Introduction to Precision CNC Machining

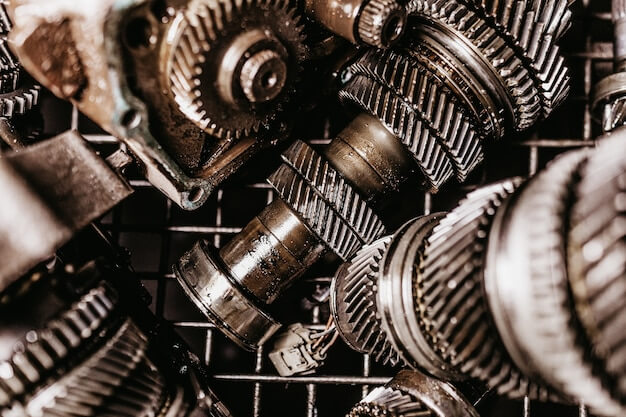

Precision CNC (Computer Numerical Control) machining is a subtractive manufacturing technology that utilizes advanced computer systems to control and execute precise machining processes. The implementation of this high-tech machinery allows manufacturers to sculpt various types of materials including steel, into intricate parts with extreme detail and precision. This process is essential in the manufacturing industry due to its accuracy and efficiency.

- The fundamental attribute of precision CNC machining lies in its name: precision. Equipped with highly developed technical software capable of translating a digital model into specific machine instructions, it facilitates detailed fabrication resulting in minimal waste of material.

- In essence, precision CNC machining plays a pivotal role in the production of high-quality steel parts. Its applications extend across industries such as aerospace, automotive, medical, and more – wherever complex designs on hard metals are required.

- To illustrate, consider an automobile manufacturer who seeks consistent and flawlessly replicated engine parts – Thanks to CNC’s automated and precisely controlled movements, this level of replication becomes feasible at optimized speed and cost.

Understanding Precision Manufacturing for High-Quality Steel Parts

Precision manufacturing plays a pivotal role in delivering high-quality steel parts. It involves the production of intricate and consistently accurate parts which demand exact measurements down to nanometers, fostering errorless results while maintaining efficiency and product quality. The process takes into consideration a multitude of factors including material selection, tooling precision, machining accuracy, and rigorous quality control.

- Material Selection: Selecting premium grade steel ensures overall strength, durability, and longevity of the components.

- Tooling Precision: State-of-the-art equipment with advanced capabilities delivers precise cutting, drilling and shaping tasks that meet specific dimensions.

- Machining Accuracy: CNC machines are used to maintain uniformity and consistency in each piece’s dimensions, reducing variability or deviation from the intended design.

- Quality Control: Rigorous inspection protocols affirm impeccable conformity to blueprint specifications and compliance with industry standards ensuring fewer rejects or reworks.

Thus, precision manufacturing not only maintains the integrity of steel parts but also enhances their functionality. Its contribution towards achieving high-quality output is immeasurable.

Roles of a Precision CNC Machining Manufacturer

The core responsibility of a precision CNC machining manufacturer revolves around the production and delivery of high-quality steel parts, utilizing advanced precision machining techniques. Their role encompasses various other key responsibilities such as design interpretation, oversight of fabrication, quality control, and timely delivery.

- Design Interpretation: They work closely with clients to understand and interpret complex design plans. This process often involves meticulous blueprints, created by engineers or architects, which guide the precise cutting and shaping of steel materials.

- Fabrication Oversight: Once they have correctly interpreted the design, they feed it into their computer-controlled machinery. These machines meticulously cut and shape the material according to the understood specifications.

- Quality Control: A significant component of their job is ensuring that every part produced meets the highest standards of reliability and durability. This implies maintaining a rigorous quality control protocol to detect any deviations in the final product from the stipulated design drawings.

- Timely Delivery: Another important role they play is satisfying client’s need for punctual delivery of products. Ensuring all orders are completed within the pre-designated time frame not only guarantees customer satisfaction but also enhances their reputation in the manufacturing industry.

In essence, the roles performed by a precision cnc machine manufacturer are integral for producing reliable, superior quality steel components usable across multiple sectors.

Overview of the CNC machining process involves:

- Material Selection: Choosing the appropriate steel grade based on the specific application requirements and desired mechanical properties.

- Tooling and Machining Techniques: Utilizing suitable cutting tools and machining techniques to achieve precision and efficiency in CNC machining of steel parts.

- Surface Finishes: Understanding the impact of different surface finishes on the appearance and functionality of machined steel parts.

For precision CNC machining of steel parts, consider utilizing a online CNC service to ensure high-quality and reliable manufacturing processes.

Advantages of Precision CNC Machining

In manufacturing sector, the advantages of precision CNC machining are aplenty. Topping the list is efficiency. This state-of-the-art technology allows for automation of processes, reducing manual labor and significantly increasing productivity levels. It notably reduces the turnaround time from production to delivery, resulting in maximized profitability.

The prime advantage lies in its accuracy. Thanks to automated controls, the possibility of human error occurring is vastly minimized, ensuring precision during high volume production runs where consistency in quality is paramount. This enduring accuracy can lead to immense cost savings due to reduced waste.

Precision CNC machining also has a superior level of flexibility, as programming changes can be made on the fly allowing mass customization which was once unthinkable with traditional methods. A computer program controls all relative movements, making complex design specifications achievable. In addition, this innovative tech allows 24/7 operation, only pausing for maintenance or repair when necessary.

Lastly, the benefit of increased worker safety cannot go unstated. As CNC machines work autonomously, they limit risks associated with handling heavy machinery, thus creating safer workplace conditions.

Application of Precision CNC Machined Parts

Precision CNC machining plays a major role in several industries requiring high-quality steel parts. A quintessential part of industries such as automotive manufacturing and aerospace engineering, precision machined components are critical for the efficient operation of their complex systems due to the requirement of superior accuracy and quality.

In the automotive industry, key parts like engine parts, suspensions, brake systems are typically produced using Precision CNC machining because these parts need strict tolerances and accurate fits for optimal functioning. For instance, even minuscule errors in brake system components could jeopardize vehicle safety, underlining the importance of exceptional precision.

The aerospace sector also heavily relies on this technology since flight control systems, landing gear, and engine accessories all necessitate precision-made components that can withstand extreme conditions. Errors or imperfections within components such as turbine disks or aircraft fuselage are simply unacceptable due to the risk they pose to safety and performance. Hence, both these sectors underscore the irreplaceable importance of precision CNC machining in optimizing product functionality while ensuring longevity and safer operations.

Things to Consider When Choosing a Precision CNC Machining Manufacturer

When selecting a manufacturing partner for high-quality steel parts, several considerations must be taken into account. First and foremost, the manufacturer’s previous experience can provide valuable insight into their capabilities. Have they worked with projects similar to yours? Do they have a track record of delivering quality results on time?

The technology used by the manufacturer is another significant factor. State-of-the-art machinery demonstrates a company’s dedication to providing superior finished products which often translates to precision manufacturing.

- Certification is yet another important consideration. A certified manufacturer adheres to strict industry standards ensuring product safety and quality.

- Evaluating client feedback can offer first-hand information regarding the manufacturer’s service quality, reliability, and professionalism.

In conclusion, by carefully examining these factors, one can more confidently choose a precision CNC machining manufacturer that will deliver high-quality steel parts in line with requirements.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(3d prototyping James)

Bead blasting is a surface treatment process extensively used within the field of Computer Numerical Control (CNC) machining, which has revolutionized manufacturing industries. This method comes under focus due to…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…