Introduction: Why Compare Brass and Gold?

If you’ve ever shopped for jewelry, home decor, or electronic components, you’ve probably faced the question of brass vs gold. On the surface, these two materials often look similar, especially when brass is polished or gold-plated. But from personal experience, I know that the choice between brass and gold isn’t always just about looks. There are important differences in durability, cost, and suitability for various applications.

In this guide, I’ll share my insights into why and when you’d want to choose brass over gold—and vice versa. I’ve encountered this dilemma in several projects, from designing custom fixtures to sourcing electronic connectors. Each time, the decision came down to a clear understanding of each material’s pros and cons.

So, why does comparing brass vs gold matter? Because making the right material choice can significantly affect your project’s cost, appearance, durability, and even its commercial success. Let’s explore this further.

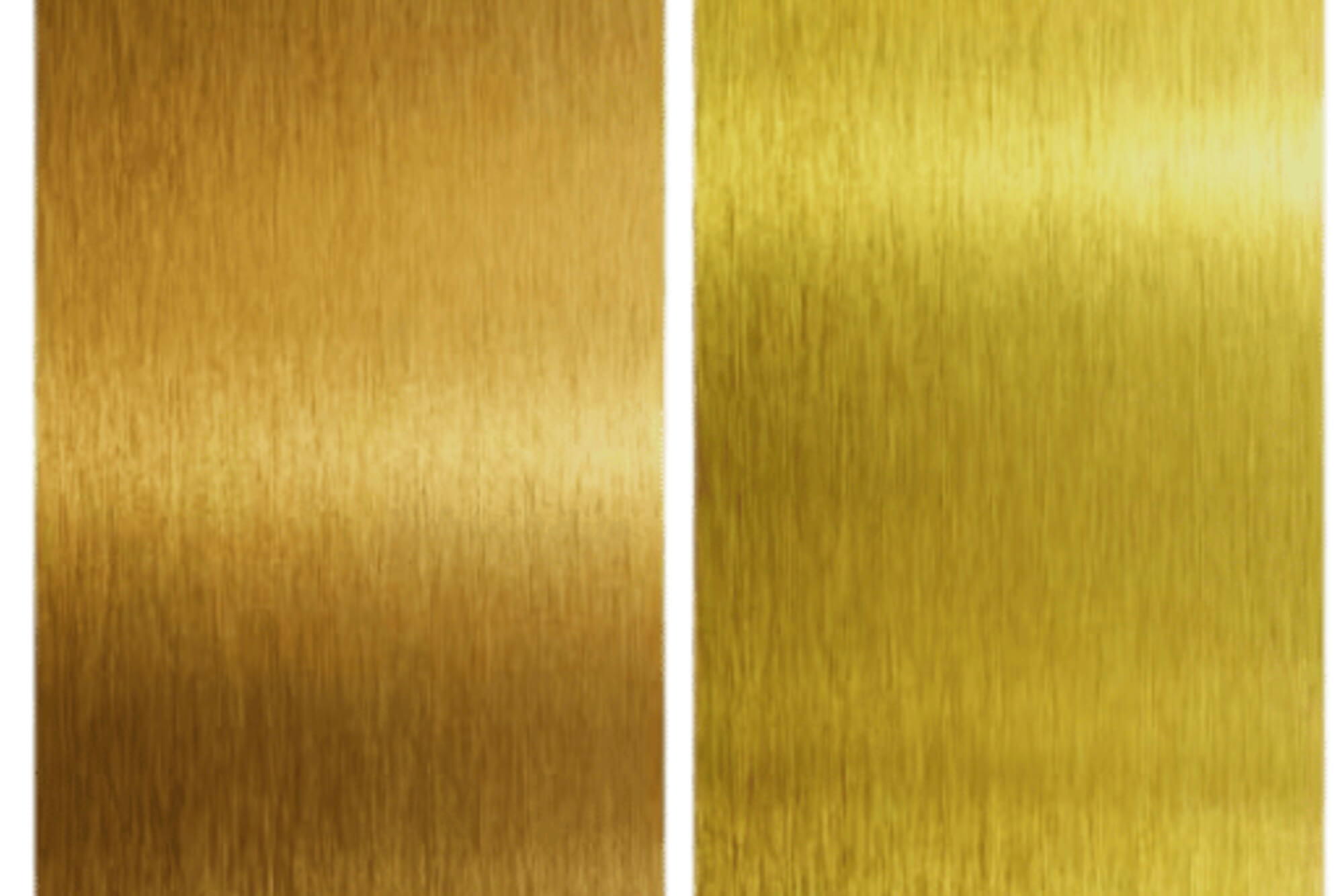

Visual & Aesthetic Comparison

Can Brass Really Imitate Gold?

One of the most common questions I hear is, “Can brass realistically imitate the look of gold?” The short answer: yes—but with limitations.

Both brass and gold share a warm, rich yellow tone. Brass, when polished and lacquered, can closely resemble gold at first glance. However, brass is an alloy composed mainly of copper and zinc, while gold is a pure metal (typically alloyed slightly to enhance durability). Over time, brass will oxidize and darken, losing that golden shine.

I’ve personally tested brass items side-by-side with gold items. Freshly polished brass can pass for gold to the untrained eye, but a closer look reveals distinct differences in color and depth of shine.

Visual Differences Between Brass and Gold (Summary):

| Feature | Brass | Gold |

|---|---|---|

| Initial Color | Bright yellow-gold | Rich, deep yellow-gold |

| Long-term Color | Darkens or tarnishes | Maintains shine, no tarnishing |

| Reflection | Less reflective over time | High, consistent reflectivity |

| Surface Feel | Smooth initially; roughens over time | Smooth, maintains texture |

When I worked on designing brass fixtures for boutique hotels, clients often worried about how quickly brass would tarnish compared to gold-plated options. After testing and observation, we found regular maintenance or sealing brass with lacquer could significantly delay discoloration. But ultimately, brass never matches gold’s long-term brilliance.

If maintaining a consistent golden appearance matters to your product, gold or gold-plated items will always outperform brass.

Cost Analysis: Raw Materials, Processing & Total Value

When comparing brass vs gold, cost is usually a deciding factor. But it’s not just the raw material price that matters; production costs, processing techniques, and long-term maintenance can dramatically change the total expense.

Material Cost Comparison (2024 average market prices):

| Material | Approximate Cost (per ounce) |

|---|---|

| Brass Alloy | $0.10–$0.30 |

| Gold (24k, pure) | $1,800–$2,000 |

| Gold Plating (per sq inch) | $0.20–$0.50 |

Clearly, pure gold is significantly more expensive than brass. Even gold plating over brass, while more affordable than solid gold, adds extra costs.

Processing Costs & Considerations:

Brass is remarkably easy and affordable to machine, mold, cast, and polish. I’ve worked with manufacturers who appreciate brass because it allows for complex shapes at a low cost. Gold, on the other hand, is costly and delicate to handle in manufacturing.

For jewelry, gold often requires skilled labor, precise tools, and careful handling—adding significantly to costs. Meanwhile, brass jewelry components are inexpensive, easily cast or stamped, and simpler to mass-produce.

Maintenance and Long-Term Costs:

Brass can tarnish and corrode if not properly sealed, requiring regular maintenance or re-plating. Gold is naturally corrosion-resistant and typically maintenance-free, though gold plating will eventually wear off and require replating.

I’ve experienced firsthand the hidden cost of maintenance. A client who initially chose brass fixtures for a restaurant later faced unexpected maintenance expenses. Despite lower upfront costs, brass proved more expensive over five years due to ongoing cleaning and polishing.

Cost Comparison Summary:

| Factor | Brass | Gold | Gold Plating |

|---|---|---|---|

| Initial Material Cost | Very Low | Very High | Moderate |

| Manufacturing Complexity | Low | High | Moderate-High |

| Maintenance Cost | Moderate-High | Very Low | Moderate (replating needed) |

| Overall Long-term Cost | Moderate (due to maintenance) | High (but durable) | Moderate |

When budget constraints exist, brass is undeniably attractive. Yet, I always advise considering the long-term expense—not just upfront cost. Gold, though costly initially, often delivers better lifetime value.

Mechanical & Physical Properties

When comparing brass vs gold, it’s essential to understand their mechanical and physical differences clearly. Each material’s unique characteristics determine their suitability for different applications, especially in fixtures, jewelry, or electronic components.

Hardness and Durability

Brass is considerably harder and stronger than pure gold. Pure gold (24k) is extremely soft, easily scratched, and quickly deformed. Typically, gold used in practical applications (like jewelry or electronics) is alloyed (18k, 14k), increasing hardness slightly but still remaining softer than brass.

During a custom jewelry project, I tested gold and brass components side-by-side. Brass withstood physical impacts and daily wear significantly better than even 14k gold, making it ideal for durable jewelry or everyday-use fixtures.

Hardness Comparison Table:

| Material | Mohs Hardness Scale | Durability & Strength |

|---|---|---|

| Brass | 3–4 | High (hard, strong) |

| 24k Pure Gold | 2.5–3 | Very Low (soft, malleable) |

| 18k Gold | ~3 | Low–Moderate |

| 14k Gold | ~3.5 | Moderate |

Density and Weight

Gold is denser than brass, meaning a gold item will weigh noticeably more than an identical-sized brass one. This density difference can be used to distinguish between gold and brass easily.

| Material | Density (g/cm³) |

|---|---|

| Brass (average) | 8.4–8.7 |

| Gold (24k) | 19.3 |

I remember a project where a client suspected counterfeit gold jewelry. Simply by weighing the pieces, it was clear they were brass plated with gold, not solid gold—since real gold items would weigh significantly more.

Conductivity and Electronics Use

In electronics, conductivity matters. Pure gold has exceptional electrical conductivity, and brass, while conductive, is less efficient. However, brass connectors are frequently gold-plated to achieve gold’s conductivity and corrosion resistance at a lower cost.

| Material | Electrical Conductivity (% IACS) |

|---|---|

| Brass (C260 alloy) | 28% |

| Gold (pure) | 70% |

For critical electronic contacts, gold plating is almost always the preferred solution. Pure brass contacts oxidize quickly, reducing electrical efficiency over time.

Corrosion and Tarnish Resistance

Gold naturally resists corrosion and tarnishing, even in harsh conditions. Brass, conversely, readily oxidizes and tarnishes without protective coatings or regular maintenance.

When designing outdoor fixtures, gold or gold-plated brass remains visually appealing far longer than untreated brass.

Corrosion Resistance Comparison:

| Material | Corrosion & Tarnish Resistance |

|---|---|

| Brass (uncoated) | Moderate–Low (oxidizes easily) |

| Brass (lacquer-coated) | Moderate–High (requires re-coating periodically) |

| Gold | Excellent (no tarnish, corrosion-resistant) |

In short, brass is strong, affordable, and practical—but gold significantly outperforms it in corrosion resistance, conductivity, and long-term aesthetics.

Health, Safety & Skin Compatibility

In jewelry or skin-contact fixtures, choosing between brass and gold isn’t just about appearance or cost. Health considerations matter significantly.

Skin Allergies and Sensitivities

Brass often contains trace amounts of lead or nickel, potentially causing allergic reactions or skin irritation. Gold, especially higher purity (14k and above), rarely triggers allergic reactions.

A client once requested brass jewelry, but after prolonged wear, developed skin irritations. Switching to gold solved this problem instantly.

Allergy Risk Comparison:

| Material Type | Lead Content | Nickel Content | Hypoallergenic? |

|---|---|---|---|

| Brass | Often trace (varies) | Sometimes | No (common skin reactions) |

| 14k–18k Gold | No | Rarely | Usually yes (safe for most) |

| 24k Gold | None | None | Yes (fully hypoallergenic) |

If skin compatibility is a priority, gold is always the safer choice.

Safety for Long-term Wear

Brass jewelry may oxidize or react with skin acids, causing discoloration or even minor chemical reactions. Gold jewelry stays chemically stable.

For wearable products (rings, watches, bracelets), gold remains the safest and most comfortable long-term option.

Use Cases: Jewelry, Fixtures, Electronics, and More

When deciding brass vs gold, application-specific contexts are key. Here’s a practical overview of recommended choices based on my experience:

Jewelry Applications

- Gold: Ideal for engagement rings, earrings, necklaces—high-value items intended for long-term daily wear.

- Brass: Suitable for costume jewelry, decorative pieces, or fashion accessories with shorter lifespan expectations.

Fixtures and Hardware

- Gold-plated Brass: Popular for luxury lighting fixtures, cabinet handles, faucets, and bathroom accessories—combining affordability and appearance.

- Solid Brass: Ideal for durable, affordable home fixtures, though regular maintenance (polishing) is required.

Electronics and Connectors

- Gold-plated Brass: Industry standard for connectors, contacts, terminals due to excellent conductivity and corrosion resistance.

- Solid Brass (uncoated): Not recommended due to oxidation and conductivity loss over time.

Commemorative Coins, Awards, Badges

- Gold: Premium awards, commemorative coins, or collector’s items with intrinsic value.

- Brass: Affordable alternative for mass-produced coins, badges, souvenirs—often plated with gold or nickel for visual appeal.

Use-Case Recommendation Table:

| Application Type | Best Material | Reasoning |

|---|---|---|

| High-end Jewelry | Gold | Hypoallergenic, lasting value, visual brilliance |

| Costume Jewelry | Brass | Low cost, easy manufacturing |

| Electronics Connectors | Gold-plated Brass | Optimal balance of cost, conductivity, durability |

| Home Fixtures | Gold-plated Brass/Brass | Cost-effective, aesthetic appeal |

| Outdoor Fixtures | Gold-plated Brass | Better corrosion resistance than brass alone |

| Commemorative Items | Gold or Gold-plated Brass | Long-lasting appearance, high perceived value |

My advice: clearly define your priorities—cost, appearance, durability—and choose accordingly.

How to Tell the Difference Between Brass and Gold

Distinguishing brass vs gold can sometimes feel challenging, especially when brass is polished or gold-plated. Over the years, I’ve learned practical ways to identify these materials quickly and accurately. Here are the methods I trust most:

Visual Inspection

Color Tone:

- Gold: Richer, deeper, consistent yellow.

- Brass: Bright yellow but slightly lighter, duller, or paler.

Under good lighting, gold always appears brighter and richer, while brass has a subtle reddish or greenish undertone when observed closely.

Surface Tarnish:

- Gold: Doesn’t tarnish or oxidize easily.

- Brass: Quickly develops a dark patina or greenish oxidation.

Weight & Density Test

Gold is much denser than brass. Simply holding items of equal size reveals gold’s noticeable weight advantage. This simple test helped me quickly identify counterfeit jewelry in past projects.

| Material | Density (g/cm³) |

|---|---|

| Brass | 8.4–8.7 |

| Pure Gold (24k) | 19.3 |

Magnetism Test

Neither brass nor gold is magnetic. However, brass alloys occasionally have small iron impurities causing very weak magnetism. If an item strongly attracts a magnet, it’s neither gold nor pure brass.

Acid Test (Professional Testing)

Jewelers often use nitric acid tests:

- Gold: No reaction with nitric acid.

- Brass: Turns greenish-blue under nitric acid.

Only perform this test professionally or under guidance, as acid is corrosive.

Hallmark Inspection

Authentic gold typically has stamped hallmarks like “14k,” “18k,” or “24k.” Brass almost never has purity hallmarks unless deliberately faked.

Quick Comparison Table:

| Test | Brass | Gold |

|---|---|---|

| Color Tone | Light, slightly reddish | Deep, consistent yellow |

| Tarnish/Oxidize | Yes, quickly | No |

| Weight | Lighter (8.4–8.7 g/cm³) | Heavier (19.3 g/cm³) |

| Magnetism | Non-magnetic (weak exceptions) | Completely non-magnetic |

| Acid Reaction | Green/blue reaction | No reaction |

| Hallmark Stamp | Usually none | Usually present (14k, 18k) |

Brass vs Gold – Pros and Cons Table

To simplify your decision-making, here’s a quick pros and cons summary from my experience across projects:

| Property | Brass (Pros) | Brass (Cons) | Gold (Pros) | Gold (Cons) |

|---|---|---|---|---|

| Cost | Affordable, economical | Needs maintenance, tarnishes | High perceived value, no tarnishing | Expensive |

| Durability | Stronger, good mechanical strength | Requires protective coatings | Corrosion-resistant, durable finish | Soft, easily scratched |

| Appearance | Looks like gold initially | Oxidizes and tarnishes over time | Rich, maintains shine | Limited color variety |

| Skin Compatibility | – | Can cause allergies (lead/nickel content) | Hypoallergenic (14k and above) | Lower purity gold less safe |

| Conductivity | Decent conductor | Oxidation reduces conductivity | Excellent conductivity, stable | High cost in electronics |

| Weight | Lightweight for fixtures/jewelry | Less valuable/heavy feel | Heavier, valuable feel | Higher production costs |

| Maintenance | Easy to restore | Needs regular polishing or re-plating | Little maintenance needed | Costly repairs if damaged |

FAQ

Here are answers to common brass vs gold questions I’ve encountered over the years:

- Can brass jewelry realistically look like real gold?

Yes initially, but brass tarnishes over time, losing its gold-like appearance. - Is brass always cheaper than gold?

Yes, significantly cheaper both as raw material and processing costs. - Why is gold better for sensitive skin?

Gold doesn’t contain lead or nickel, common irritants found in brass. - Does brass or gold last longer outdoors?

Gold or gold-plated brass lasts longer because of superior corrosion resistance. - Can brass be used safely for body jewelry?

Not recommended due to allergic reactions and tarnishing. - Is gold-plated brass a good alternative?

Yes, balancing affordability with the look and benefits of gold. - How quickly does brass tarnish compared to gold?

Brass tarnishes quickly, within weeks or months if untreated. - Which is better for electrical connectors, brass or gold?

Gold-plated brass offers best conductivity, cost-effectiveness, and durability. - Is brass suitable for engagement rings or wedding bands?

Usually not, gold offers better longevity and skin safety. - Can brass cause skin discoloration?

Yes, brass can react with skin acids, causing greenish discoloration. - What’s the main difference in weight between brass and gold?

Gold is over twice as dense as brass (19.3 vs 8.5 g/cm³). - Is brass stronger than gold?

Yes, brass has higher mechanical strength. - Why use gold if brass is cheaper and stronger?

Gold has better corrosion resistance, aesthetics, perceived value, and hypoallergenic properties. - Can brass be safely plated with gold?

Yes, gold plating brass is common and effective for cost and performance. - Does gold plating last long on brass?

It depends on thickness; thicker plating (2–5 microns) can last several years. - Does brass jewelry require special maintenance?

Yes, regular polishing or lacquer sealing is necessary to maintain shine. - Which metal retains value better, brass or gold?

Gold retains value much better due to intrinsic market value.

📚 Further Reading & Authoritative References

To support the facts and comparisons provided in this guide, here are some reputable sources and databases where you can find additional information on brass, gold, and material selection in industrial and consumer applications:

- Copper Development Association (CDA)

A trusted source for technical data on brass and other copper alloys.

👉 https://www.copper.org - Matmatch – Brass & Gold Material Data Sheets

Offers precise mechanical, thermal, and chemical properties of metals.

👉 https://www.matmatch.com - ASM International – Materials Property Database

A comprehensive library of engineering-grade metal properties.

👉 https://www.asminternational.org - Engineering Toolbox – Physical & Electrical Properties of Metals

A go-to reference for practical comparison of density, conductivity, etc.

👉 https://www.engineeringtoolbox.com - Jewelrywise – Gold Types and Value

Consumer-friendly resource for understanding gold purity, durability, and care.

👉 https://www.jewelrywise.com - IPC Standards (for Electronics)

For those in electronics manufacturing, IPC standards guide the use of gold-plated brass connectors.

👉 https://www.ipc.org - Gold.org – World Gold Council

Offers market data and general knowledge about gold’s industrial and consumer value.

👉 https://www.gold.org

Other Articles You Might Enjoy

- Brass Pipe Customization via CNC: What Engineers and Buyers Must Consider

Introduction: Why Brass Pipe Matters in CNC Projects Brass pipe is one of those materials engineers and buyers often overlook until they face a challenge only brass can solve. Early…

- Brass Bushings Explained: Machining Tips, Tolerances, and Use Cases

Introduction: Why Brass Bushings? I remember the first time I truly understood why brass bushings mattered so much in mechanical setups.I was standing in a small workshop, looking at the inner components…

- Brass vs Copper: The Ultimate Guide for Manufacturers and Machinists

Chapter 1: Introduction I’m excited to share my ultimate comparison of brass vs copper for manufacturers and machinists. Having worked with both materials in various machining and manufacturing environments, I know how…

- Brass Punch Machining Guide: Materials, Techniques, and Best Practices

I’m excited to share my comprehensive guide on brass punch machining. I’ve spent years working with different CNC setups, trying various alloys, and optimizing cutting parameters. In this guide, I’ll…

- Custom Brass Fasteners: How CNC Machining Enhances Strength, Precision, and Durability

Hello, and welcome to this comprehensive guide on Brass Fasteners and the pivotal role that CNC machining plays in crafting custom solutions. I’ve spent years working alongside design engineers, procurement managers, and…

- Brass Tacks Demystified: A Deep Dive into Machining Techniques and Innovations

I’ve spent a fair bit of time learning about different metal fasteners, and brass tacks are one of those intriguing items that bridge function and design. When you look at…

- Copper Custom Innovations: Exploring New Alloys and Hybrid Manufacturing

I’ve spent a significant amount of time exploring various manufacturing processes, and one of the most intriguing areas I’ve encountered is what I call “Copper Custom.” This term encapsulates the…

- Red Copper Machining: Techniques and Best Practices

Introduction: Why Focus on Red Copper Machining? Red copper, also known as pure copper, has long been a material of choice across industries due to its unparalleled properties. Its unique…

- Understanding the Density of Copper in Precision CNC Machining

The Relationship Between Copper’s Density and CNC Machining Copper is a highly versatile material, and its use in CNC machining is well-established, particularly for industries requiring high precision. But one…