Blog

Unlocking the Secrets of CNC Machining Parts with Spindle Rotation Control

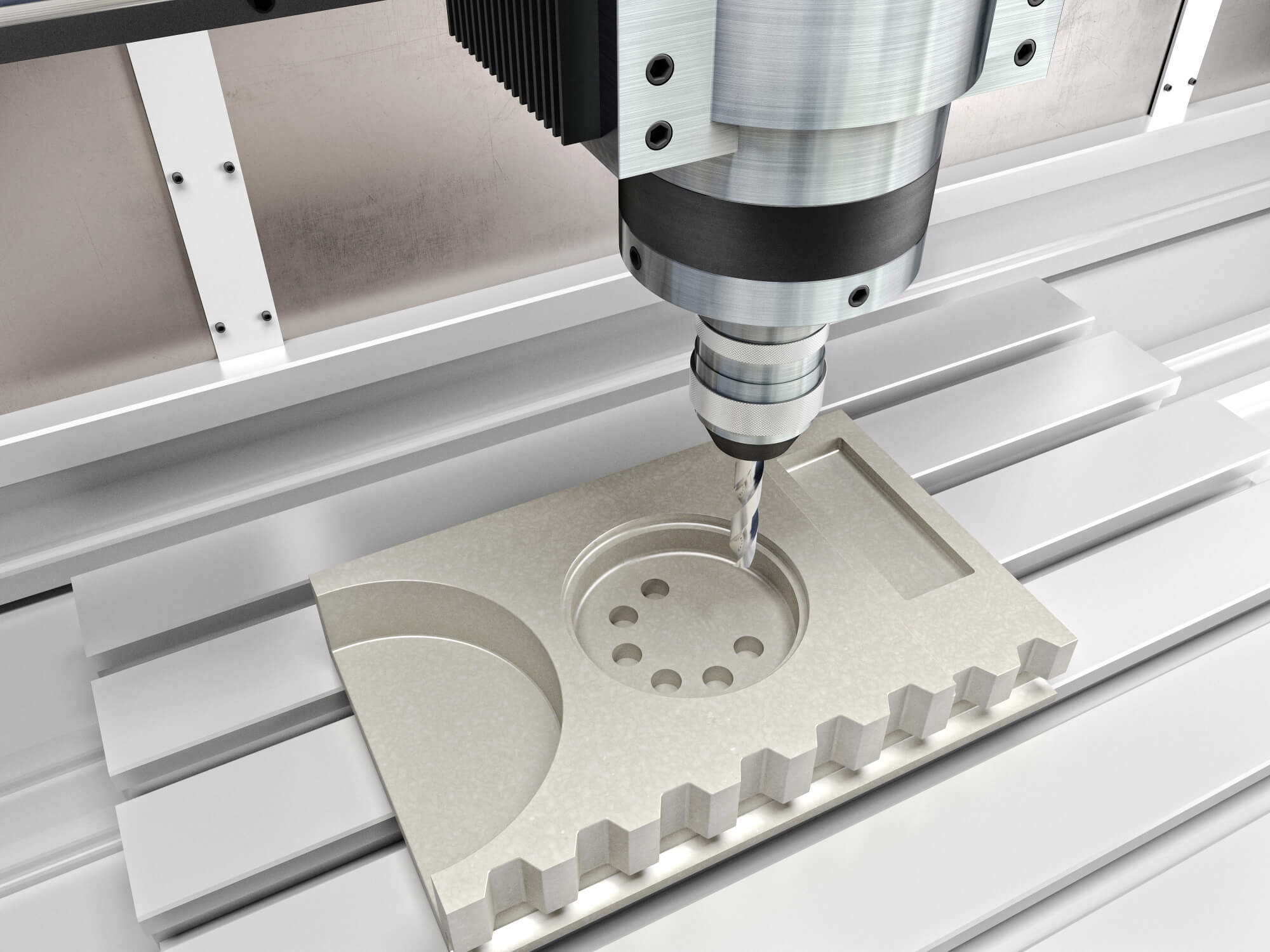

CNC machining is a blend of art and science, and mastering spindle rotation control can significantly enhance the quality and efficiency of machining parts. Whether

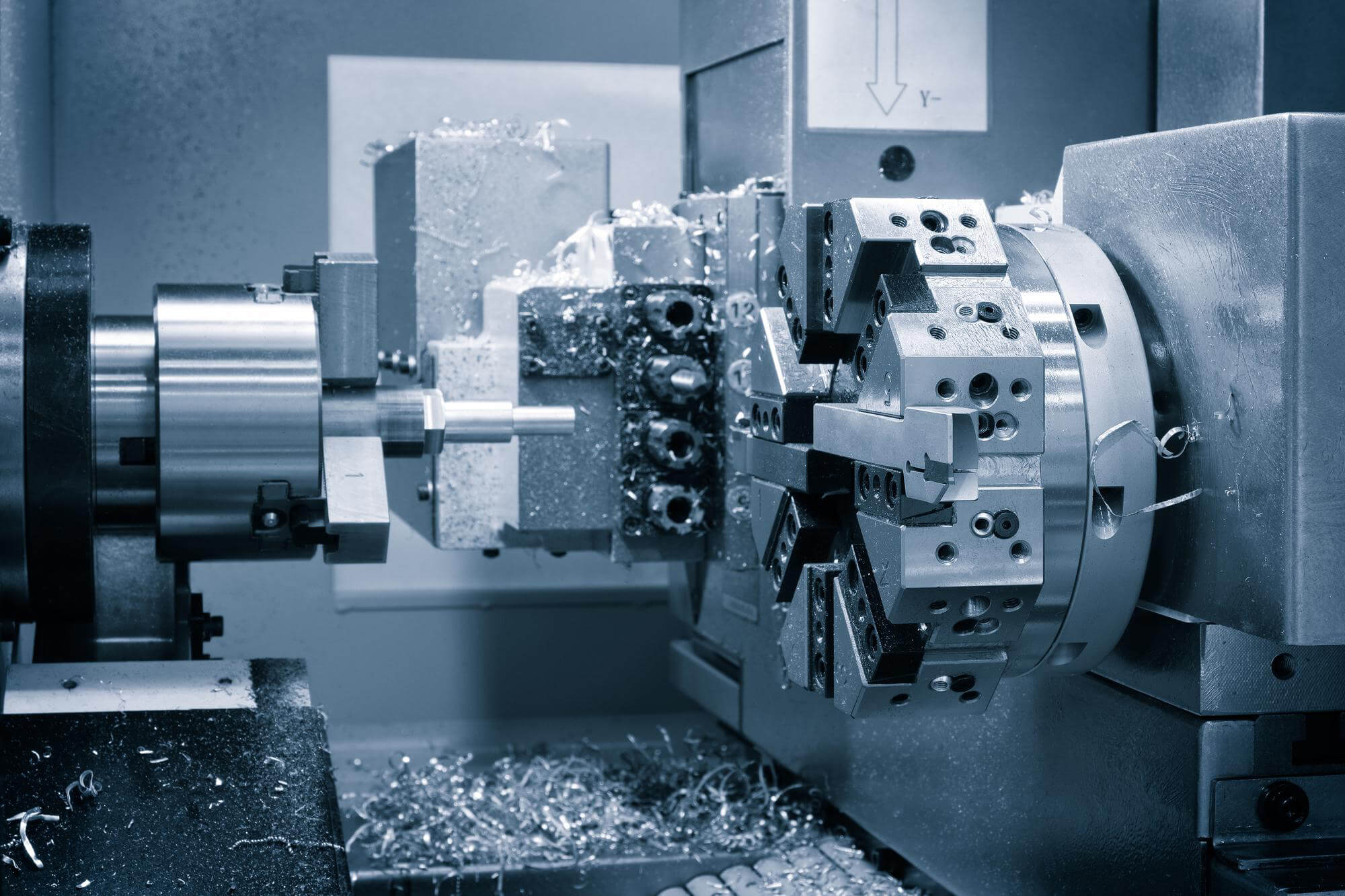

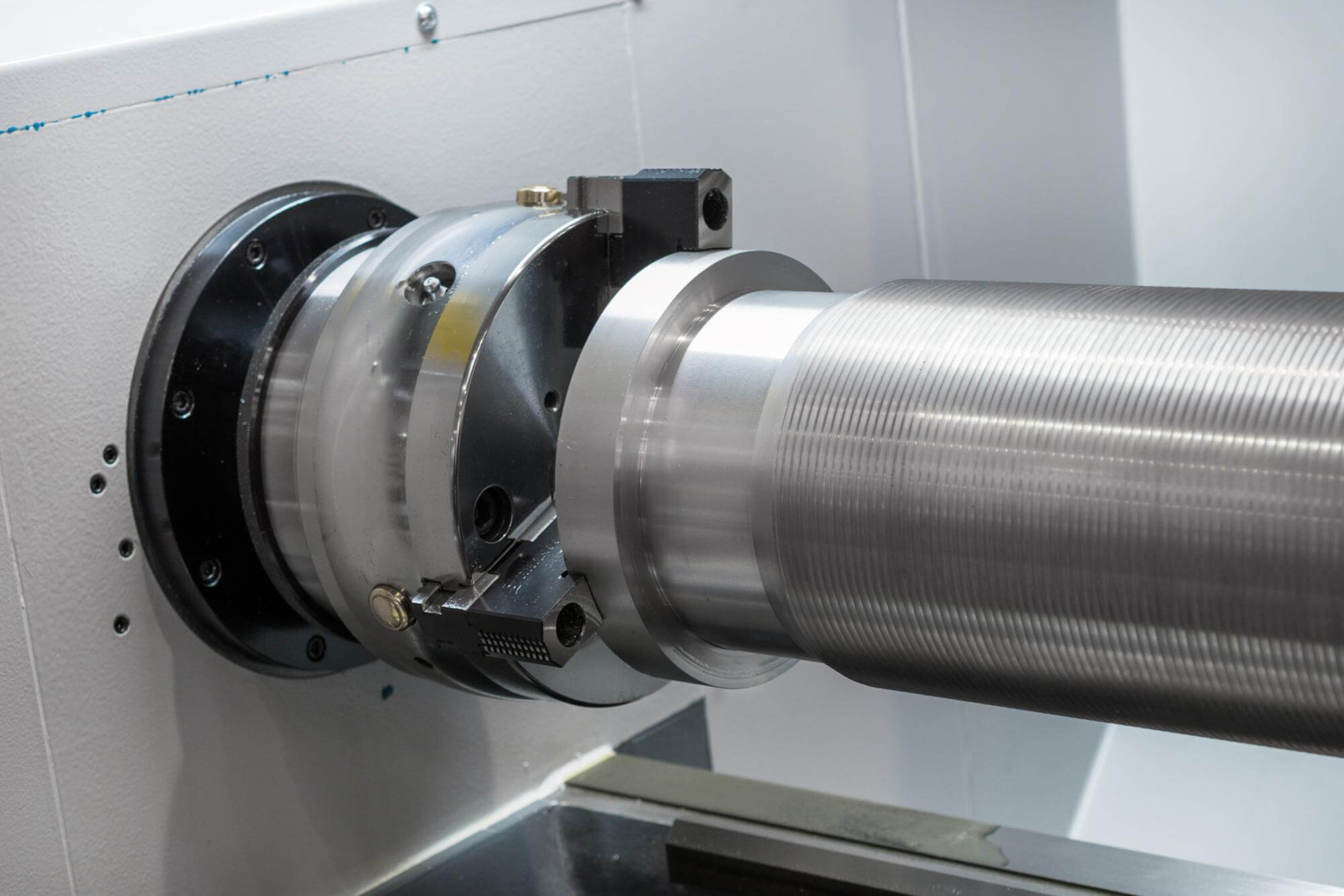

CNC Machining Parts: The Art of Spindle Speed and Direction Control

CNC machining is a fascinating world where precision meets creativity. At the heart of this intricate dance is the spindle, a critical component that dictates

Summary of CNC Turning Tool Knowledge

Insert Shapes and Naming Standards International Insert Naming Standards The naming of CNC turning inserts follows international standards, which mainly include the shape, material, and

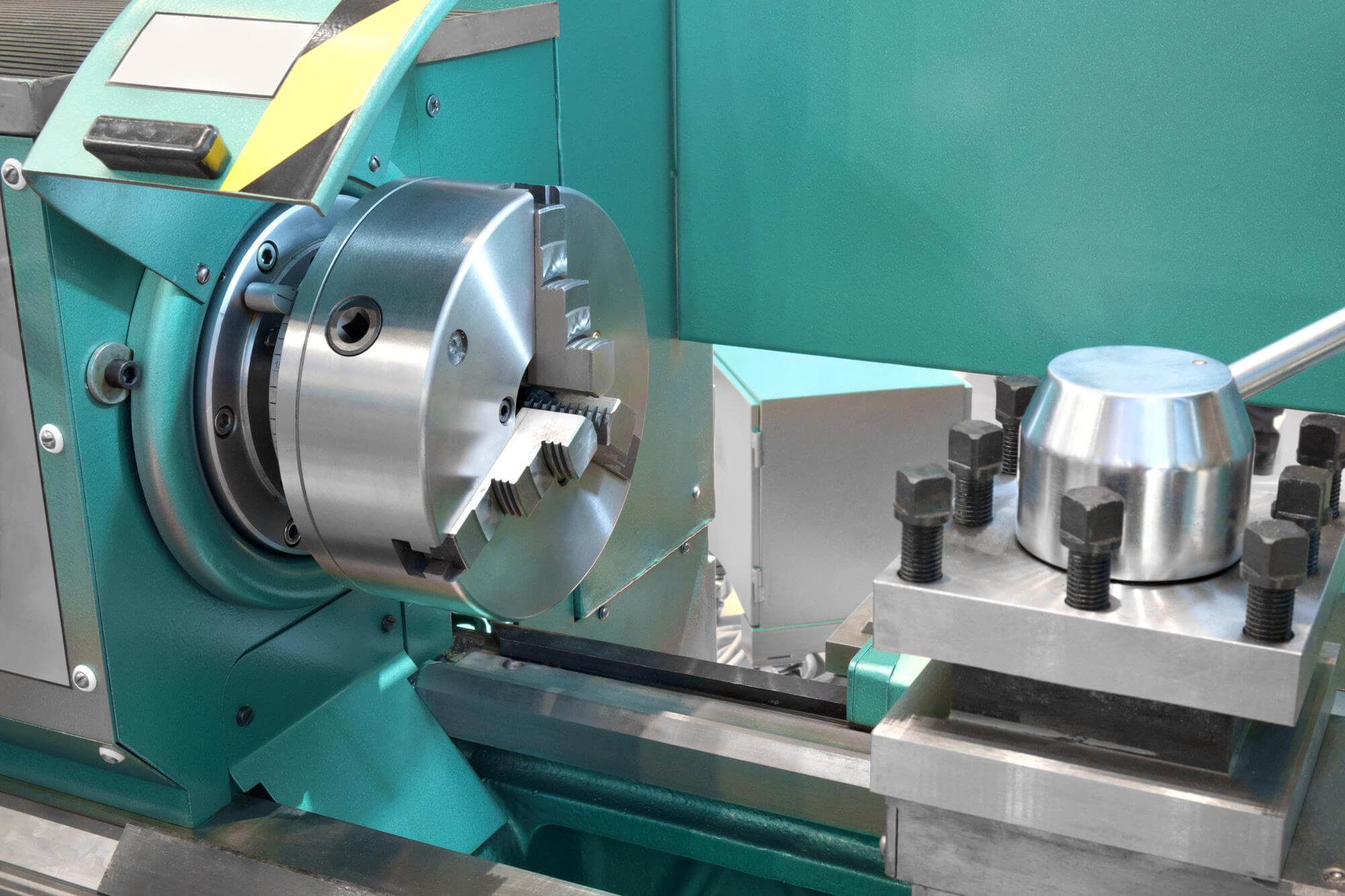

Metal Cutting Machine Tool Design: Exploring the Fascinating World of Metal Processing

Overview of Metal Cutting Machine Tools Metal cutting machine tools are machines that use tools or abrasives to cut metal workpieces. They are known as

Selection and Comparison of Blank Forming Methods for Parts

Principles of Blank Selection In mechanical manufacturing, the selection of blanks is crucial as it not only affects product quality but also influences manufacturing costs

Machining Precision and Its Control

In machining, controlling precision is a crucial aspect that directly affects the quality and performance of the final product. This chapter details the factors influencing

Control of Machining Precision

Machining precision refers to the degree to which the actual geometric parameters of a machined part conform to the ideal geometric parameters (such as size,

Analysis of Part Structural Manufacturability

Part structural manufacturability refers to the feasibility and cost-effectiveness of manufacturing a designed part while meeting the required standards. Designing a part that is easy

Unveiling the Technological Craftsmanship of Part Structures

Common Casting Structures Taper To facilitate the removal of the cast from the mold and reduce resistance, a certain degree of taper is added in

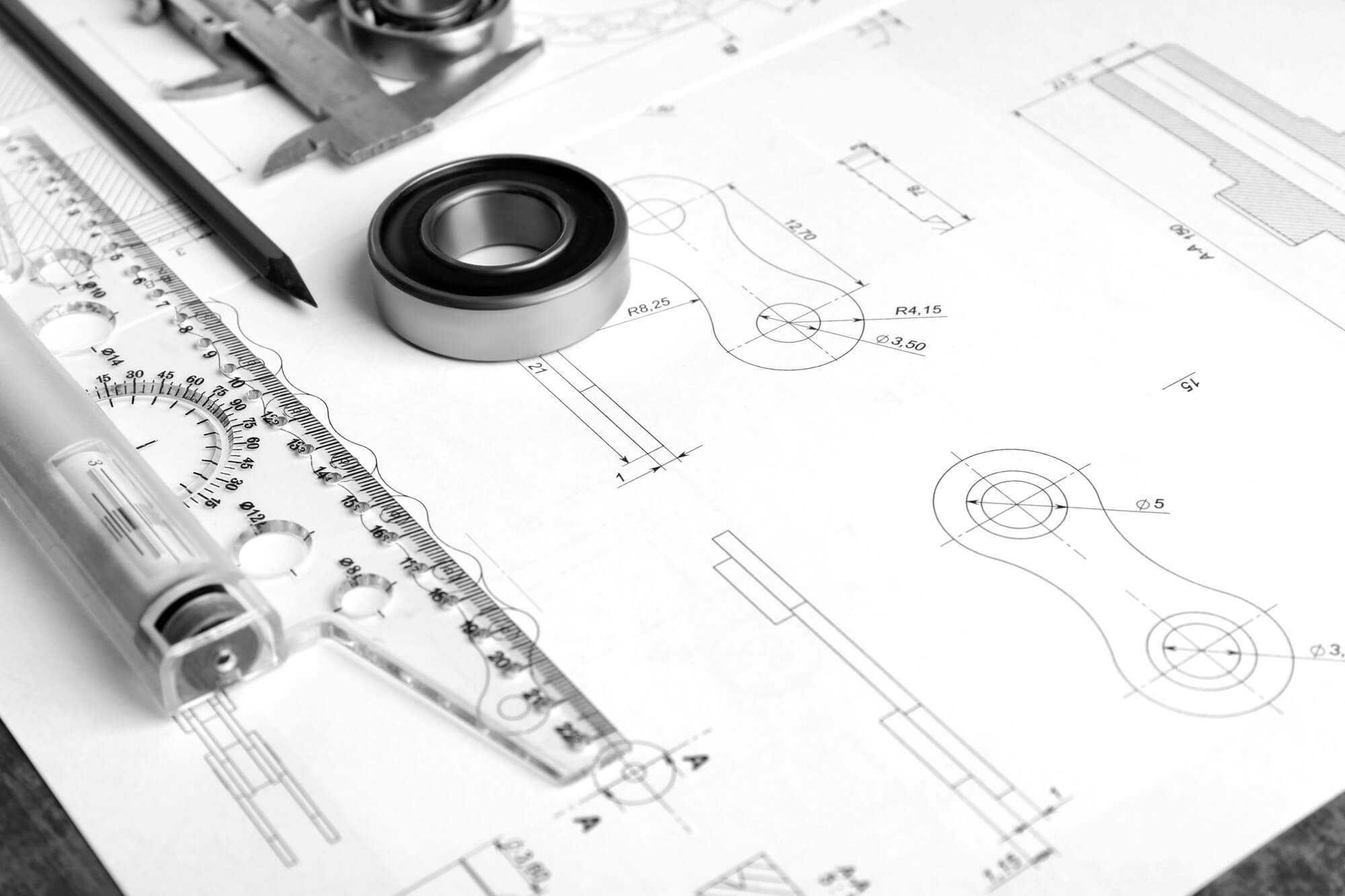

Mechanical Drawing Annotation Methods and Common Issues and Requirements

In mechanical processing, drawing annotations play a crucial role. The first key point is that the true size of the part should be based on

Mechanical Machining Surface Quality: From Principles to Practical Application

Mechanical machining surface quality is a crucial aspect of mechanical manufacturing that directly impacts the performance and longevity of parts. This article will discuss the

Exploring Different Dimension Formats in CNC Machining Parts Programming

In the world of CNC machining, how you input dimensions can significantly impact the ease and accuracy of your programming. Since CNC technology began being

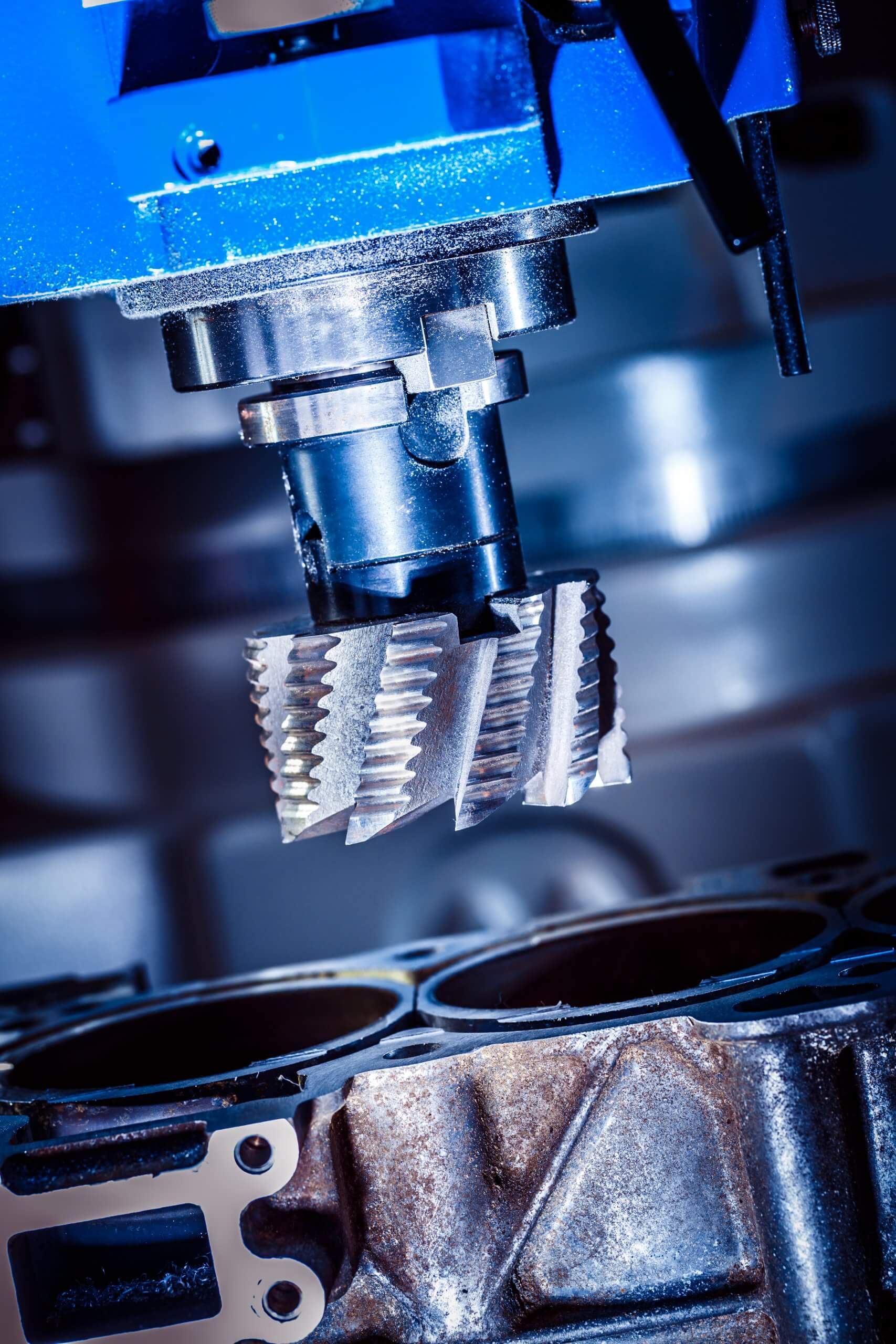

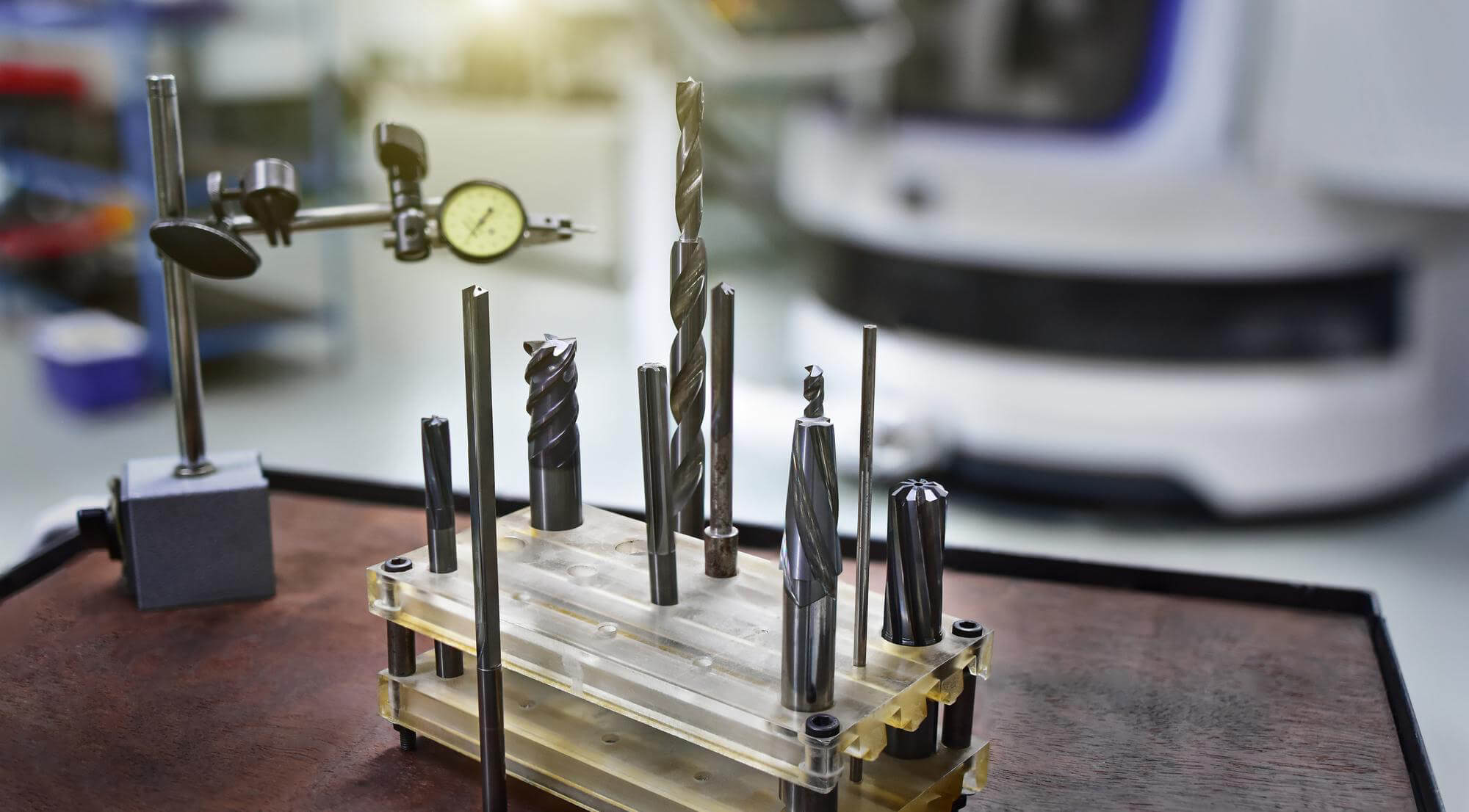

Comprehensive Guide to Metal Cutting Tools

In modern mechanical manufacturing, metal cutting processes are the most widely used methods, accounting for over 50% of the total workload in mechanical manufacturing. Whether

Practical Guide to Absolute and Incremental Modes in CNC Machining Parts Programming

When it comes to CNC machining, understanding the difference between absolute and incremental modes is crucial. These two modes define how the machine interprets the

Metric vs. Imperial Units Conversion and Usage: CNC Machining Parts Programming

When it comes to CNC machining, precision is key. This precision hinges significantly on the proper use of units, whether metric or imperial. Each unit

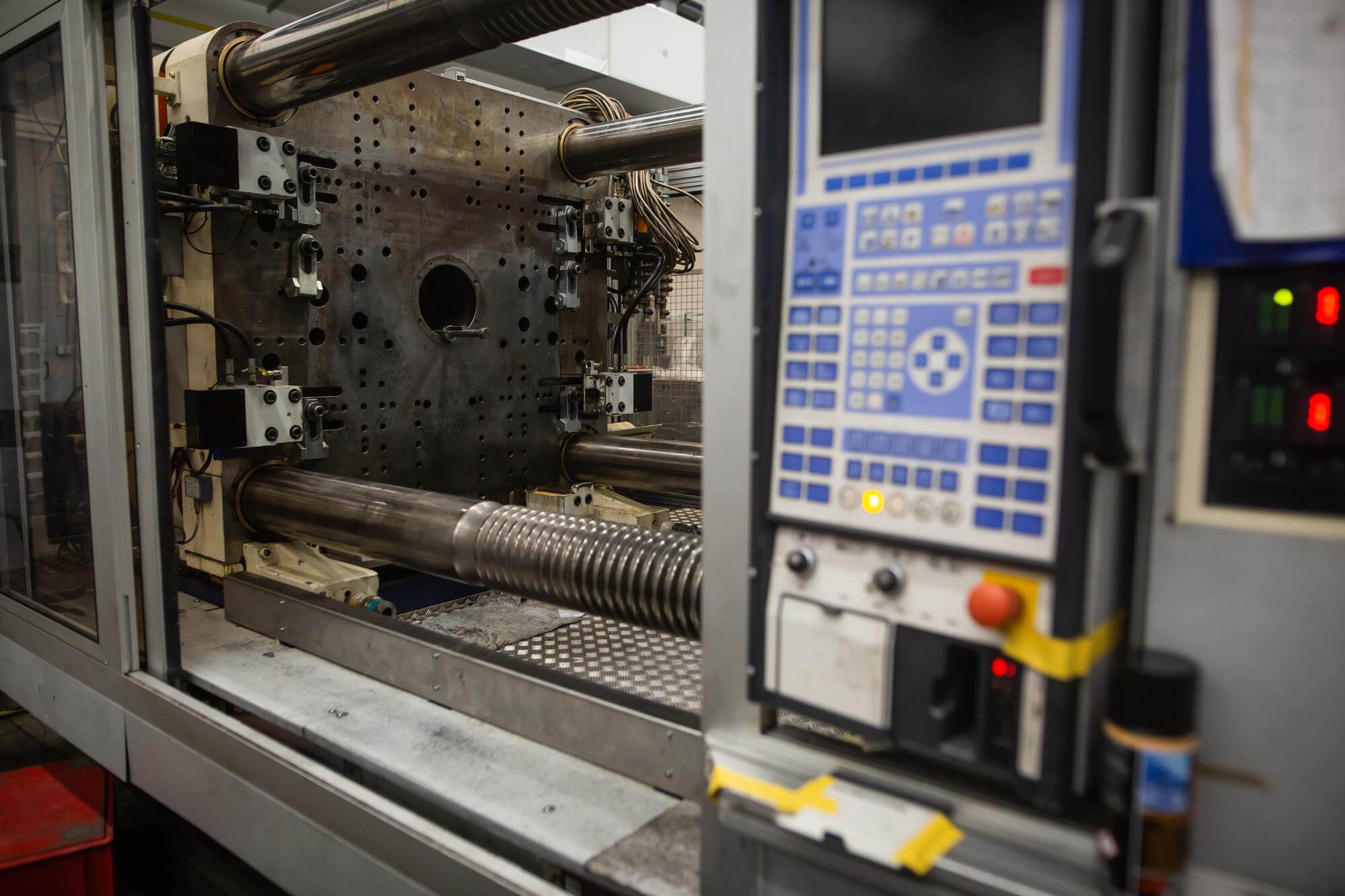

Detailed Overview of Injection Molding and Plastic Manufacturing Processes

Plastic manufacturing involves the process of converting plastic raw materials into final products through various techniques. These techniques range from simple cutting and shaping to

How Do Import Regulations Affect the Procurement of Brass CNC Machining Parts?

What Are the Global Import Regulations for Brass CNC Machining Parts? The global landscape for importing brass CNC machining parts is complex and varies significantly

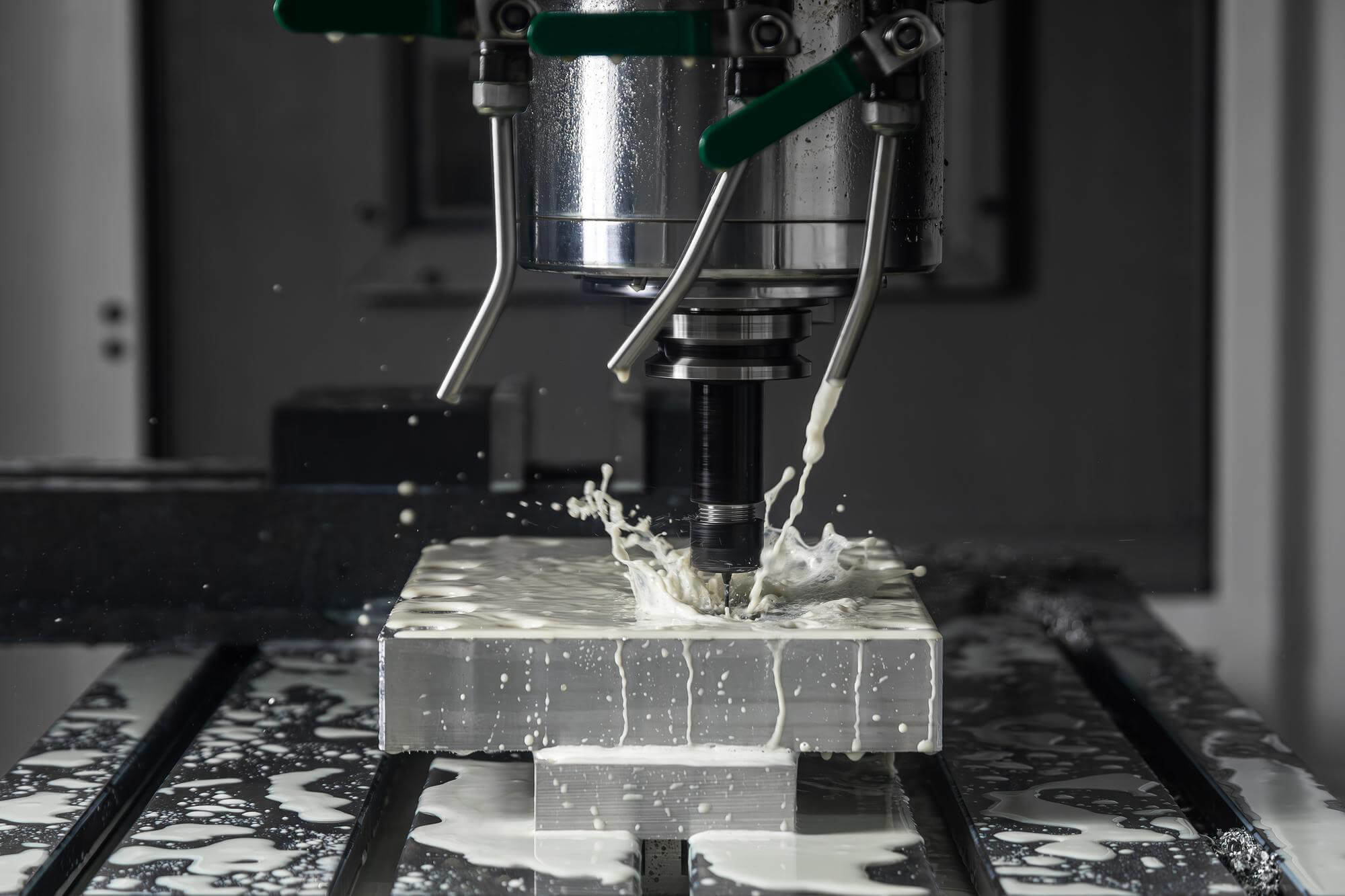

High-Speed Machining Techniques in CNC Machining Parts: Secrets to Enhanced Efficiency and Quality

High-speed machining (HSM) is an intriguing and evolving field within CNC machining. The term “high-speed” is relative and varies depending on the machining method, workpiece

What Are the Latest Trends in Sourcing Brass CNC Machining Parts?

How Are Global Market Dynamics Shaping the Sourcing of Brass CNC Machining Parts? The global landscape for sourcing brass CNC machining parts is heavily influenced

Mastering CNC Machining: Overcoming Thin-Walled Aluminum Alloy Part Deformations

In the world of CNC machining, creating precise and complex parts from aluminum alloys is a common yet challenging task. When it comes to thin-walled

Enhancing Surface Quality of CNC Machining Parts with Mechanical Preprocessing

Mechanical preprocessing When it comes to CNC machining, achieving a perfect surface finish is crucial. It’s not just about making parts look good; it’s about

Advanced Peck Drilling Methods for Precision CNC Machining Parts

Peck drilling, also known as intermittent feed drilling, is an essential technique in the world of CNC machining. It uses fixed cycles, such as G83

Comparative Analysis: Injection Molding vs. Transfer Molding – Which Technique is Superior?

Plastic and rubber parts are a common sight in the industry. Most of these parts are made through molding techniques, with injection and transfer molding

High-Speed CNC Machining Parts: The Secret Sauce of Tool Material Selection

To high-speed CNC machining, the selection of tool materials is crucial. Imagine you’re a chef preparing a gourmet meal; the ingredients you choose will significantly

Heat Treatment Insights for Wrought Aluminum Alloys in CNC Machining Parts

In the field of CNC machining, achieving the desired mechanical and physical properties often hinges on effective heat treatment. For wrought aluminum alloys, which are

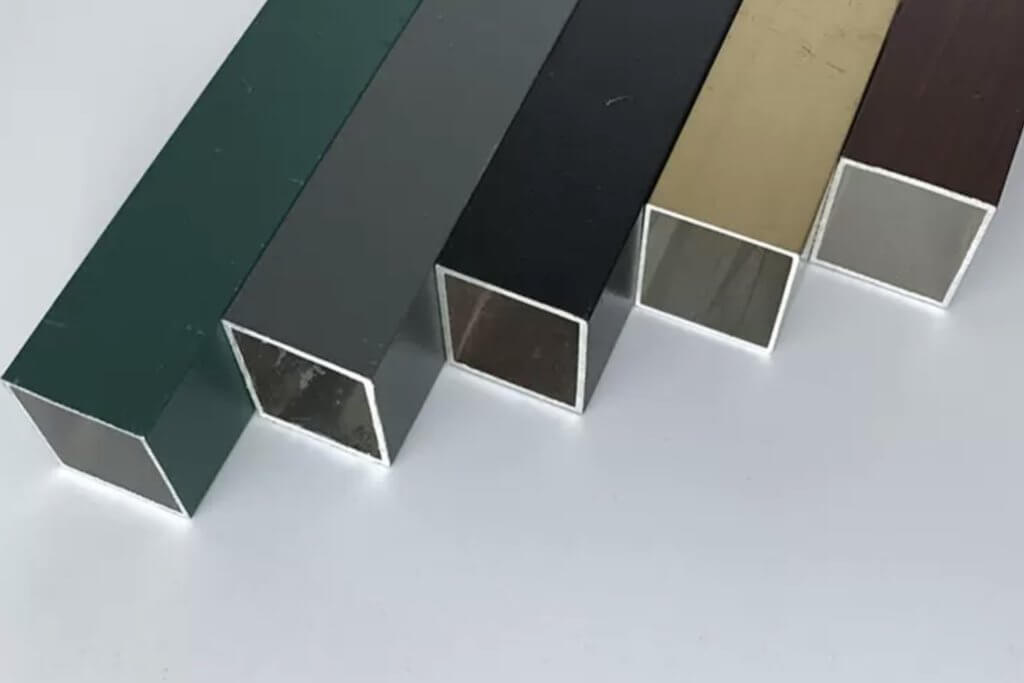

Revealing the Annealing Process of Copper and Alloys in CNC Machining Parts

In the realm of CNC machined parts, achieving the perfect balance of strength, flexibility, and durability often requires meticulous heat treatment processes. One such crucial

CNC Machining and Sheet Metal Processing in the Automotive Industry: Driving Innovation and Precision

Since its beginnings in the 1860s, the automotive industry has built itself on continuous innovation and technology advancements. One of the most significant drivers of

Blog

- All

- 14c28n

- 304

- 3D Print

- 4140

- ABS

- Acetal

- Acrylic

- aerospace cnc machining

- alloy

- Aluminum

- annealing

- Anodized Aluminum

- anodizing

- bead blasting

- bearing

- bevel

- blasting

- bolts

- Brass

- brass tap

- Brittleness

- Bronze

- bulk modulus

- bushes

- cad file

- camshaft

- carbon fiber

- Carbon Steel

- cast iron

- ceramic

- CFRP

- Chamfer

- chitubox

- chrome plating

- CMM

- cnc drilling

- cnc machine

- cnc machined parts

- cnc machining

- cnc machining aerospace parts

- cnc machining in aerospace industry

- cnc machining prototype

- cnc measurement

- cnc milling

- cnc plastic drilling

- cnc plastic machining

- cnc plastic milling

- cnc plastic turning

- cnc turning

- coating

- composite

- Copper

- counterbore

- countersink

- custom metal parts

- cutting

- cutting fluids

- delrin

- Density

- Die Casting

- drilling

- Ductile iron

- ductility

- EDM

- electroplating

- engraving

- enlarging holes

- fastener

- ferrous metals

- Fiberglass

- flanges

- Formula

- galling

- Gauge Size

- gcode

- GD&T

- gear

- GFRP

- grill

- grinder

- Grinding

- HDPE

- heat treatment

- heatsink

- High-speed

- High-speed cutting

- HMCs

- hub

- Inconel

- iron

- jigs

- Joint

- KFRP

- knurling

- large

- laser

- Lathe

- lathe chucks

- Lathe Tools

- lattice

- machine

- machining

- Machinist

- manganese

- material

- metal

- Metal Fabrication

- metalloids

- milling

- mold

- motor shaft

- nipple

- nuts

- Nylon

- PCB

- PEEK

- pewter

- Plastic

- polishing

- polyamide

- Polycarbonat

- Polycarbonate

- polyester

- Polypropylene

- POM

- powder coating

- precision machining

- prototype

- prototype cnc machining

- punch

- PVC

- quality control

- reamer

- Resin

- Rivets

- sandblasting

- screws

- sfm

- shaft

- shear

- Stainless Steel

- Steel

- stl

- Strain

- stress

- stud

- supplier

- surface finishes

- Teflon

- tensile

- Thermoplastic

- Thermoset

- thread

- Titanium

- tpe

- tungsten

- UHMW

- VMCs

- Waspaloy

- watch

- Zinc

- Zirconium

What Is a Brass Nipple? Full Guide to Types, Threads, Custom and CNC Machining

I’ve been working with brass fittings for years, and one of the most common questions I get is, “What exactly …

CNC Machining the Brilliant Cut Grinder: A Deep Dive into Design, Manufacturing And Commercial Potential

Introduction A “Brilliant Cut Grinder” has become symbolic of high-end design and precision manufacturing. At a glance, it’s a grinder …

Bench Grinder Uses In CNC Shop Should Know:Complete Guide for Operators and Engineers

I’m thrilled to share my in-depth perspective on the many ways a Bench Grinder can transform life in a CNC …

Powder Coating Cost Calculator Guide: Estimating Jobs by Size, Shape, and Volume

Introduction: Why Accurate Powder Coating Cost Estimation Matters When I first started exploring powder coating as an option for metal …

Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or …

Grinder Types And Operation Tips: Explained for Surface, Cylindrical, and CNC Use

What is a Grinder? When I first started working in precision machining, I remember feeling a bit overwhelmed by all …

Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing …

CNC Machine Cost Explained: A Complete Guide by Type, Application, and ROI Considerations

Introduction: Why CNC Machine Cost Matters When I first started exploring CNC machining, the first question I had—and probably yours …

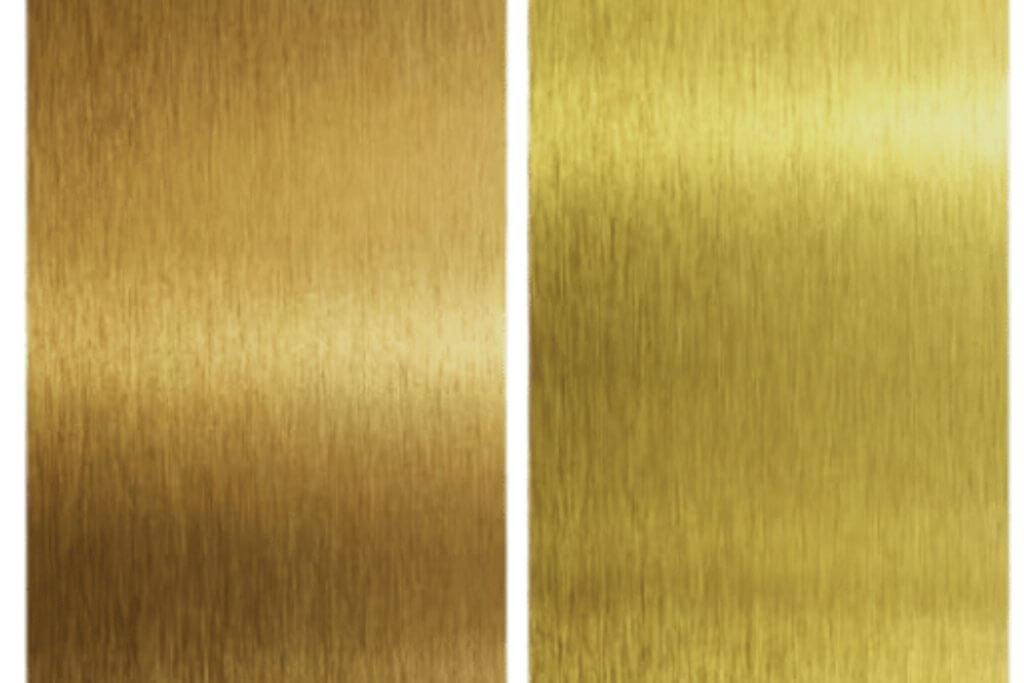

Brass vs Gold for Jewelry, Fixtures, and Electronics Etc: Pros and Cons

Introduction: Why Compare Brass and Gold? If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced …

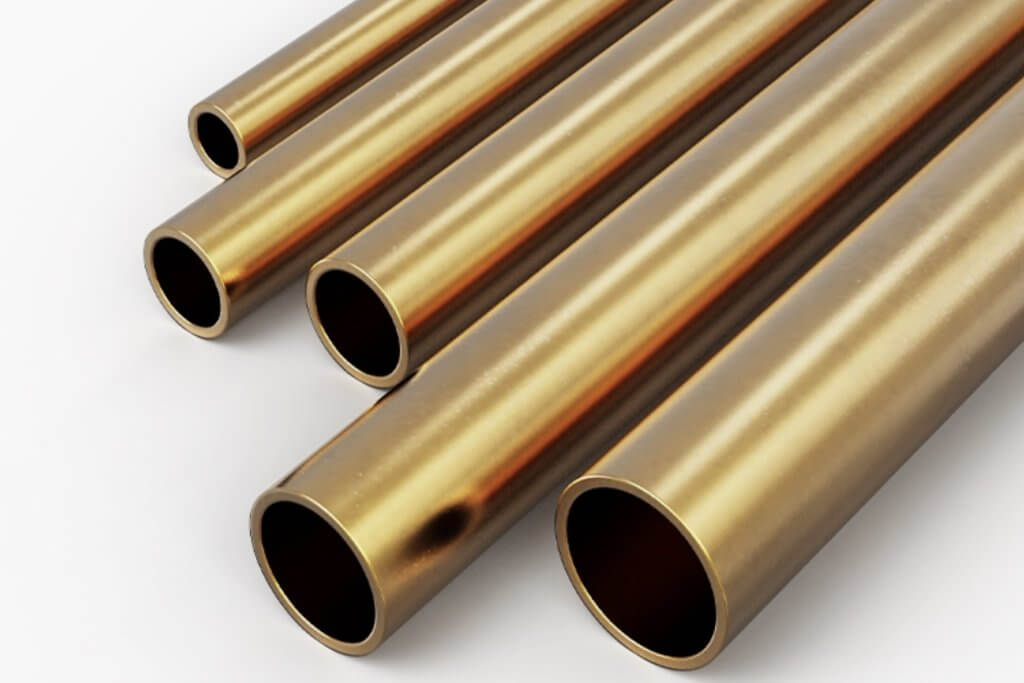

Brass Pipe Customization via CNC: What Engineers and Buyers Must Consider

Introduction: Why Brass Pipe Matters in CNC Projects Brass pipe is one of those materials engineers and buyers often overlook …

Fiberglass Rod for CNC Applications: Material Guide, Machining Tips & Use Cases

🟩 Introduction: Why Fiberglass Rods Matter in CNC Projects Fiberglass rods might seem like basic materials at first glance—just solid, …

Choosing the Right Metal Fasteners: A Practical Guide for CNC Customization or Purchasing

Introduction: Why Metal Fasteners Matter in CNC Projects If you’re involved in CNC machining or design, you’ve likely realized metal …