Blog

Vertical vs Horizontal CNC Machines: Which Boosts Your Productivity?

Introduction to Vertical and Horizontal CNC Machines Choosing between vertical CNC machining centers (VMCs) and horizontal CNC machining centers (HMCs) is crucial for optimizing production

Low carbon steel in CNC machining offers affordable and reliable solutions

Why Low Carbon Steel Is Ideal for CNC Machining Low carbon steel, often referred to as mild steel, is a versatile material favored across industries

How to Prevent Galling Metal in CNC Machining

Introduction to Galling in Metal Machining In the world of CNC machining, one common challenge is galling—an adhesive wear phenomenon that occurs between metal surfaces

The Ultimate Flange Size Chart for International Standards Comparison

From years of hands-on experience working with flanges in various industries, I can confidently say that choosing the right flange size and standard is one

Comprehensive Guide to CNC Machining: Carbon Steel vs Stainless Steel

Choosing the right material for CNC machining is a crucial decision for any manufacturer or engineer. Two of the most commonly used materials in various

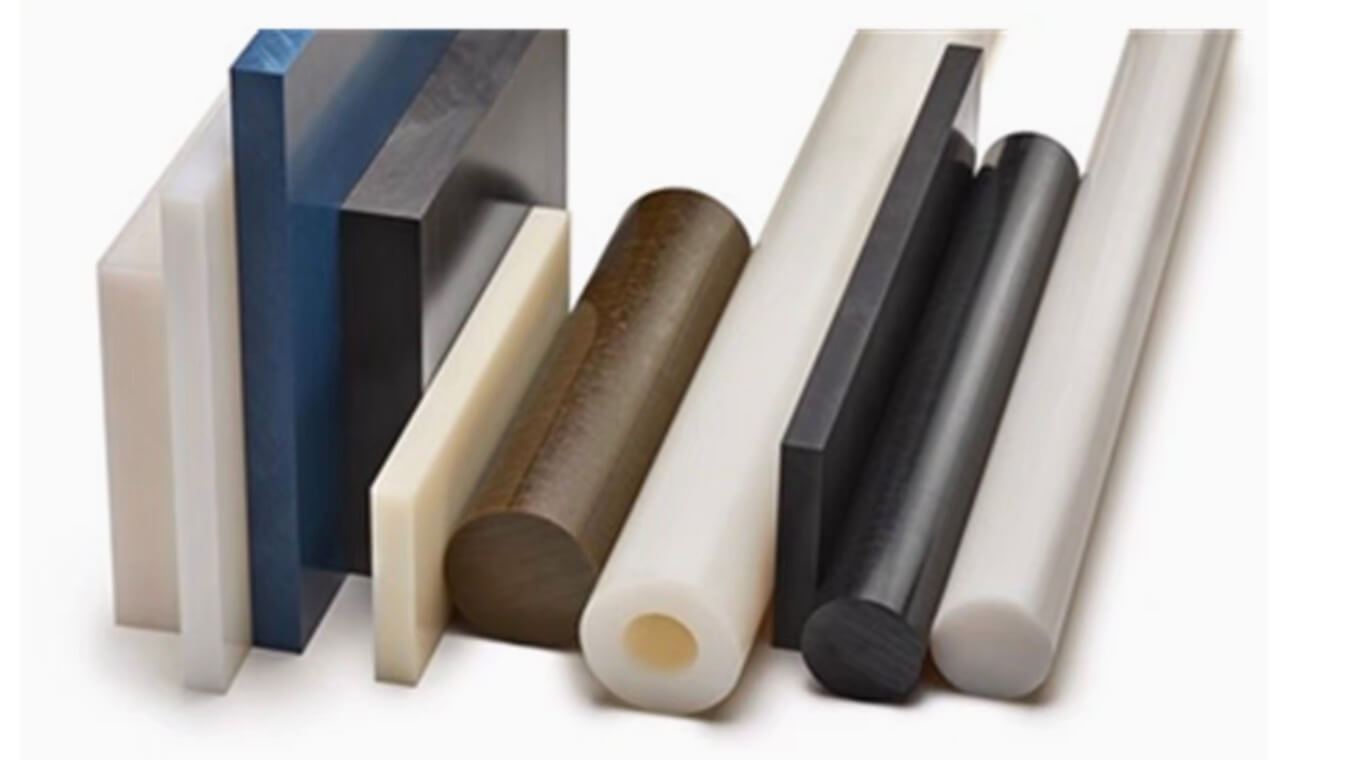

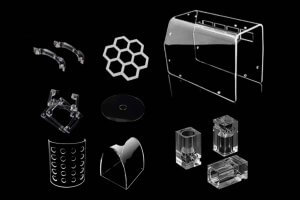

How CNC Machining Delivers Precision in Custom POM Plastic Parts

Working with POM plastic in CNC machining has become a popular choice for manufacturers due to its excellent mechanical properties, low friction, and high dimensional

Why Delrin Is the Ideal Material for CNC Machined Parts

Working with CNC machining over the years has revealed the importance of choosing the right material for precision parts. Delrin, a type of acetal homopolymer,

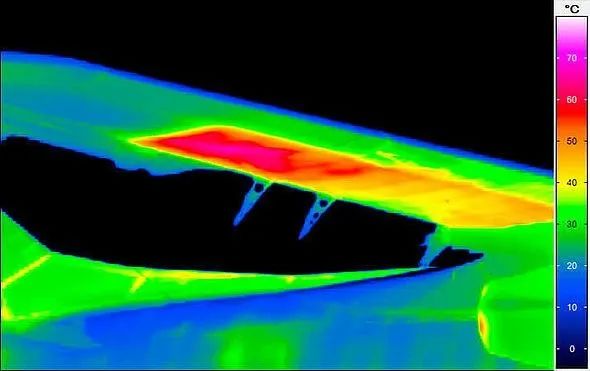

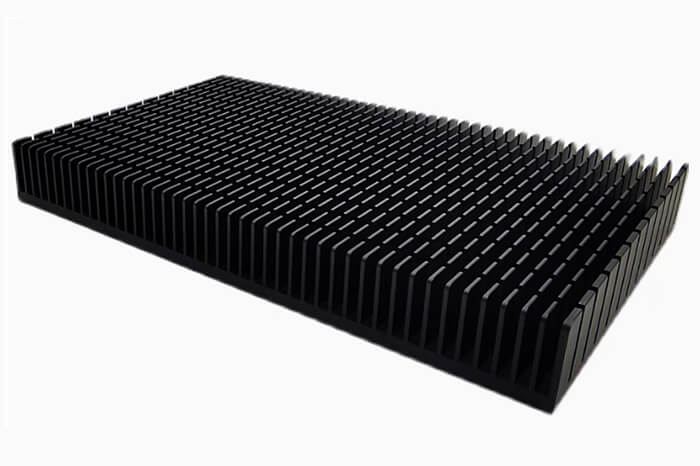

Why Custom Aluminum Heat Sinks Are Best Made with CNC Machining

In today’s advanced electronics and mechanical systems, aluminum heat sinks play a crucial role in thermal management, helping to dissipate heat and maintain optimal operating

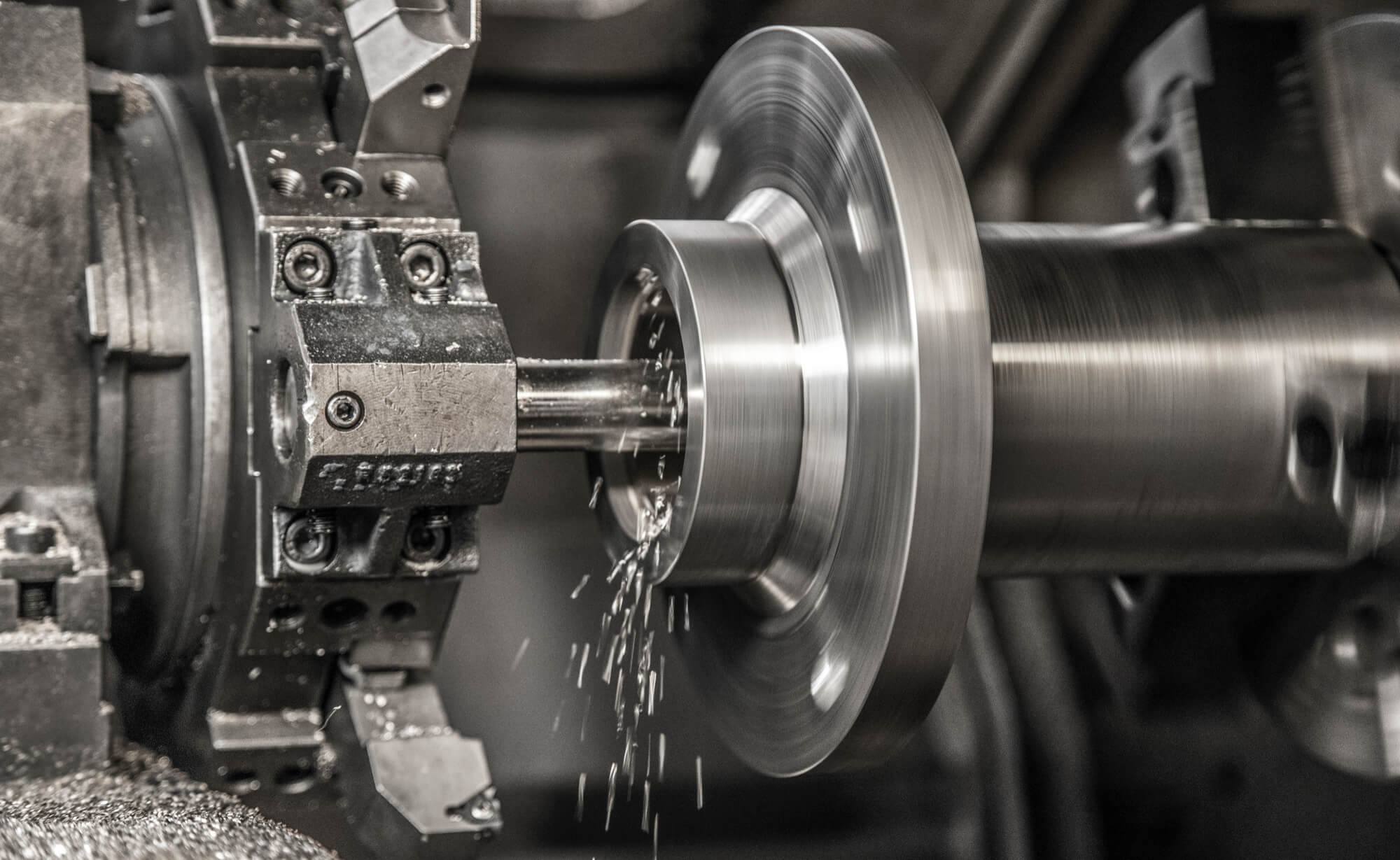

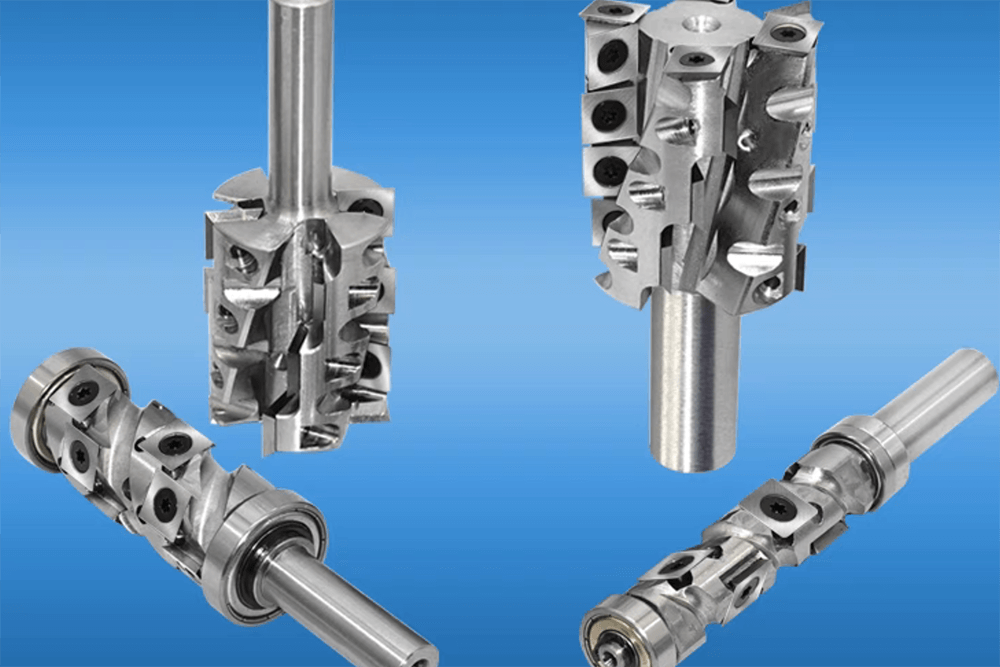

Using Lathe Tools for Complex CNC Machining Parts

In CNC machining, precision and efficiency are crucial. For engineers working on complex parts, choosing the right lathe tools is essential. When dealing with intricate

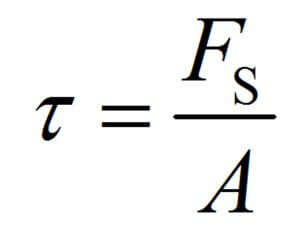

How to Use Shear Stress Formula in CNC Design and Production

In the field of CNC machining, understanding mechanical properties and stresses in materials is crucial for designing parts that can withstand operational loads without failure.

Polyamide vs Polyester: Cost, Durability & CNC Machining Tips

When it comes to CNC machining custom parts, material selection is one of the most critical decisions. Two of the most popular engineering plastics—polyamide (commonly

Choosing the Right Chamfer Bit for Optimal CNC Edge Processing

In the world of CNC machining, precision is everything. Whether you’re crafting complex components for aerospace or simple fixtures for everyday use, the attention to

Comparing Tungsten vs Titanium for Custom Parts with CNC Technology

Introduction In high-performance industries such as aerospace, medical devices, automotive, and defense, selecting the right material is crucial to meeting specific application needs. Two materials

Why Tungsten Alloy Tooling is Critical for CNC Suppliers Handling Tough Materials

Introduction In modern manufacturing, the ability to machine tough materials like titanium, stainless steel, and high-strength alloys is a significant competitive advantage for CNC suppliers.

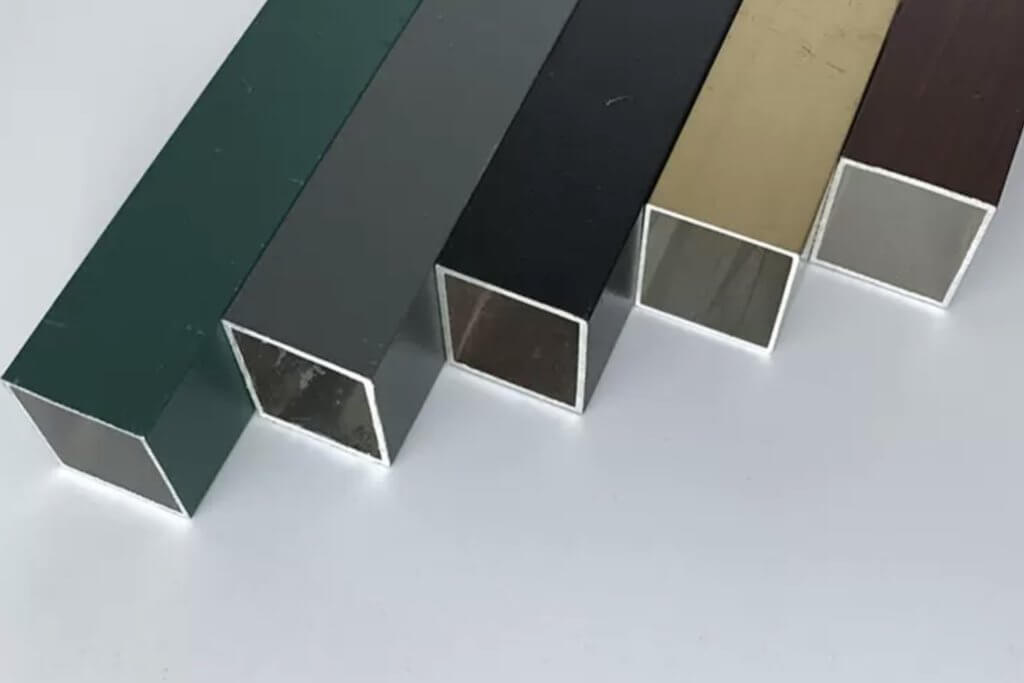

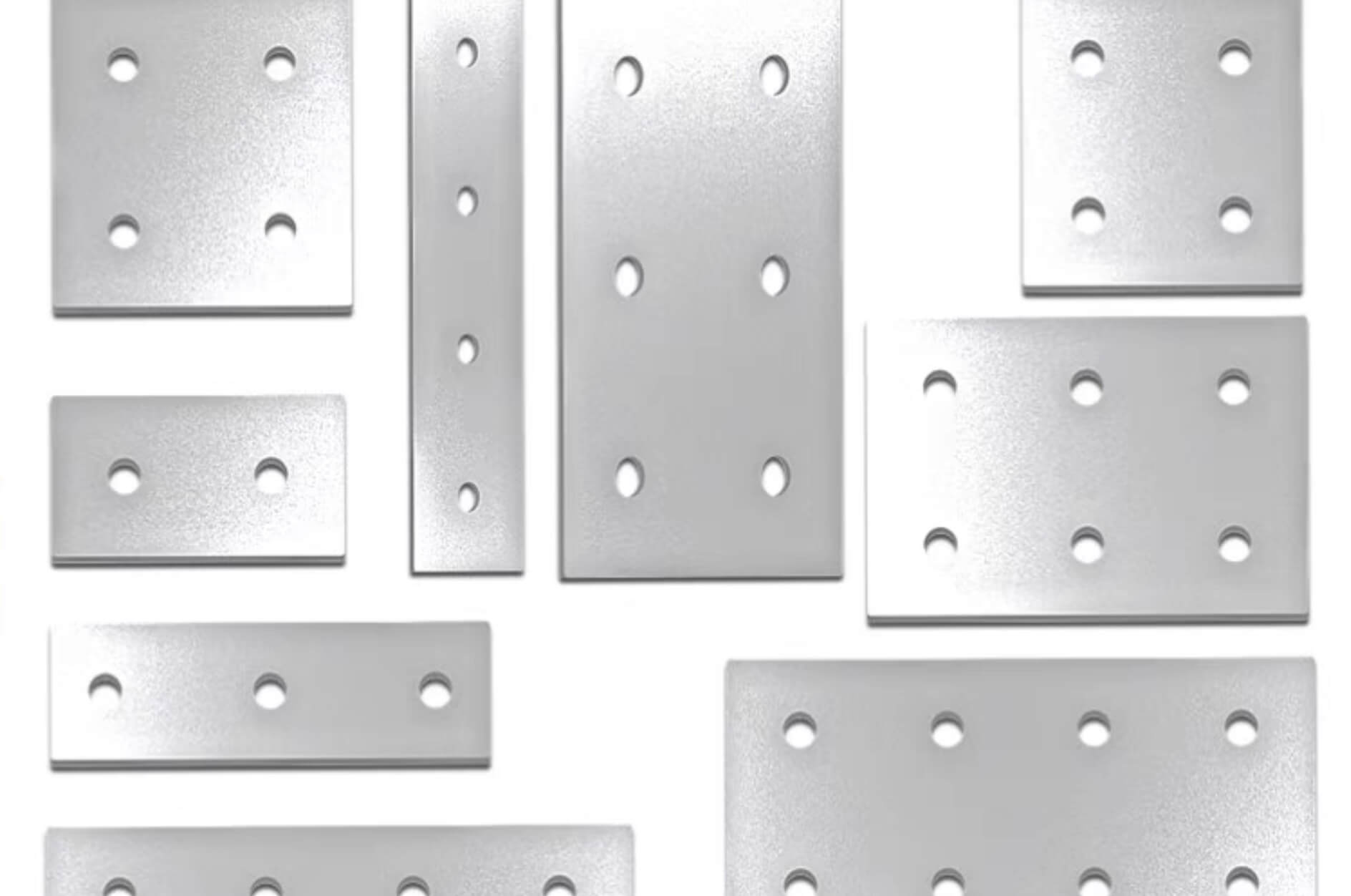

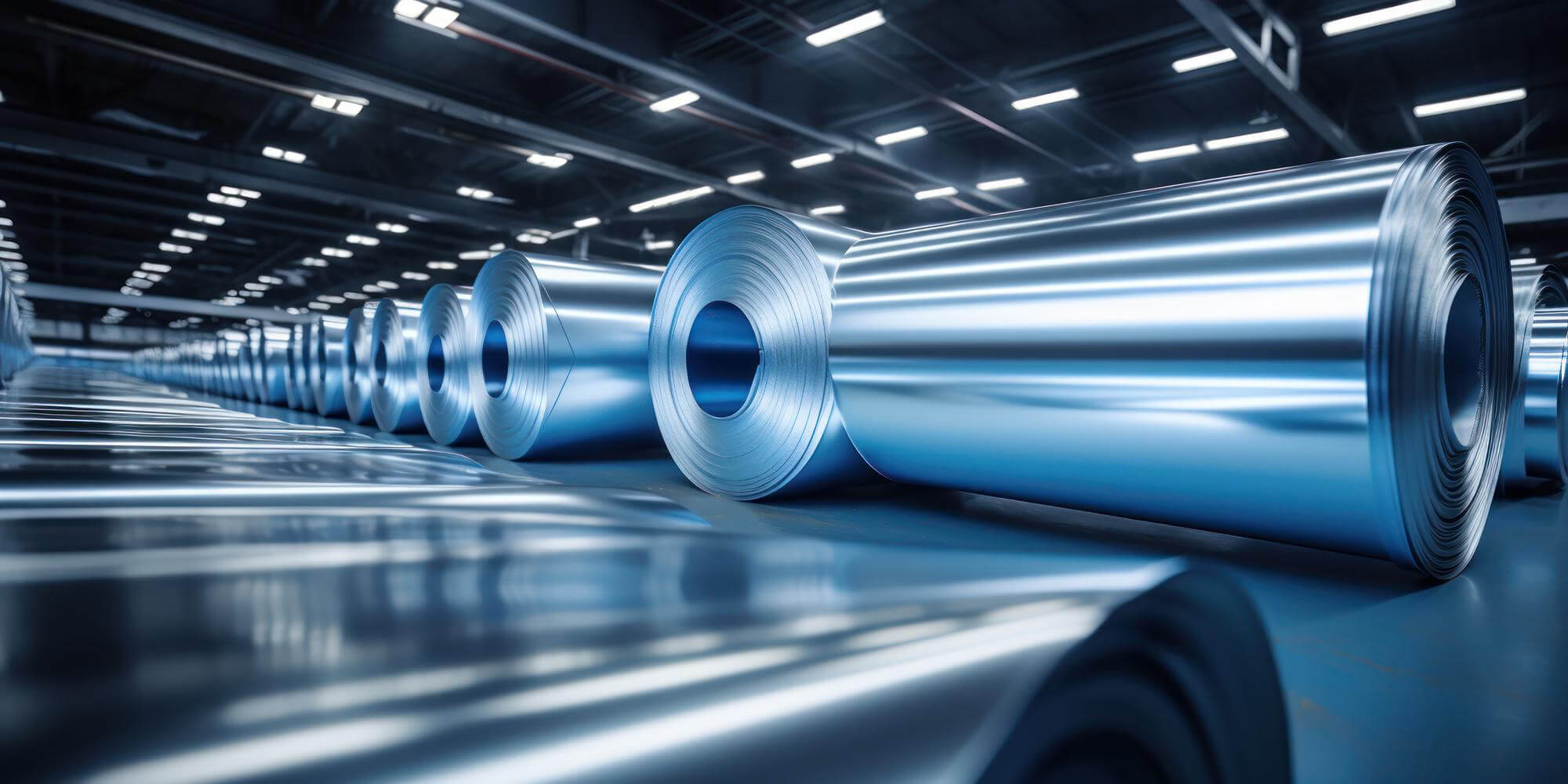

Optimizing Your Supply Chain with CNC Customized Aluminum Sheet Components

Introduction In today’s competitive manufacturing environment, efficiency and precision are key to meeting market demands. Custom aluminum sheet components play a critical role in many

Motor Shaft Customization: Why CNC Machining is the Best Option

The Importance of Customizing Motor Shafts for Precision and Efficiency Motor shafts are the heart of any machine that involves rotation. They are used in

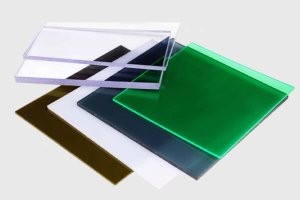

Polycarbonate Roofing and CNC: A Comprehensive Guide to Efficient Production

Why Polycarbonate Roofing Is in High Demand Polycarbonate roofing has become a popular choice in construction due to its durability, energy efficiency, and ability to

Why Polycarbonat Excels in CNC Applications

The Intersection of Polycarbonat and CNC Machining Polycarbonat, a versatile and highly durable thermoplastic, has revolutionized modern manufacturing. Combining excellent strength, optical clarity, and processability,

What is a CV Joint and How CNC Machining Improves Its Production

The CV Joint, or Constant Velocity Joint, is a critical component in modern automotive drivetrains, especially in vehicles with front-wheel drive (FWD) or all-wheel drive

What is a CV Shaft and How CNC Machining Enhances Its Production

Introduction to the CV Shaft A CV Shaft (Constant Velocity Shaft) is a critical component in the drivetrain of many vehicles, especially in front-wheel drive

What is a Steering Shaft and How Does CNC Technology Improve Its Manufacturing

Introduction: The Backbone of a Vehicle’s Steering System When I first entered the manufacturing world, I was fascinated by the complexity of even the most

The Role of the Shear Stress Equation in CNC Process Optimization

A Personal Approach to CNC Process Optimization As someone who’s spent years working in the CNC machining field, I’ve come to realize that understanding the

Precision Stainless Steel Grill Designs: Custom Features and Benefits

Introduction to Stainless Steel Grill Stainless Steel Grill are a staple in both residential and commercial cooking, offering durability, sleek aesthetics, and superior cooking performance.

Understanding AISI 4140: The Ultimate Guide for CNC Machinists

Introduction to AISI 4140: A Versatile Alloy Steel When it comes to CNC machining, material selection is crucial, and AISI 4140 stands out as one

Delrin in CNC Machining: The Ultimate Guide for Engineers

Introduction to Delrin and Its Role in CNC Machining Delrin, a high-performance engineering plastic, has become a cornerstone material for industries relying on precision machining.

Ferrous Metals List Explained: A Guide to Material Selection

Understanding Ferrous Metals and Their Importance Ferrous metals are the backbone of modern manufacturing, offering strength, durability, and versatility. If you’re like me, you’ve probably

Precision Machining: Crafting the Future of High-Tolerance Manufacturing

Why Precision Machining Matters in Modern Manufacturing Precision machining is a cornerstone of modern manufacturing. It enables the creation of complex, high-tolerance parts used across

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

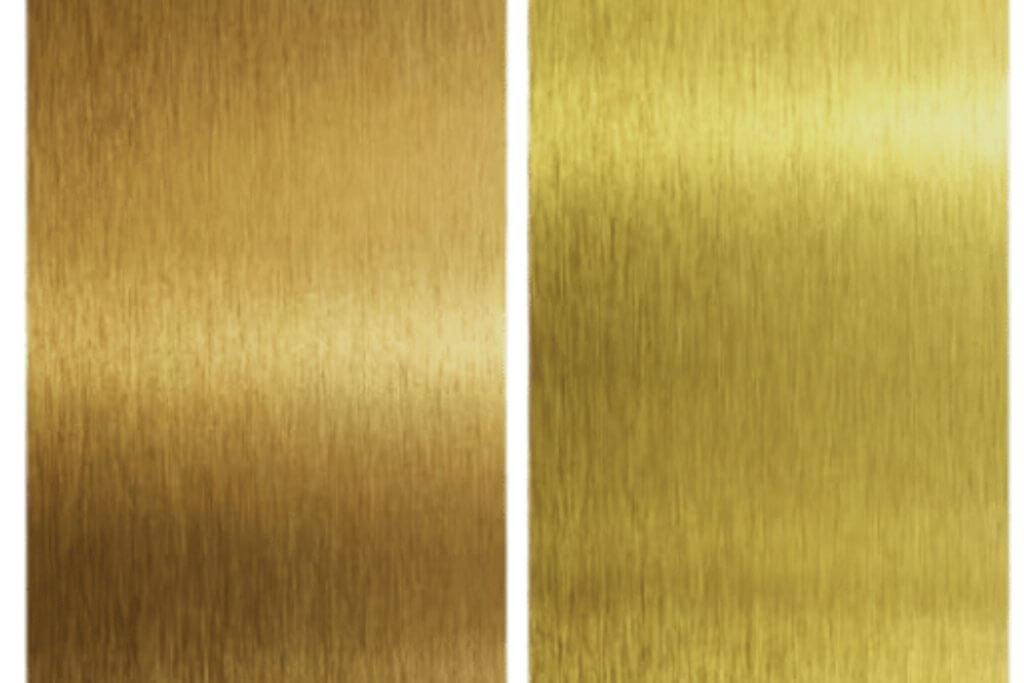

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …