Blog

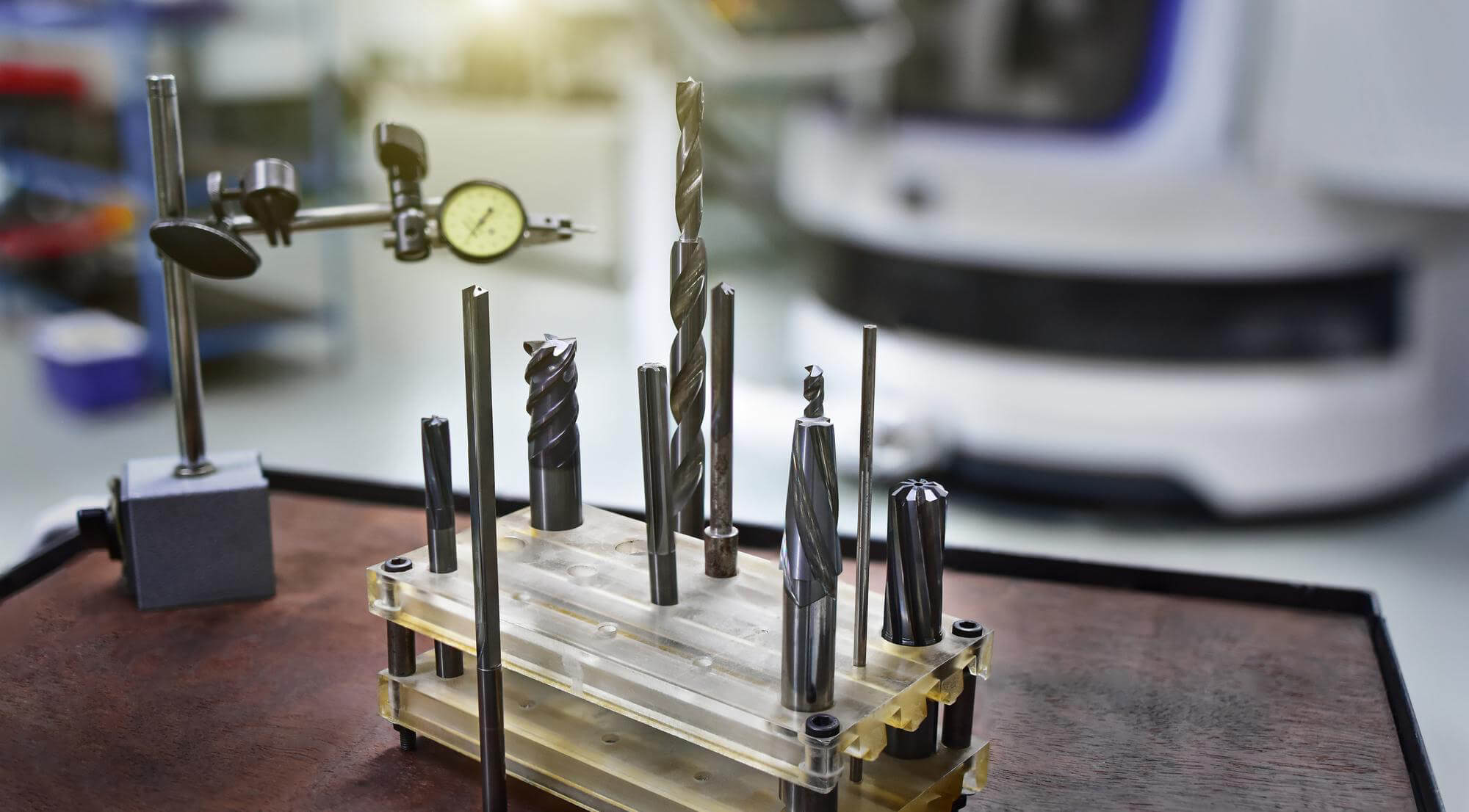

Mastering Thread Tapping in CNC Machining Parts

Thread tapping is one of the most common hole machining operations on CNC machining centers, right after drilling. Due to its widespread application in many

Enhancing Durability with Copper and Nickel Plating on CNC Machining Parts

Electroplating is like giving metal parts a shiny, protective armor. Imagine turning a dull, rusty piece of metal into a gleaming, robust part ready to

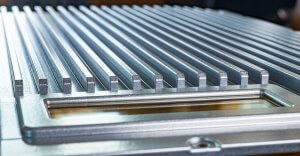

Detailed Explanation of Surface Quality in Machining

Surface quality in machining not only affects the appearance of the product but also has a significant impact on its performance, reliability, and durability. Studying

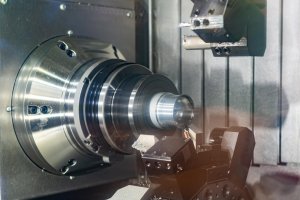

Overview of Machining Accuracy

In the field of machining, the quality of parts is fundamental to ensuring the performance and longevity of mechanical products. The main indicators for measuring

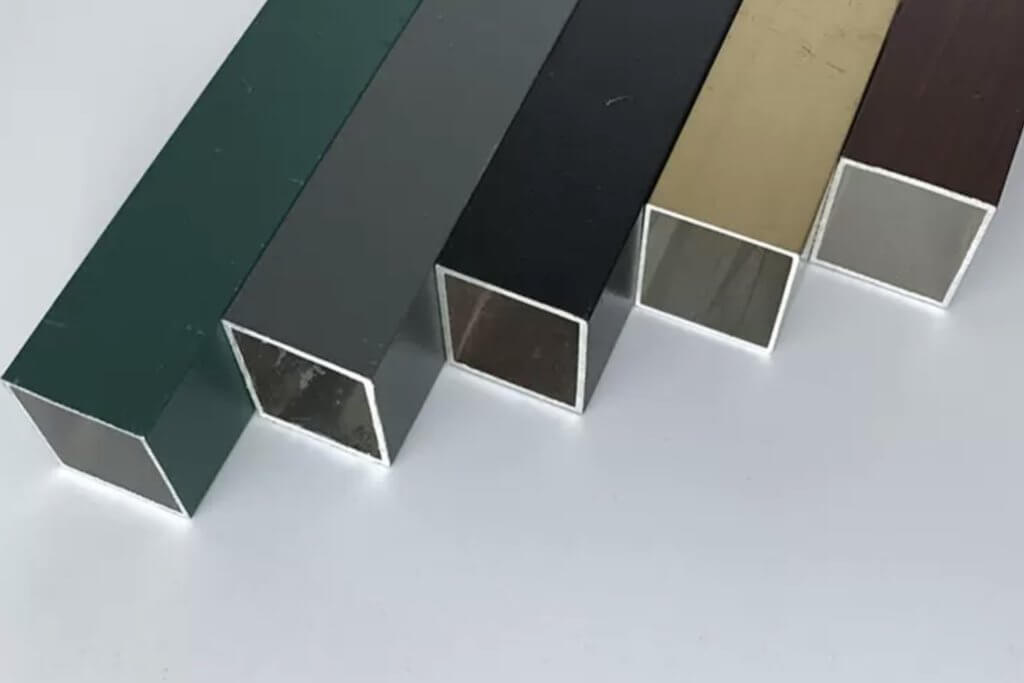

Mastering Chemical Coloring for CNC Machining Copper Parts

In the world of metal surface finishes, chemical coloring has gained significant traction, especially for aluminum and copper. This technique not only enhances the aesthetic

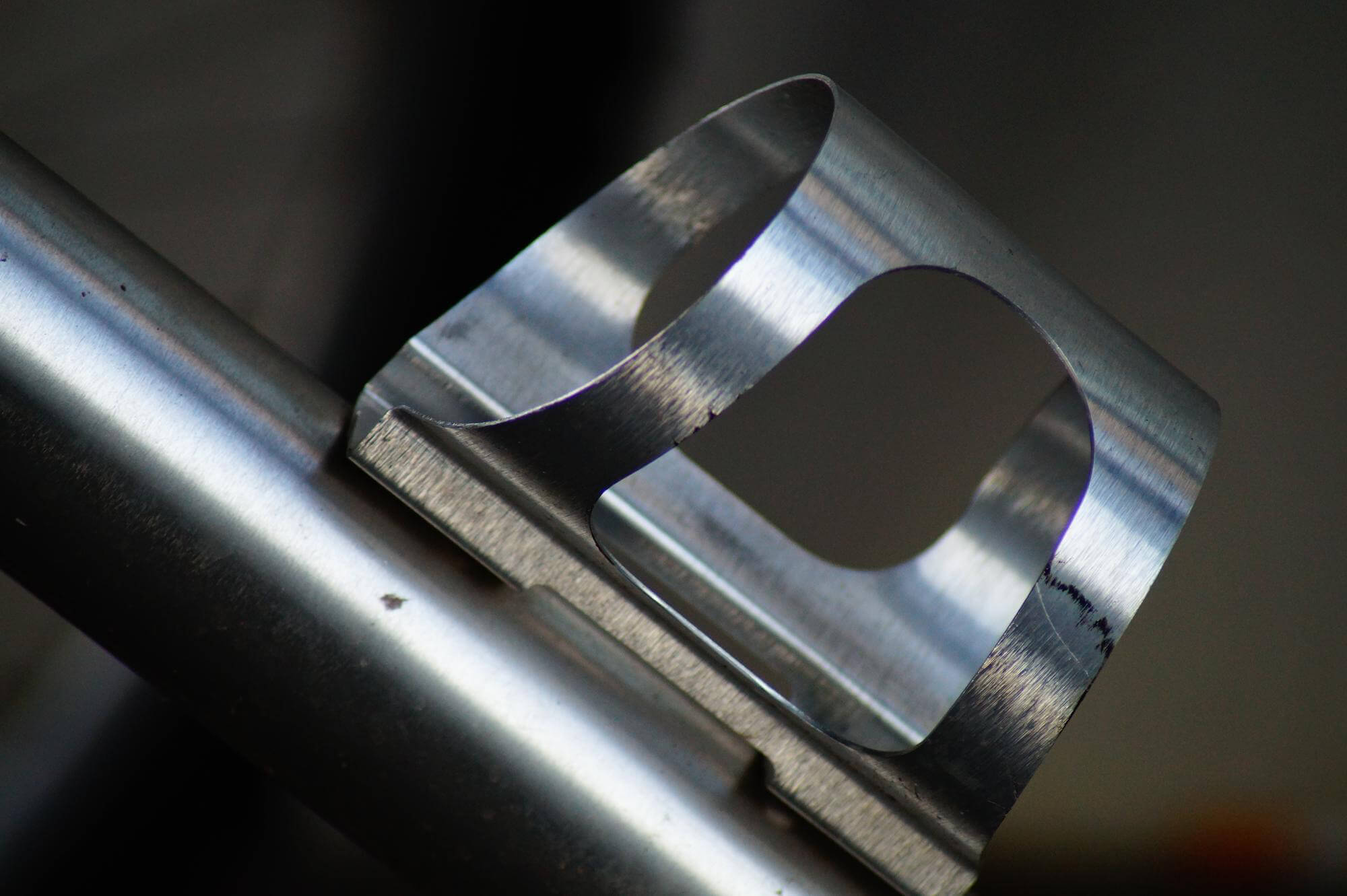

The Essential Guide to Countersinking, Counterboring, and Spotfacing in CNC Machining Parts

In every machine shop, Often, after CNC drilling is complete, it is necessary to enlarging holes.There are three common methods for enlarging holes from the

Part Structural Processability

Selection of Blank Forming Methods and Machining Processability In the process of mechanical manufacturing, selecting appropriate blank forming methods and machining processability is crucial for

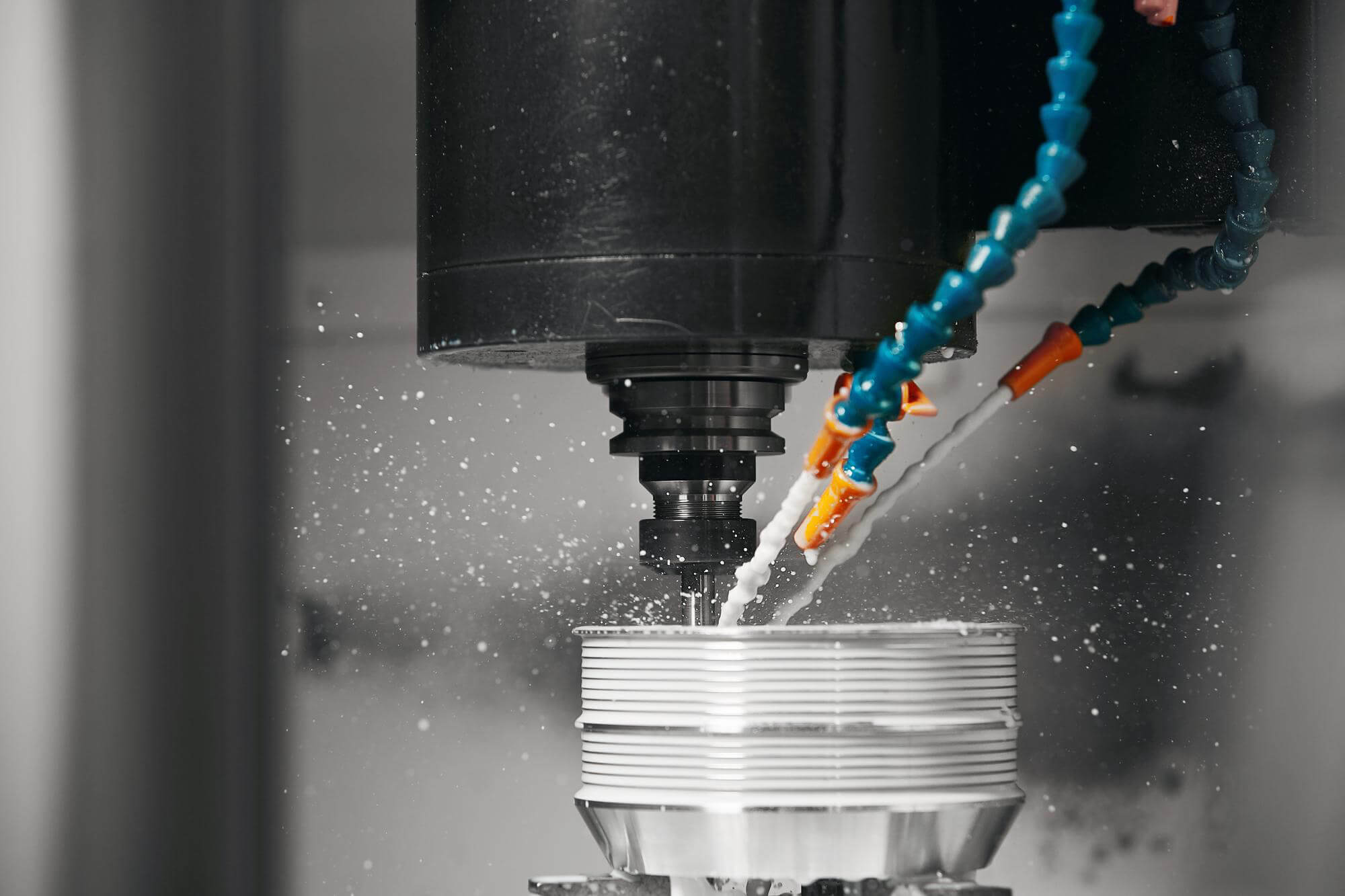

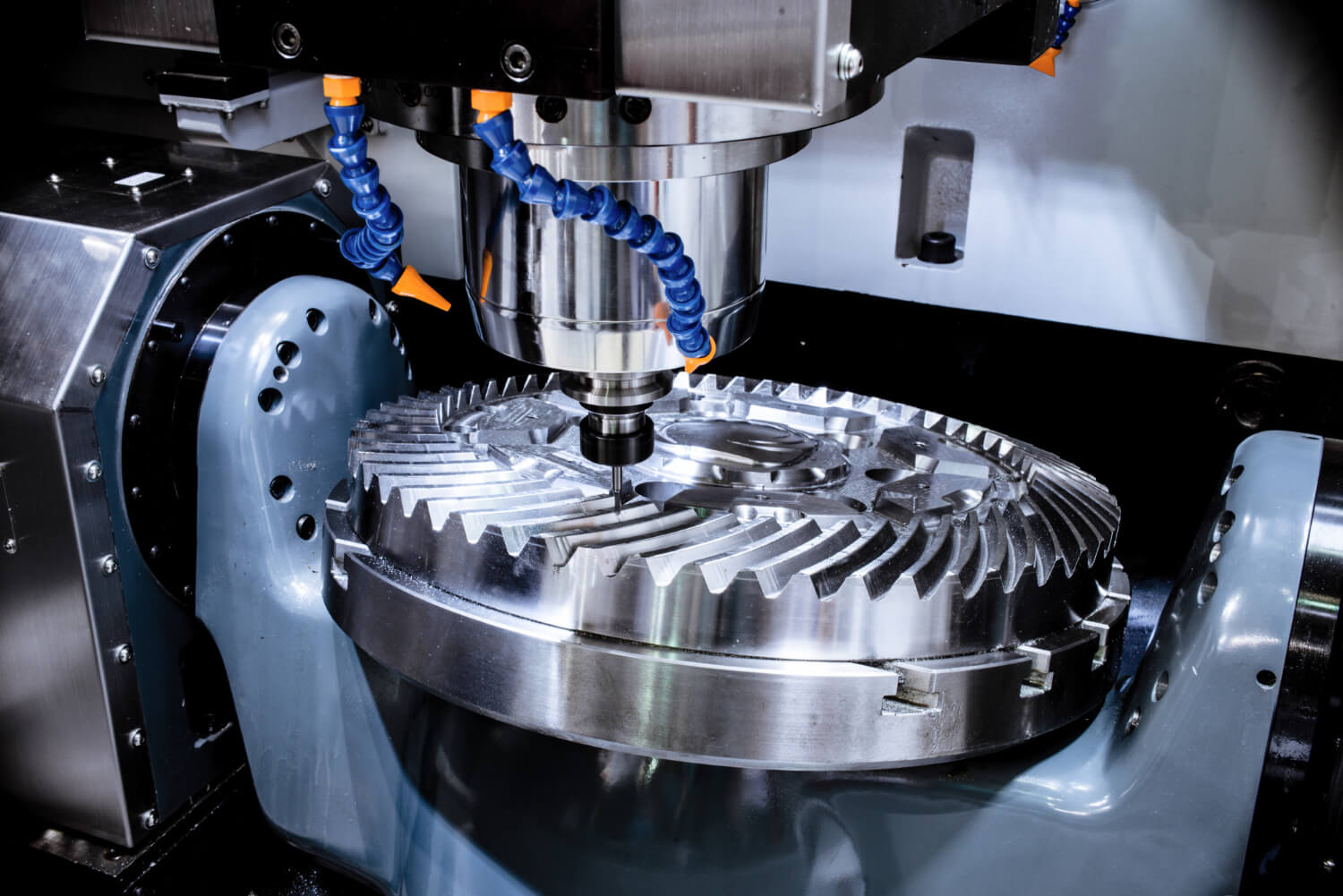

High-Speed Spiral Milling Techniques for CNC Machining Parts

In the world of mold and aerospace machining, two-dimensional cavity machining stands out as one of the most material-intensive and time-consuming processes. For example, the

Blank Selection and Forming Methods in Mechanical Manufacturing

In mechanical manufacturing, selecting and forming blanks are critical factors that influence product quality, cost, and performance. Choosing the right blank can improve production efficiency

From Rust to Shine: Chemical Conversion Films in CNC Machining Parts

Many metals naturally form a protective oxide film on their surfaces, a process known as passivation. Chemical conversion films take advantage of this by creating

High-Speed Cutting Legends Transforming CNC Machining Parts

High-speed cutting (HSM or HSC) is not just a technological advancement; it’s a fascinating journey of innovation that has transformed CNC machining parts over the

Mastering CNC Machining Parts With G76 and G87 Boring Tricks

Boring holes with precision and quality in CNC machining can be a bit tricky, but with the right techniques, it becomes much more manageable. Two

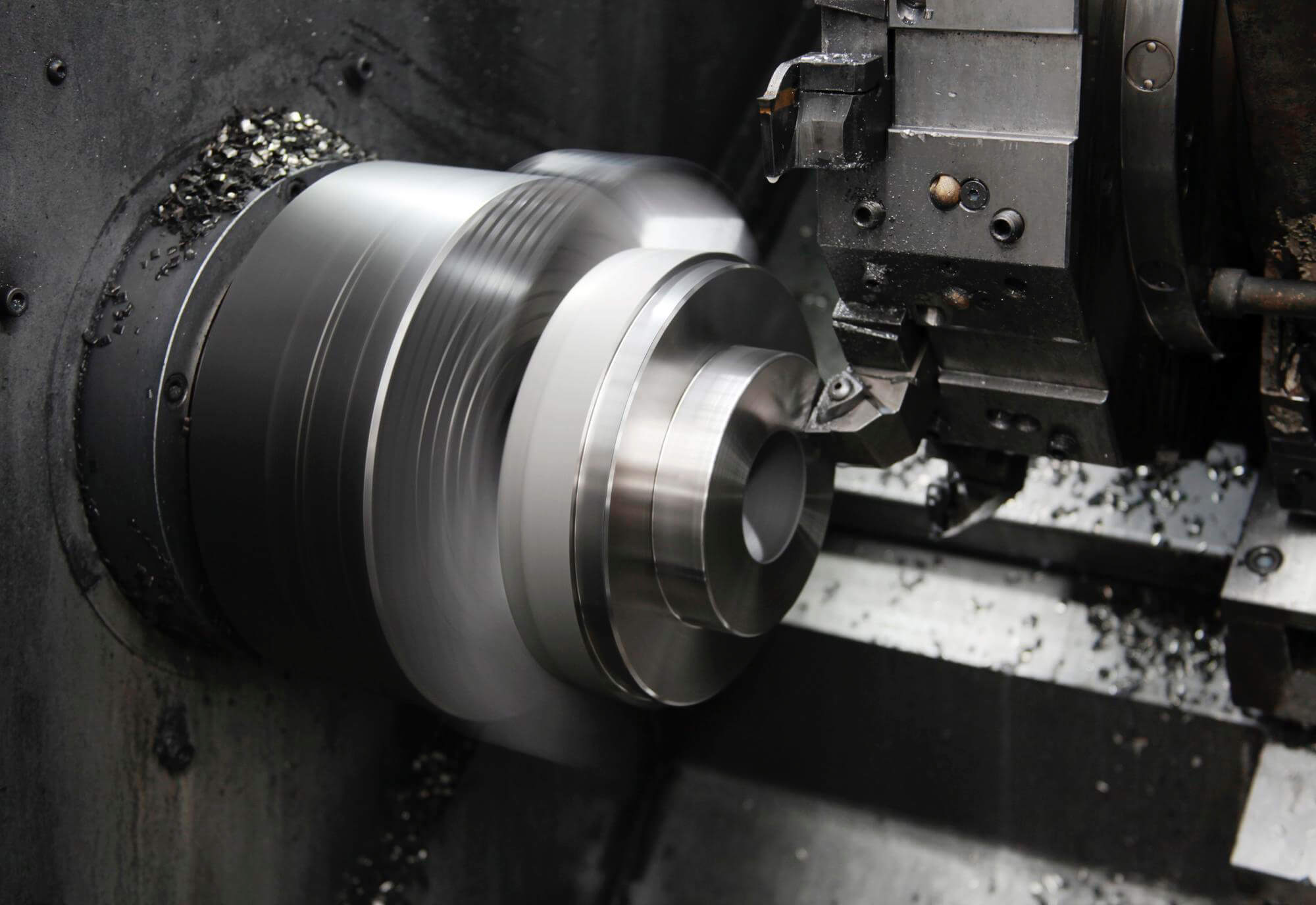

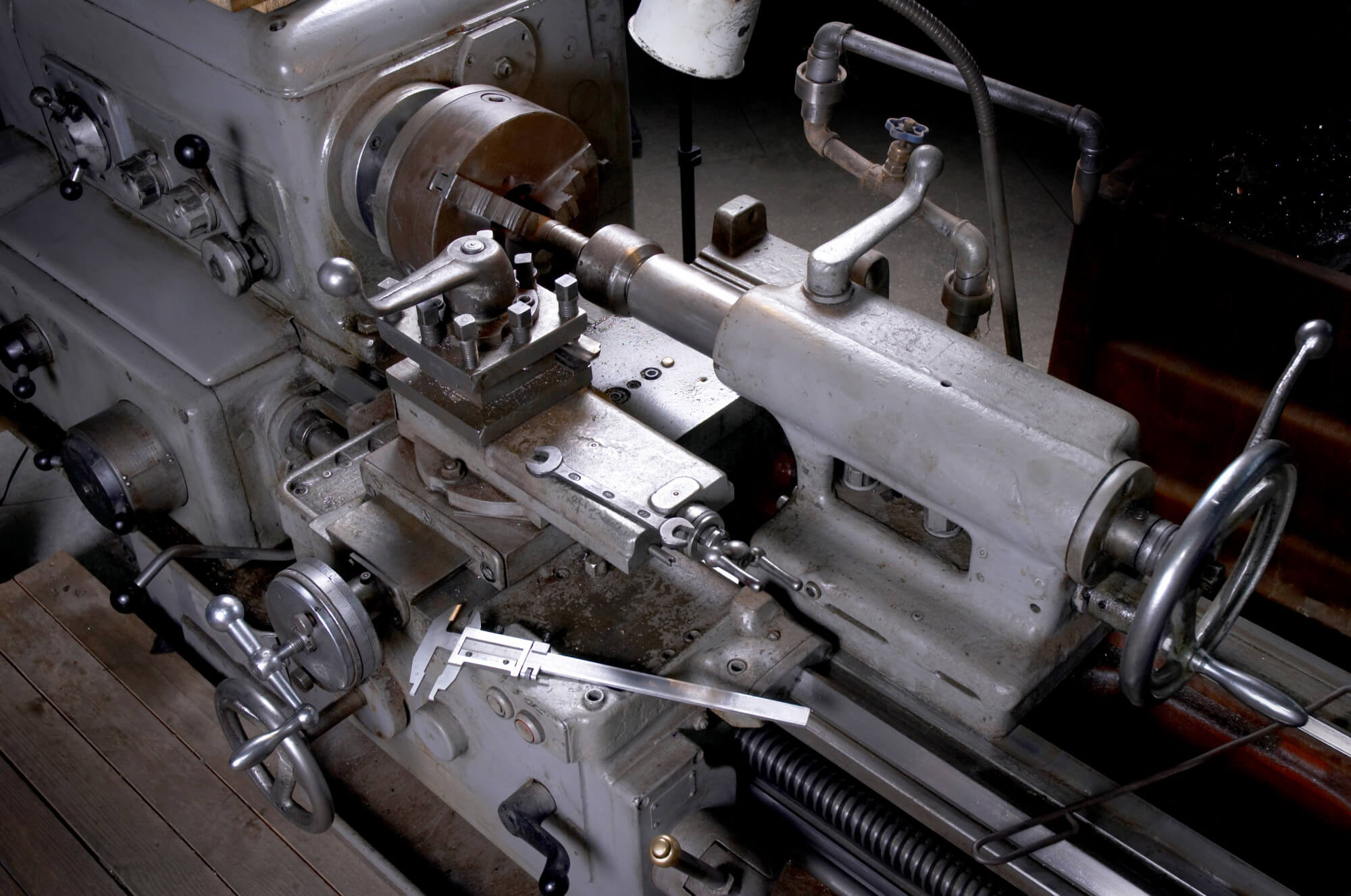

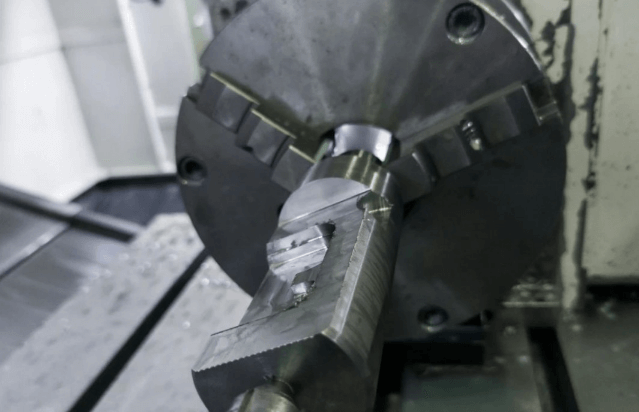

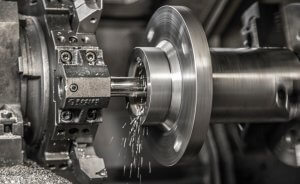

The Basics of CNC Turning-Milling Compound Machining

The Basics of CNC Turning-Milling Compound Machining Programming The programming basics for CNC turning-milling compound machining can vary due to different CNC systems used in

Surface Quality in Machining

Surface quality in machining refers to the overall condition of a part’s surface after machining, encompassing its geometric shape, physical-mechanical properties, and chemical properties. Studying

Typical Machining Processes for Mechanical Manufacturing

Shaft Parts Machining Function of Shaft Parts Shaft parts are primarily used to support transmission components and transmit torque. Common shaft parts include plain shafts,

Optimizing High-Speed CNC Machining Surface Quality Using Glass Beads for Blasting

Introduction to CNC Machining and Surface Quality CNC machining is a cornerstone of modern manufacturing, enabling the production of intricate and precise components across various

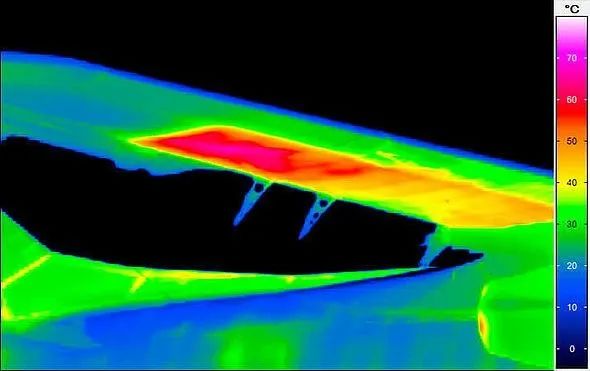

Controlling Surface Roughness Challenges and Solutions in High-Speed CNC Machining of Galvanneal Sheet Metal

In the world of manufacturing, surface quality is a critical factor that can determine the success of a product. For buyers and engineers involved in

Mastering Titanium Alloy CNC Machining A Practical Guide

Introduction In the world of CNC machining, titanium alloys have carved a niche for themselves, known for their excellent strength-to-weight ratio, corrosion resistance, and ability

Mastering Flanges Production Tips for Cutting High-Manganese Steel in CNC Machining

Introduction High-manganese steel is renowned for its exceptional wear resistance and toughness, making it an ideal choice for producing durable flanges. However, its high strength

CNC Machining Guide Choosing the Right Tools for Drilling Polymer Composites

Drilling polymer composites in CNC machining is a task that demands precision, expertise, and the right tools. As composite materials continue to grow in popularity

Handling Composite Materials in CNC Turning A Straightforward Approach to Tools and Techniques

Composite materials have become increasingly important in modern manufacturing due to their superior strength-to-weight ratios and excellent resistance to corrosion and fatigue. As industries such

A Comprehensive Guide to the Most Common Types of Welding Joints: How to Choose the Right One for Your Project

Welding plays a crucial role in metal fabrication, serving as a fundamental process for joining materials in various industrial applications. The strength, durability, and quality

Conquering High-Strength and Ultra-High-Strength Steel in CNC Machining Precision and Techniques Revealed

High-strength and ultra-high-strength steels (HSS and UHSS) are engineering marvels, known for their exceptional combination of strength and toughness. These steels are crucial in industries

Cracking the Code to Stainless Steel in CNC Machining A Complete Guide to Tools and Techniques

Stainless steel is a go-to material in industries ranging from aerospace to medical devices, thanks to its corrosion resistance, strength, and aesthetic appeal. However, these

Mastering Quenched Steel in CNC Machining Tips on Tool Selection and Optimization

In the demanding world of CNC machining, mastering the art of cutting quenched steel is crucial for both suppliers and buyers. Quenched steel, known for

Tough Opponents in the CNC World The Clash of Flanges and Difficult to Cut Materials

In the world of CNC machining, the battle between machine tools and difficult-to-cut materials is nothing short of a high-stakes chess match. For buyers seeking

Understanding Material Machinability in CNC Machining: What Every Engineer Should Know

Introduction When it comes to CNC machining, the material you choose can make or break your project. Whether you’re working on a high-precision component or

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- NDT

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We …

Best CNC-Cut Acrylic Signs for Retail and Events: Design and Production Guide

Chapter I:Introduction I want to start by sharing how I first realized the power of CNC-cut acrylic signs.I was working …

What Is NDT? Complete Guide to Non-Destructive Testing Methods And Use Cases

Chapter I: Introduction to NDT Non-Destructive Testing, or NDT, plays a huge role in modern engineering.I remember the first time …

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

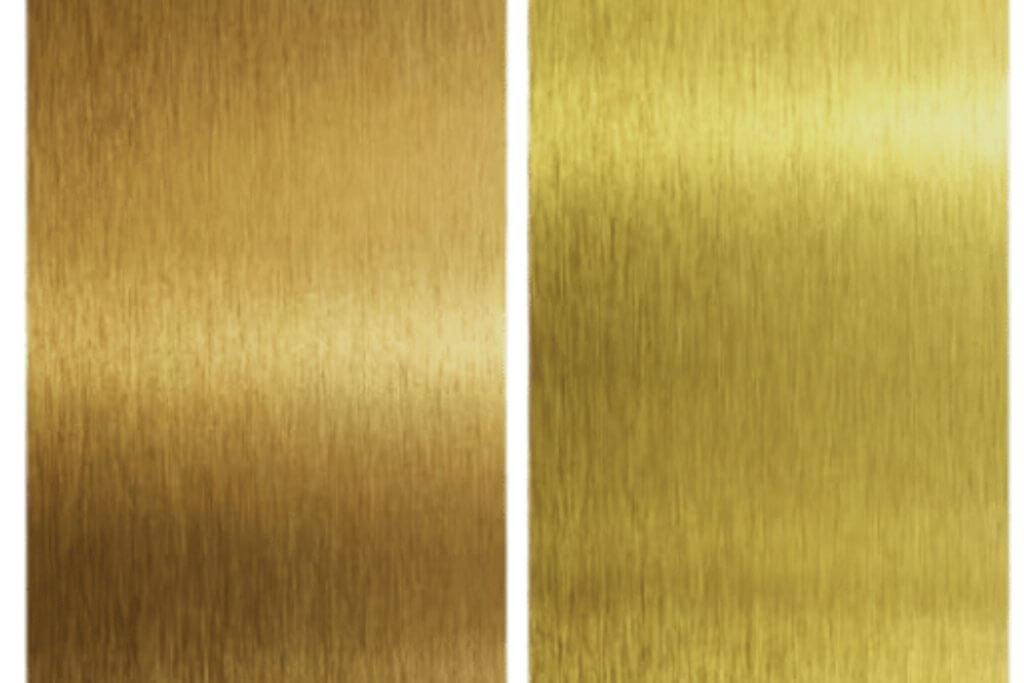

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …