Blog

Advanced Peck Drilling Methods for Precision CNC Machining Parts

Peck drilling, also known as intermittent feed drilling, is an essential technique in the world of CNC machining. It uses fixed cycles, such as G83

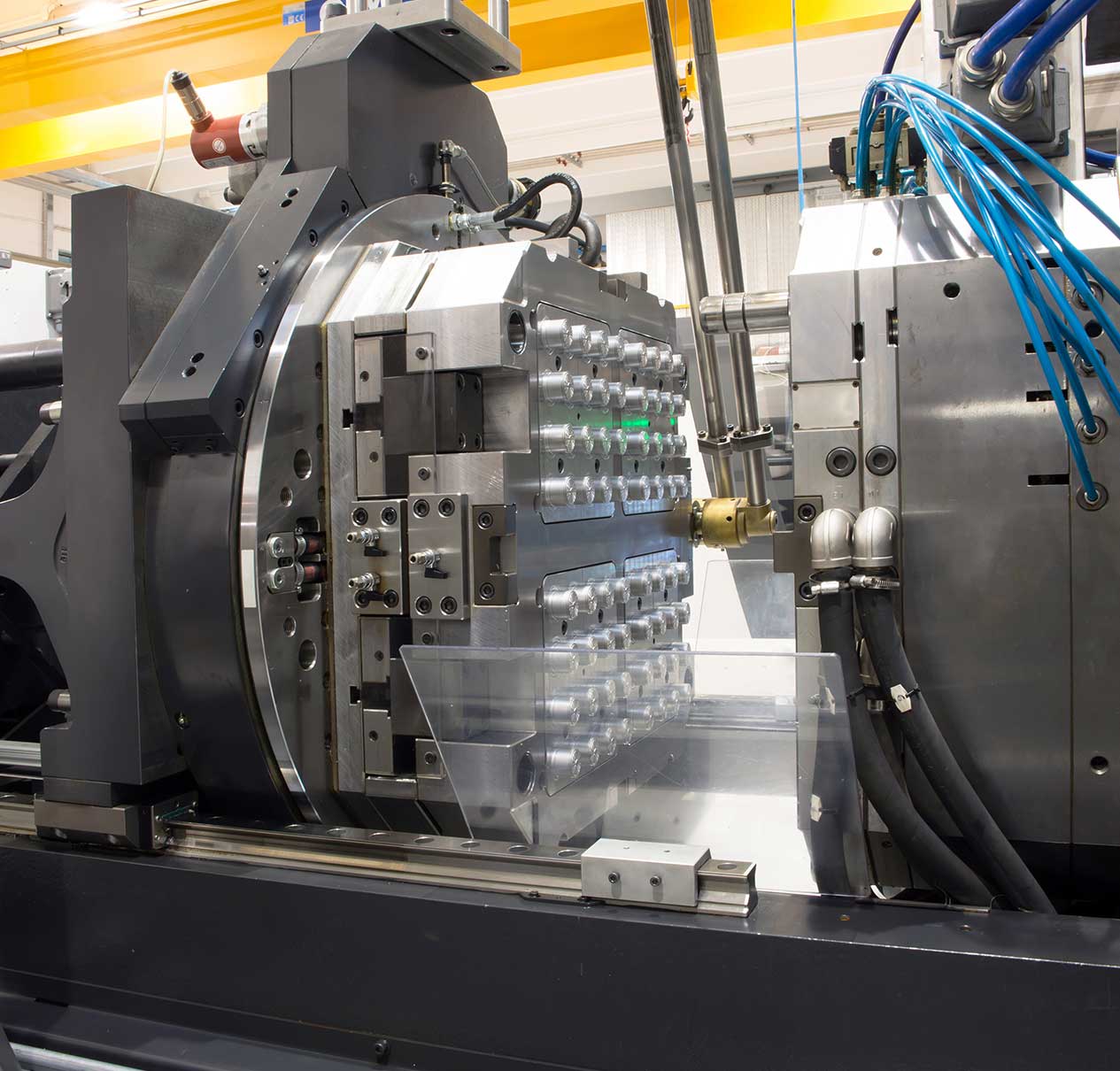

Comparative Analysis: Injection Molding vs. Transfer Molding – Which Technique is Superior?

Plastic and rubber parts are a common sight in the industry. Most of these parts are made through molding techniques, with injection and transfer molding

High-Speed CNC Machining Parts: The Secret Sauce of Tool Material Selection

To high-speed CNC machining, the selection of tool materials is crucial. Imagine you’re a chef preparing a gourmet meal; the ingredients you choose will significantly

Heat Treatment Insights for Wrought Aluminum Alloys in CNC Machining Parts

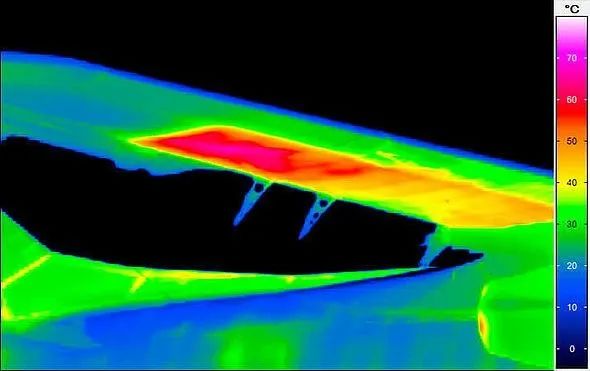

In the field of CNC machining, achieving the desired mechanical and physical properties often hinges on effective heat treatment. For wrought aluminum alloys, which are

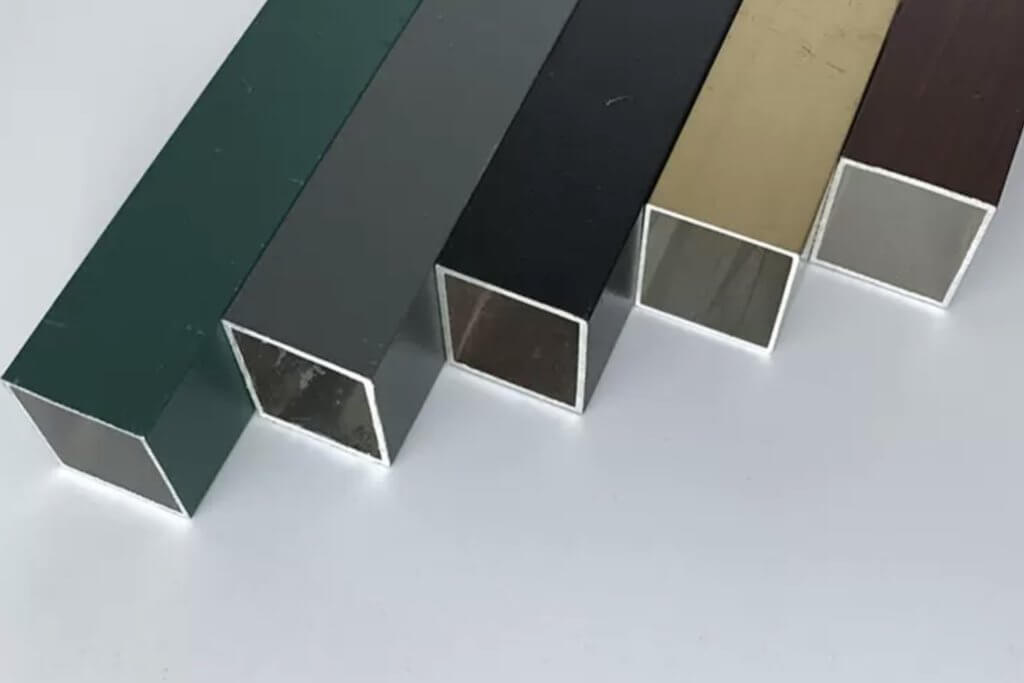

Revealing the Annealing Process of Copper and Alloys in CNC Machining Parts

In the realm of CNC machined parts, achieving the perfect balance of strength, flexibility, and durability often requires meticulous heat treatment processes. One such crucial

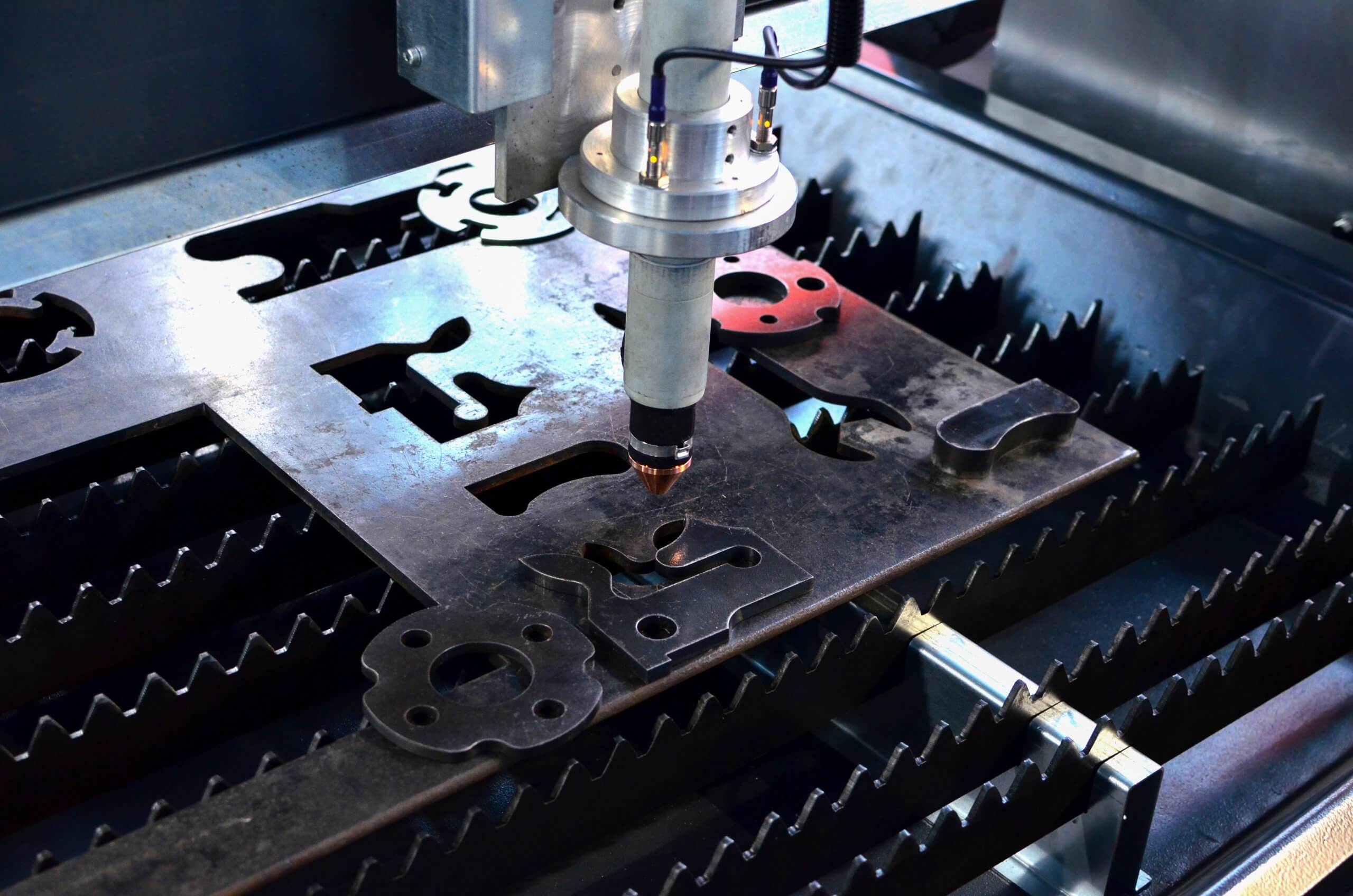

CNC Machining and Sheet Metal Processing in the Automotive Industry: Driving Innovation and Precision

Since its beginnings in the 1860s, the automotive industry has built itself on continuous innovation and technology advancements. One of the most significant drivers of

High-Speed Cutting in CNC Machining Parts: The Power of TiC(N)-Based Hard Alloys

To CNC machining, the choice of tool material is crucial, especially for high-speed cutting. TiC(N)-based hard alloys have emerged as a game-changer, offering a unique

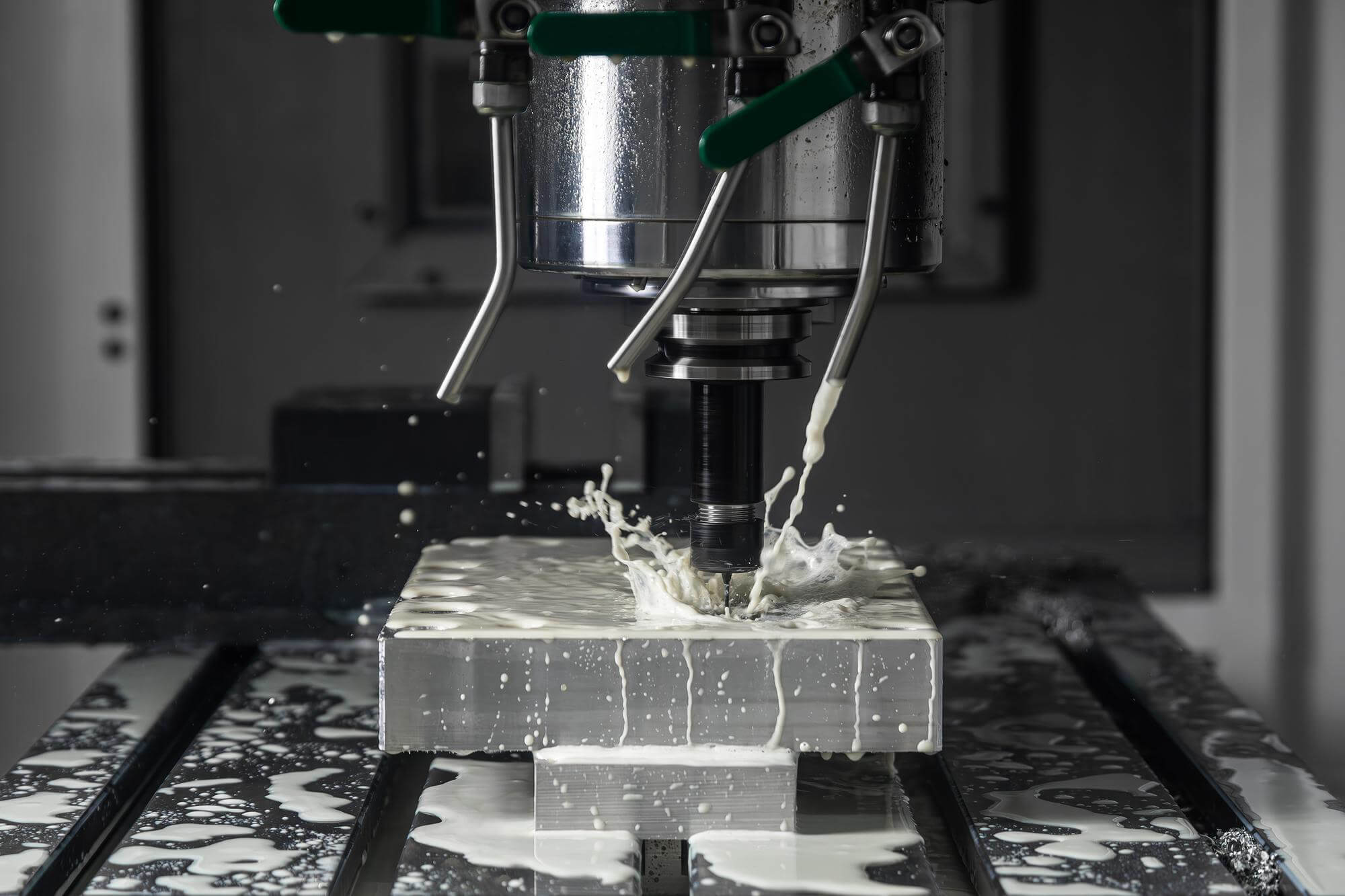

Exploring the Wonders of Cutting Fluids in CNC Machining Parts

Cutting fluids play a crucial role in the world of CNC machining, and their significance cannot be overstated. Whether it’s reducing friction and wear, cooling

Casting: The Magic of Metal Shaping

Metal products are everywhere in our daily lives. From lamps and kitchen utensils to cars and skyscrapers, metal manufacturing processes are integral to our existence.

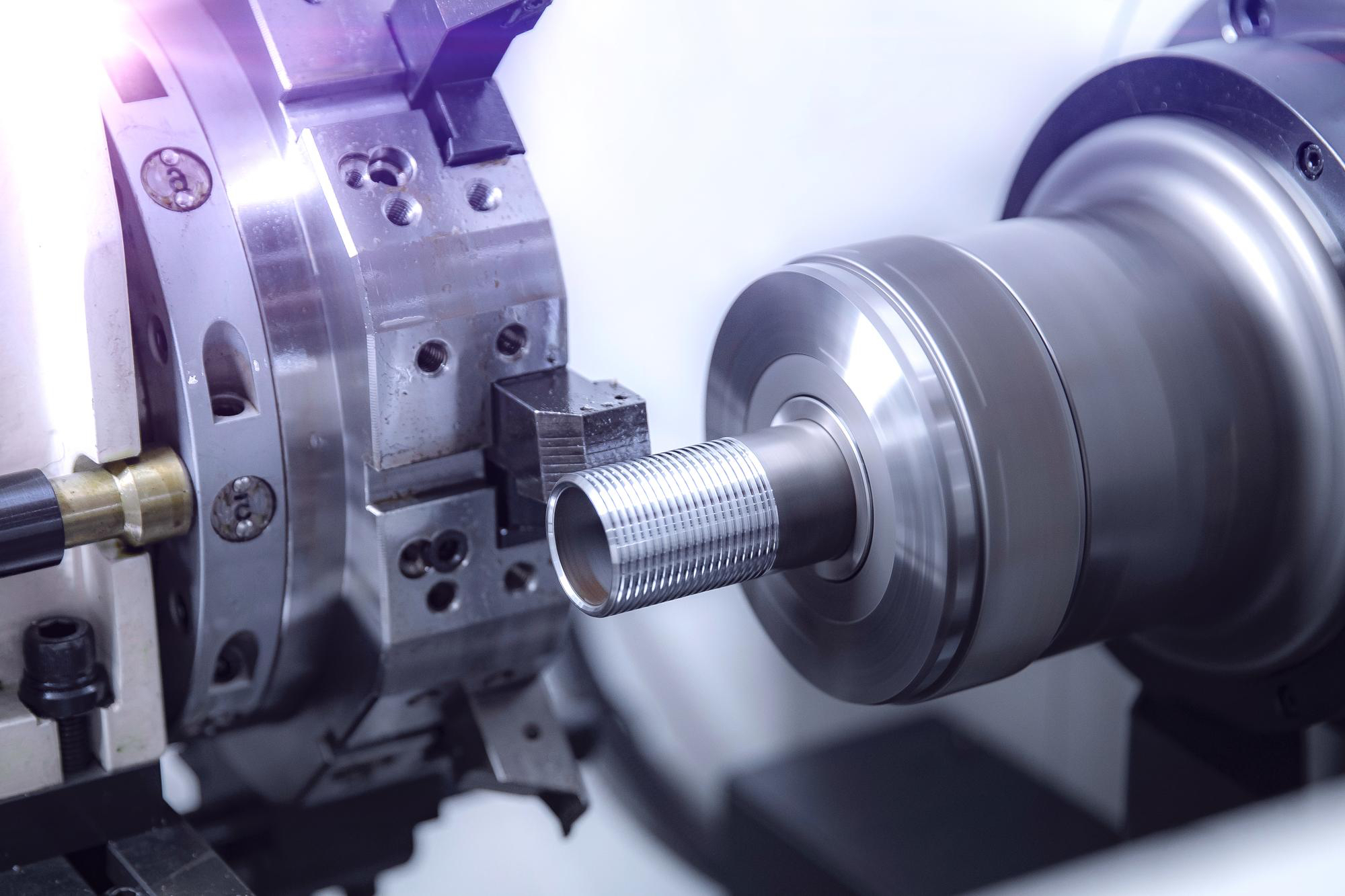

G32 Programming and Manual Threading in CNC Machining

When it comes to CNC machining, threading is one of those tasks where precision is paramount. Most of the time, the G76 threading cycle is

Unlocking the Secrets of Thread Insertion in CNC Machining Parts

When it comes to CNC machining, thread insertion methods are crucial for ensuring high-quality results. Different approaches to thread insertion can significantly impact the efficiency,

Waterjet Cutting: A Comprehensive Guide

Waterjet cutting is a fascinating and versatile technology that’s widely used across various industries due to its precision, efficiency, and environmental benefits. This article will

The Versatility and Precision of Waterjet Cutting

Waterjet cutting stands as a testament to the marvels of modern manufacturing. This innovative technology harnesses the power of high-pressure water streams to slice through

Precision CNC Machining for Medical Devices: Titanium and Stainless Steel

Precision CNC Machining for Medical Devices: Titanium and Stainless Steel The field of CNC machining plays an essential role in the medical device industry. It

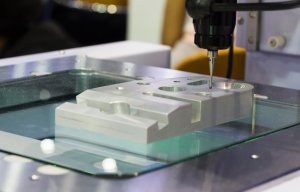

Precision Machining: The Foundation of Modern Industry

Our world is surrounded by rapidly advancing complex technologies. In our daily lives, we see many intricate parts, such as gears and internal components of

What is a Lathe and How is it Used

What is a Lathe and Why is it Important? What is a Lathe? A lathe is one of the oldest and most versatile machine tools

What is CNC Drilling: Types, Process & Key Techniques?

What is CNC Drilling Technology? CNC (Computer Numerical Control) drilling is a precise and automated manufacturing process used to create holes in various materials with

Is Titanium Lighter Than Aluminum in the World of CNC Machining

Introduction In the world of manufacturing, particularly in CNC machining, the choice of material plays a pivotal role in the performance, cost, and durability of

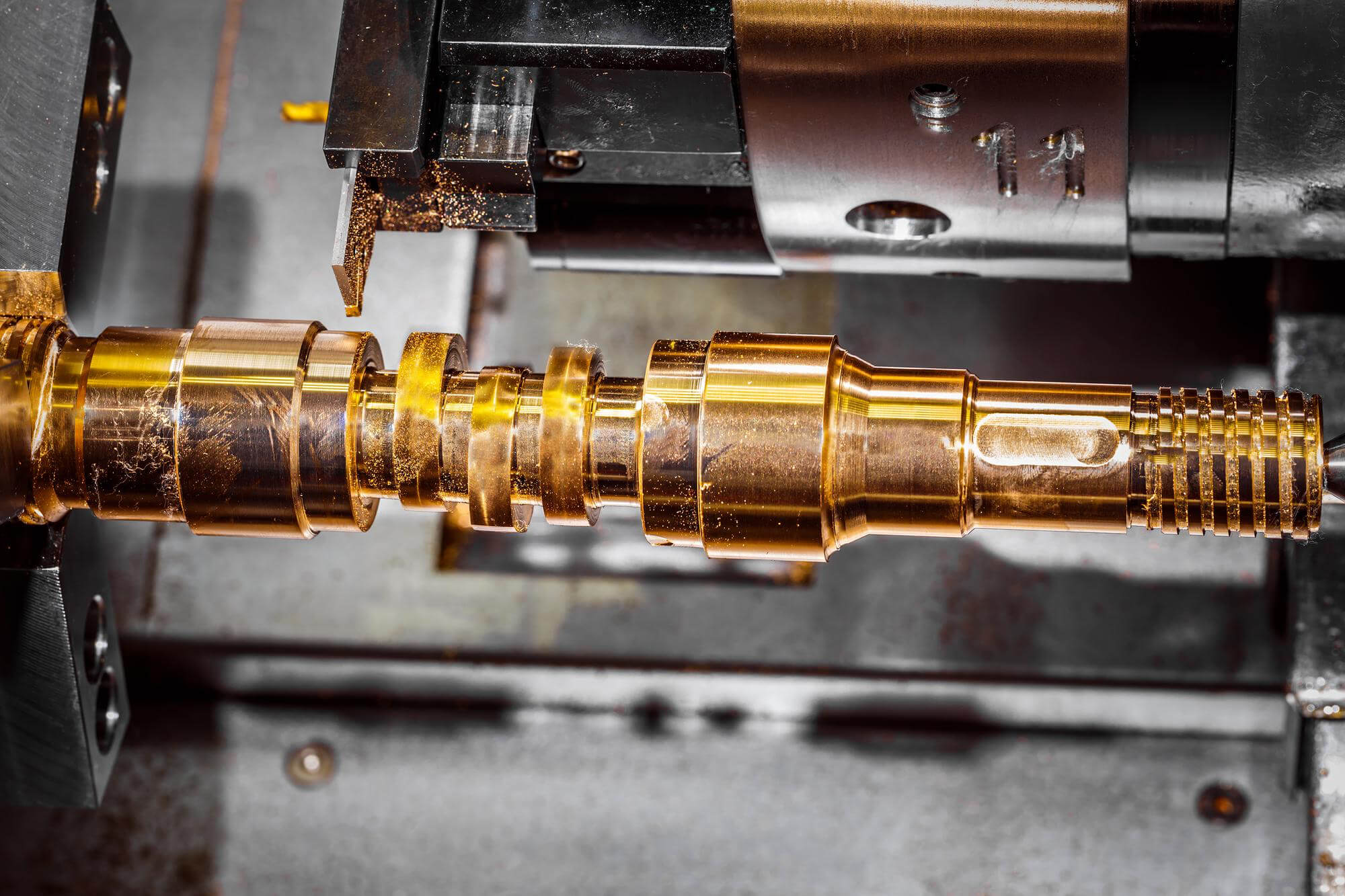

What is CNC Turning: Definition, Process & Applications

What is CNC Turning Technology? CNC (Computer Numerical Control) turning is a machining process where a cutting tool, typically a non-rotary tool bit, removes material

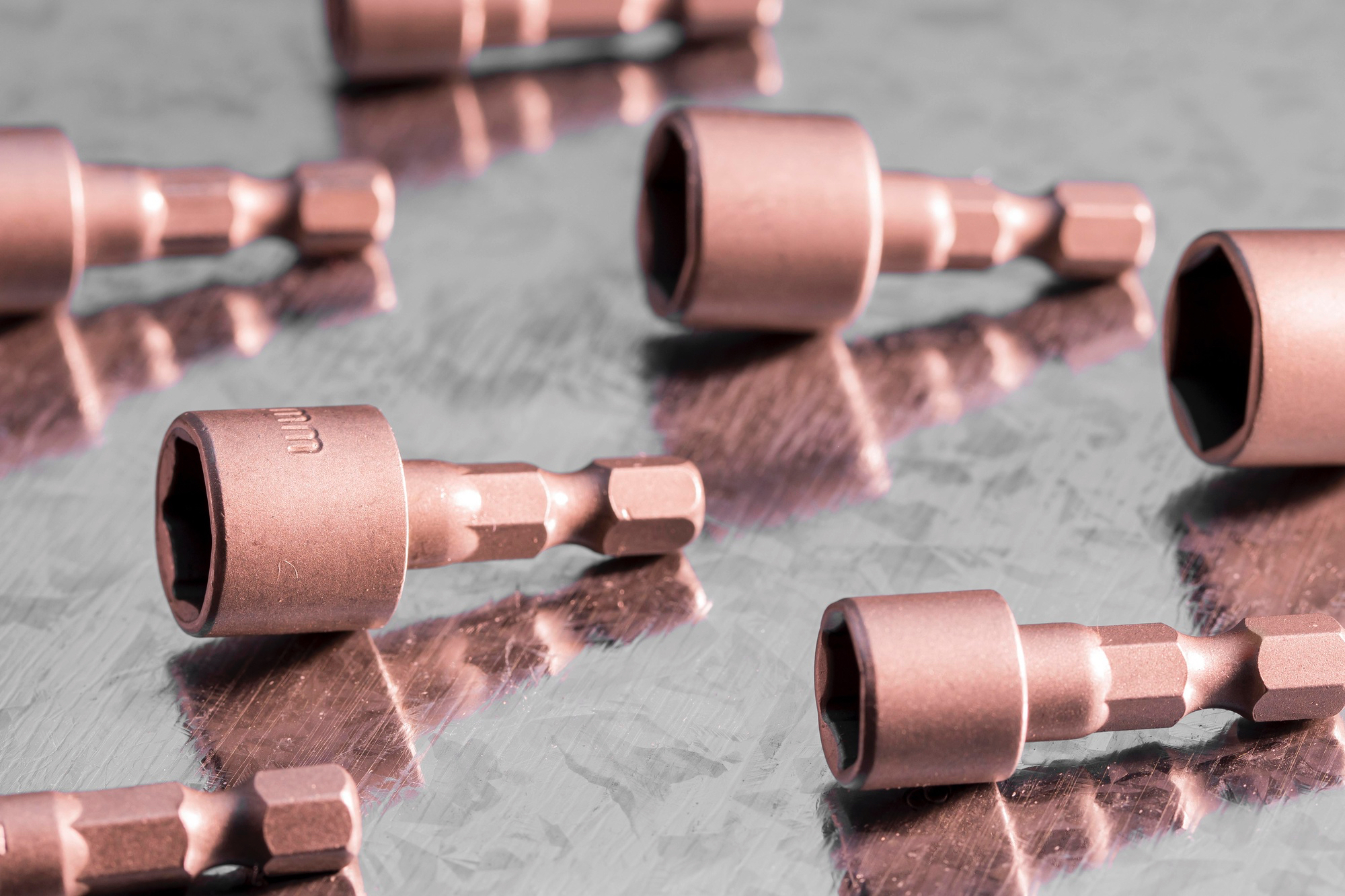

Crafting Custom Bolts with CNC Machining and Exploring Screw Innovation

The precision and reliability of custom bolts are critical in industries such as aerospace, automotive, and construction. With the increasing complexity of modern engineering, standard

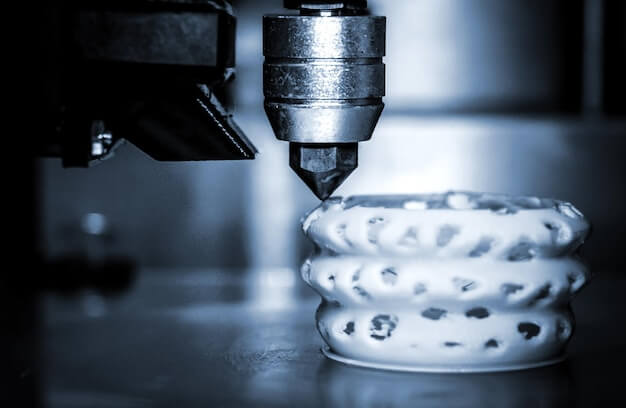

What is CNC Milling: Types, Processes & Benefits

What is CNC Milling? How Does it Differ from Traditional Milling? Milling is one of the most versatile machining processes used to manufacture parts with

Thermoset vs Thermoplastic Who Dominates CNC Machining

Introduction In the world of manufacturing, especially for buyers looking to source plastic components, material selection is crucial. Two types of plastics dominate the discussion:

Optimizing Steel Plates for Welding Through CNC Machining

In the manufacturing industry, precision and reliability are critical, especially when dealing with materials like stainless steel. For companies that require custom steel plates for

Titanium vs Steel Choosing the Right Material for CNC Machining

A Brief Introduction to the Importance of Titanium and Steel in Manufacturing In the modern world, manufacturing has become the backbone of economic development, driving

Delrin Material Introduction and Its Precision Machining Applications

Introduction to Delrin Material Delrin, also known as POM-H (Polyoxymethylene Homopolymer), is a high-performance engineering thermoplastic. It is widely used in precision machining, 3D printing,

How do you choose between injection molding and CNC plastic fabrication for your project?

Choosing the right plastic fabrication process can determine the success of your product, the efficiency of your supply chain, and your overall costs. Whether you’re

Is Titanium Stronger Than Steel Unveiling the Power of Titanium in CNC Machining

In the field of CNC machining, material selection is critical for determining product quality, durability, and cost-effectiveness. For procurement specialists and engineers alike, the question

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

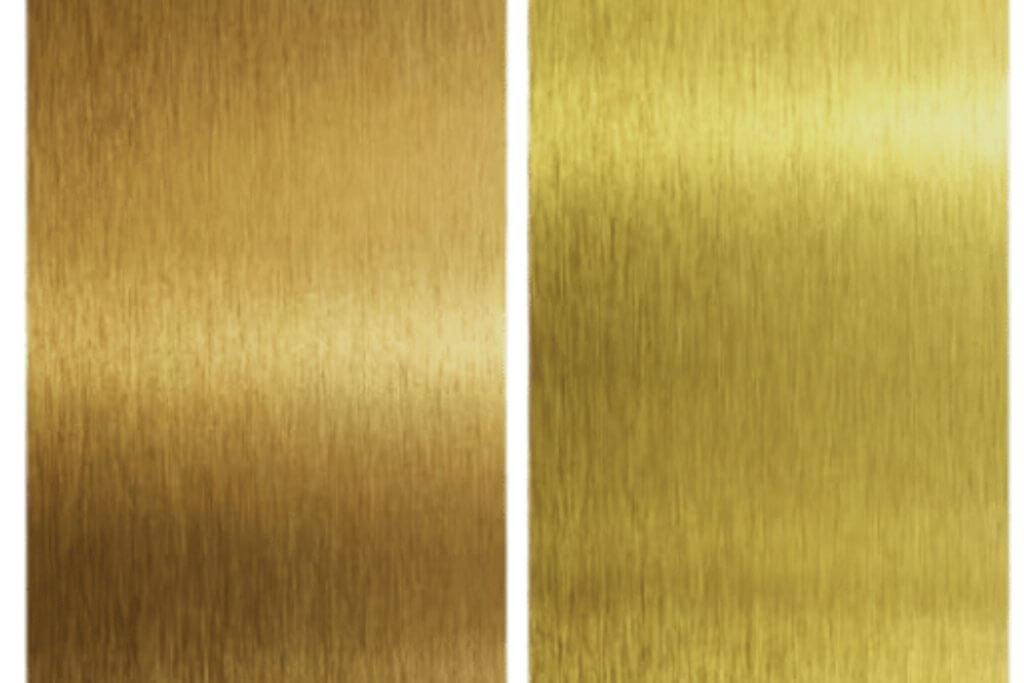

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …