CNC Machining and Its Significance in The Defense Industry

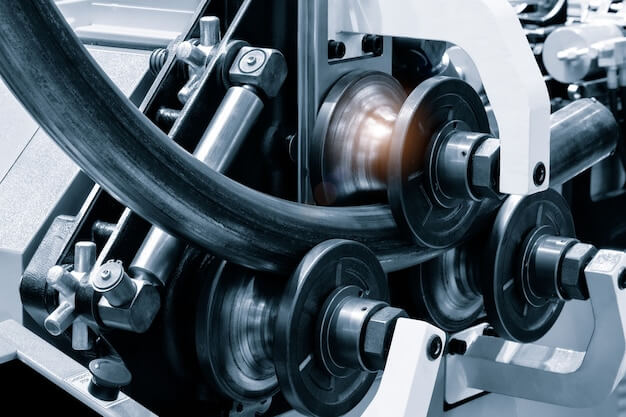

Computer Numerical Control (CNC) machining is a crucial manufacturing process whereby pre-programmed computer software dictates the movement of machinery and tools. It facilitates intricate and precise production, essential for the varied components used within the defense sector. CNC machining assures efficiency, repeatability, and accuracy vital to meet stringent military specifications.

In the context of the defense industry, materials selection – particularly titanium versus aluminum alloy – plays an influential role in CNC machining operations. Both metals offer unique traits; their respective attributes can significantly impact overall performance, durability, and longevity of defense equipment. For instance,

- Titanium’s robustness and corrosion resistance make it suitable for producing high-strength parts capable of withstanding harsh operating conditions encountered in various defense applications.

- Conversely, Aluminum Alloy offers advantages in terms of weight reduction and cost-efficiency.

Therefore, careful consideration in material choice via CNC machining ensures optimal functionality and reliability of mission-critical defense components.

Understanding Titanium as a Material for Defense Industry

Titanium is a highly valuable material in the defense industry due to its exceptional properties and performance. Here are some key points to consider:

Advantages of Titanium:

- Strength-to-Weight Ratio: Titanium is known for its high strength-to-weight ratio, making it ideal for applications where lightweight yet strong materials are required.

- Corrosion Resistance: Titanium exhibits excellent corrosion resistance, allowing it to withstand harsh environments and prolonged exposure to moisture or chemicals.

- Heat Resistance: Titanium has a high melting point and can withstand extreme temperatures, making it suitable for defense applications that involve high heat or thermal stress.

- Biocompatibility: Titanium is biocompatible, meaning it is compatible with the human body and can be used in medical implants or devices.

Applications in the Defense Industry:

Titanium finds various applications in the defense industry, including:

| Application | Description |

|---|---|

| Aircraft Components | Titanium is used in the construction of aircraft components such as airframes, landing gear, and engine parts due to its lightweight and high strength properties. |

| Armor Systems | Titanium alloys are utilized in the manufacturing of armor systems, providing protection against ballistic threats while maintaining a lightweight profile. |

| Missile Components | Titanium is used in missile components due to its high strength, heat resistance, and ability to withstand high-speed impacts. |

| Naval Vessels | Titanium is employed in naval vessels for its corrosion resistance, reducing maintenance requirements and increasing the lifespan of critical components. |

With its unique properties and versatile applications, titanium plays a vital role in the defense industry. To explore CNC machining services for defense industry applications, you can visit our Precision Machining Service.

Grasping Aluminum Alloy in Defense Industry Context

Understanding the signature traits and applications of aluminum alloy within the defense industry is integral to comprehending CNC machining’s evolution. Amongst a diverse range of alloys, aluminum stands out due to its lightweight nature, outstanding conductive properties, durability, as well as corrosion resistance. Its weight becomes an invaluable asset when looking at vehicle armor and aerospace components where weight reduction directly impacts operational efficiencies.

Tapping into aluminum alloy involves certain advantages for defense applications. In particular, its lightness plays a crucial role in creating highly mobile machinery; for example, the Bradley Fighting Vehicles use aluminum alloy extensively to offer lightweight yet strong armor enabling them to move at higher speeds across rugged terrains while providing effective protection against adversarial attacks.

However, despite these advantages,

- Their comparatively lesser tensile strength compared to counterparts like titanium makes them vulnerable under extremely high-stress conditions,

- Aluminum’s reactive nature may cause issues such as galvanic corrosion when paired with other metals without adequate prevention measures. Thus selecting appropriate manufacturing processes is key in mitigating these potential drawbacks.

Comparison Between Titanium and Aluminum Alloy in Defense-oriented CNC Machining

In the defense manufacturing industry, both titanium and aluminum alloy have their distinct attributes that make them conducive to certain applications. Beginning with titanium, its impressive strength-to-weight ratio makes it an essential component for military aircrafts along with submarines where high strength, low weight and resistance to sea water are significant considerations. It’s also corrosion resistant, withstands extreme temperatures and is non-magnetic properties making it ideal for sensitive electronic equipment.

- An application of titanium comes into play in manufacturing armor plating due to its superior ballistic characteristics.

On the other hand, aluminum alloy is generally lighter than titanium and just as strong in many contexts, thereby reducing fuel consumption in vehicles and contributing to better maneuverability of weapons systems and equipment. Furthermore, it shows excellent machinability in CNC processes which simply means less wear on tooling and faster production cycles.

- For instance, its thermal conductivity and electrical insulation properties render aluminum alloy desirable in manufacturing heat sinks used in several radar, communication or electronic warfare systems.

Nevertheless, a comparative analysis between these two metals based purely on their individual physical features may not always provide an accurate prediction of their performance under real-world conditions experienced during defense-oriented CNC machining operations.

Guidance on Material Selection: Titanium vs Aluminum Alloy

In the defense industry, selecting the right material is of paramount importance, and it usually boils down to choosing between two materials – titanium and aluminum alloy. Both of them are popular due to their respective strengths such as lightweight (aluminum) and high strength-to-weight ratio (titanium). The decision primarily depends on factors including specific equipment requirements, cost constraints, and environmental conditions.

- Practical Case Study: For example, in manufacturing a fighter jet, where elevated heat resistance and durability against pressure are priorities, titanium would be more advantageous considering its higher melting point and strength.

- Tentative Scenarios: On the other hand, when producing large volumes of lighter battle gear like helmets or shields, aluminum alloy, being cheaper and easier to manufacture, might be the material of choice.

The key lies in meticulously analyzing individual specifications and scenarios before making an informed material selection for defense equipment manufacturing. Ultimately, each situation will uphold the suitability of either titanium or aluminum alloy based on these considerations.

Other Articles You Might Enjoy

- The Advantages of Using LSR (Liquid Silicone Rubber) in CNC Prototyping and Production?

Introduction to LSR in CNC Prototyping and Production The utilization of Liquid Silicone Rubber (LSR) in CNC prototyping and production has been growing exponentially due to its numerous advantages. For…

- The Evolution of Plastics in CNC Machining: From ABS to PEEK?

The Evolution of Plastics in CNC Machining: From ABS to PEEK CNC machining, also known as Computer Numerical Control machining, plays an integral role in contemporary manufacturing processes. It enables…

- CNC Machining for Aerospace: Titanium vs. Aluminum Alloys Comparison

CNC Machining in Aerospace Industry: Material Choice Significance CNC machining, an abbreviation for Computer Numerical Control machining, is a process utilized extensively in the aerospace sector. The technology relies on…