Bronze Precision CNC Machining Services

Want.net is a trusted brand in bronze CNC precision machining. With advanced CNC equipment and CNC Machining technology, we perform complex precision machining on various CNC materials, including bronze. We can manufacture the highest precision parts with the strictest tolerances. Get your free quote today!

- Instant Quote

- Fast Turnaround

- Pay After Delivery

Home » CNC Machining » Bronze Precision CNC Machining Services

Bronze Parts CNC Machining Custom Services

Seeking reliable and fast bronze CNC machining services? Your search ends here!

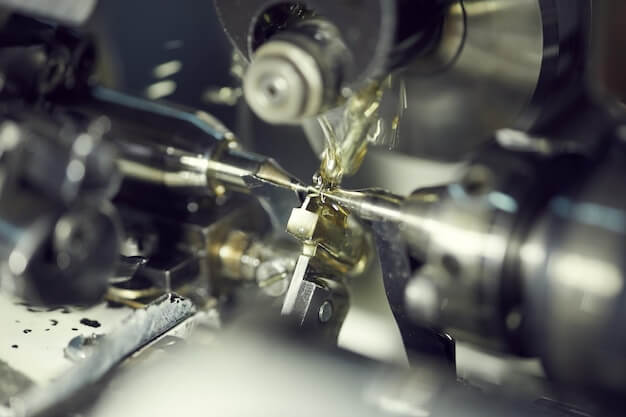

At Want.net, we employ state-of-the-art CNC technologies to deliver exceptional bronze machining results with speed and accuracy. Our team of experienced machinists, engineers, and quality control experts ensures your bronze components are manufactured to the highest standards and delivered on time.

Our ISO 9001:2015 certified facility is designed for both rapid prototyping and low-volume production of bronze parts, catering to a wide range of applications.

Additionally, our bronze CNC machining services integrate seamlessly with our other manufacturing capabilities, including 3D printing and injection molding, providing you with a complete manufacturing solution.

From simple to highly complex bronze parts, we manage a variety of designs and surface finishes with precision and expertise.

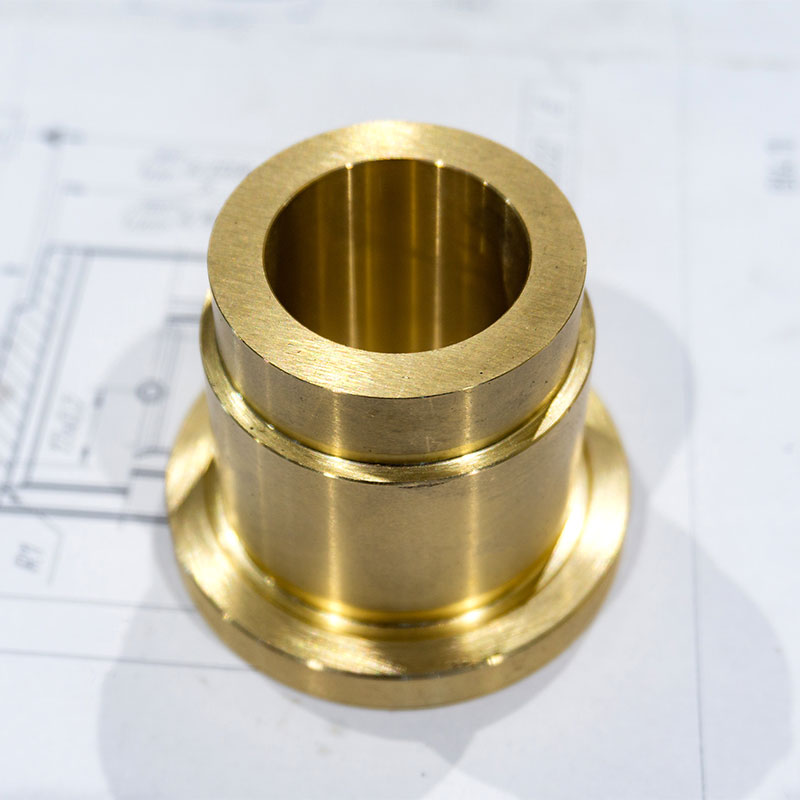

High Precision CNC Machined Parts

Our precision bronze machining services include machining of a wide variety of components such as nuts, bolts, threaded parts, bearings, bushings, screws, etc. We use advanced machining techniques to achieve tight tolerances and precision in every part we machine.

Here is an example list of bronze components that can be machined:

- Mechanical components, such as bearings, bushings, and gears

- Marine components, such as propellers, ship fittings, and stern tubes

- Architectural components, such as door handles, fixtures, and sculptures

- Artistic components, such as statues, fountains, and relief sculptures

- Industrial components, such as pumps, valves, and heat exchanger components

- Musical instrument components, such as cymbals and bells

- Automotive components, such as engine components and transmission parts

Bronze Grades For CNC Machining

| Bronze Grade | Composition | Key Properties | Common Applications |

|---|---|---|---|

| C93200 (Bearing Bronze) | Copper, Tin, Lead, Zinc | Good wear resistance, machinability, and corrosion resistance | Bushings, bearings, wear plates |

| C95400 (Aluminum Bronze) | Copper, Aluminum, Iron | High strength, excellent corrosion resistance, good machinability | Gears, valve components, marine hardware |

| C90700 (High Tin Bronze) | Copper, Tin | High strength, good wear resistance, good corrosion resistance | Bearings, bushings, gear parts |

| C95500 (Nickel Aluminum Bronze) | Copper, Aluminum, Nickel, Iron | Superior strength, excellent corrosion and wear resistance | Heavy-duty bushings, gears, valve seats |

| C83600 (Red Brass) | Copper, Zinc, Tin, Lead | Good corrosion resistance, moderate strength, good machinability | Plumbing fittings, valves, pump components |

| C86300 (Manganese Bronze) | Copper, Zinc, Aluminum, Iron | High strength, good wear resistance, moderate corrosion resistance | High-load bearings, hydraulic cylinder parts |

| C90300 (Tin Bronze) | Copper, Tin | Good corrosion resistance, high strength, good machinability | Marine hardware, pump components, bearings |

| C87850 (Silicon Bronze) | Copper, Silicon, Zinc, Manganese | Excellent corrosion resistance, good strength, good machinability | Marine hardware, fasteners, valve parts |

| C95200 (Aluminum Bronze) | Copper, Aluminum, Iron | High strength, excellent corrosion resistance, good wear resistance | Marine components, pump parts, valve stems |

| C26000 (Cartridge Brass) | Copper, Zinc | Good strength, good corrosion resistance, excellent machinability | Ammunition casings, hardware, automotive parts |

Our CNC Machining Capabilities

Advantages of Bronze Precision CNC Machining Services

1. High Precision and Accuracy: Bronze CNC machining provides exceptional precision, ensuring tight tolerances and accurate dimensions for complex parts.

2. Durability and Strength: Bronze is known for its strength and durability, making it ideal for components that require long-lasting performance and resistance to wear and corrosion.

3. Excellent Surface Finish: CNC machining allows for superior surface finishes on bronze parts, reducing the need for additional finishing processes and enhancing the aesthetic and functional quality of the components.

4. Versatility in Design: CNC technology can handle intricate and complex designs with ease, enabling the creation of detailed and customized bronze parts for various applications.

5. Cost-Effective Production: CNC machining is highly efficient, reducing material waste and lowering production costs, especially for low-volume and prototyping projects.

6. Quick Turnaround Time: Advanced CNC equipment and skilled operators ensure fast production cycles, allowing for rapid prototyping and timely delivery of finished parts.

7. Consistency and Repeatability: CNC machining ensures consistent quality and repeatability across multiple production runs, maintaining the same high standards for every batch of bronze parts.

8. Integration with Other Manufacturing Processes: Bronze CNC machining can be seamlessly integrated with other manufacturing techniques such as 3D printing and injection molding, providing a comprehensive solution for complex projects.

9. Enhanced Mechanical Properties: Machined bronze components exhibit excellent mechanical properties, including high tensile strength and good machinability, making them suitable for demanding applications.

10. Corrosion Resistance: Bronze’s natural resistance to corrosion makes it an ideal choice for parts exposed to harsh environments, ensuring longevity and reliability.

Why Choose Our Online Bronze Precision CNC Machining Services

Bronze Precision CNC Machining Services FAQs

The cost of your CNC machining project depends on some factors such as the design, tolerance require, material, machining times, and human resources that have to be input into the project. You can send us your CAD file so we can prepare the quote for you.

- Select The Right Machining Process: One of the best techniques to reduce the cost f CNC machining is to choose an efficient machining process. Generally, you need a professional machining company that will guide you through the complete CNC machining cost-reduction process.

- Refine The Design of The Part: If you have a perfect design for the CNC machining part, it can significantly reduce machining costs.

- Right Tooling Reduces The Cost: Generally, traditional machining centers have manual tooling which increases the cost of the metal part. Find the best CNC machining company near you with the latest CNC machining equipment.

We can accommodate the prototyping and production of large machined parts, plastic or metal. Our maximum CNC machining build envelope is 2000 mm x 1500 mm x 300 mm — suitable even for large-scale furniture and architectural components.

If you want to start CNC machining parts production with Want.net, the process is quite convenient. Get in touch with us by clicking the Instant Quote button.

We follow the highest standards for manufacturing custom CNC machined parts. Since we have the latest CNC milling and turning equipment, you can drop your order in both small and bulk quantities.

Yes, we provide 5 Axis CNC machining solutions for metal parts with complex geometry and high precision standards. We offer our services for a range of materials with precise tolerances, curved surfaces, and fine detailing. Additionally, we provide post-processing services like plating, powder coating, and anodizing.

In a traditional machining shop, accuracy and precision are the biggest problems. Similarly, they follow traditional tooling methods which lack precision. Want.net ensures the highest manufacturing standards and has the industry’s leading CNC machining equipment along with expert operators.

Down to 0.001mm.

Put Your Machined Parts into Production Today!

You’re one-step away from the most affordable CNC machining service. Fill the form beside and we will get back to you within 24 hours.

GET QUICK QUOTE

- All uploads are secure and confidential