Blog

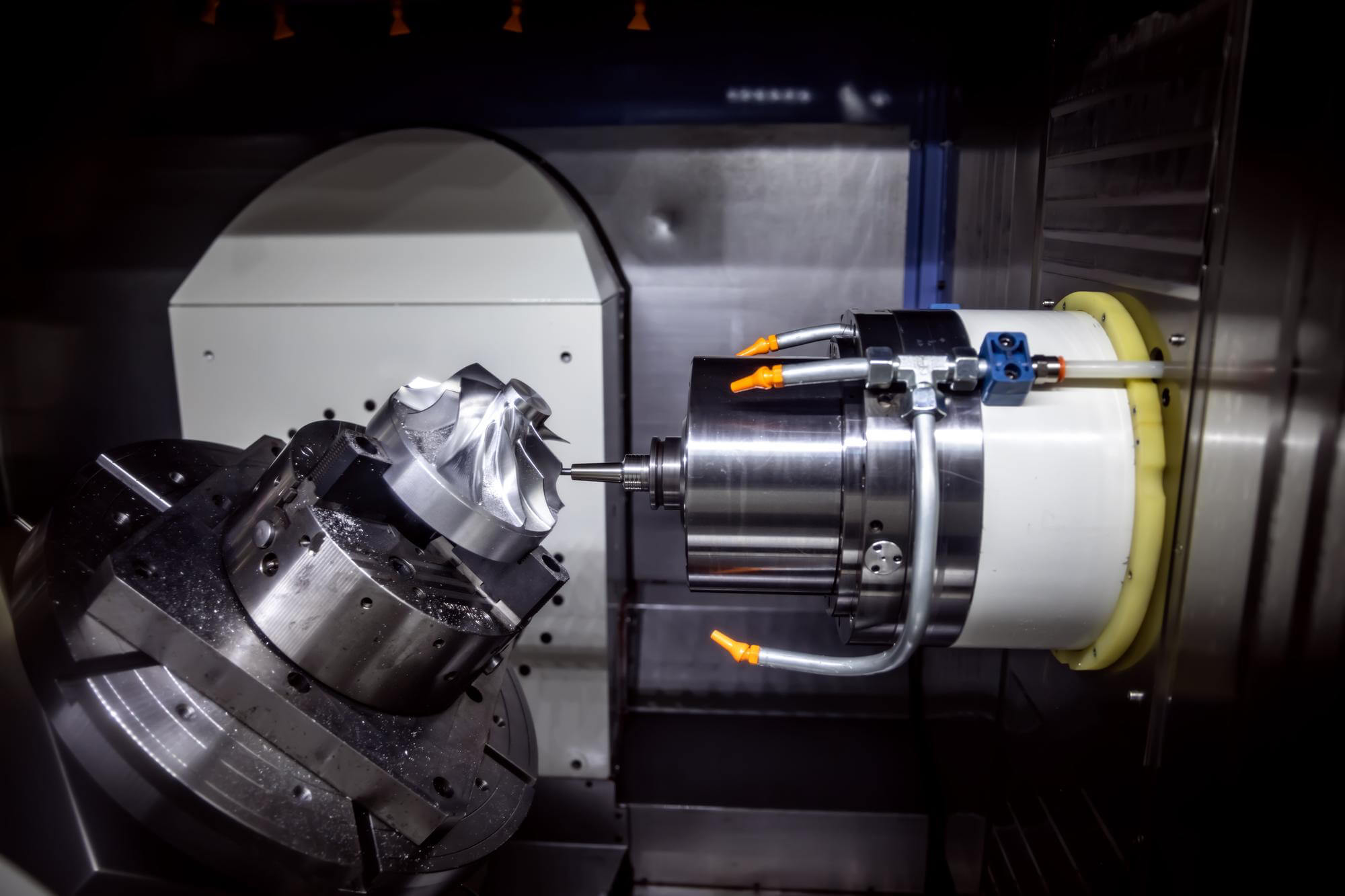

Unveiling the Magic of Diamond Tools for CNC Machining Parts

When it comes to CNC machining, the choice of tools can make a world of difference. Over the past 30 years, advanced cutting tools have

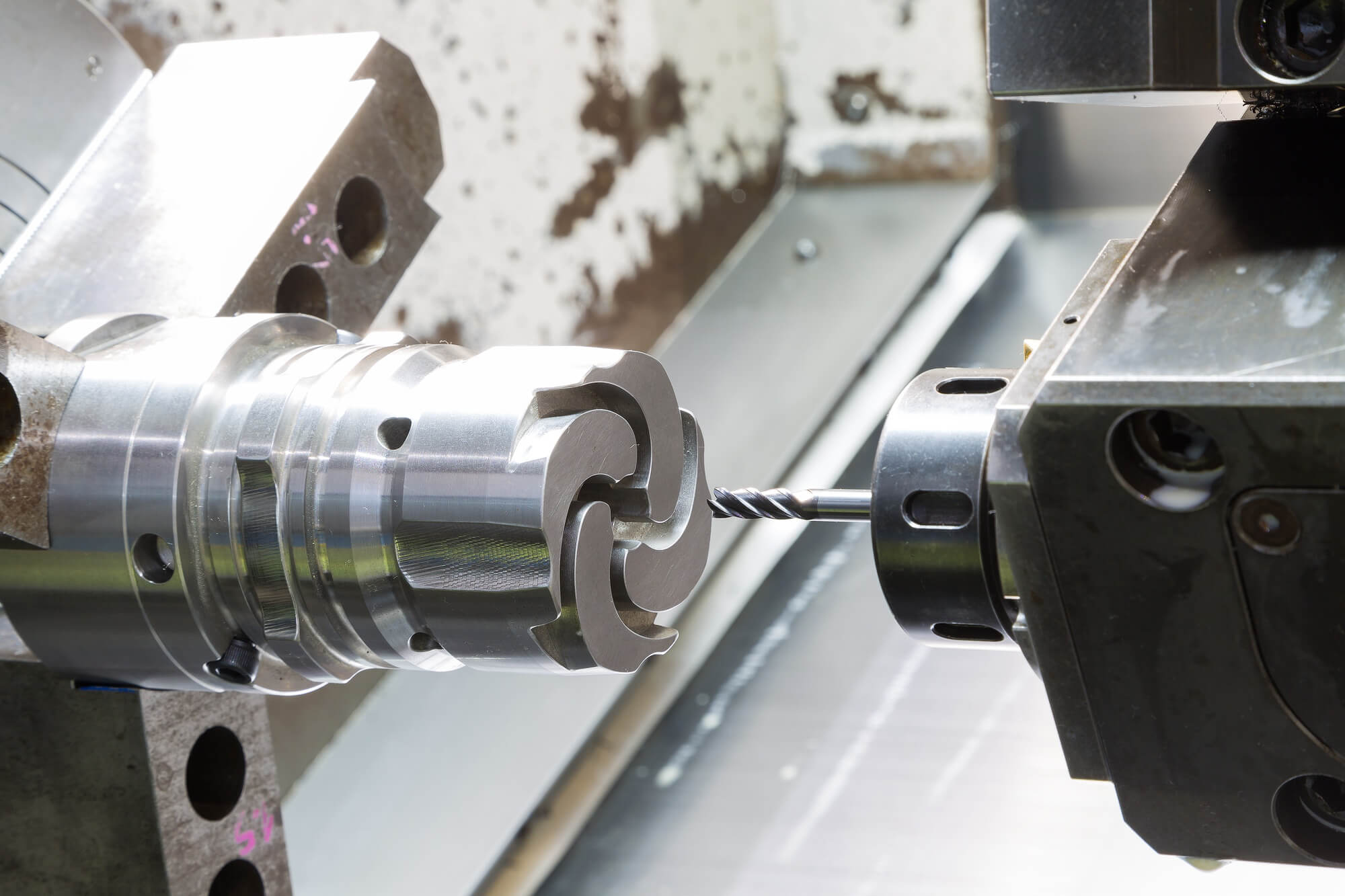

Mastering Cylindrical Cavity Machining for CNC Machined Parts

Cylindrical cavities are a staple in CNC machining, offering a versatile range of applications from simple bores to complex recesses. This guide aims to walk

Understanding Direct and Indirect Measurement Techniques for CNC Machined Parts

When it comes to CNC machining parts, quality control is key to ensuring everything fits together perfectly. In the quality inspection process of CNC parts,

Mastering Measurement Techniques for CNC Machining Parts

Measurement tools are the unsung heroes in the world of CNC machining. They ensure that every part produced meets the necessary specifications and standards. Understanding

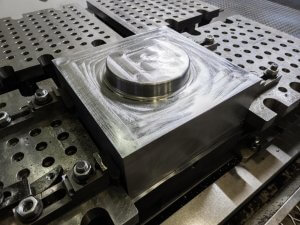

Mastering Cavity Milling Techniques for CNC Machined Parts

Cavity milling is a common operation in CNC machining centers. It involves removing material from a closed area defined by its boundary lines, which can

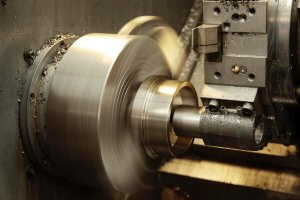

Revolutionizing Metalwork with High-Speed Cutting Tools

High-speed cutting tools are the backbone of modern metalworking. They play a pivotal role in shaping, cutting, and finishing metal parts with precision and efficiency.

Exploring Milling Modes and Tool Optimization in CNC Machining

Milling, especially flat milling, is an essential process in CNC machining. To achieve the best results, several factors need to be considered, including tool selection,

Mechanical Design Training Lesson 6: Mechanical Accessories, Threads, and Modules

In the field of mechanical design, mechanical accessories and thread modules are critical components. They are not just miscellaneous small parts, but essential elements that

Structural Design Process Standards: A Detailed Guide to Machining

In the field of industrial manufacturing, structural design process standards are crucial guidelines that ensure product quality and manufacturing efficiency. This article provides a detailed

Detailed Explanation of the Metal Cutting Process

Basic Knowledge of Metal Cutting Detailed Explanation of the Metal Cutting Process Basic Knowledge of Metal Cutting When cutting metal, we encounter various cutting phenomena.

Face Milling Essentials for CNC Machining Parts

Face milling is an essential operation in CNC machining, aimed at controlling the height of the workpiece and ensuring a smooth surface finish. This process

Mastering Hole Patterns in CNC Machined Parts

When it comes to point-to-point cnc machining operations like cnc drilling, reaming, tapping, and boring, using the same tool for single or multiple holes is

Understanding Shape and Position Tolerances in CNC Machining Parts

When producing CNC machining parts, it’s not just about hitting the right dimensions and achieving the desired surface roughness. The shape and the relative positions

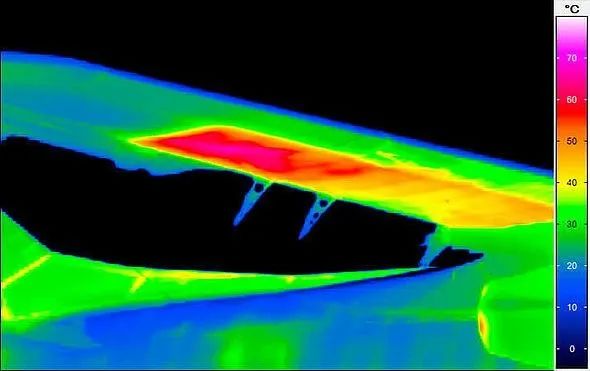

Exploring the Influence of Cutting Factors on CNC Machining Parts

When it comes to CNC machining, understanding the mechanics of cutting is crucial. Various factors influence the cutting process, impacting everything from the quality of

Detailed Explanation of Surface Quality in Machining

Surface quality in machining not only affects the appearance of the product but also has a significant impact on its performance, reliability, and durability. Studying

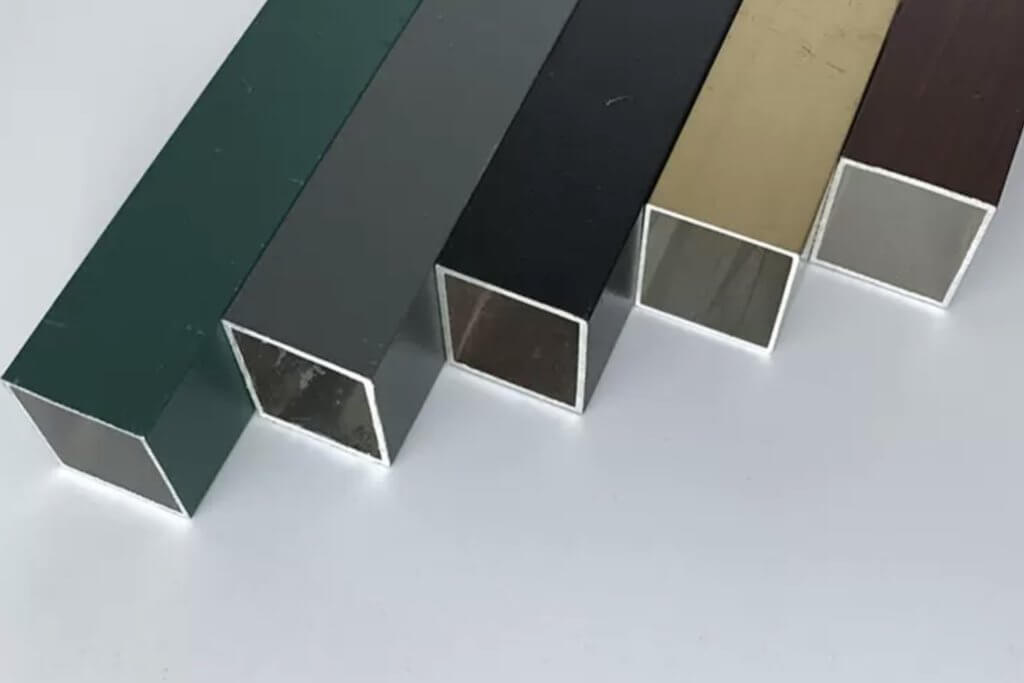

Surface Treatment After CNC Machining Applications of the Anodized Aluminum Colors Chart

In the world of manufacturing, CNC machining is a cornerstone of precision and efficiency, especially when it comes to working with aluminum. However, the journey

Mastering CNC Drilling: Creating Exact Fits for Pull Through Rivets

CNC machining has become an essential part of modern manufacturing, offering unmatched precision and efficiency. One of the most critical aspects of CNC machining is

How Wire Brushed Finish Complements CNC Machining for Superior Surface

CNC machining has revolutionized the manufacturing industry by enabling the precise production of complex parts. However, even with the advanced capabilities of CNC machines, the

The Perfect Synergy Between Chrome Plating Cast Iron and CNC Machining

In the realm of industrial manufacturing, the integration of CNC machining and chrome plating on cast iron components stands as a pivotal advancement, driving quality,

7075 vs 7050 Aluminum Alloys: How to Minimize Deformation in CNC Machining

Aluminum alloys, particularly 7075 and 7050, are widely used in the aerospace industry due to their high strength-to-weight ratio, excellent corrosion resistance, and good machinability.

Mastering CNC Drills for Precision in Composite Materials

CNC drilling is a critical process in modern manufacturing, particularly when working with composite materials. As industries like aerospace, automotive, and renewable energy continue to

Key Techniques for Stainless Steel Cutting: How CNC Machining Enhances Electrical Enclosure Design

Stainless steel, known for its corrosion resistance and high strength, is a popular material choice in the manufacturing of electrical enclosures. However, cutting and machining

Exploring Milling and Filing Techniques for CNC Precision Machining and Moulding Line Management

In the world of CNC precision machining, managing and refining moulding lines is a critical aspect that can significantly impact the quality of the final

A Guide to Finishing Techniques and Their Application in CNC Production of Micro Molding Machines Parts

When it comes to producing parts for micro molding machines, the finishing techniques used in the CNC machining process play a crucial role in ensuring

How CNC Machining Centers Tackle the Complex Challenges of Sink Molding Parts

In today’s fast-paced manufacturing environment, finding the right supplier for complex, custom-shaped parts like sink molding is crucial. CNC machining centers have revolutionized the way

Mastering CNC Machining Techniques for Tooling Die Casting with High-Strength Steels

In the world of precision manufacturing, CNC machining plays a crucial role, especially when it comes to tooling die casting with high-strength steels. These materials,

Tackling Tough High-Temperature Alloys in CNC Machining with Sand Blasting Glass Beads

High-temperature alloys, also known as superalloys, are designed to withstand extreme environments where ordinary materials would fail. These alloys are crucial in industries such as

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

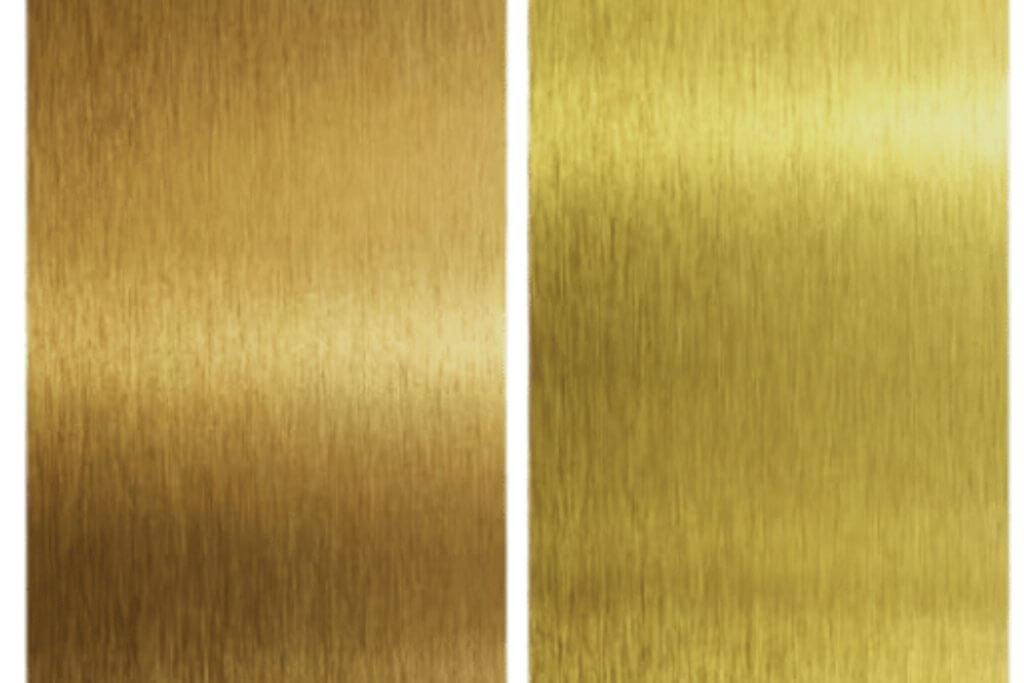

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …