Blog

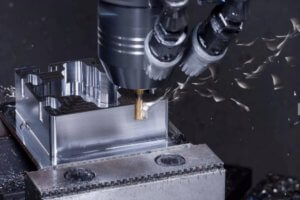

How to Machine 316L Stainless Steel with CNC: Tips and Techniques

Introduction to 316L Stainless Steel in CNC Machining When I first encountered 316L stainless steel, I was struck by its versatility and exceptional properties. It’s

Deep Dive into Metal Fabrication Unleashed: Key Techniques and Industry Trends

Introduction to Metal Fabrication When I first started learning about metal fabrication, I was fascinated by the complexity and precision required to transform raw metal

Avoid Common Pitfalls When Choosing or Working with a Metal Fabrication Company: Insider Advice

Chapter 1: Introduction Choosing the right metal fabrication company can be the difference between a successful project and a costly failure. Whether you’re in the

Unlocking the Power of Horizontal Milling Machine in CNC Operations

Introduction In the ever-evolving world of CNC machining, the horizontal milling machine stands as one of the most powerful tools for precision, efficiency, and versatility.

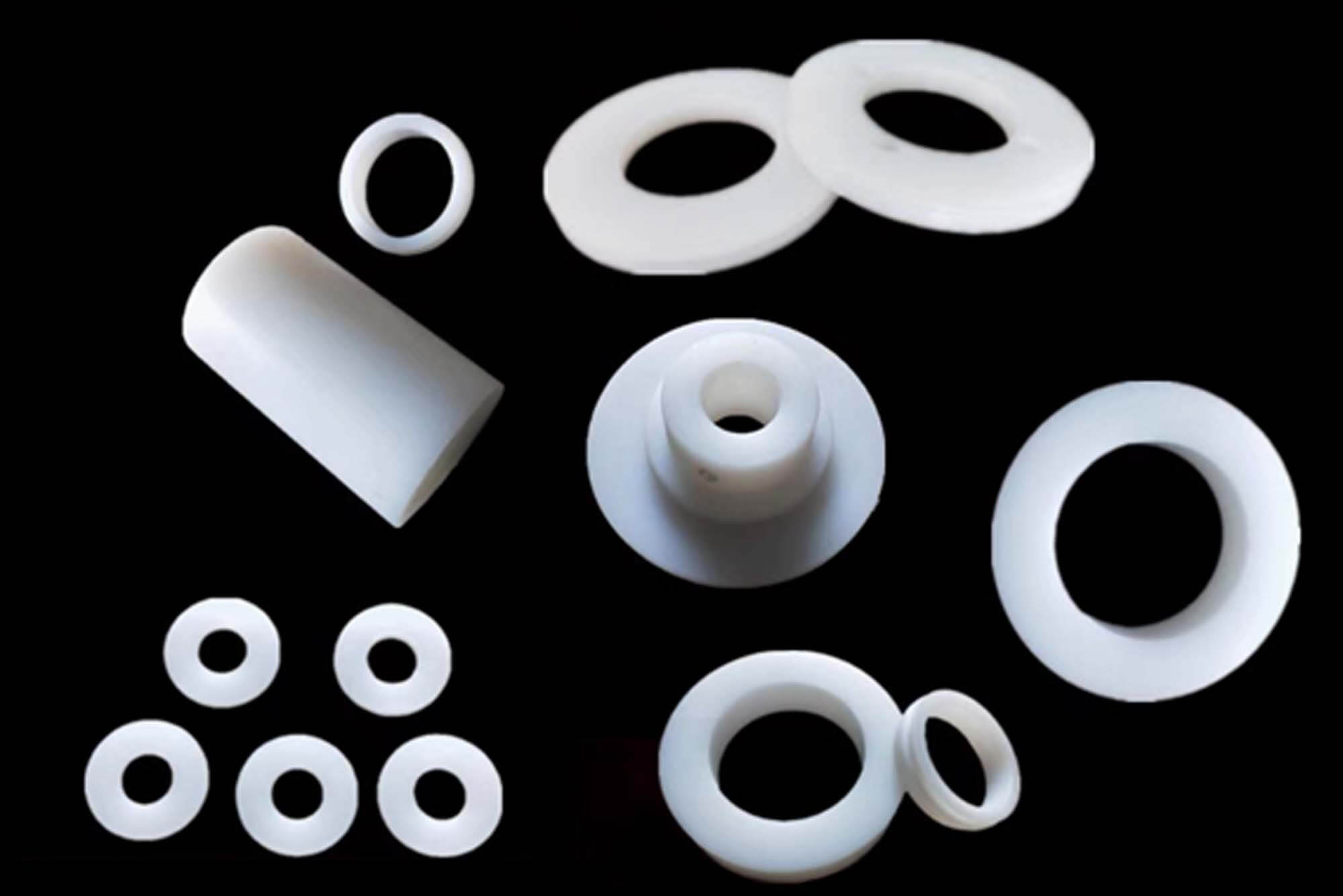

The Benefits of Using Nylons in CNC Machining for Precision Parts

Introduction to Nylons and CNC Machining As someone who has worked extensively with materials in CNC machining, I’ve come to appreciate the versatility and advantages

Does Titanium Rust? Exploring the Corrosion Resistance of Titanium in CNC Machining

Introduction: Understanding Titanium’s Properties What is Titanium? Titanium is a metal that has gained significant attention in engineering, aerospace, medical, and industrial applications due to

How to CNC Machine UHMW for High-Performance Parts in Industry

Introduction: Understanding UHMW and CNC Machining When it comes to manufacturing high-performance parts for industries such as mining, food processing, and automotive, the choice of

What is 4140 Steel and Why is it Popular in CNC Machining

What is 4140 Steel? What are Its Key Characteristics? When I first encountered 4140 steel in CNC machining projects, I was struck by its versatility

From Table to Tool:Where Are Metalloids Located on the Periodic Table for CNC Efficiency

Introduction I’ve spent years working with CNC machines, and there’s always one piece of advice I return to: understanding the material’s properties is as important

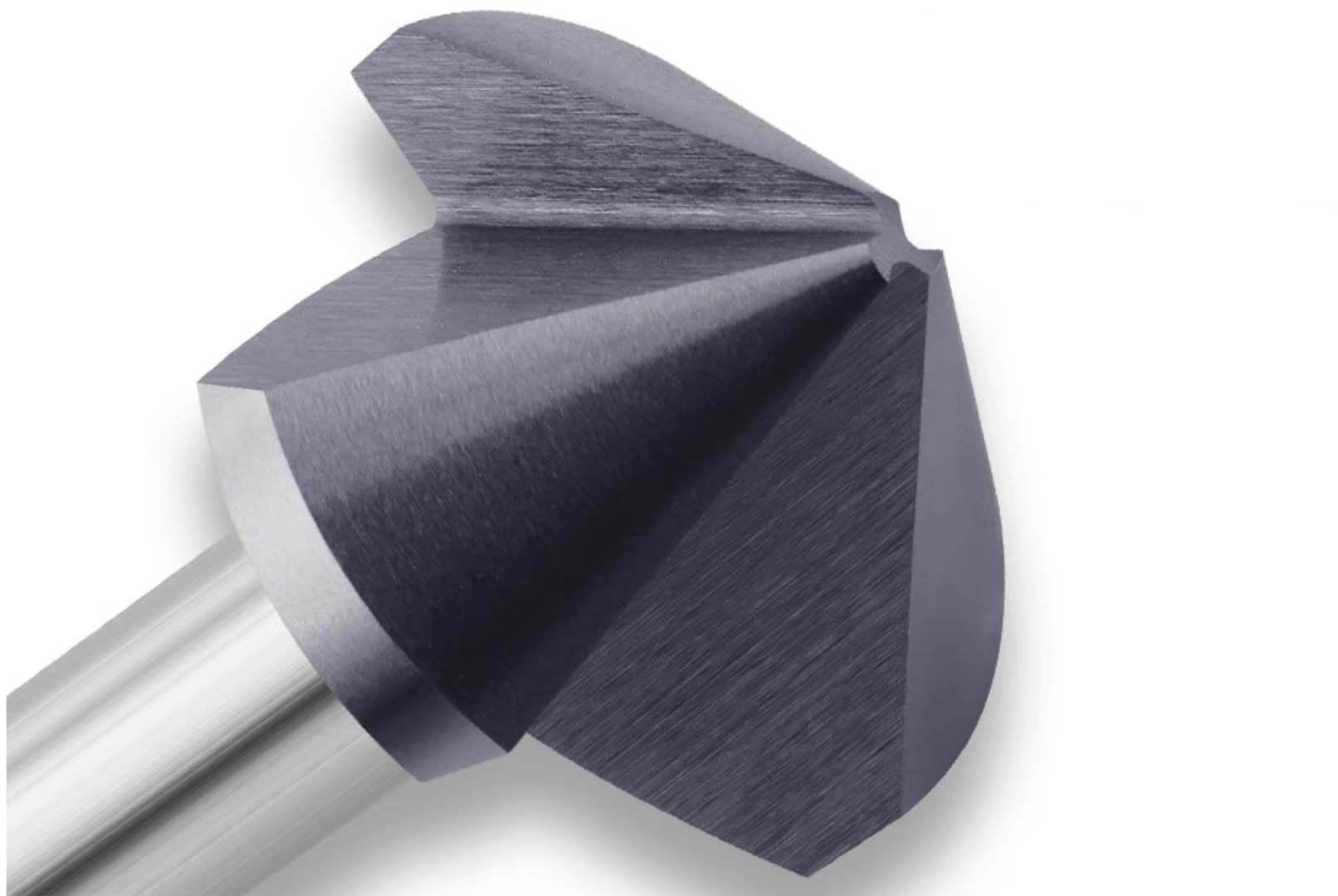

Chamfer Tool Essentials: Boost Your CNC Machining Efficiency

As I embarked on my journey in the world of CNC machining, one tool quickly became indispensable in my arsenal—the Chamfer Tool. Whether you’re a

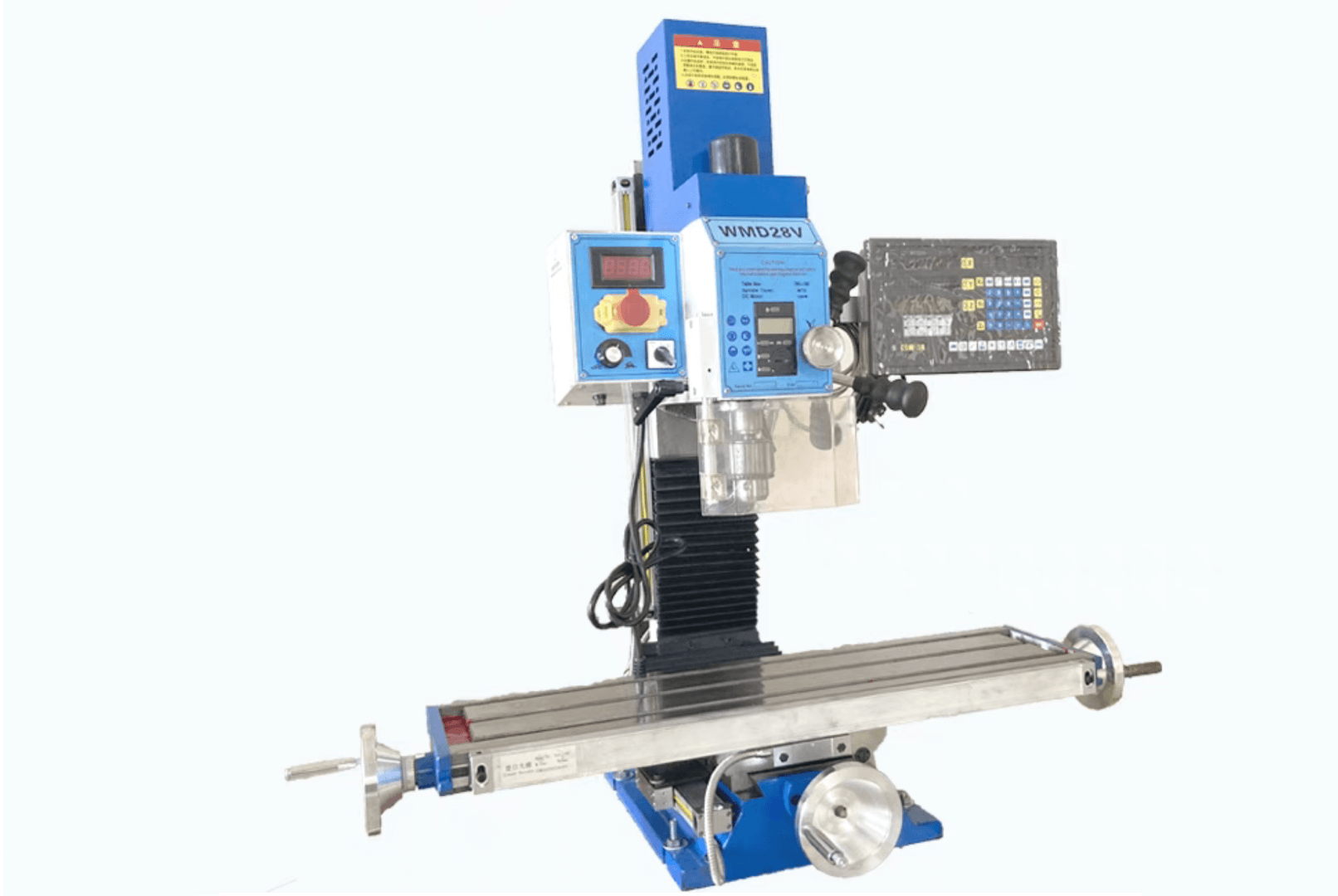

Vertical Milling Machine Operation: Essential Steps for Accurate Machining

I. Introduction When I first heard the term “vertical milling machine”, I didn’t realize just how central this piece of equipment would become to modern

What Does CNC Stand For? A Deep Dive into Industry Applications and Trends

What Does CNC Stand For?

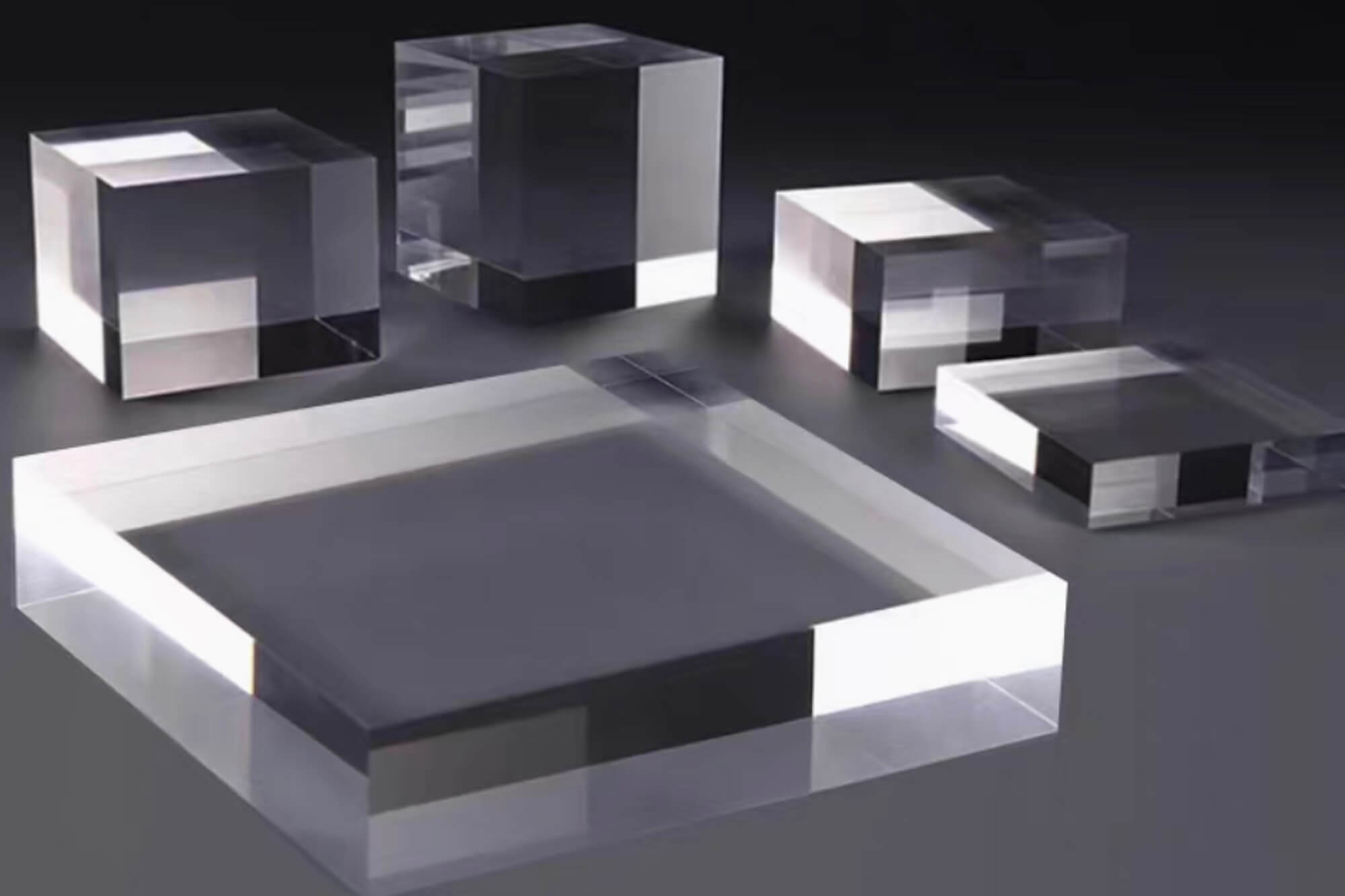

How to Cut Acrylic Sheet Cleanly and Precisely for Professional Use

Introduction to Acrylic and Its Uses Acrylic, also known as PMMA (Polymethyl Methacrylate), is one of the most versatile materials used across various industries today.

CNC for Copper Pipe: Revolutionizing the Efficiency and Precision of Copper Pipe Processing

How CNC Technology Plays a Vital Role in Copper Pipe Processing Copper pipes are indispensable across multiple industries, from plumbing and HVAC systems to automotive

Brass Tap Manufacturing with CNC Technology: Efficiency and Precision

Introduction to Brass Tap Manufacturing with CNC Technology The world of manufacturing is constantly evolving, and one of the most significant advancements has been the

Unlocking the Potential of Bronze Bushings with CNC Machining

I. Introduction Bronze bushings are an indispensable component in the world of mechanical engineering. They provide critical support for rotating parts, reduce friction, and enhance

The Art of Burnished Bronze: Exploring Machining and Polishing Methods

Introduction Burnished bronze has been a material of fascination for many over the centuries. Whether you’re an artist crafting a masterpiece or an engineer designing

Creative CNC Projects: Ideas, Techniques, and Profitable Applications

Chapter 1: Introduction What Are CNC Projects? CNC projects involve using Computer Numerical Control (CNC) machines to create physical objects. These machines operate based on

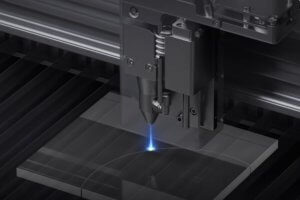

CNC Laser Applications That Are Reshaping Industries Today

I’ve spent a significant amount of time looking into how different manufacturing technologies evolve, and one technology that keeps grabbing my attention is CNC laser.

Brass Tacks Demystified: A Deep Dive into Machining Techniques and Innovations

I’ve spent a fair bit of time learning about different metal fasteners, and brass tacks are one of those intriguing items that bridge function and

Billet Aluminum Unlocked: Expert Machining Techniques and Real-World Applications

Introduction: Why Billet Aluminum Matters in Machining I’ve worked with various metals and alloys, but billet aluminum has always stood out for its potential and

The Complete Guide to Polishing Aluminum: Challenges and Solutions for Machinists

Introduction – Polishing Aluminum and Why It Matters I remember the first time I tried polishing aluminum. I wanted a clean, glossy finish but ended

Brushed Aluminum Demystified: From Elegance to Engineering

I’ve spent a fair amount of time working with different metals, and Brushed Aluminum has always caught my eye. It’s a material that combines an

Copper Custom Innovations: Exploring New Alloys and Hybrid Manufacturing

I’ve spent a significant amount of time exploring various manufacturing processes, and one of the most intriguing areas I’ve encountered is what I call “Copper

Red Copper Machining: Techniques and Best Practices

Introduction: Why Focus on Red Copper Machining? Red copper, also known as pure copper, has long been a material of choice across industries due to

Machining Techniques for Parts: Unlocking CNC and Cutting-Edge Tech

I. Introduction I remember the first time I realized how critical machining is to modern manufacturing. I was interning at a small shop, watching a

Acetal Material Overview: Why It Excels in CNC Machining Applications

I. Introduction I’ve been fascinated by engineering plastics for quite some time. In my early days as a mechanical enthusiast, I spent hours experimenting with

Selecting the Right Surface Finish for Your CNC Machined Part: Matte vs. Glossy Materials

Selecting the Right Surface Finish for Your CNC Machined Part: Matte vs. Glossy Materials CNC machining, an abbreviation of Computer Numerical Control machining, is a

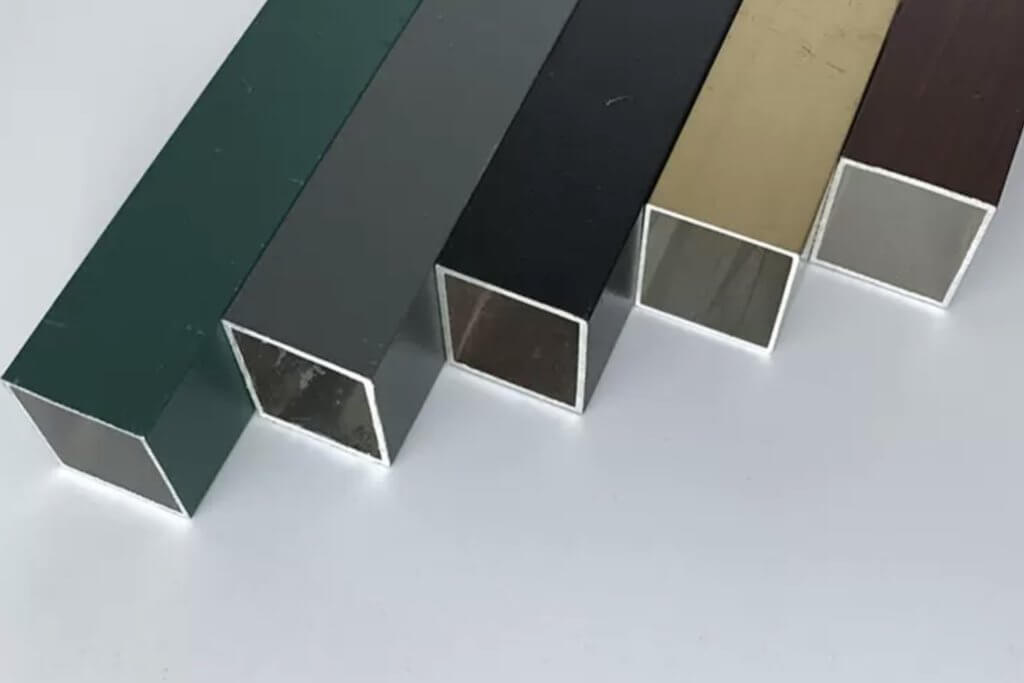

Enhancing Aesthetic Appeal in CNC Machining: Anodized Aluminum vs. Painted Steel

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a high-precision manufacturing process that uses pre-programmed computer software to direct the movement of complex

Laser Cutting Materials: MDF vs. Plywood – What’s Best for Your Project?

Introduction to MDF and Plywood in Laser Cutting In the world of laser cutting materials, Medium Density Fibreboard (MDF) and plywood are commonly used resources.

The Impact of Material Density on CNC Machining Costs and Efficiency

The Importance and Role of CNC Machining in Manufacturing CNC (Computer Numerical Control) machining is a critical element within modern manufacturing. As an advanced technology,

The Engineer’s Guide to Machining Composites: Challenges and Material Selection

Introduction to Machining Composites The process of machining composites, a field that utilizes a variety of substances with different properties skillfully merged to create a

HDPE vs. LDPE: A Detailed Comparison for Manufacturers

Introduction: Understanding HDPE and LDPE In the realm of plastics, High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) play significant roles. HDPE is a rigid plastic

Navigating the World of Non-Metal CNC Machining: Wood vs. Plastic Material Insights

Introduction to CNC Machining: Special Focus on Wood and Plastic Materials CNC machining, or Computer Numerical Control machining, is a manufacturing process wherein pre-programmed computer

The Art of CNC Machining: Aesthetic Materials for Consumer Products

Introduction to CNC Machining and its Aesthetic Significance in Consumer Products CNC Machining, known formally as Computer Numerical Control Machining, serves a significant role in

CNC Machining in Robotics: Material Selection for Durability and Functionality

Introduction: The Significance of CNC Machining in Robotics and the Importance of Material Selection The field of robotics has significantly benefited from the advancements in

ABS Plastic vs. Nylon: A Detailed 3D Printing Material Comparison

Introduction: The Importance of Material Selection in 3D Printing In the field of 3D printing, material selection plays a pivotal role in determining not only

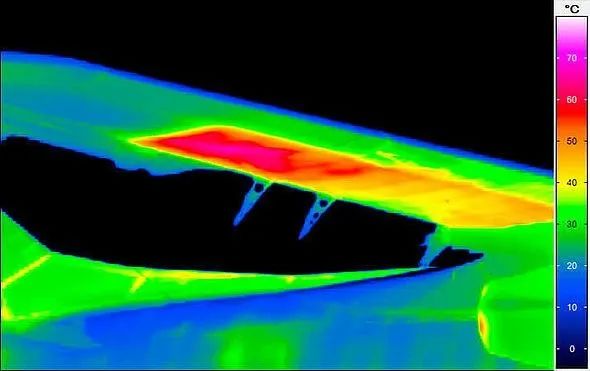

Strategies for Enhancing Thermal Conductivity in CNC Machined Parts

The Importance of Thermal Conductivity in CNC Machined Parts In the sphere of CNC machining, thermal conductivity is an extremely vital factor. It has crucial

Optimizing Optical Clarity in CNC Machined Components: PMMA vs. PC Materials

Introduction to CNC Machined Components CNC machined components are parts produced using Computer Numerical Control (CNC) machines, which operate via digitally-encoded coordinates. These automated devices

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

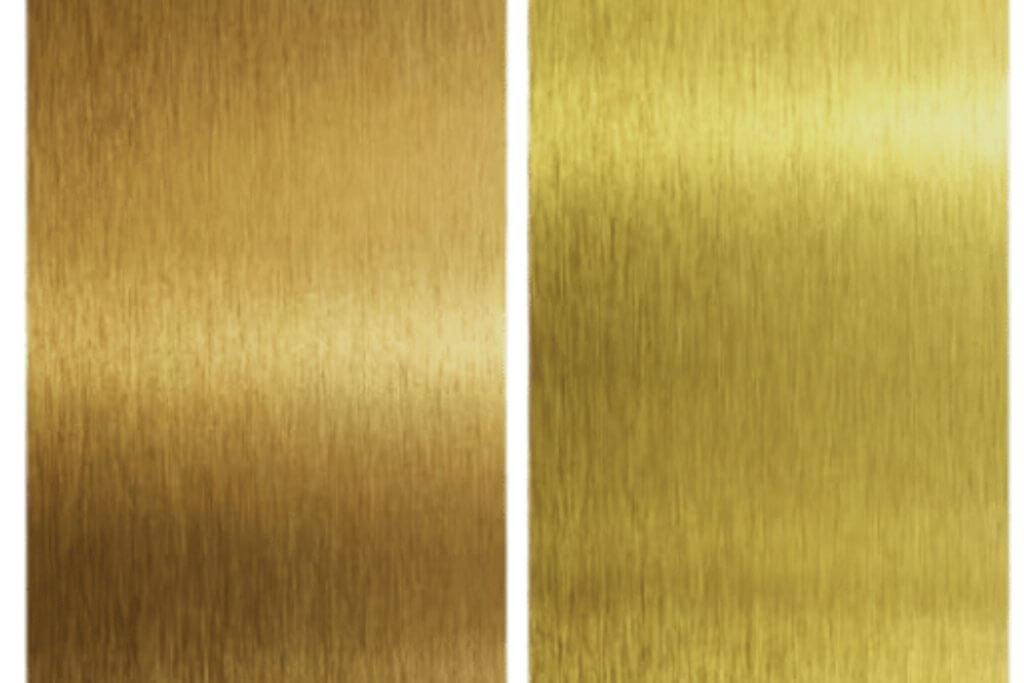

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …