Blog

Mastering Aluminum Frame CNC Machining Parts: Overcoming Deformation from Residual Stress

Aluminum frames are essential components in aerospace, replacing traditional assembly structures with large integral structures. These frames, such as the X3280 frame for helicopters, have

Revolutionizing High-Speed Cutting in CNC Machining Parts with Ceramic Tools

Ceramic tools have brought a significant transformation in the realm of high-speed cutting for CNC machining parts. These tools are celebrated for their superior hardness,

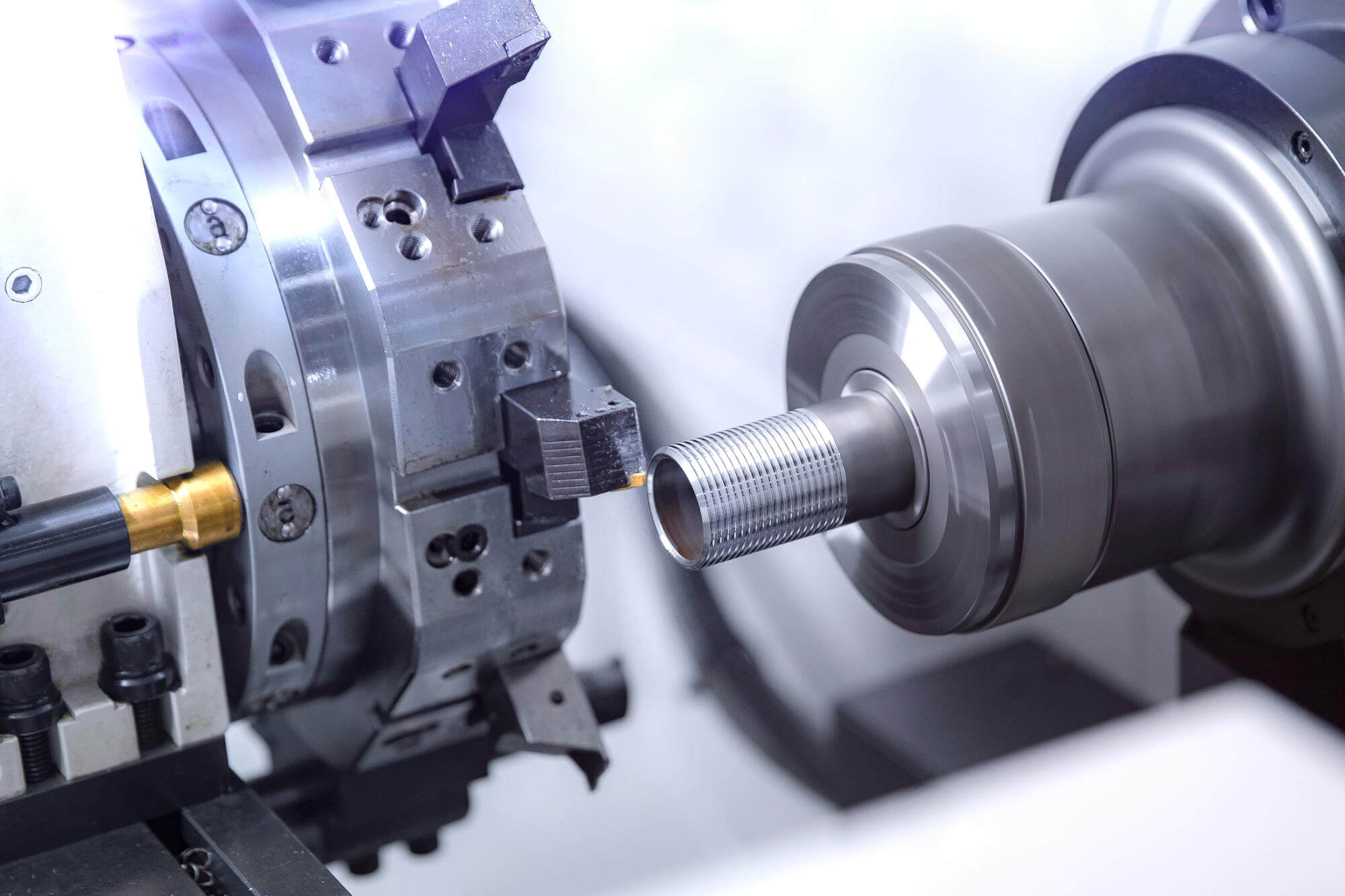

Advanced Thread Turning Techniques: G76 Cycles in CNC Machining Parts

In the early days of CNC development, the G92 simple thread cutting cycle was a breakthrough in computer technology, providing an efficient method for thread

The Essential Guide to Feed Rate and Spindle Speed in CNC Thread Turning

When it comes to CNC machining, understanding the intricacies of feed rate and spindle speed is essential, especially for thread turning. These two parameters play

Grinding Machines: Definition, Uses, Types, and Applications – The Core Tools of Manufacturing

The term “grinding machine” might be unfamiliar to many, but it plays an indispensable role in our daily lives. Whether it’s the car you drive,

Mastering Single-Head Thread Turning in CNC Machining Parts

Thread turning is an essential process in machining, particularly in the realm of CNC (Computer Numerical Control) operations. It involves creating helical grooves on cylindrical

Precise Grooving Methods to Enhance Quality of CNC Machining Parts

Grooving on CNC lathes is a multi-step operation crucial for creating specific, high-quality parts. Grooving usually involves cutting narrow slots of a particular depth on cylindrical, conical,

Mastering CNC Machining Parts Cut-Off Operations

Cut-off operations on a CNC lathe are common and essential for many manufacturing processes. This task typically involves separating a completed part from a bar

Elevating Surface Finish of CNC Machining Parts with High-Speed Techniques

High-speed cutting techniques have revolutionized CNC machining, offering not only increased production efficiency but also superior surface finishes on machined parts. The appeal of high-speed

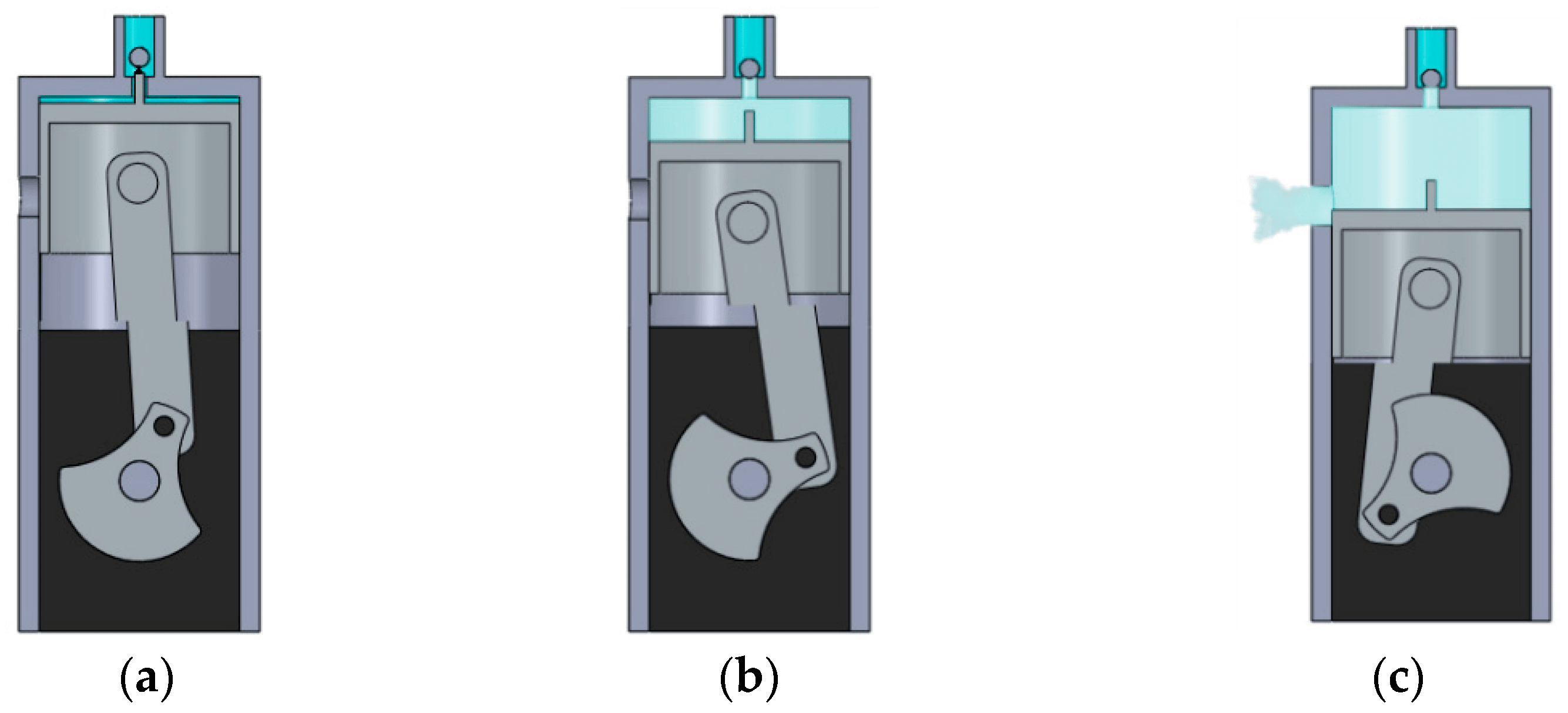

Detailed Explanation of Pneumatic, Hydraulic, and Transmission Components

Detailed Explanation of Pneumatic, Hydraulic, and Transmission Components Welcome to the world of mechanical design. In this article, we will explore pneumatic systems, hydraulic systems,

Superior Performance of CBN Tools in High-Speed CNC Machining Parts

In the realm of high-speed CNC machining, the choice of cutting tool material is paramount. Over the last three decades, the development of advanced cutting

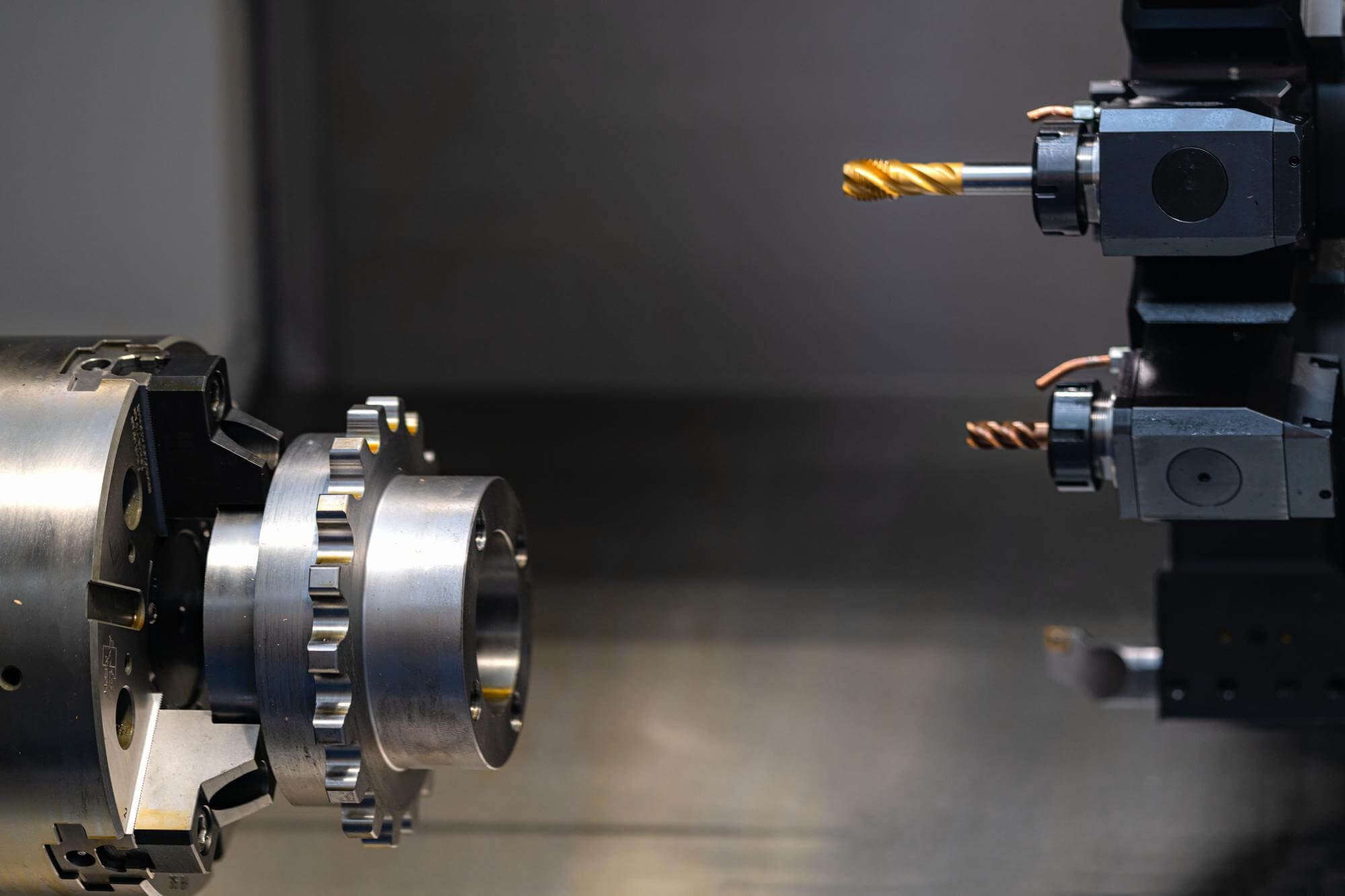

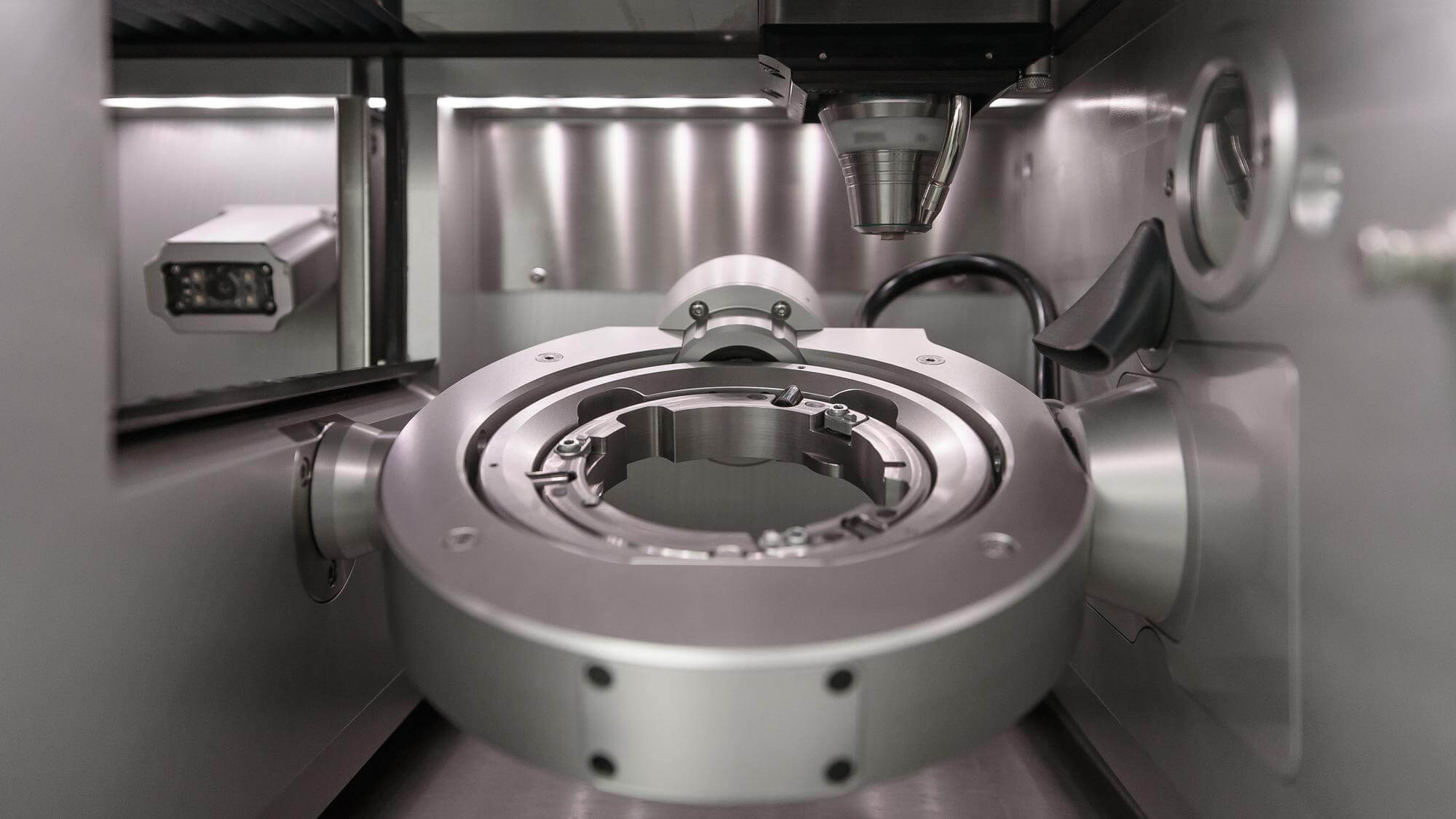

Enhancing Efficiency in CNC Machining Parts Production with Cutting-Edge Machining Centers

Machining centers are game-changers in the world of CNC machining. Imagine a workshop where a single machine can perform multiple operations—turning, milling, drilling, and more—without

Mastering Automatic Corner Transitions in Precision Machining

In CNC turning and boring operations in the world of precision machining, transitioning from shoulders to outer diameters (or vice versa) often requires corner transitions.

Precision and Control in Machining

Machining precision is the foundation for ensuring the performance and longevity of mechanical products. During machining, various factors can cause the correct position between the

Precision Machining with Tool Offsets for CNC Lathe Parts

When it comes to CNC machining, precision is key. Achieving high precision in CNC lathe parts requires a deep understanding of tool offsets and their

Key Insights into Plasma Cutting Stainless Steel and Its Perfect Fit with CNC Machining

Introduction Plasma cutting has long been a go-to method for efficiently cutting stainless steel and other conductive metals. When combined with CNC machining, this process

Carbide vs PCD Tools Understanding Aluminum Injection Mold Tool Life in CNC Machining

Introduction Aluminum injection mold tools are a critical component in industries ranging from aerospace to automotive. In today’s fast-paced manufacturing environment, especially with CNC machining,

Glass Bead Blasting Material and Its Impact on CNC Machining Performance

In the world of CNC machining, precision, quality, and surface finish are critical factors, especially for industries that demand high-performance components. Among the various surface

How CNC Machining and Laser Cutting Enhance Sheet Metal Hinge Production

Introduction In today’s fast-paced manufacturing environment, industries such as automotive, aerospace, and furniture production rely on precision components like sheet metal hinges. Hinges may seem

How CNC Machining Powers High-Precision Prototypage Plastique

Introduction In modern manufacturing, precision is no longer a luxury—it’s a necessity. Whether you’re designing intricate components for automotive parts, medical devices, or aerospace applications,

CNC Precision Machining High-Temperature Alloys for Heavy-Duty Vehicle Parts

1. Introduction In the automotive, aerospace, and maritime industries, high-temperature alloys have become vital materials for manufacturing components that must withstand extreme temperatures and stress.

Grinding Techniques and CNC Machining in Rubber Compression Molding Machine Production

Rubber compression molding machines are essential in various industries that require precise and durable rubber components. One of the key processes in manufacturing these machines

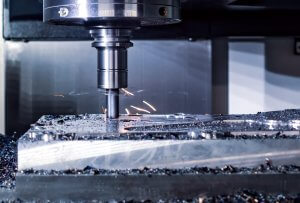

Mastering Milling Basics with CNC Machining Techniques and Tools

Milling is one of the most fundamental and widely used processes in CNC machining. Whether you are a technician looking to deepen your understanding of

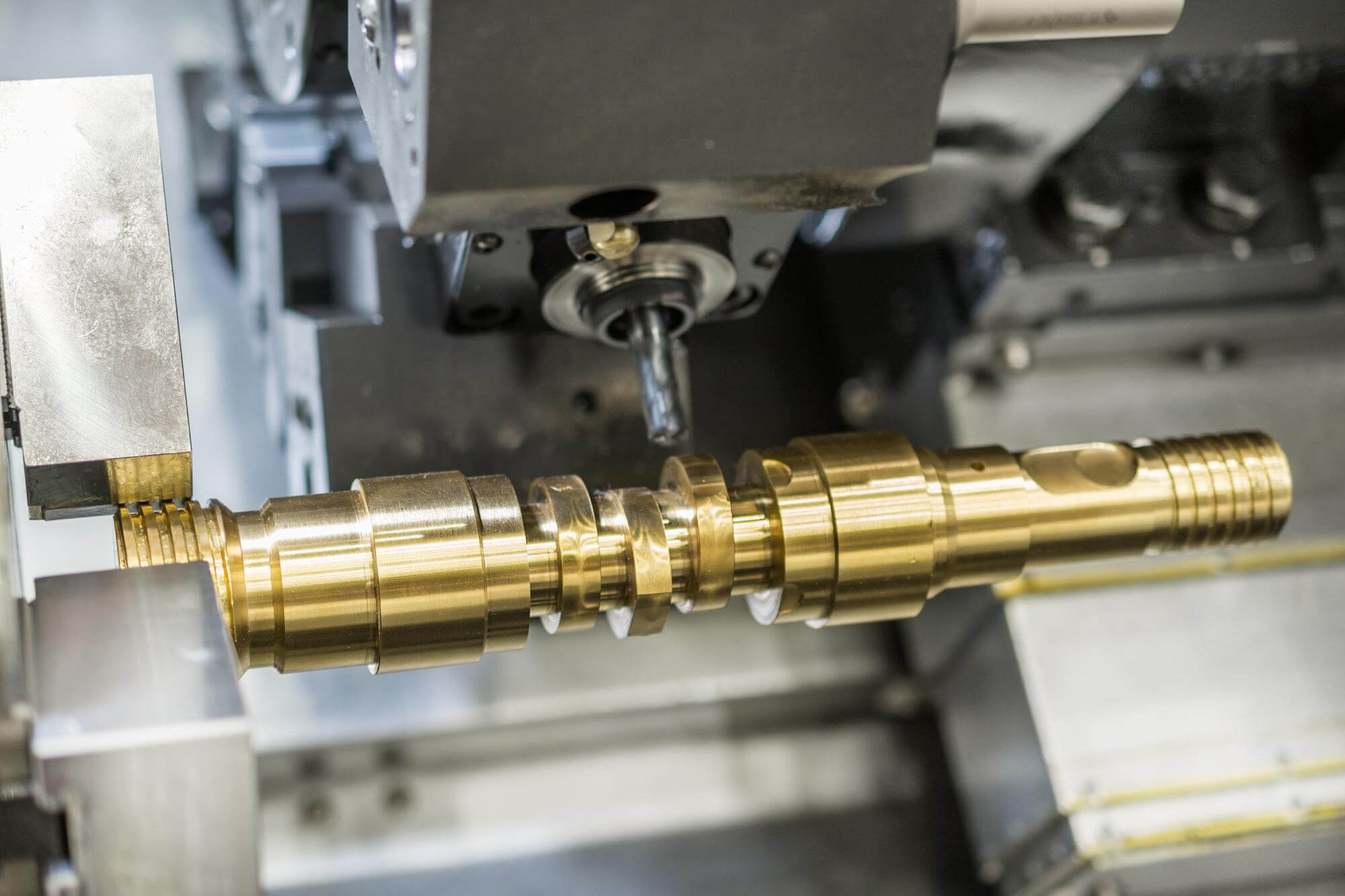

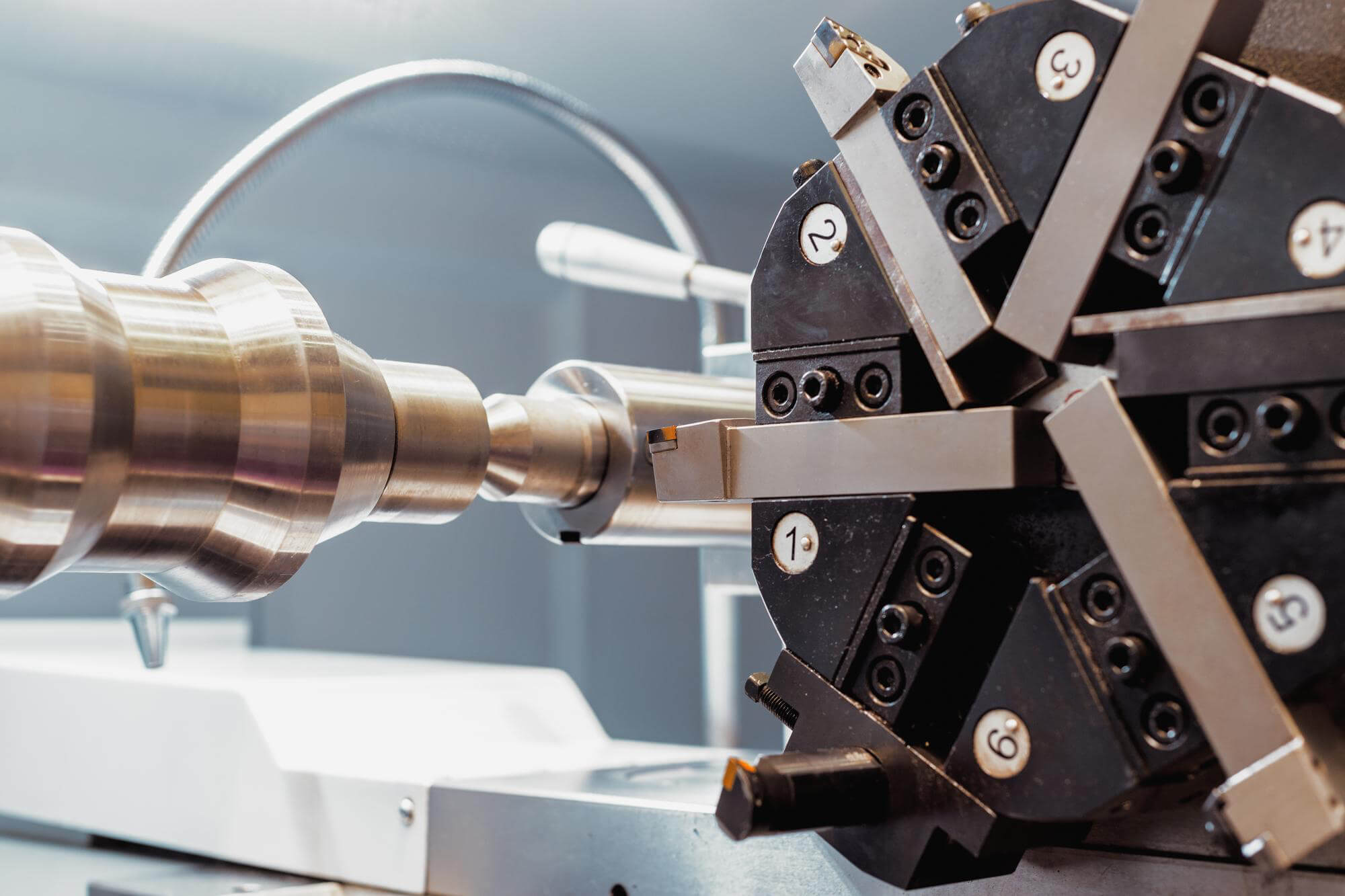

In-Depth Look at CNC Turning and the Key to Choosing High Quality Lathe Tools

CNC turning is a critical aspect of modern manufacturing, enabling the precise production of cylindrical parts used across various industries, from automotive to aerospace. The

Practical Guide to CNC Machining iPhone 14 Titanium Case

The iPhone 14’s titanium case represents a pinnacle of design and engineering, marrying aesthetics with durability. For those in the CNC machining industry, crafting this

Weighing the Costs Titanium vs Aluminum in CNC Machined Parts

When it comes to CNC machining, choosing the right material is a crucial decision that can significantly impact the cost, performance, and longevity of the

Precision Challenges in CNC Machining of Large-Format Parts Deformation Analysis and Solutions

The CNC machining of large-format parts presents unique challenges, particularly in industries like aerospace, where precision and reliability are paramount. These components, often spanning several

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …