Blog

Top 5 Desktop CNC Milling Machines

Desktop CNC milling machines are compact and powerful tools for prototyping or small-scale fabrication work. They enable users to create precise parts using various materials,

How to Machining Custom Wheel Bearing with CNC Precision

Introduction Wheel bearings are critical components in vehicles, ensuring that the wheels rotate smoothly and can support the weight of the vehicle. These bearings are

Precision PVC Flange Customization with CNC Technology

Introduction PVC flanges are essential components in various industries, including water treatment, chemical processing, agriculture, and construction. They serve as connectors that ensure the secure

How Custom Metal Parts Are Made with CNC Technology

Introduction How Custom Metal Parts Are Made with CNC Technology In today’s manufacturing landscape, custom metal parts are essential components across a variety of industries.

Global Metal Material Standards Comparison Table for CNC Machining

In the world of precision manufacturing, CNC machining plays a pivotal role across various industries, from aerospace and automotive to medical devices and consumer electronics. One of

What is Grinding: Definition, Methods & Applications?

The Concept and History of Grinding Technology Introduction Grinding is one of the most critical processes in modern manufacturing, especially for achieving high levels of

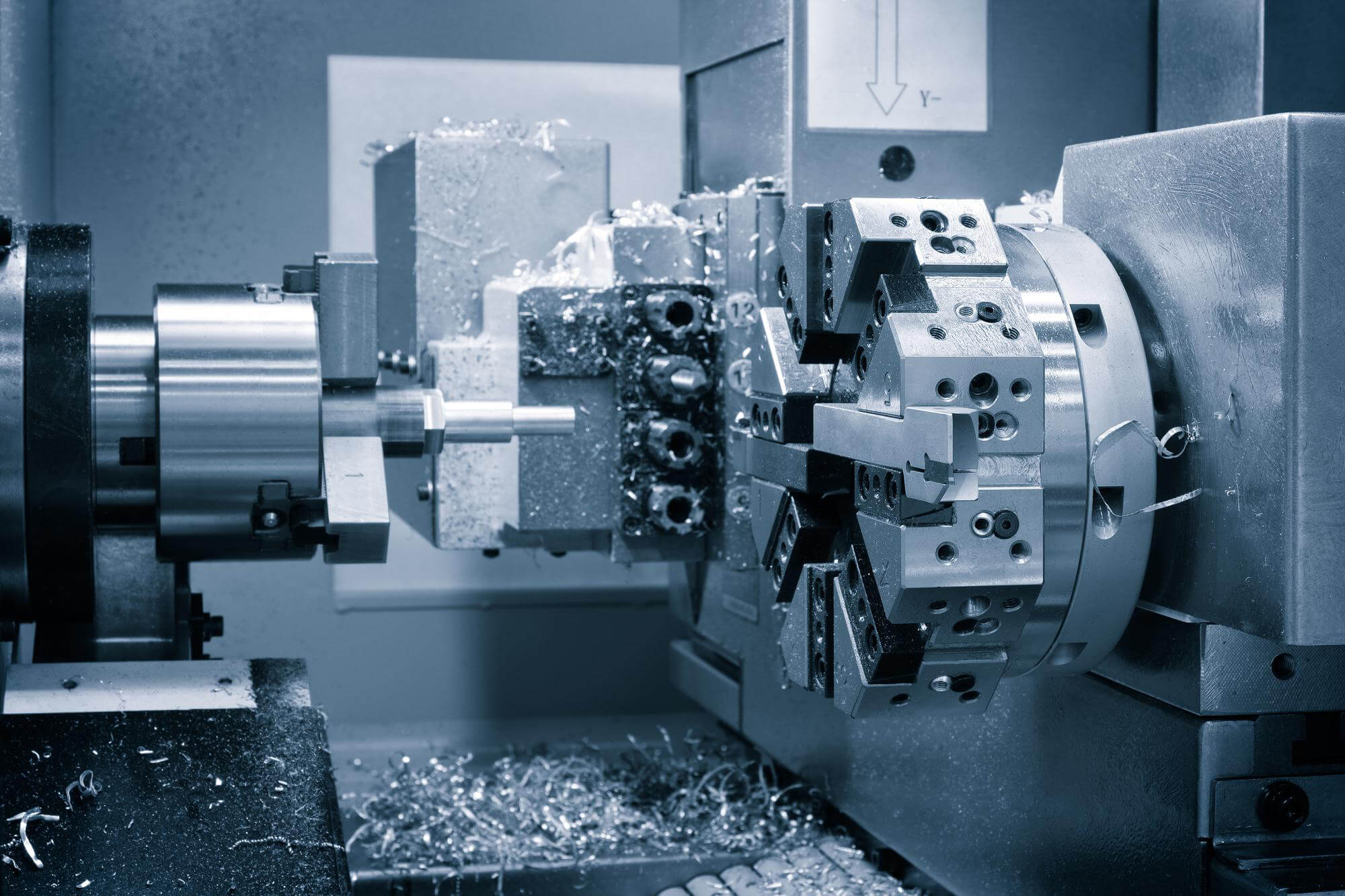

What is a Lathe and How is it Used

What is a Lathe and Why is it Important? What is a Lathe? A lathe is one of the oldest and most versatile machine tools

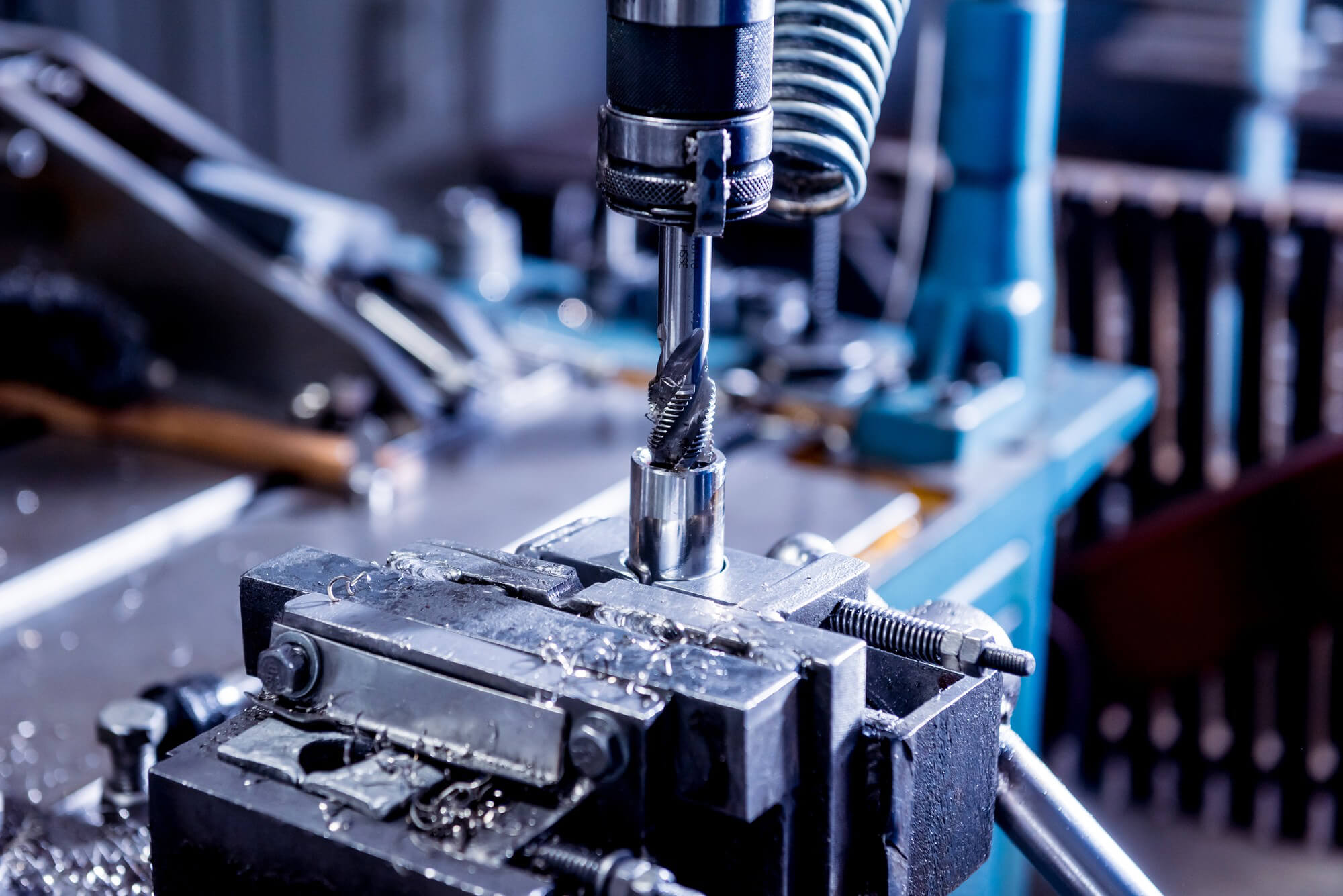

What is CNC Drilling: Types, Process & Key Techniques?

What is CNC Drilling Technology? CNC (Computer Numerical Control) drilling is a precise and automated manufacturing process used to create holes in various materials with

Is Titanium Lighter Than Aluminum in the World of CNC Machining

Introduction In the world of manufacturing, particularly in CNC machining, the choice of material plays a pivotal role in the performance, cost, and durability of

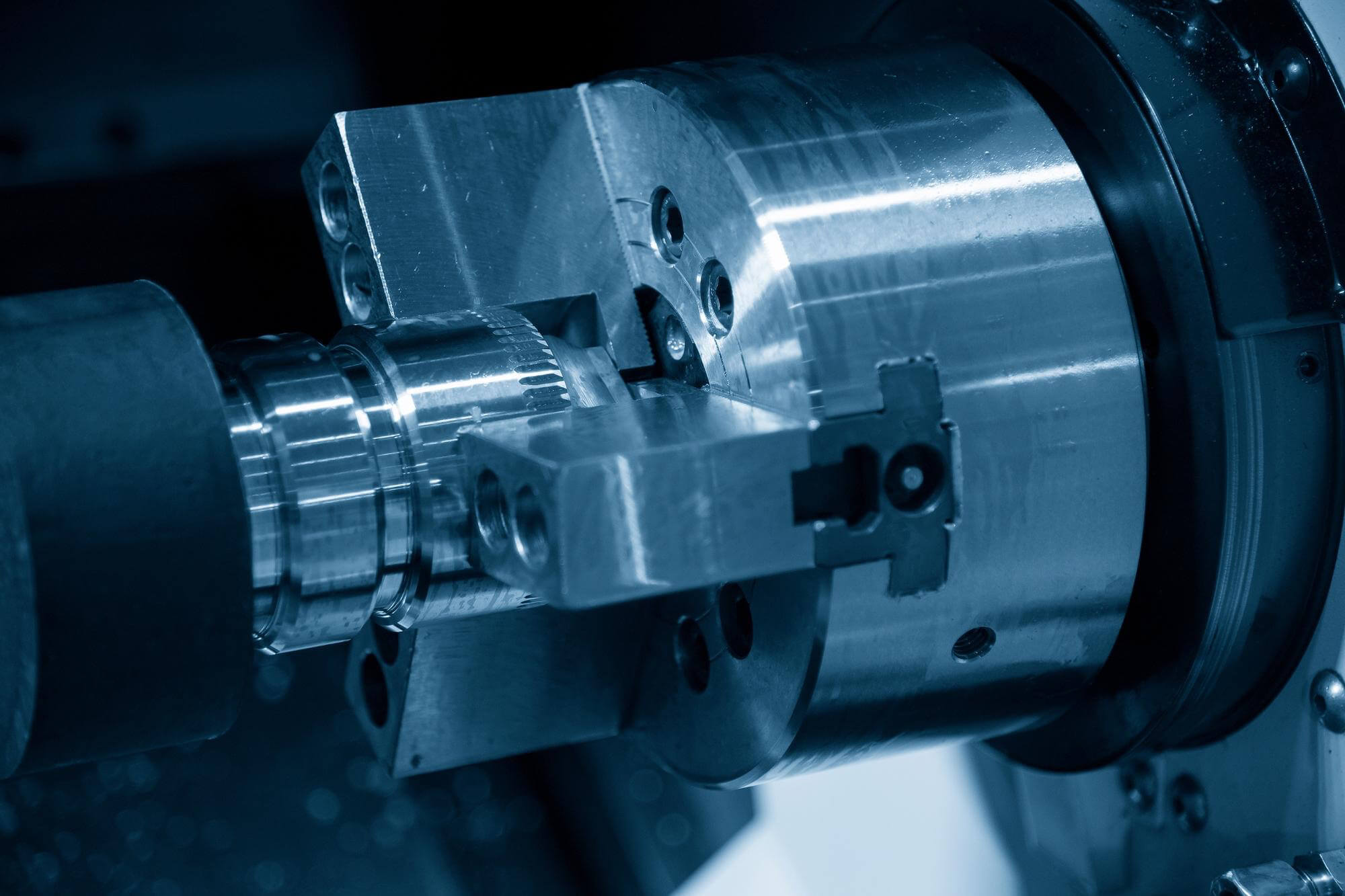

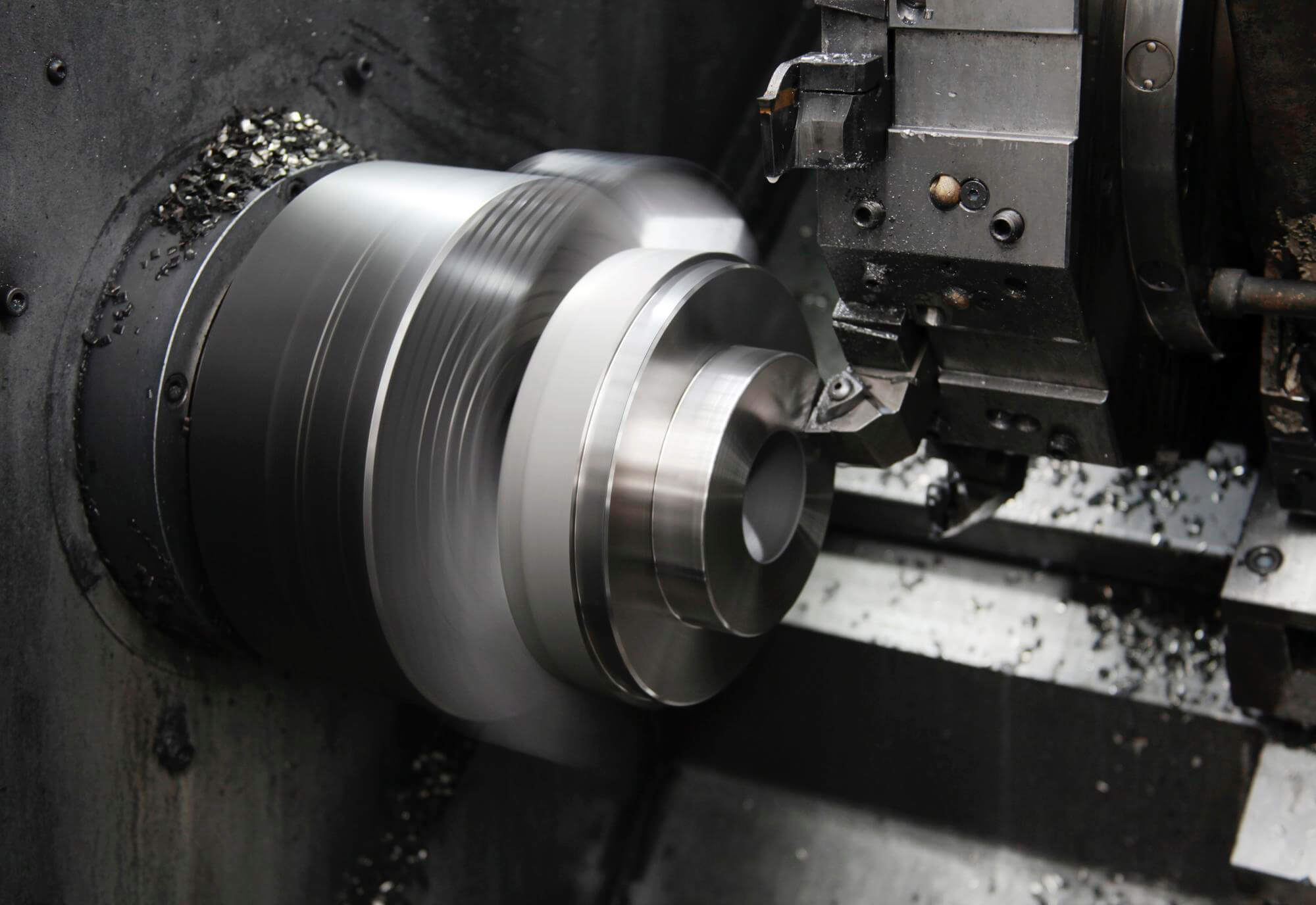

What is CNC Turning: Definition, Process & Applications

What is CNC Turning Technology? CNC (Computer Numerical Control) turning is a machining process where a cutting tool, typically a non-rotary tool bit, removes material

Crafting Custom Bolts with CNC Machining and Exploring Screw Innovation

The precision and reliability of custom bolts are critical in industries such as aerospace, automotive, and construction. With the increasing complexity of modern engineering, standard

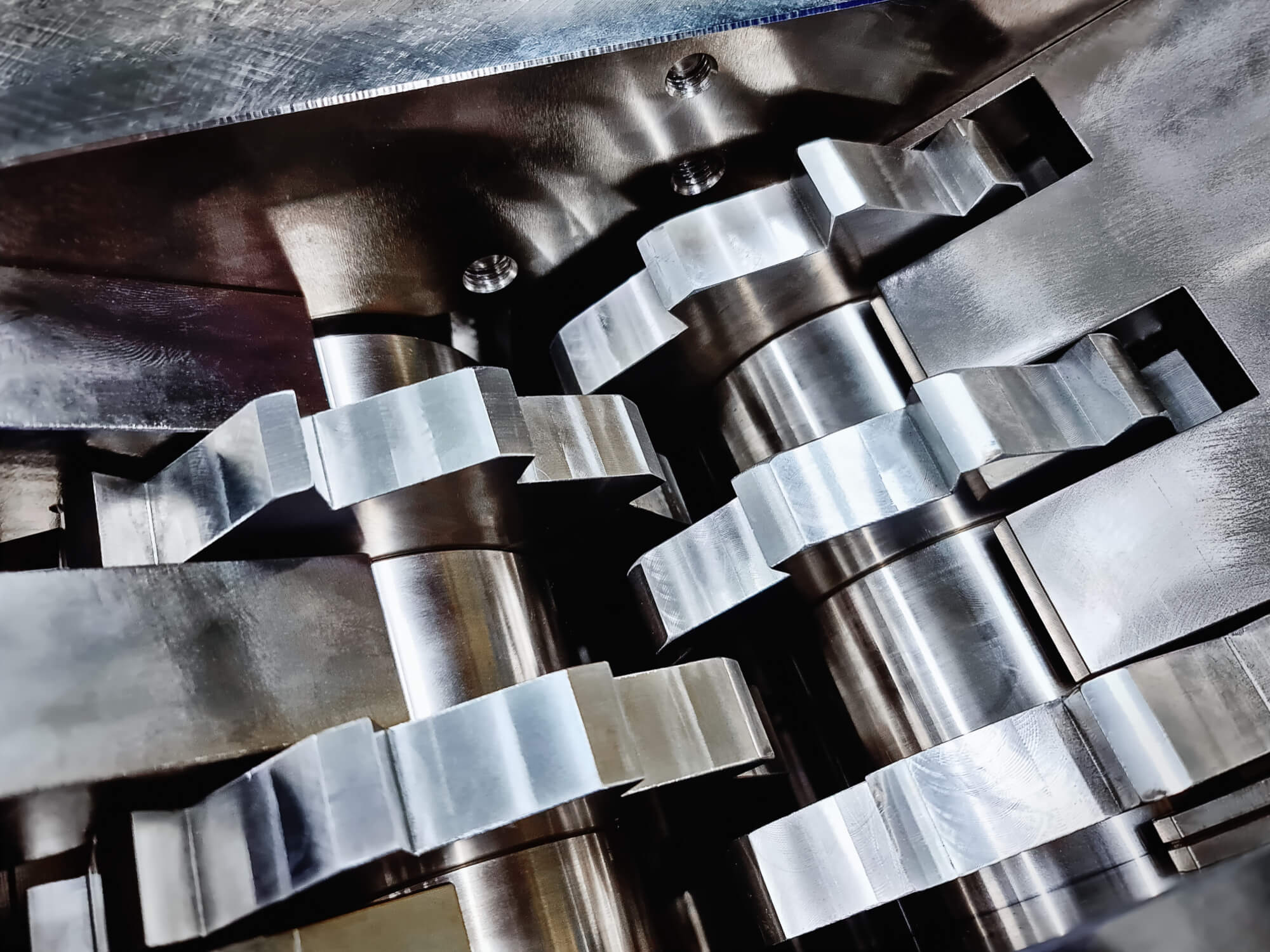

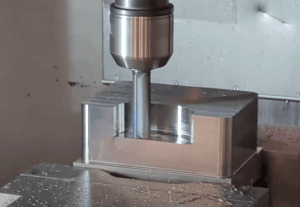

What is CNC Milling: Types, Processes & Benefits

What is CNC Milling? How Does it Differ from Traditional Milling? Milling is one of the most versatile machining processes used to manufacture parts with

Thermoset vs Thermoplastic Who Dominates CNC Machining

Introduction In the world of manufacturing, especially for buyers looking to source plastic components, material selection is crucial. Two types of plastics dominate the discussion:

Optimizing Steel Plates for Welding Through CNC Machining

In the manufacturing industry, precision and reliability are critical, especially when dealing with materials like stainless steel. For companies that require custom steel plates for

Titanium vs Steel Choosing the Right Material for CNC Machining

A Brief Introduction to the Importance of Titanium and Steel in Manufacturing In the modern world, manufacturing has become the backbone of economic development, driving

Applications of 18/10 Stainless Steel in CNC Precision Engineering

Why 18/10 Stainless Steel and CNC Precision Engineering Are a Perfect Match When exploring materials for precision manufacturing, 18/10 stainless steel consistently stands out as

What Is a 304 and How CNC Unlocks Its Potential

What Is a 304: Understanding 304 and Its Role in CNC Machining When I first encountered the term “304 stainless steel”, I was struck by

Countersink in CNC Machining: A Complete Guide

Understanding Countersink in CNC Machining In CNC machining, precision isn’t just a feature—it’s a requirement. One critical process that often gets overlooked is the countersink. A

Countersink Bit in CNC Machining: Tips, Techniques, and Tools

The Unsung Hero of CNC Machining In CNC machining, precision is everything. Whether you’re crafting aerospace components, automotive parts, or custom furniture, a tiny misalignment

How to Choose the Right Reamer for CNC Precision Machining

The Importance of Choosing the Right Reamer in CNC Precision Machining When it comes to CNC precision machining, choosing the right reamer can make all

How CNC Machining Transforms Stainless Steel Sheet Metal for Industrial Use

The Power of CNC Machining in Shaping Stainless Steel Sheet Metal Stainless steel sheet metal has become a cornerstone material across many industries, prized for

Mini Milling Machine for Beginners: Tips, Tricks, and Techniques

What is a Mini Milling Machine? A mini milling machine is a compact, versatile tool that allows beginners and professionals alike to create intricate parts,

Inconel 625 CNC Machining Best Practices and Cost Analysis

Introduction to Inconel 625 and Its Applications Inconel 625 is a nickel-based superalloy known for its high strength, corrosion resistance, and exceptional performance in high-temperature

Antique Brass Customization with CNC: Best Practices and Tips

Introduction to Antique Brass and Its Applications Antique brass is a sought-after material in fields that value both aesthetic charm and functionality, such as interior

Choosing Between Bronze vs Brass for CNC Applications

Introduction to Bronze vs Brass in CNC Machining When selecting materials for CNC machining, bronze vs brass is a common comparison for machinists and designers

Master Mold Creation: CNC Techniques and Tips

What is a Master Mold and Its Role in Manufacturing In the manufacturing world, a master mold is a critical component that serves as a

How to Make Silicone Molds with CNC: A Complete Guide

Why Choose Silicone Molds and the Role of CNC Technology Creating high-quality silicone molds can be a game-changer in prototyping and small-batch production. Silicone molds

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …