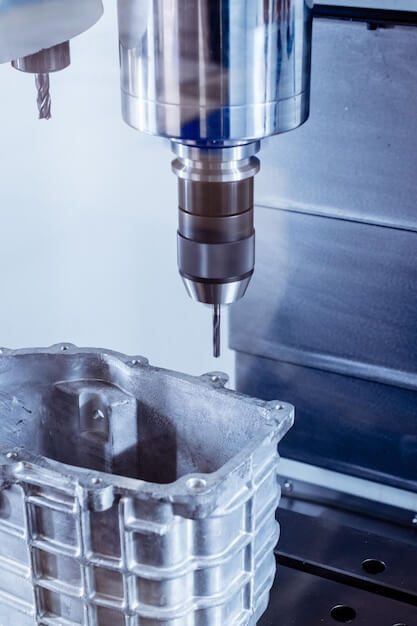

- Machining Execution: Implement the custom metal fabrication process using state-of-the-art CNC machines to accurately shape and create the custom-designed parts.

- Quality Assurance: Perform rigorous quality checks to ensure the custom-fabricated metal parts meet the highest standards and specifications.

- Service Provider: When seeking custom metal fabrication and CNC machining services, it is essential to partner with a reliable online CNC service that offers expertise in precision machining and proven capabilities in metal fabrication.

Introduction to Bronze as a Material for Custom Metal Fabrication & CNC Machining

Bronze, an alloy primarily constituted of copper and tin, exhibits remarkable characteristics that makes it highly versatile in several manufacturing genres. Its unique attributes include excellent mechanical properties, easy machinability, great resistance to wear and tear, low friction against other metals, and notable corrosion resistance, especially against seawater corrosion. These features not only enhance its durability but also make it suitable for precision components in numerous machinery.

- Mechanical Properties: bronze boasts significant strength and hardness, which allows the creation of sturdy and robust products.

- Machinability: its ease of casting and machining helps produce intricate designs with high accuracy.

- Resistance to Wear and Tear: being a tough material, it can endure heavy loads, reducing the need for frequent replacements.

- Low Friction: this property aids in reducing energy losses whilst operating machinery, thereby increasing efficiency.

In terms of applications, given its durability and anti-corrosive nature, bronze is typically used for making gears, bearings, auto parts, statues, and musical instruments among other items. For instance, phosphor bronze, recognized for its resilience and toughness, is particularly popular for making durable gears and springs. Similarly, silicon bronze sometimes replaces steel, thanks to its superior weldability, in crafting stunning works of art and beautiful sculptures, thereby supporting creative endeavors along with industrial applications.

Introduction to Stainless Steel as a Material

Stainless steel, a staple in the metal fabrication industry, sets itself apart with distinct properties that make it highly valued in many manufacturing processes. One of its acclaimed attributes is its corrosion resistance; thanks to at least 10.5% chromium present in its composition which oxide layer protects its surface, ensuring longevity and durability within challenging environments. Stainless steel also possesses high-temperature endurance, making it suitable for applications requiring heat resistance. Moreover, this versatile material offers significant strength-to-weight advantage due to its low weight and high strength.

These notable characteristics lead to broad applications of stainless steel across various sectors. They include but are not limited to:

- Kitchen appliances and cookware owing to its rust-resistance and easy maintenance features.

- Metal sculptures and monuments given its aesthetic appeal and sturdiness.

- Automotive components for their need of enduring harsh conditions and loads while maintaining lightweight structures.

- Medical equipment as the metal’s hygienic aspect coupled with its easy sterilization process makes it an ideal material.

In conclusion, through custom metal fabrication and CNC machining techniques, the limitless capabilities and application of stainless steel can be fully explored to create products that command efficacy, resilience, and aesthetics.

The Process: In-depth Look at Custom Metal Fabrication & CNC Machining

Custom metal fabrication and CNC machining are intricate processes in which bronze and stainless steel are shaped into distinct forms. Initially, a computer model is designed with the target dimensions of the bespoke piece. The actual process starts with cutting of the selected sheet using either water jets or lasers following precise measurements from the model. During the bending phase, hydraulic press brakes shape these cut pieces that match exact specifications.

- Cutting: Cutting methods such as laser cutting or water jet cutting are utilized. These further include plasma cutting for thicker materials.

- Bending: Shapes are then bent using hydraulic press brakes according to design specification. Complex angles can be achieved with a method known as V-die bending.

Subsequently, various welding techniques fuse these shapes together depending upon the type of material; Tungsten Inert Gas(TIG) welding works well for more delicate tasks whereas Metallic Inert Gas(MIG) effectively handles heavier workloads. Ultimately, through a series of meticulous steps involving shearing, drilling, punching, folding, spinning, drawing, pressing, and welding aided by Computer Numerical Control (CNC) technology, a clean, professional finish achieved – perfect for specific industrial applications.

Elucidating the Process of Custom Metal Fabrication

The process of custom metal fabrication involves a collection of various techniques including cutting, bending and assembling processes to create an end product from raw materials. To start with, metal fabricators typically employ welding techniques- MIG, TIG or stick welding – based on the project requirements in order to safely merge separate pieces of metal into one single piece. Secondly, for each custom project, there are different kinds of cutting methods such as shearing (for straight lines), plasma arc cutting (for precision cuts) and water jet cutting (for non-metal materials). Lastly, a common technique involved is forming, where tools like press brake machines come into play by applying force to a section of metal causing it to bend at an angle and form the desired shape.

For instance, let’s take a sample project of creating a customized bronze statue. Here, initial design templates are created using Computer Numerical Controlled (CNC) machinery. The sheet of bronze is then cut according to these designs using laser cutting techniques for precisions. Afterwards, the individual parts are welded together, and finally, finishing touches are added by engraving details onto the surface of the statue, demonstrating an amalgamation of all aforementioned techniques that render a spectacular final product.

CNC Machining: Understanding its Functionality and Application

Computer Numerical Control (CNC) machining offers precision in metal fabrication, especially when dealing with materials such as bronze and stainless steel. An integral part of many industrial processes, CNC technology facilitates automatic control over complex machinery. A typical setup involves a computer interface hosting intricate software programs that interpret digital blueprints for diverse applications. These directives are then issued to motorized tools and instruments capable of executing precise material removal operations.

In the realm of custom metal fabrication, one prominent application can be found in the aerospace industry where accurateness is paramount. For instance, creating engine components out of highly durable metals like bronze or stainless steel. Here, advanced 5-axis CNC machines ensure supreme accuracy, while efficiently handling large scale production runs. Such capabilities not only boost productivity but also accomplish stringent quality standards.

- Bronze Material Handling: In CNC machining, bronze requires slower spindle speeds due to its hardness level compared to other alloy counterparts which ultimately ensures minimal tool wear.

- Stainless Steel Manipulation: With properties similar to bronze’s, stainless steel necessitates rigorous cooling methods during the machining process to prevent overheating and potential deformities.

Advantages: Comparison Between Traditional Method vs Custom Metal Fabrication and CNC Machining

In terms of metalworking, custom metal fabrication and CNC machining exhibit significant advantages over traditional methods. Firstly, precision is one key benefit where both of these modern techniques allow complex cuts with exact specifications that can be repeated in high volumes without deviation. This repeatability ensures consistency in the quality produced which can be unachievable through manual processes.

- Secondly, versatility offers another advantage as these comprehensive technologies allow for the fabrication or machining of various materials including bronze and stainless steel among others.

- Efficacy also sets them apart; less waste is generated because computer controlled tools are programmed to utilise material optimally. Also, faster production times signify improved efficiency due to automated function eliminating human error.

- Last but not least, flexibility adds further beneficence where intricate designs and patterns can be easily accommodated by CNC machine programming capabilities thus abolishing limitations presented by conventional, manual techniques.

Precise, versatile, effectual, flexible – custom metal fabrication and CNC machining are advanced solutions that trump the restrictions related to traditional metalworking methods.

Advantages of Custom Metal Fabrication & Precision CNC Machining

Opting for custom metal fabrication and precision Computer Numerical Control (CNC) machining over traditional methods provides a plethora of advantages. Firstly, these techniques yield an enhanced level of accuracy and control in production which leads to higher quality and consistency – something that is not always achievable with traditional processes. The modern, automated nature of CNC machining facilitates precise component replicability on a large scale, thereby minimizing variations and ensuring superior product uniformity.

- CNC Machining ensures high precision and intricate detailing by controlling various 3 Dimensional cutting tasks simultaneously. This results in reduced material wastage and promotes sustainability.

- The customization aspect allows manufacturers to tailor fabrication as per specific dimensions and design intricacies, hence enabling the creation of unique pieces that fit perfectly into their intended applications.

- Due to the high speed and efficiency of CNC machines, there’s a significant reduction in lead-time compared to manual labor giving businesses a competitive edge through faster project completion times.

In conclusion, leveraging custom fabrications along with precision CNC machining increase efficiency, reduces waste, enhance precision and offers robust scalability- critical traits advantageous to any industry dealing in bronze or stainless steel manufacturing.

Practical Applications of Custom Metal Fabrication and CNC Machining in Industries

In the world of manufacturing, custom metal fabrication and CNC machining are not just theories, they find their practical applications across a myriad of industries. One such industry is the automotive sector, which leverages these techniques extensively for parts production. For example, stainless steel is employed to manufacture engine parts, while bronze has been used traditionally in making bushings and bearings due to its low friction properties.

- Automotive Industry: Complex parts like gears, shafts, or even entire engines can be fabricated with precision using CNC machining, increasing efficiency and reducing waste materials.

- Aerospace Industry: Due to strenuous safety regulations and standards set by governing bodies, this industry often requires specialized and highly precise parts. Stainless steel’s corrosion resistance makes it an excellent choice for components exposed to harsh conditions.

- Medical Field: Surgical instruments, implants, and medical devices all utilize stainless steel and bronze through both fabrication methods because of their bio-compatibility and easy sterilization properties.

Your understanding of how custom metal fabrication and CNC machining works can hence help in recognizing their importance and wide-scale applicability in various industrial processes far away from the confines of technical jargon.

Implementation of Custom Metal Fabrications: A Case Study

The process of custom metal fabrication plays a vital role in various industries, particularly when it comes to manufacturing durable goods. The application can be illustrated through the case study of a high-end automobile manufacturer. Implementing custom metal fabrications revolutionized their production line by enhancing both efficiency and product quality.

- Bronze Fabrication: Through bronze metal fabrication, intricately designed components were manufactured for car interiors, enriching aesthetic appeal while ensuring longevity.

- Stainless Steel Fabrication: Strength is paramount in the production of vehicles. Stainless steel fabrication allowed them to construct robust chassis and other essential parts with ease, providing enhanced sustainability and safety features.

- Critical Elements Function: With such implementation, every single component right from engine parts, body structure elements to interior details had demonstrated superior performance and resilience.

CNC Machining in Everyday Products

CNC machining finds extensive everyday applications, like in smartphone production – an item we all encounter daily. Employing Computer Numerical Control (CNC) technology ensures precision and consistency that manual handling could never attain.

- Smartphone Body: To ensure durability, multiple smartphones use CNC machined aluminum bodies. Every design detail remains consistent across millions of units due to this precise technique.

- Tuning Smartphone Components: Minute but critical parts like camera mounting brackets or SIM card slots are meticulously crafted using CNC machining. This provides perfect fit and flawless functionality for each unit.

- Product Evolution: From prototype development stage to mass manufacture, CNC machining has streamlined product evolution, granting us reliable, high-quality devices.

Other Articles You Might Enjoy

- Precision Aluminum Machining for Aerospace: Custom CNC Services

Precision Aluminum Machining for Aerospace: Custom CNC Services In the world of manufacturing, precision aluminum machining plays a pivotal role, particularly in aerospace industries where superior precision is required. As…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…