Blog

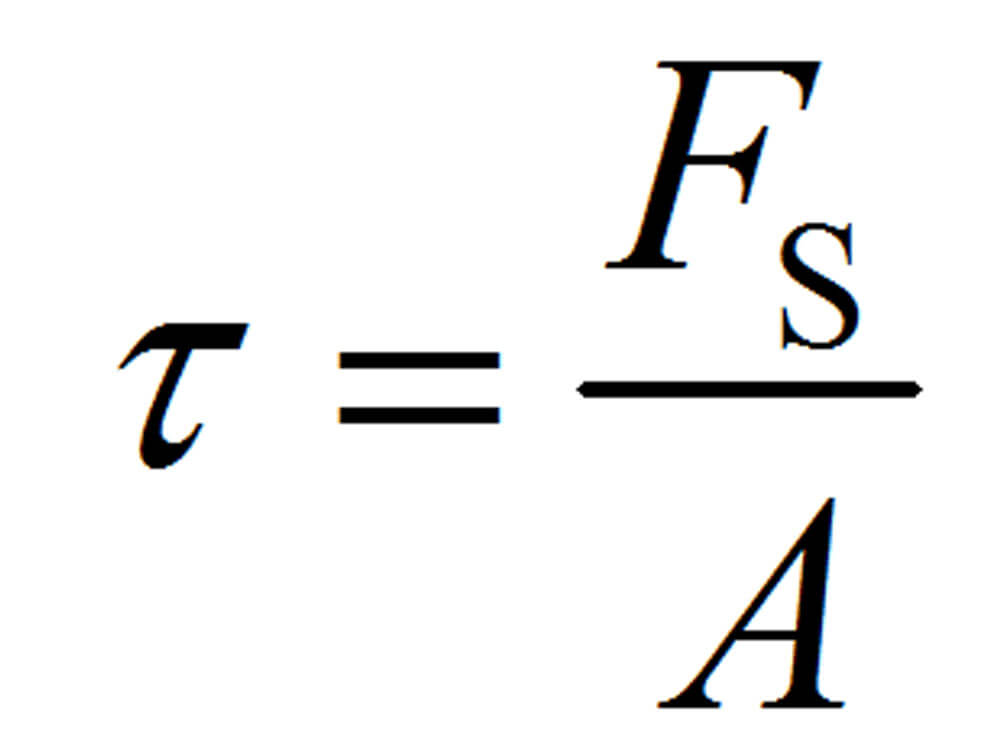

The Role of the Shear Stress Equation in CNC Process Optimization

A Personal Approach to CNC Process Optimization As someone who’s spent years working in the CNC machining field, I’ve come to realize that understanding the

Precision Stainless Steel Grill Designs: Custom Features and Benefits

Introduction to Stainless Steel Grill Stainless Steel Grill are a staple in both residential and commercial cooking, offering durability, sleek aesthetics, and superior cooking performance.

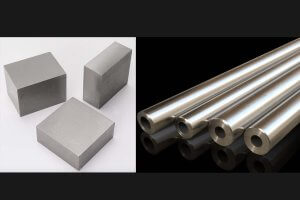

Understanding AISI 4140: The Ultimate Guide for CNC Machinists

Introduction to AISI 4140: A Versatile Alloy Steel When it comes to CNC machining, material selection is crucial, and AISI 4140 stands out as one

Delrin in CNC Machining: The Ultimate Guide for Engineers

Introduction to Delrin and Its Role in CNC Machining Delrin, a high-performance engineering plastic, has become a cornerstone material for industries relying on precision machining.

Ferrous Metals List Explained: A Guide to Material Selection

Understanding Ferrous Metals and Their Importance Ferrous metals are the backbone of modern manufacturing, offering strength, durability, and versatility. If you’re like me, you’ve probably

Precision Machining: Crafting the Future of High-Tolerance Manufacturing

Why Precision Machining Matters in Modern Manufacturing Precision machining is a cornerstone of modern manufacturing. It enables the creation of complex, high-tolerance parts used across

Applications of 18/10 Stainless Steel in CNC Precision Engineering

Why 18/10 Stainless Steel and CNC Precision Engineering Are a Perfect Match When exploring materials for precision manufacturing, 18/10 stainless steel consistently stands out as

What Is a 304 and How CNC Unlocks Its Potential

What Is a 304: Understanding 304 and Its Role in CNC Machining When I first encountered the term “304 stainless steel”, I was struck by

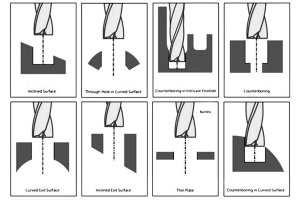

Countersink in CNC Machining: A Complete Guide

Understanding Countersink in CNC Machining In CNC machining, precision isn’t just a feature—it’s a requirement. One critical process that often gets overlooked is the countersink. A

Countersink Bit in CNC Machining: Tips, Techniques, and Tools

The Unsung Hero of CNC Machining In CNC machining, precision is everything. Whether you’re crafting aerospace components, automotive parts, or custom furniture, a tiny misalignment

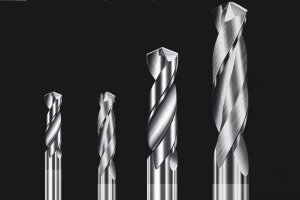

How to Choose the Right Reamer for CNC Precision Machining

The Importance of Choosing the Right Reamer in CNC Precision Machining When it comes to CNC precision machining, choosing the right reamer can make all

How CNC Machining Transforms Stainless Steel Sheet Metal for Industrial Use

The Power of CNC Machining in Shaping Stainless Steel Sheet Metal Stainless steel sheet metal has become a cornerstone material across many industries, prized for

Mini Milling Machine for Beginners: Tips, Tricks, and Techniques

What is a Mini Milling Machine? A mini milling machine is a compact, versatile tool that allows beginners and professionals alike to create intricate parts,

Inconel 625 CNC Machining Best Practices and Cost Analysis

Introduction to Inconel 625 and Its Applications Inconel 625 is a nickel-based superalloy known for its high strength, corrosion resistance, and exceptional performance in high-temperature

Antique Brass Customization with CNC: Best Practices and Tips

Introduction to Antique Brass and Its Applications Antique brass is a sought-after material in fields that value both aesthetic charm and functionality, such as interior

Understanding Counterbore and CNC Techniques Tools and Applications

What is Counterbore and Why Does It Matter in CNC Machining? Counterbore is a term that frequently comes up in machining and manufacturing, especially in

Iron vs Steel: Decoding Their Strengths for Real-World Needs

What Is Iron and Steel? Their Definitions and Basic Properties Iron and steel are two materials that have shaped human civilization for centuries. Iron, a

Metal Engraving Techniques Explained: From CNC to Laser

Introduction: The Art and Science of Metal Engraving with CNC Metal engraving has always been a craft that combines precision, artistry, and functionality. Historically, it

How to Choose the Best Metric Drill Bits for CNC Projects

Why Metric Drill Bits Are Essential in CNC Machining When it comes to CNC machining, precision isn’t just a goal—it’s a requirement. The quality of

What Does Fiberglass Look Like? A Comprehensive Guide for Identification and Application

Why Knowing What Fiberglass Looks Like Matters Fiberglass is a material that has permeated many industries, yet it remains somewhat mysterious to those outside of

Top 5 Techniques for Prototype Manufacturing: CNC Machining, 3D Printing, and More

Introduction: What Is Prototype Manufacturing and Why Is It Important? When I first encountered the term “prototype manufacturing,” I realized it was a turning point

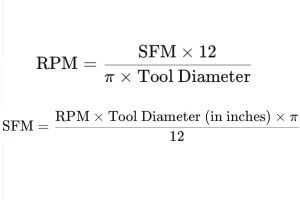

SFM Meaning and Its Importance in CNC Machining for Different Materials

Introduction: What Is SFM and Why Does It Matter in CNC? When I first heard the phrase “sfm meaning” in the context of CNC machining,

Is Brass Magnetic? How to Test, Use, and Identify Brass in Practical Scenarios

Introduction: Why People Ask “Is Brass Magnetic?” “Is brass magnetic?” is a question that seems simple on the surface. I recall the first time I

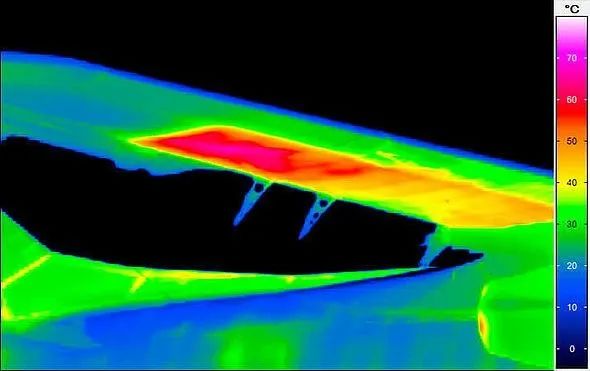

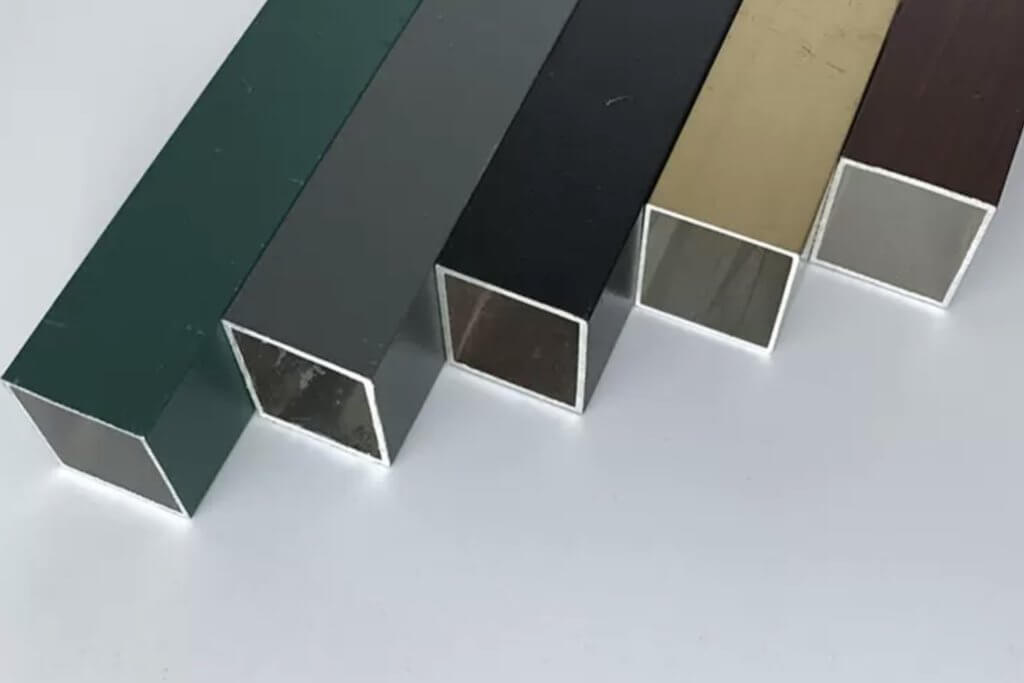

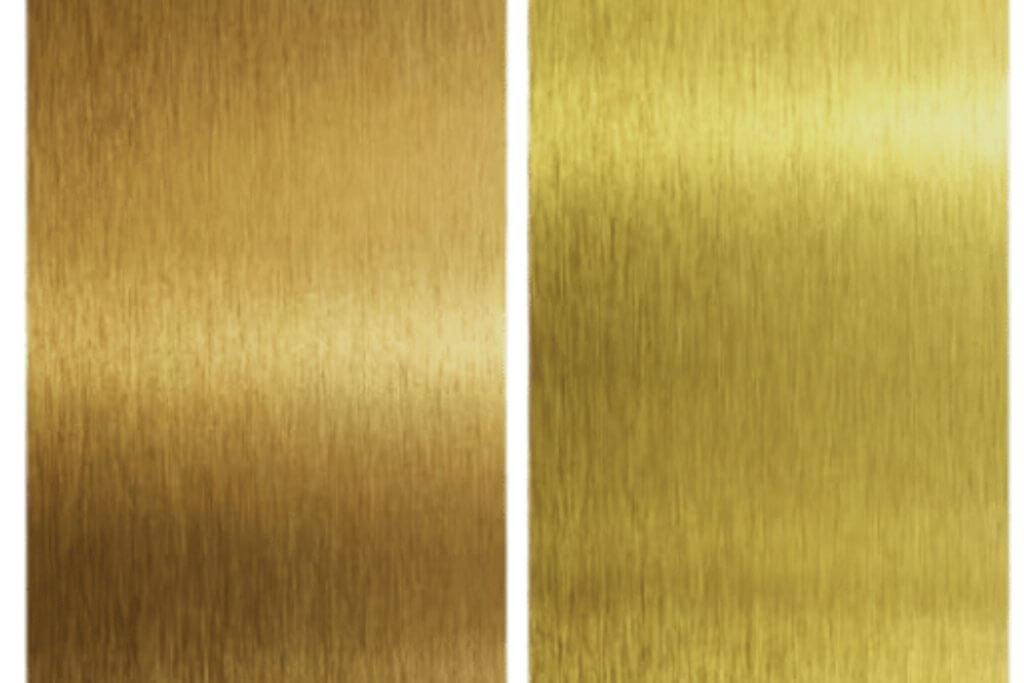

How CNC Machining Enhances Brass Color for Perfect Finishes

Chapter 1: Understanding Brass Color and Its Unique Characteristics I’ve always found the natural appeal of brass color to be something that sparks an immediate

Types of Screws Perfected Through CNC Precision

How CNC Precision Redefines Types of Screws Screws are fundamental components in countless industries, from construction to aerospace. Yet, many people overlook the role that

Unlocking the Secrets of Types of Screws: A Must-Read for Every User

Introduction: Why Knowing Types of Screws Matters Screws are one of those everyday items that most people overlook until they’re needed. But when it comes

How to Choose the Best EDM Machine for Your Manufacturing Needs

Why Choosing the Right EDM Machine Matters When I first explored the world of EDM machines, I quickly realized their transformative potential in modern manufacturing.

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …